Egr JEEP LIBERTY 2002 KJ / 1.G Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 516 of 1803

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the overhead console from the head-

liner. (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

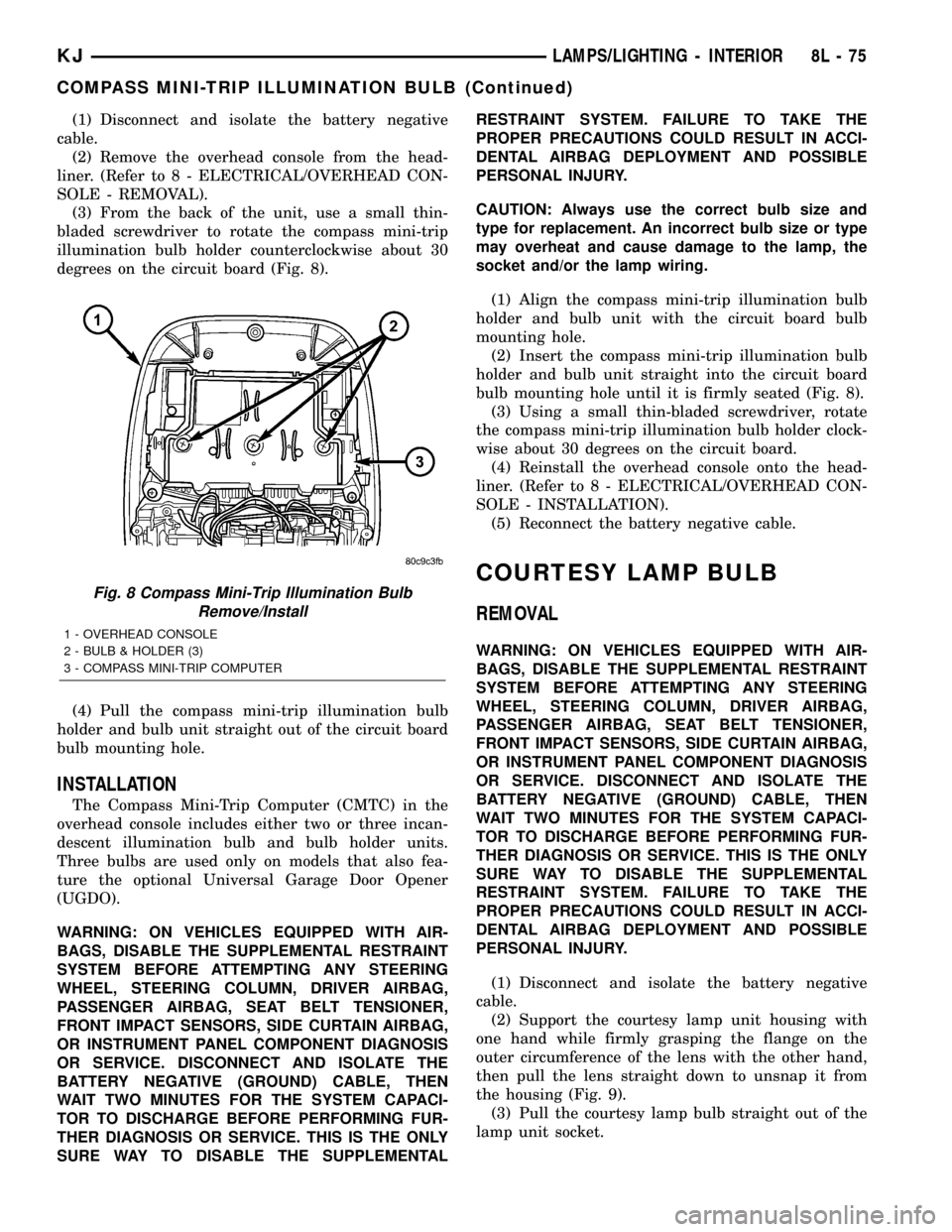

(3) From the back of the unit, use a small thin-

bladed screwdriver to rotate the compass mini-trip

illumination bulb holder counterclockwise about 30

degrees on the circuit board (Fig. 8).

(4) Pull the compass mini-trip illumination bulb

holder and bulb unit straight out of the circuit board

bulb mounting hole.

INSTALLATION

The Compass Mini-Trip Computer (CMTC) in the

overhead console includes either two or three incan-

descent illumination bulb and bulb holder units.

Three bulbs are used only on models that also fea-

ture the optional Universal Garage Door Opener

(UGDO).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTALRESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the compass mini-trip illumination bulb

holder and bulb unit with the circuit board bulb

mounting hole.

(2) Insert the compass mini-trip illumination bulb

holder and bulb unit straight into the circuit board

bulb mounting hole until it is firmly seated (Fig. 8).

(3) Using a small thin-bladed screwdriver, rotate

the compass mini-trip illumination bulb holder clock-

wise about 30 degrees on the circuit board.

(4) Reinstall the overhead console onto the head-

liner. (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - INSTALLATION).

(5) Reconnect the battery negative cable.

