Cylinder Head JEEP LIBERTY 2002 KJ / 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1292 of 1803

IDLER SHAFT

REMOVAL

(1) Remove the primary and secondary timing

chains and sprockets. Refer to procedure in this sec-

tion.

NOTE: To remove the idler shaft, it is necessary to

tap threads into the shaft, to install the removal

tool.

(2) Using a 12 mm X 1.75 tap, cut threads in the

idler shaft center bore.

(3) Cover the radiator core with a suitable cover.

CAUTION: Use care when removing the idler shaft,

Do not strike the radiator cooling fins with the slide

hammer.

(4) Using Special Tool 8517 Slide Hammer, remove

the idler shaft.

INSTALLATION

(1) Thoroughly clean the idler shaft bore.

(2) Position the idler shaft in the bore.

NOTE: The two lubrication holes in the idler shaft

do not require any special alignment.

NOTE: Before using the retaining bolt to install the

idler shaft, coat the threads and the pilot on the

idler shaft, with clean engine oil.

(3) Using the primary idler sprocket retaining bolt

and washer, carefully draw the idler shaft into the

bore until fully seated.

(4) Coat the idler shaft with clean engine oil.

(5) Install the timing chains and sprockets. Refer

to procedure in this section.

TIMING BELT/CHAIN AND

SPROCKET(S

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. Refer to COOLING SYS-

TEM for procedures.

(3) Remove right and left cylinder head covers.

Refer to CYLINDER HEAD COVER.

(4) Remove radiator fan shroud. Refer to COOL-

ING SYSTEM for procedure.