COURTESY LAMP BULB

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

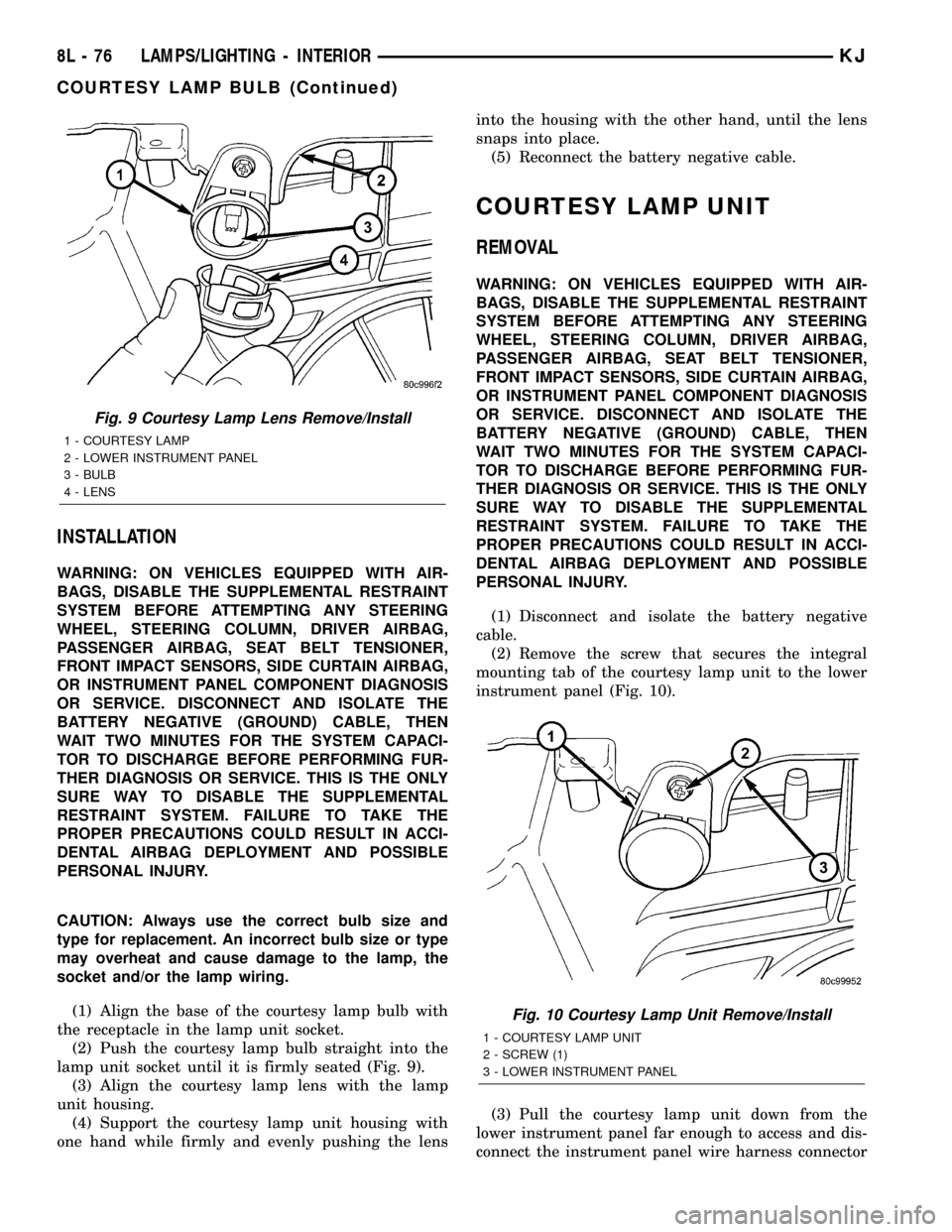

(2) Support the courtesy lamp unit housing with

one hand while firmly grasping the flange on the

outer circumference of the lens with the other hand,

then pull the lens straight down to unsnap it from

the housing (Fig. 9).

(3) Pull the courtesy lamp bulb straight out of the

lamp unit socket.

Fig. 8 Compass Mini-Trip Illumination Bulb

Remove/Install

1 - OVERHEAD CONSOLE

2 - BULB & HOLDER (3)

3 - COMPASS MINI-TRIP COMPUTER

KJLAMPS/LIGHTING - INTERIOR 8L - 75

COMPASS MINI-TRIP ILLUMINATION BULB (Continued)

Page 517 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the courtesy lamp bulb with

the receptacle in the lamp unit socket.

(2) Push the courtesy lamp bulb straight into the

lamp unit socket until it is firmly seated (Fig. 9).

(3) Align the courtesy lamp lens with the lamp

unit housing.

(4) Support the courtesy lamp unit housing with

one hand while firmly and evenly pushing the lensinto the housing with the other hand, until the lens

snaps into place.

(5) Reconnect the battery negative cable.