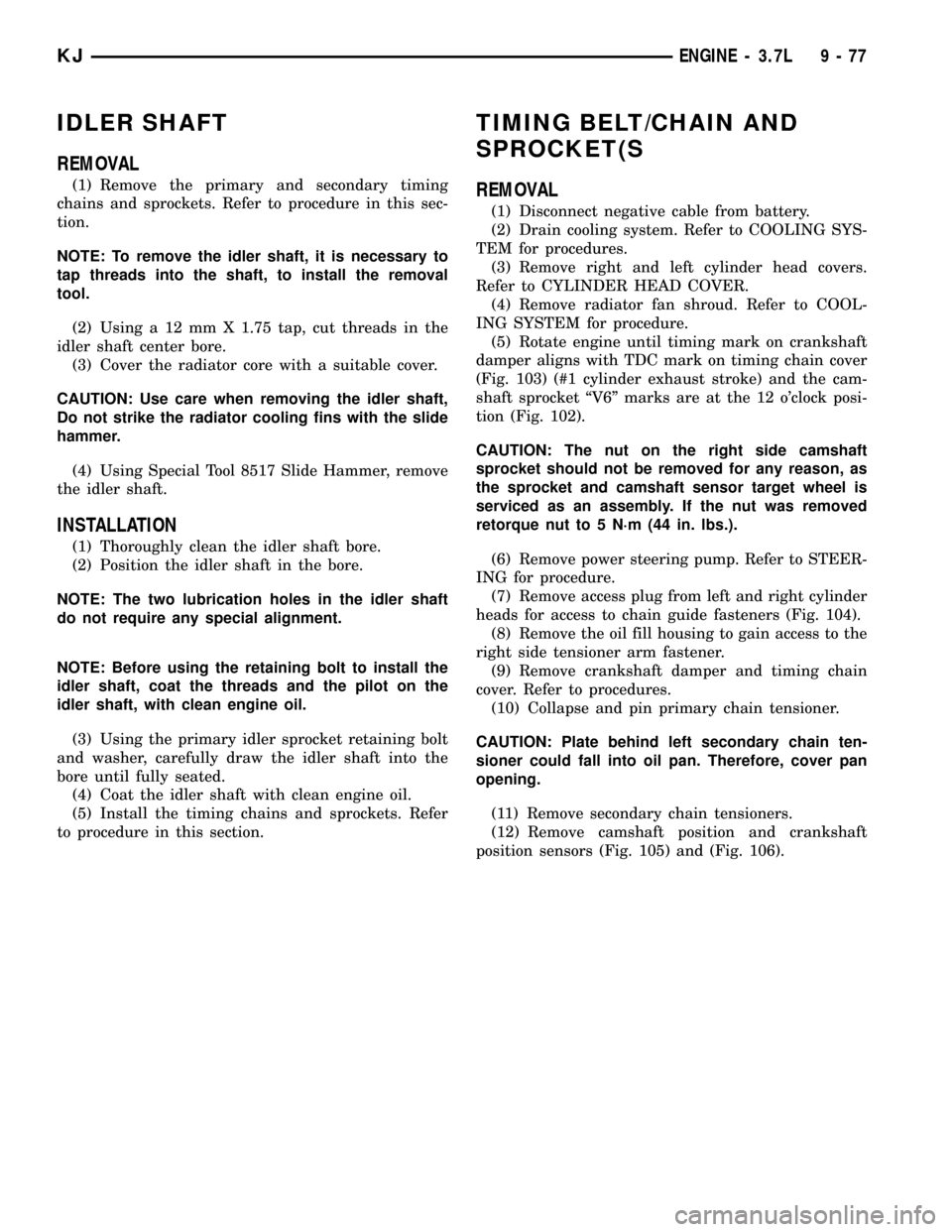

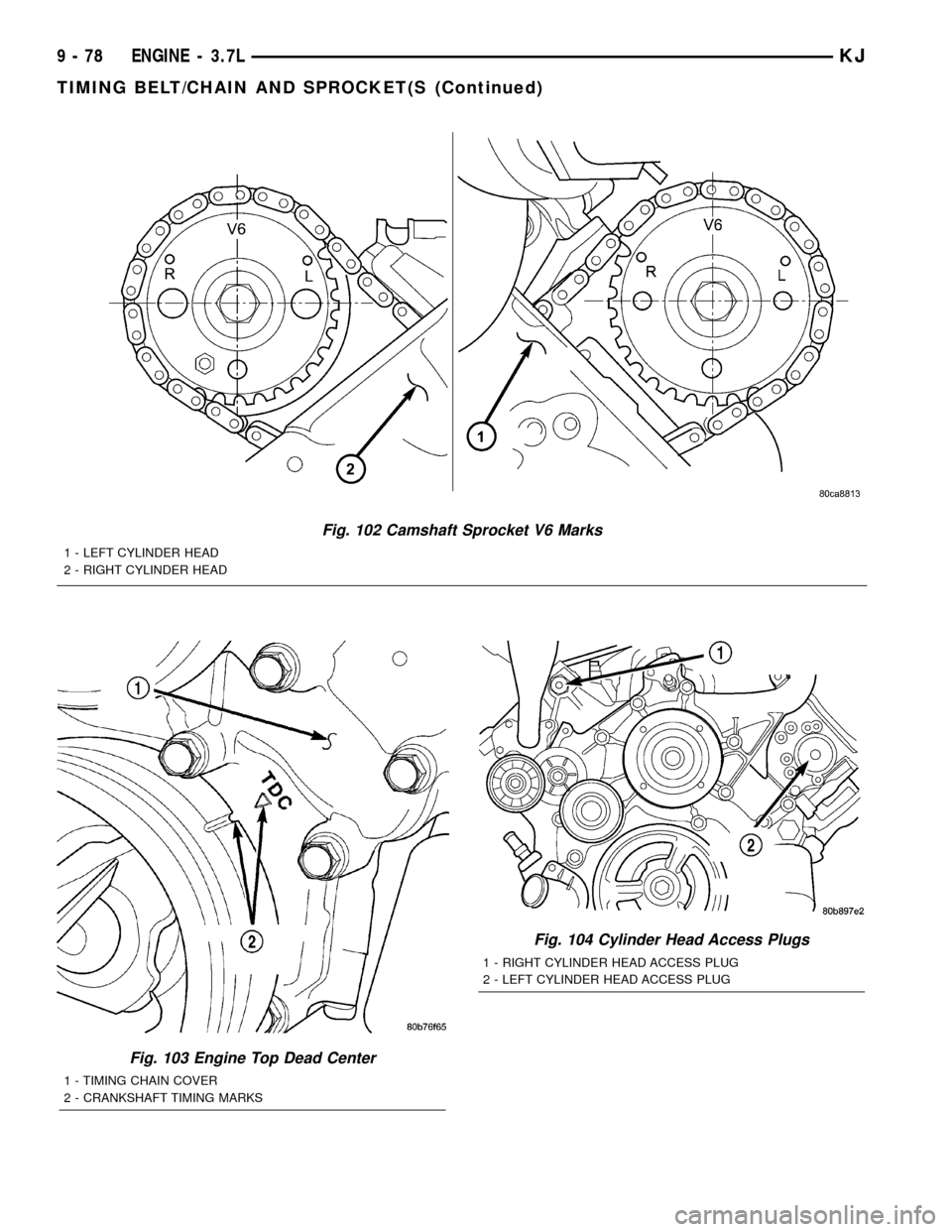

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 103) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV6º marks are at the 12 o'clock posi-

tion (Fig. 102).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(6) Remove power steering pump. Refer to STEER-

ING for procedure.