COURTESY LAMP UNIT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

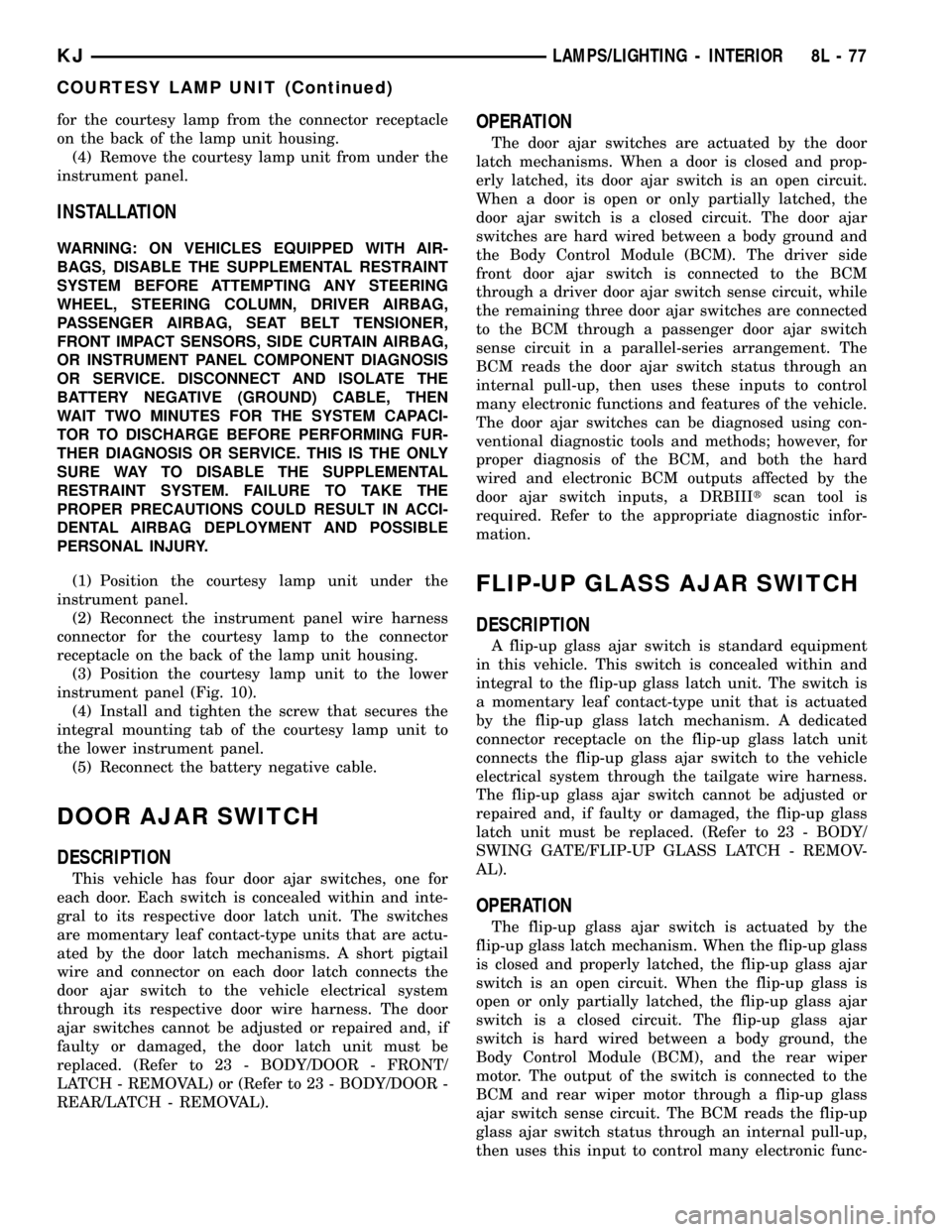

(2) Remove the screw that secures the integral

mounting tab of the courtesy lamp unit to the lower

instrument panel (Fig. 10).

(3) Pull the courtesy lamp unit down from the

lower instrument panel far enough to access and dis-

connect the instrument panel wire harness connector

Fig. 9 Courtesy Lamp Lens Remove/Install

1 - COURTESY LAMP

2 - LOWER INSTRUMENT PANEL

3 - BULB

4 - LENS

Fig. 10 Courtesy Lamp Unit Remove/Install

1 - COURTESY LAMP UNIT

2 - SCREW (1)

3 - LOWER INSTRUMENT PANEL

8L - 76 LAMPS/LIGHTING - INTERIORKJ

COURTESY LAMP BULB (Continued)

Page 518 of 1803

for the courtesy lamp from the connector receptacle

on the back of the lamp unit housing.

(4) Remove the courtesy lamp unit from under the

instrument panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the courtesy lamp unit under the

instrument panel.

(2) Reconnect the instrument panel wire harness

connector for the courtesy lamp to the connector

receptacle on the back of the lamp unit housing.

(3) Position the courtesy lamp unit to the lower

instrument panel (Fig. 10).

(4) Install and tighten the screw that secures the

integral mounting tab of the courtesy lamp unit to

the lower instrument panel.

(5) Reconnect the battery negative cable.

DOOR AJAR SWITCH

DESCRIPTION

This vehicle has four door ajar switches, one for

each door. Each switch is concealed within and inte-

gral to its respective door latch unit. The switches

are momentary leaf contact-type units that are actu-

ated by the door latch mechanisms. A short pigtail

wire and connector on each door latch connects the

door ajar switch to the vehicle electrical system

through its respective door wire harness. The door

ajar switches cannot be adjusted or repaired and, if

faulty or damaged, the door latch unit must be

replaced. (Refer to 23 - BODY/DOOR - FRONT/

LATCH - REMOVAL) or (Refer to 23 - BODY/DOOR -

REAR/LATCH - REMOVAL).

OPERATION

The door ajar switches are actuated by the door

latch mechanisms. When a door is closed and prop-

erly latched, its door ajar switch is an open circuit.

When a door is open or only partially latched, the

door ajar switch is a closed circuit. The door ajar

switches are hard wired between a body ground and

the Body Control Module (BCM). The driver side

front door ajar switch is connected to the BCM

through a driver door ajar switch sense circuit, while

the remaining three door ajar switches are connected

to the BCM through a passenger door ajar switch

sense circuit in a parallel-series arrangement. The

BCM reads the door ajar switch status through an

internal pull-up, then uses these inputs to control

many electronic functions and features of the vehicle.

The door ajar switches can be diagnosed using con-

ventional diagnostic tools and methods; however, for

proper diagnosis of the BCM, and both the hard

wired and electronic BCM outputs affected by the

door ajar switch inputs, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

FLIP-UP GLASS AJAR SWITCH

DESCRIPTION

A flip-up glass ajar switch is standard equipment

in this vehicle. This switch is concealed within and

integral to the flip-up glass latch unit. The switch is

a momentary leaf contact-type unit that is actuated

by the flip-up glass latch mechanism. A dedicated

connector receptacle on the flip-up glass latch unit

connects the flip-up glass ajar switch to the vehicle

electrical system through the tailgate wire harness.

The flip-up glass ajar switch cannot be adjusted or

repaired and, if faulty or damaged, the flip-up glass

latch unit must be replaced. (Refer to 23 - BODY/

SWING GATE/FLIP-UP GLASS LATCH - REMOV-

AL).

OPERATION

The flip-up glass ajar switch is actuated by the

flip-up glass latch mechanism. When the flip-up glass

is closed and properly latched, the flip-up glass ajar

switch is an open circuit. When the flip-up glass is

open or only partially latched, the flip-up glass ajar

switch is a closed circuit. The flip-up glass ajar

switch is hard wired between a body ground, the

Body Control Module (BCM), and the rear wiper

motor. The output of the switch is connected to the

BCM and rear wiper motor through a flip-up glass

ajar switch sense circuit. The BCM reads the flip-up

glass ajar switch status through an internal pull-up,

then uses this input to control many electronic func-

KJLAMPS/LIGHTING - INTERIOR 8L - 77

COURTESY LAMP UNIT (Continued)

Page 519 of 1803

tions and features of the vehicle. The rear wiper

motor uses this input to restrict rear wiper operation

when the flip-up glass is ajar. The flip-up glass ajar

switch can be diagnosed using conventional diagnos-

tic tools and methods; however, for proper diagnosis

of the BCM, and both the hard wired and electronic

BCM outputs affected by the flip-up glass ajar switch

input, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

HEATER-A/C CONTROL

ILLUMINATION BULB

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

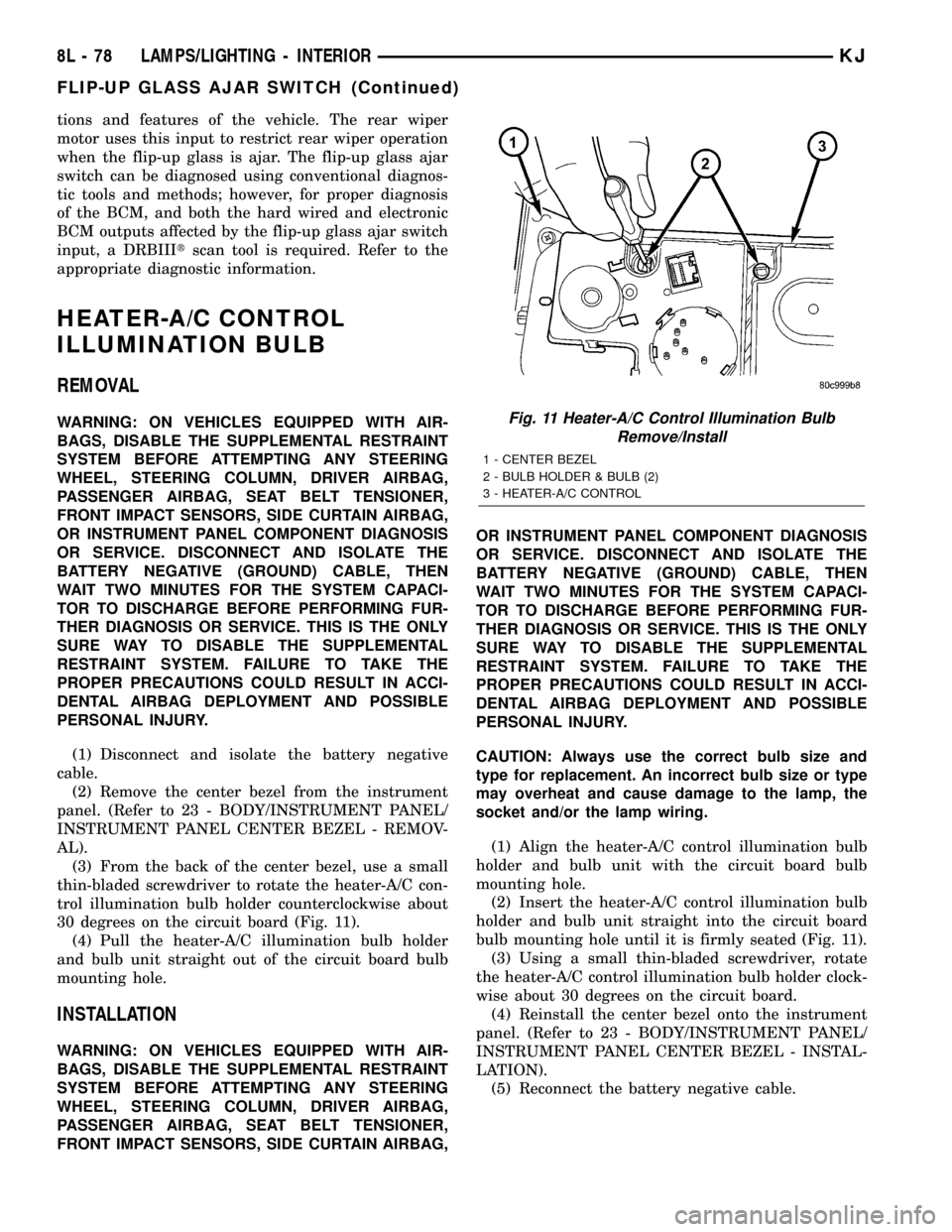

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(3) From the back of the center bezel, use a small

thin-bladed screwdriver to rotate the heater-A/C con-

trol illumination bulb holder counterclockwise about

30 degrees on the circuit board (Fig. 11).

(4) Pull the heater-A/C illumination bulb holder

and bulb unit straight out of the circuit board bulb

mounting hole.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the heater-A/C control illumination bulb

holder and bulb unit with the circuit board bulb

mounting hole.

(2) Insert the heater-A/C control illumination bulb

holder and bulb unit straight into the circuit board

bulb mounting hole until it is firmly seated (Fig. 11).

(3) Using a small thin-bladed screwdriver, rotate

the heater-A/C control illumination bulb holder clock-

wise about 30 degrees on the circuit board.

(4) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(5) Reconnect the battery negative cable.

Fig. 11 Heater-A/C Control Illumination Bulb

Remove/Install

1 - CENTER BEZEL

2 - BULB HOLDER & BULB (2)

3 - HEATER-A/C CONTROL

8L - 78 LAMPS/LIGHTING - INTERIORKJ

FLIP-UP GLASS AJAR SWITCH (Continued)

Page 520 of 1803

READING LAMP BULB

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is not equipped with the optional

Compass Mini-Trip Computer (CMTC), remove the

reading lamp unit from the headliner mounting hole.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/READING LAMP UNIT - REMOVAL). If

the vehicle is equipped with the optional CMTC,

remove the overhead console from the headliner.