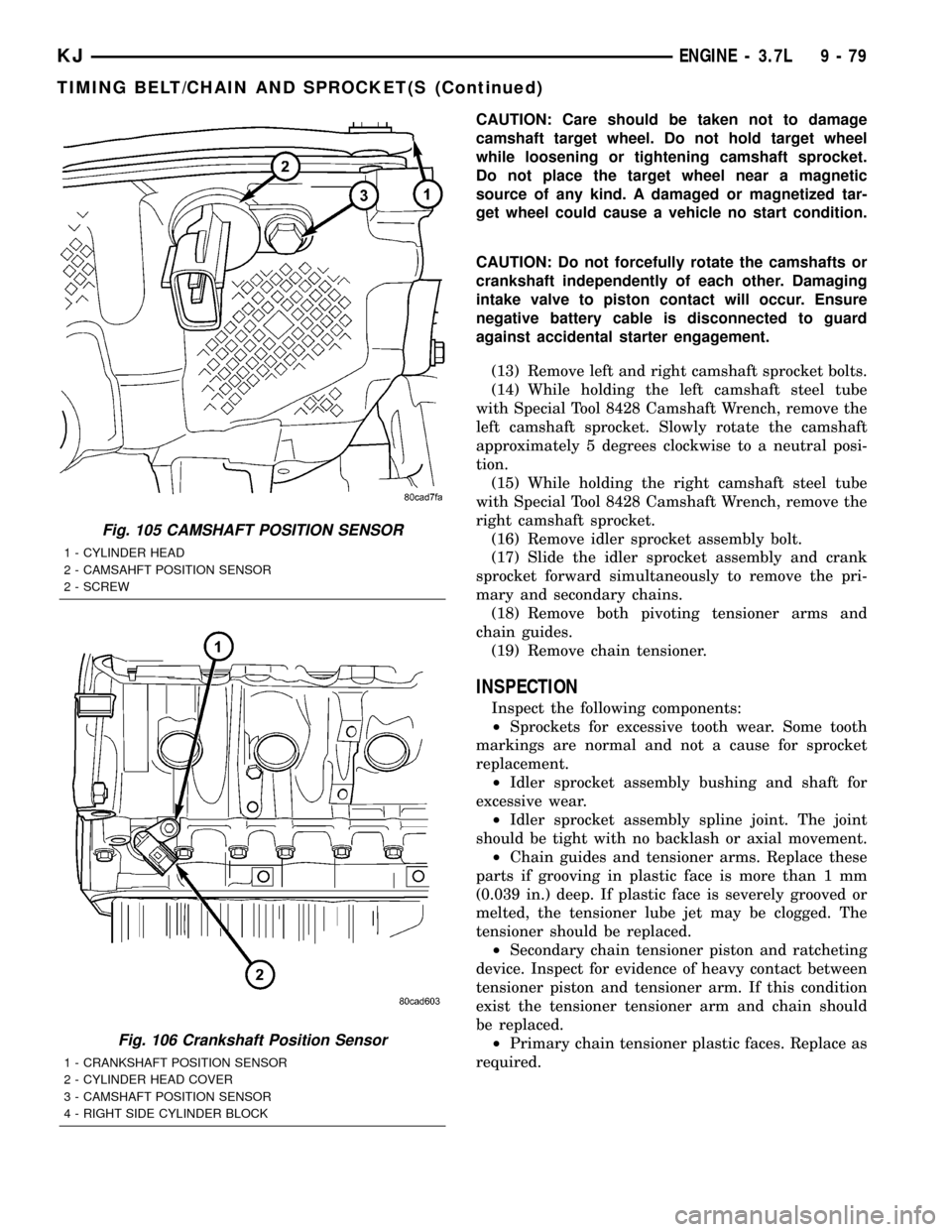

(7) Remove access plug from left and right cylinder

heads for access to chain guide fasteners (Fig. 104).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper and timing chain

cover. Refer to procedures.

(10) Collapse and pin primary chain tensioner.

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position and crankshaft

position sensors (Fig. 105) and (Fig. 106).

KJENGINE - 3.7L 9 - 77

Page 1293 of 1803

Fig. 102 Camshaft Sprocket V6 Marks

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD

Fig. 103 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

Fig. 104 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

9 - 78 ENGINE - 3.7LKJ

TIMING BELT/CHAIN AND SPROCKET(S (Continued)

Page 1294 of 1803

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with Special Tool 8428 Camshaft Wrench, remove the

left camshaft sprocket. Slowly rotate the camshaft

approximately 5 degrees clockwise to a neutral posi-

tion.

(15) While holding the right camshaft steel tube

with Special Tool 8428 Camshaft Wrench, remove the

right camshaft sprocket.

(16) Remove idler sprocket assembly bolt.

(17) Slide the idler sprocket assembly and crank

sprocket forward simultaneously to remove the pri-

mary and secondary chains.

(18) Remove both pivoting tensioner arms and

chain guides.

(19) Remove chain tensioner.

INSPECTION

Inspect the following components:

²Sprockets for excessive tooth wear. Some tooth

markings are normal and not a cause for sprocket

replacement.

²Idler sprocket assembly bushing and shaft for

excessive wear.

²Idler sprocket assembly spline joint. The joint

should be tight with no backlash or axial movement.

²Chain guides and tensioner arms. Replace these

parts if grooving in plastic face is more than 1 mm

(0.039 in.) deep. If plastic face is severely grooved or

melted, the tensioner lube jet may be clogged. The

tensioner should be replaced.

²Secondary chain tensioner piston and ratcheting

device. Inspect for evidence of heavy contact between

tensioner piston and tensioner arm. If this condition

exist the tensioner tensioner arm and chain should

be replaced.

²Primary chain tensioner plastic faces. Replace as

required.

Fig. 105 CAMSHAFT POSITION SENSOR

1 - CYLINDER HEAD

2 - CAMSAHFT POSITION SENSOR

2 - SCREW

Fig. 106 Crankshaft Position Sensor

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCK

KJENGINE - 3.7L 9 - 79

TIMING BELT/CHAIN AND SPROCKET(S (Continued)

Page 1295 of 1803

INSTALLATION

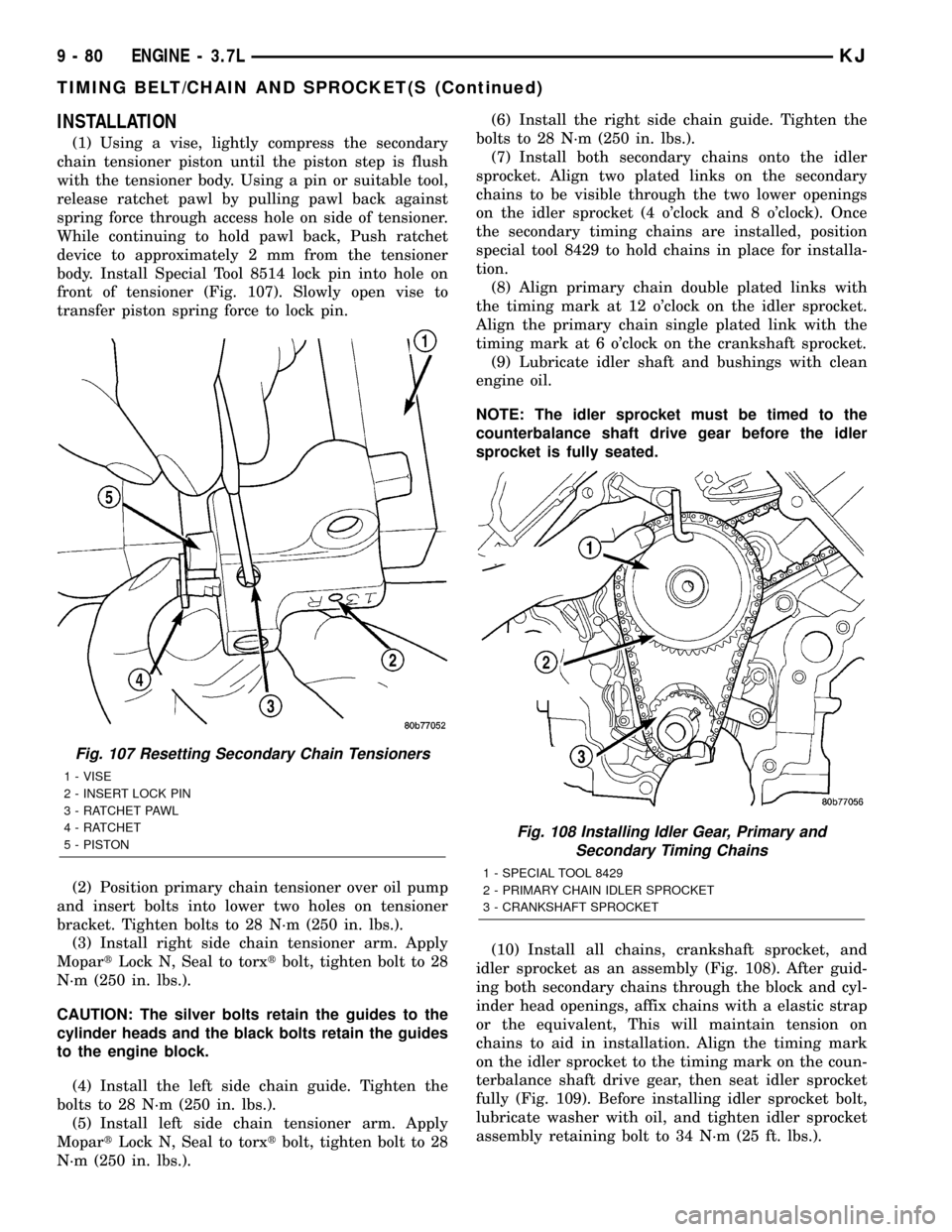

(1) Using a vise, lightly compress the secondary

chain tensioner piston until the piston step is flush

with the tensioner body. Using a pin or suitable tool,

release ratchet pawl by pulling pawl back against

spring force through access hole on side of tensioner.

While continuing to hold pawl back, Push ratchet

device to approximately 2 mm from the tensioner

body. Install Special Tool 8514 lock pin into hole on

front of tensioner (Fig. 107). Slowly open vise to

transfer piston spring force to lock pin.

(2) Position primary chain tensioner over oil pump

and insert bolts into lower two holes on tensioner

bracket. Tighten bolts to 28 N´m (250 in. lbs.).

(3) Install right side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 28

N´m (250 in. lbs.).

CAUTION: The silver bolts retain the guides to the

cylinder heads and the black bolts retain the guides

to the engine block.

(4) Install the left side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

(5) Install left side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 28

N´m (250 in. lbs.).(6) Install the right side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

(7) Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o'clock and 8 o'clock). Once

the secondary timing chains are installed, position

special tool 8429 to hold chains in place for installa-

tion.

(8) Align primary chain double plated links with

the timing mark at 12 o'clock on the idler sprocket.

Align the primary chain single plated link with the

timing mark at 6 o'clock on the crankshaft sprocket.

(9) Lubricate idler shaft and bushings with clean

engine oil.

NOTE: The idler sprocket must be timed to the

counterbalance shaft drive gear before the idler

sprocket is fully seated.

(10) Install all chains, crankshaft sprocket, and

idler sprocket as an assembly (Fig. 108). After guid-

ing both secondary chains through the block and cyl-

inder head openings, affix chains with a elastic strap

or the equivalent, This will maintain tension on

chains to aid in installation. Align the timing mark

on the idler sprocket to the timing mark on the coun-

terbalance shaft drive gear, then seat idler sprocket

fully (Fig. 109). Before installing idler sprocket bolt,

lubricate washer with oil, and tighten idler sprocket

assembly retaining bolt to 34 N´m (25 ft. lbs.).