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

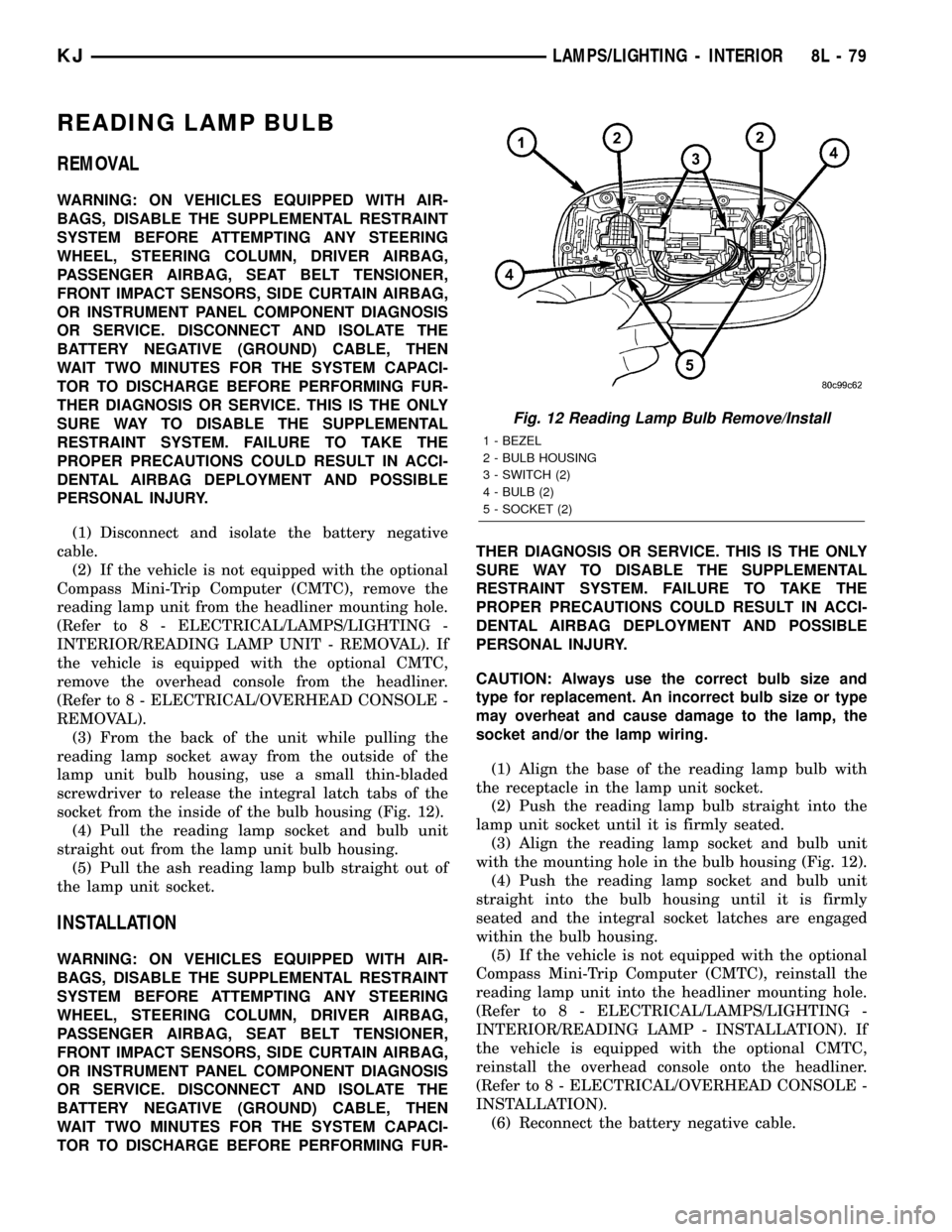

(3) From the back of the unit while pulling the

reading lamp socket away from the outside of the

lamp unit bulb housing, use a small thin-bladed

screwdriver to release the integral latch tabs of the

socket from the inside of the bulb housing (Fig. 12).

(4) Pull the reading lamp socket and bulb unit

straight out from the lamp unit bulb housing.

(5) Pull the ash reading lamp bulb straight out of

the lamp unit socket.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the reading lamp bulb with

the receptacle in the lamp unit socket.

(2) Push the reading lamp bulb straight into the

lamp unit socket until it is firmly seated.

(3) Align the reading lamp socket and bulb unit

with the mounting hole in the bulb housing (Fig. 12).

(4) Push the reading lamp socket and bulb unit

straight into the bulb housing until it is firmly

seated and the integral socket latches are engaged

within the bulb housing.

(5) If the vehicle is not equipped with the optional

Compass Mini-Trip Computer (CMTC), reinstall the

reading lamp unit into the headliner mounting hole.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/READING LAMP - INSTALLATION). If

the vehicle is equipped with the optional CMTC,

reinstall the overhead console onto the headliner.

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

(6) Reconnect the battery negative cable.

Fig. 12 Reading Lamp Bulb Remove/Install

1 - BEZEL

2 - BULB HOUSING

3 - SWITCH (2)

4 - BULB (2)

5 - SOCKET (2)

KJLAMPS/LIGHTING - INTERIOR 8L - 79

Page 524 of 1803

(4) Rotate the transmission range indicator illumi-

nation lamp socket counterclockwise about 30

degrees on the bottom of the range indicator.

(5) Pull the transmission range indicator illumina-

tion lamp socket and bulb unit straight out of the

bulb mounting hole in the bottom of the indicator.

(6) Pull the transmission range indicator illumina-

tion lamp bulb straight out of the socket.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the transmission range indi-

cator illumination lamp bulb with the receptacle in

the lamp socket.