Fig. 107 Resetting Secondary Chain Tensioners

1 - VISE

2 - INSERT LOCK PIN

3 - RATCHET PAWL

4 - RATCHET

5 - PISTON

Fig. 108 Installing Idler Gear, Primary and

Secondary Timing Chains

1 - SPECIAL TOOL 8429

2 - PRIMARY CHAIN IDLER SPROCKET

3 - CRANKSHAFT SPROCKET

9 - 80 ENGINE - 3.7LKJ

TIMING BELT/CHAIN AND SPROCKET(S (Continued)

Page 1296 of 1803

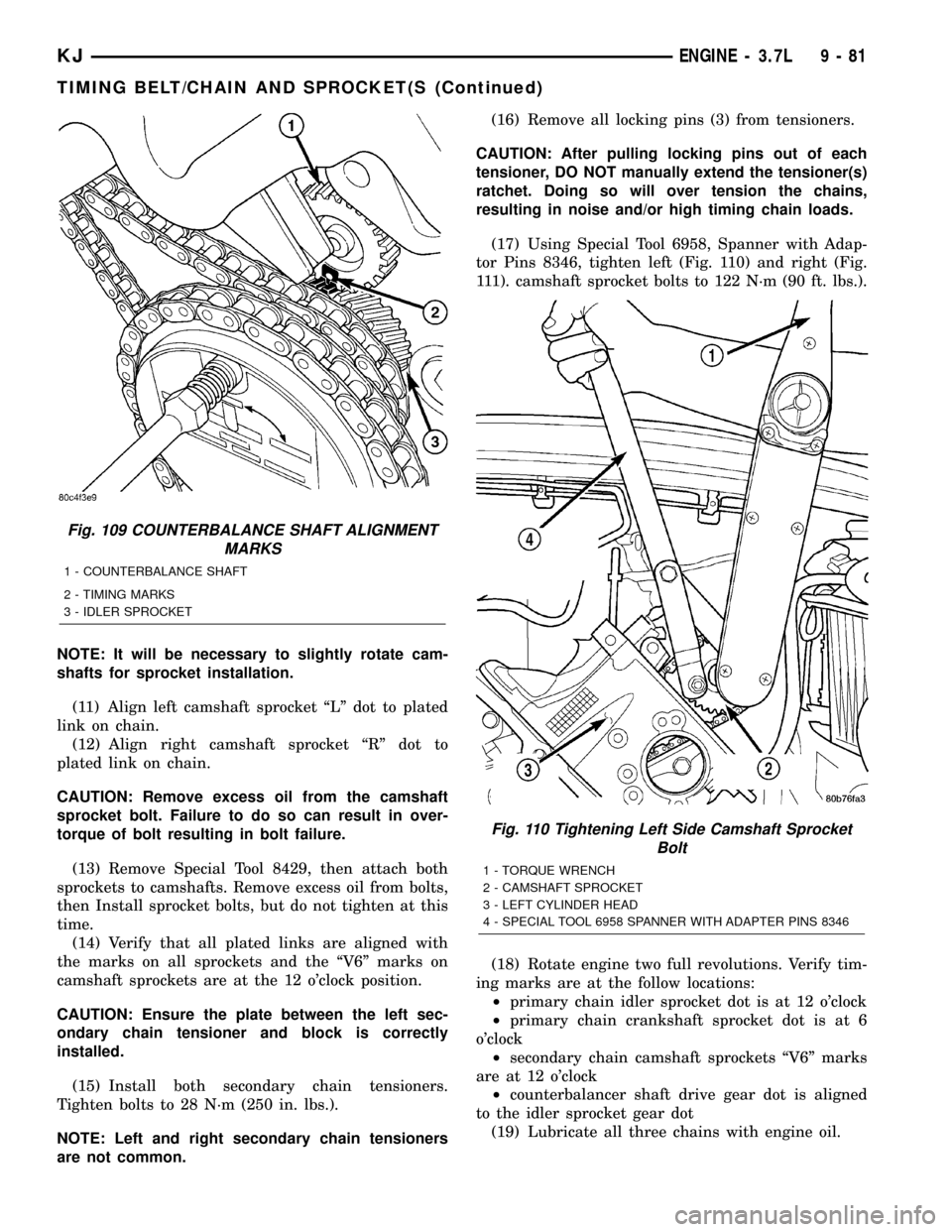

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

(11) Align left camshaft sprocket ªLº dot to plated

link on chain.

(12) Align right camshaft sprocket ªRº dot to

plated link on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

(13) Remove Special Tool 8429, then attach both

sprockets to camshafts. Remove excess oil from bolts,

then Install sprocket bolts, but do not tighten at this

time.

(14) Verify that all plated links are aligned with

the marks on all sprockets and the ªV6º marks on

camshaft sprockets are at the 12 o'clock position.

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.

(15) Install both secondary chain tensioners.

Tighten bolts to 28 N´m (250 in. lbs.).

NOTE: Left and right secondary chain tensioners

are not common.(16) Remove all locking pins (3) from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tensioner(s)

ratchet. Doing so will over tension the chains,

resulting in noise and/or high timing chain loads.

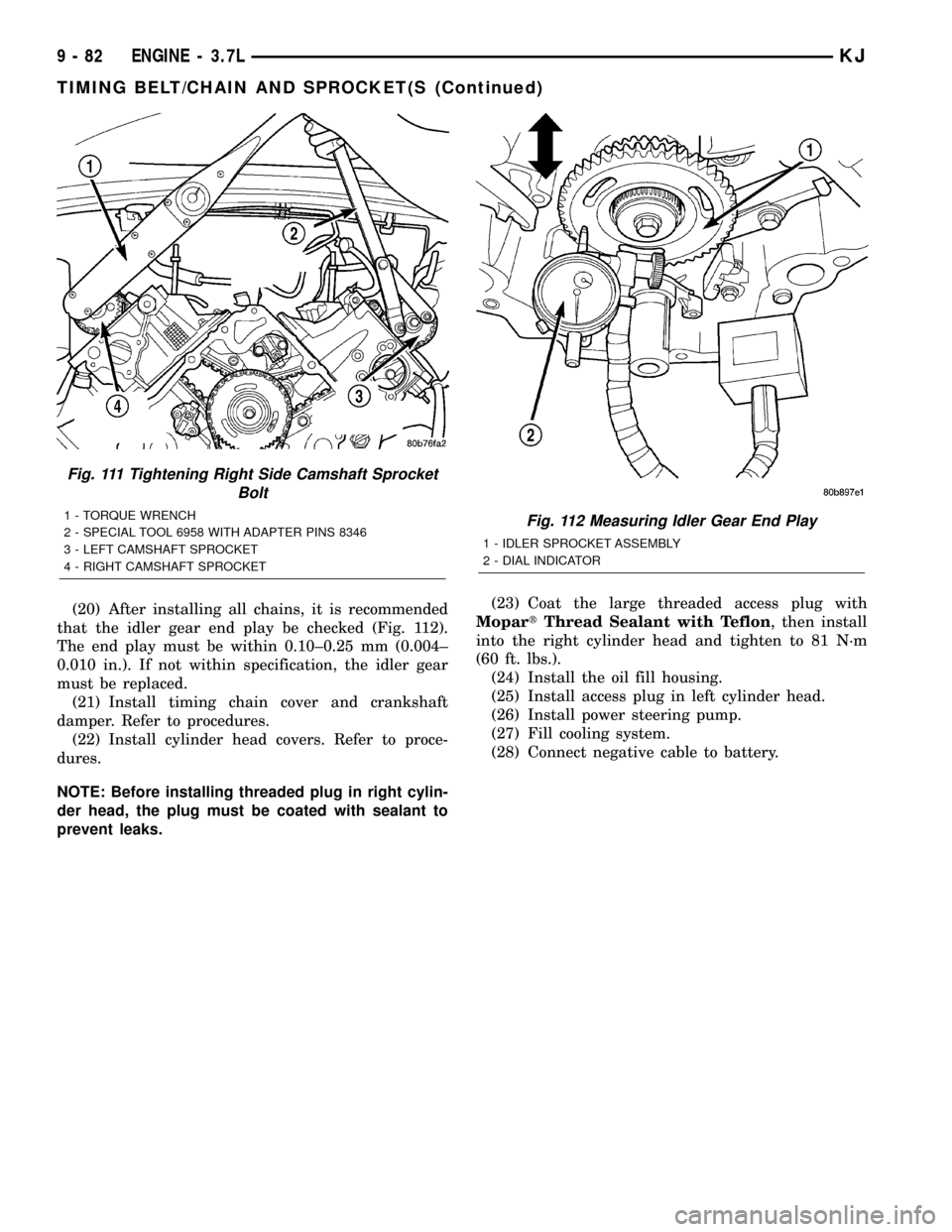

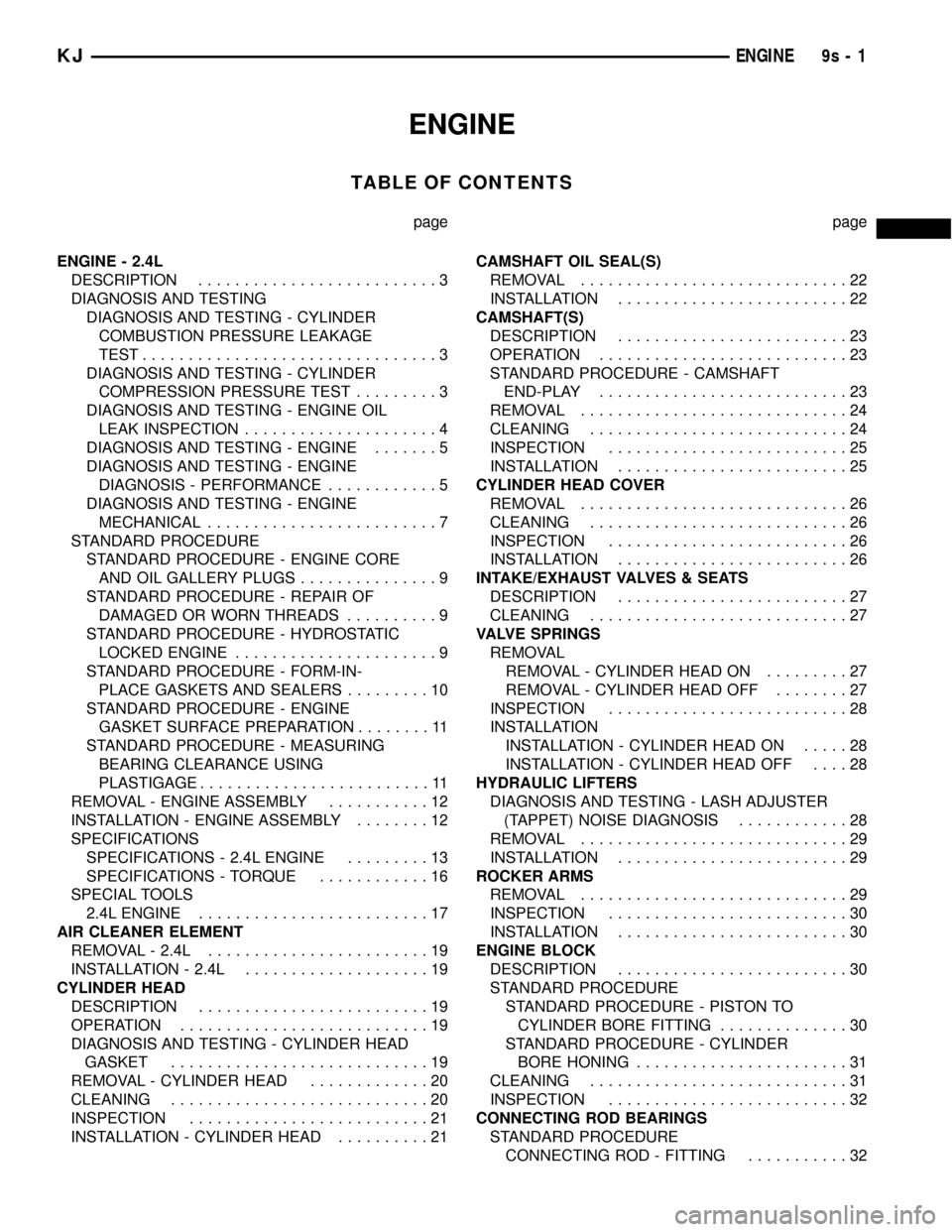

(17) Using Special Tool 6958, Spanner with Adap-

tor Pins 8346, tighten left (Fig. 110) and right (Fig.

111). camshaft sprocket bolts to 122 N´m (90 ft. lbs.).

(18) Rotate engine two full revolutions. Verify tim-

ing marks are at the follow locations:

²primary chain idler sprocket dot is at 12 o'clock

²primary chain crankshaft sprocket dot is at 6

o'clock

²secondary chain camshaft sprockets ªV6º marks

are at 12 o'clock

²counterbalancer shaft drive gear dot is aligned

to the idler sprocket gear dot

(19) Lubricate all three chains with engine oil.

Fig. 109 COUNTERBALANCE SHAFT ALIGNMENT

MARKS

1 - COUNTERBALANCE SHAFT

2 - TIMING MARKS

3 - IDLER SPROCKET

Fig. 110 Tightening Left Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

KJENGINE - 3.7L 9 - 81

TIMING BELT/CHAIN AND SPROCKET(S (Continued)

Page 1297 of 1803

(20) After installing all chains, it is recommended

that the idler gear end play be checked (Fig. 112).

The end play must be within 0.10±0.25 mm (0.004±

0.010 in.). If not within specification, the idler gear

must be replaced.

(21) Install timing chain cover and crankshaft

damper. Refer to procedures.

(22) Install cylinder head covers. Refer to proce-

dures.

NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.(23) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.).

(24) Install the oil fill housing.

(25) Install access plug in left cylinder head.

(26) Install power steering pump.

(27) Fill cooling system.

(28) Connect negative cable to battery.

Fig. 111 Tightening Right Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKETFig. 112 Measuring Idler Gear End Play

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

9 - 82 ENGINE - 3.7LKJ

TIMING BELT/CHAIN AND SPROCKET(S (Continued)

Page 1298 of 1803

ENGINE

TABLE OF CONTENTS

page page

ENGINE - 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................3

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........3

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................4

DIAGNOSIS AND TESTING - ENGINE.......5

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............5

DIAGNOSIS AND TESTING - ENGINE

MECHANICAL.........................7

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS...............9

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS..........9

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE......................9

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........10

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE.........................11