(2) Push the transmission range indicator illumi-

nation lamp bulb straight into the lamp socket until

it is firmly seated.

(3) Align the transmission range indicator illumi-

nation lamp socket and bulb unit with the mounting

hole on the bottom of the indicator (Fig. 15).

(4) Push the transmission range indicator illumi-

nation lamp socket and bulb unit straight into the

bottom of the indicator until it is firmly seated.

(5) Rotate the transmission range indicator illumi-

nation lamp socket clockwise about 30 degrees on the

bottom of the indicator.

(6) Reinstall the center console onto the floor panel

transmission tunnel. (Refer to 23 - BODY/INTERI-

OR/FLOOR CONSOLE - INSTALLATION).

(7) Reconnect the battery negative cable.

VANITY LAMP BULB

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

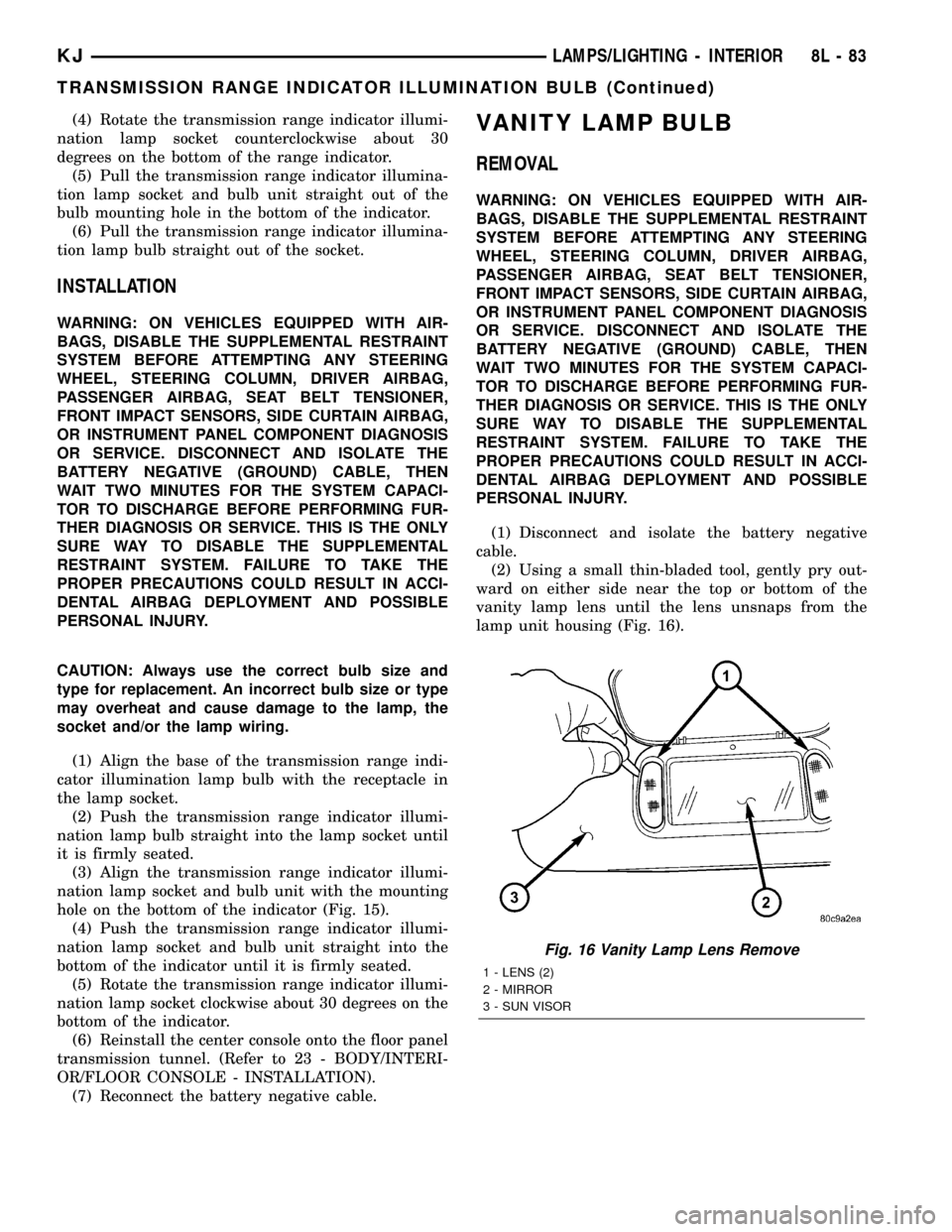

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small thin-bladed tool, gently pry out-

ward on either side near the top or bottom of the

vanity lamp lens until the lens unsnaps from the

lamp unit housing (Fig. 16).

Fig. 16 Vanity Lamp Lens Remove

1 - LENS (2)

2 - MIRROR

3 - SUN VISOR

KJLAMPS/LIGHTING - INTERIOR 8L - 83

TRANSMISSION RANGE INDICATOR ILLUMINATION BULB (Continued)