REMOVAL - ENGINE ASSEMBLY...........12

INSTALLATION - ENGINE ASSEMBLY........12

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........13

SPECIFICATIONS - TORQUE............16

SPECIAL TOOLS

2.4L ENGINE.........................17

AIR CLEANER ELEMENT

REMOVAL - 2.4L........................19

INSTALLATION - 2.4L....................19

CYLINDER HEAD

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET............................19

REMOVAL - CYLINDER HEAD.............20

CLEANING............................20

INSPECTION..........................21

INSTALLATION - CYLINDER HEAD..........21CAMSHAFT OIL SEAL(S)

REMOVAL.............................22

INSTALLATION.........................22

CAMSHAFT(S)

DESCRIPTION.........................23

OPERATION...........................23

STANDARD PROCEDURE - CAMSHAFT

END-PLAY...........................23

REMOVAL.............................24

CLEANING............................24

INSPECTION..........................25

INSTALLATION.........................25

CYLINDER HEAD COVER

REMOVAL.............................26

CLEANING............................26

INSPECTION..........................26

INSTALLATION.........................26

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................27

CLEANING............................27

VALVE SPRINGS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........27

REMOVAL - CYLINDER HEAD OFF........27

INSPECTION..........................28

INSTALLATION

INSTALLATION - CYLINDER HEAD ON.....28

INSTALLATION - CYLINDER HEAD OFF....28

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTING - LASH ADJUSTER

(TAPPET) NOISE DIAGNOSIS............28

REMOVAL.............................29

INSTALLATION.........................29

ROCKER ARMS

REMOVAL.............................29

INSPECTION..........................30

INSTALLATION.........................30

ENGINE BLOCK

DESCRIPTION.........................30

STANDARD PROCEDURE

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING..............30

STANDARD PROCEDURE - CYLINDER

BORE HONING.......................31

CLEANING............................31

INSPECTION..........................32

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING...........32

KJENGINE 9s - 1

Page 1300 of 1803

ENGINE - 2.4L

DESCRIPTION

The 2.4 Liter (148 cu. in.) in-line four cylinder

engine is a double over head camshaft with hydraulic

lifters and four valve per cylinder design. The engine

is free-wheeling; meaning it has provisions for piston-

to-valve clearance. However valve-to-valve interference

can occur, if camshafts are rotated independently.

The cylinders are numbered from front of the

engine to the rear. The firing order is 1±3±4±2.

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer with cable adaptors to the DRBIIIt.

Fig. 1 ENGINE IDENTIFICATION

1 - ENGINE IDENTIFICATION

KJENGINE9s-3

Page 1301 of 1803

(7) Crank engine until maximum pressure is

reached on gage. Record this pressure as #1 cylinder

pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

9s - 4 ENGINEKJ

ENGINE - 2.4L (Continued)

Page 1302 of 1803

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - ENGINE

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

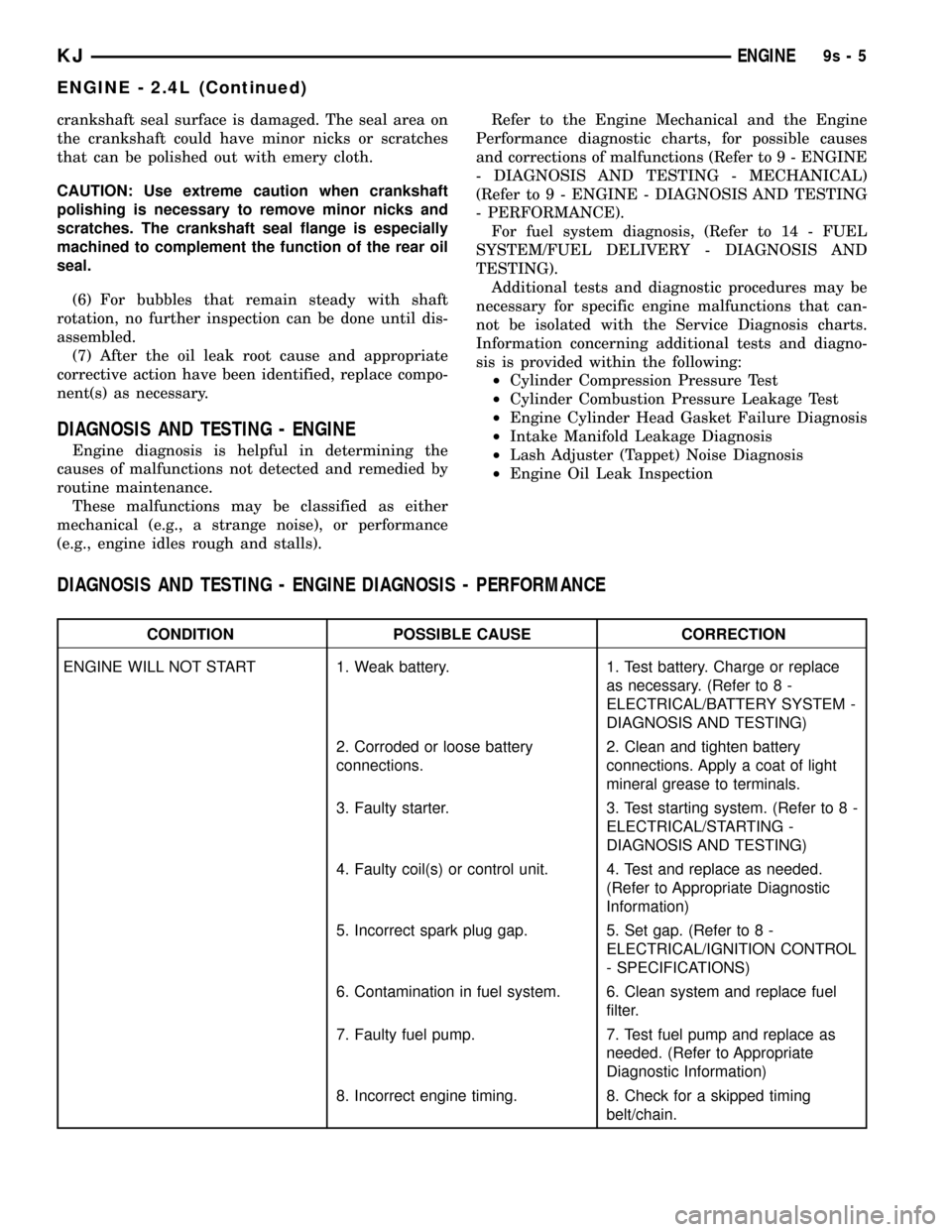

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery. 1. Test battery. Charge or replace

as necessary. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM -

DIAGNOSIS AND TESTING)

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Faulty starter. 3. Test starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Faulty coil(s) or control unit. 4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Incorrect spark plug gap. 5. Set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- SPECIFICATIONS)

6. Contamination in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Incorrect engine timing. 8. Check for a skipped timing

belt/chain.

KJENGINE9s-5

ENGINE - 2.4L (Continued)