Page 527 of 1803

LICENSE PLATE LAMP BULB

REMOVAL.............................44

INSTALLATION.........................45

LICENSE PLATE LAMP UNIT

REMOVAL.............................45

INSTALLATION.........................46

MULTI-FUNCTION SWITCH

DESCRIPTION.........................46

OPERATION...........................48

DIAGNOSIS AND TESTING - MULTI-

FUNCTION SWITCH...................50

REMOVAL.............................53

INSTALLATION.........................53

PARK LAMP RELAY

DESCRIPTION.........................54

OPERATION...........................54

DIAGNOSIS AND TESTING - PARK LAMP

RELAY..............................55

REMOVAL.............................55

INSTALLATION.........................56

REAR FOG LAMP RELAY

DESCRIPTION.........................56

OPERATION...........................57

DIAGNOSIS AND TESTING - REAR FOG

LAMP RELAY.........................57

REMOVAL.............................58

INSTALLATION.........................58

REAR LAMP BULB

REMOVAL.............................59

INSTALLATION.........................59

REAR LAMP UNIT

REMOVAL.............................59

INSTALLATION.........................60

REPEATER LAMP BULB

REMOVAL.............................60INSTALLATION.........................60

REPEATER LAMP UNIT

REMOVAL.............................61

INSTALLATION.........................61

TRAILER TOW CONNECTOR

REMOVAL.............................61

INSTALLATION.........................61

TRAILER TOW RELAY

DESCRIPTION.........................62

OPERATION...........................62

DIAGNOSIS AND TESTING - TRAILER TOW

RELAY..............................62

REMOVAL.............................63

INSTALLATION.........................63

TRAILER TOW WIRING

DESCRIPTION.........................64

LAMP BAR

DESCRIPTION.........................65

OPERATION...........................65

DIAGNOSIS AND TESTING - LAMP BAR.....65

STANDARD PROCEDURE - LAMP BAR

AIMING.............................65

REMOVAL

REMOVAL - LAMP BAR.................65

REMOVAL - LAMP.....................66

INSTALLATION

INSTALLATION - LAMP BAR.............66

INSTALLATION - LAMP.................66

LAMP BAR SWITCH

DESCRIPTION.........................67

REMOVAL.............................67

INSTALLATION.........................67

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

The exterior lighting system for this model

includes the following exterior lamps (Fig. 1):

²Backup Lamps- The backup (or reverse) lamps

are integral to the rear lamp units mounted to the

back of the quarter panel on each side of the tailgate

at the rear of the vehicle.

²Brake Lamps- The brake (or stop) lamps

include a lamp that is integral to the rear lamp units

mounted to the back of the quarter panel on each

side of the tailgate, and the Center High Mounted

Stop Lamp (CHMSL) that is centered on the rear

edge of the roof panel above the flip-up glass opening

at the rear of the vehicle.

²Daytime Running Lamps- Vehicles manufac-

tured for sale in Canada illuminate the high beam

filament in each headlamp bulb serves as the Day-

time Running Lamps (DRL).²Front Fog Lamps- Optional front fog lamps

include a single round front fog lamp unit with an

adjustable reflector and a removable bulb that is

secured behind a dedicated opening on each forward-

facing end of the front bumper fascia.

²Hazard Warning Lamps- The hazard warning

lamps include all of the right and left turn signal

lamps.

²Headlamps- A single round headlamp housing

with a fixed lens, an adjustable reflector, and a single

removable halogen bulb is secured to the grille open-

ing panel on each side of the grille opening at the

front of the vehicle. In certain markets where

required, a headlamp leveling actuator motor is

included on each headlamp.

²Park Lamps- The park lamps include the front

park lamps and front side marker lamps that are

integral to the front lamp units mounted at each end

of the bumper fascia at the front of the vehicle, as

well as the rear park lamps and rear side marker

lamps that are integral to the rear lamp units

8Ls - 2 LAMPSKJ

Page 529 of 1803

mounted to the back of the quarter panel on each

side of the tailgate at the rear of the vehicle. The

park lamps include a license plate lamp or lamps,

depending upon the requirements of the market for

which the vehicle is manufactured. Vehicles with a

license plate tub located near the left end of the rear

bumper fascia have a single lamp, while vehicles

with a license plate module located on the spare tire

carrier have two license plate lamps. In certain mar-

kets where required, a front position lamp that is

integral to each headlamp unit is illuminated instead

of the front park lamps and front side marker lamps

in the park lamps circuit; and, a rectangular, red

reflector is located on the rear bumper fascia just

inboard and below each rear lamp unit.

²Rear Fog Lamps- Rear fog lamps are avail-

able only in certain markets where they are required

equipment. The rear fog lamps are integral to the

rear lamp units mounted to the back of the quarter

panel on each side of the tailgate at the rear of the

vehicle.

²Turn Signal Lamps- The turn signal lamps

include the front turn signal and front side marker

lamps that are integral to the front lamp units

mounted at each end of the bumper fascia at the

front of the vehicle, as well as rear turn signal lamps

that are integral to the rear lamp units mounted to

the back of the quarter panel on each side of the tail-

gate at the rear of the vehicle. In certain markets

where required, a repeater lamp unit mounted to

each front fender just behind the front wheel opening

is illuminated instead of the front side marker lamp

in each turn signal lamp circuit.

Other components of the exterior lighting system

for this model include:

²Combination Flasher- An electronic combina-

tion flasher is integral to the hazard warning switch

in the center of the instrument panel.

²Backup Lamp Switch- Vehicles equipped with

a manual transmission have a plunger-type backup

lamp switch located on the transmission housing. A

Transmission Range Sensor (TRS) integral to the

solenoid pack on the valve body of the optional elec-

tronic automatic transmission performs the backup

lamp switch function on models that are so equipped.

²Brake Lamp Switch- A plunger-type brake

lamp switch is located on the steering column sup-

port bracket under the instrument panel and actu-

ated by the brake pedal arm.²Body Control Module- The Body Control

Module (BCM) is located on the Junction Block (JB)

under the driver side outboard end of the instrument

panel. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/BODY CONTROL MODULE

- DESCRIPTION).

²Daytime Running Lamp Relay- Vehicles

manufactured for sale in Canada use a solid state

Daytime Running Lamps (DRL) relay installed in the

Junction Block (JB) instead of the conventional high

beam relay.

²Front Fog Lamp Relay- Vehicles equipped

with the optional front fog lamps have a front fog

lamp relay located in the Junction Block (JB).

²Hazard Switch- The hazard switch is located

near the center of the instrument panel and includes

the integral electronic combination flasher circuitry

for the hazard warning system and the turn signal

system.

²Headlamp Leveling Motor- A headlamp lev-

eling actuator motor is located on the back of each

headlamp housing of vehicles manufactured for cer-

tain markets where this equipment is required.

²Headlamp Leveling Switch- A thumbwheel

actuated headlamp leveling switch is mounted in the

driver side inboard instrument panel trim bezel of

vehicles manufactured for certain markets where this

equipment is required.

²High Beam Relay- A high beam relay is

located in the Junction Block (JB) of all vehicles

except those that are manufactured for sale in Can-

ada. Canadian vehicles have a solid state Daytime

Running Lamps (DRL) relay in the JB instead of the

high beam relay.

²Low Beam Relay- A low beam relay is located

in the Junction Block (JB) of all vehicles.

²Multi-Function Switch- The multi-function

switch is located on the top of the steering column,

just below the steering wheel. The multi-function

switch includes a left (lighting) control stalk and a

right (wiper) control stalk. The left control stalk is

dedicated to providing almost all of the driver con-

trols for both the exterior and interior lighting sys-

tems.

²Park Lamp Relay- A park lamp relay is

located in the Junction Block (JB) of all vehicles.

²Rear Fog Lamp Relay- Vehicles manufac-

tured for certain markets where rear fog lamps are

required equipment have a rear fog lamp relay

located in the Junction Block (JB).

1 - HEADLAMP UNIT (2)

2 - REPEATER LAMP UNIT (2)

3 - FRONT POSITION LAMP (2)

4 - FRONT LAMP UNIT (2)5 - FRONT FOG LAMP (2)

6 - CENTER HIGH MOUNTED STOP LAMP UNIT

7 - REAR LAMP UNIT

8 - LICENSE PLATE LAMP UNIT

8Ls - 4 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 530 of 1803

²Trailer Tow Adapter- Vehicles equipped with

a factory-installed trailer towing package have an

adapter provided that adapts the factory-installed

heavy duty 7-way trailer tow connector to a conven-

tional 4-way light duty connector.

²Trailer Tow Connector- Vehicles equipped

with a factory-installed trailer towing package have a

heavy duty 7-way trailer tow connector installed in a

bracket on the trailer hitch receiver.

²Trailer Tow Relays- Vehicles equipped with a

factory-installed trailer towing package have a con-

nector bank containing four relays located behind the

right quarter trim panel and over the right rear

wheel housing. The four relays are used to supply

fused ignition switch output (run), brake lamps, right

turn signal, and left turn signal outputs to a trailer

through the trailer tow wiring and connectors.

Hard wired circuitry connects the exterior lighting

system components to the electrical system of the

vehicle. These hard wired circuits are integral to sev-

eral wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the exterior lighting

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

Following are paragraphs that briefly describe the

operation of each of the major exterior lighting sys-

tems. The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, the PCM, and the PCI data bus

network inputs and outputs related to the various

exterior lighting systems requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.BACKUP LAMPS

The backup (or reverse) lamps have a path to

ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

backup lamps receive battery current from a fused

ignition switch output (run) fuse in the Junction

Block (JB) on the back-up lamp feed circuit only

when the backup lamp switch (manual transmission),

or backup lamp switch circuit of the Transmission

Range Sensor (TRS - electronic automatic transmis-

sion) is closed by the gearshift mechanism within the

transmission.

BRAKE LAMPS

The brake (or stop) lamps have a path to ground at

all times through their connection to the rear light-

ing wire harness from a take out of the rear body

wire harness with an eyelet terminal connector that

is secured by a screw to the base of the right D-pillar

behind the quarter trim panel. The Center High

Mounted Stop Lamp (CHMSL) has a path to ground

at all times through its connection to the rear body

wire harness from a take out of the rear body wire

harness with an eyelet terminal connector that is

secured by a ground screw to the driver side D-pillar

(left side D-pillar for left-hand drive, right side D-pil-

lar for right-hand drive) behind the quarter trim

panel. The brake lamps and CHMSL receive battery

current from a fused B(+) fuse in the Junction Block

(JB) on the brake lamp switch output circuit only

when the brake lamp switch circuit of the brake

lamp switch is closed by the brake pedal arm.

DAYTIME RUNNING LAMPS

Vehicles manufactured for sale in Canada illumi-

nate the high beam filament at a reduced intensity

when the engine is running and the exterior lamps

are turned off. This feature is enabled by the Body

Control Module (BCM) and a solid state Daytime

Running Lamps (DRL) relay, which is installed in the

Junction Block (JB) and the high beam relay is omit-

ted. When the BCM monitors an engine speed signal

of greater than 450 RPM and the status of the exte-

rior lighting switch input from the multi-function

switch is Off, the BCM duty cycles the DRL relay to

produce illumination of the headlamp high beam fil-

aments at a reduced intensity. The BCM also pro-

vides normal headlamp high beam operation through

the DRL relay on vehicles so equipped. When the

DRL relay is energized, it provides battery current

from a fused B(+) fuse in the JB to the headlamp

high beam filament through the DRL relay output

circuit.

KJLAMPS8Ls-5

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 531 of 1803

FRONT FOG LAMPS

Vehicles equipped with optional front fog lamps

have a premium Body Control Module (BCM), a front

fog lamp relay installed in the Junction Block (JB),

and a front fog lamp switch integral to the left (light-

ing) control stalk of the multi-function switch. The

front fog lamps have a path to ground at all times

through their connection to the front fascia wire har-

ness from two take outs of the headlamp and dash

wire harness with eyelet terminal connectors that

are secured by ground screws to the left inner fender

shield in the engine compartment. The BCM controls

front fog lamp operation by monitoring the exterior

lighting switch input from the multi-function switch,

then energizing or de-energizing the front fog lamp

relay control coil; and, by sending the appropriate

electronic message to the instrument cluster over the

Programmable Communications Interface (PCI) data

bus to turn the front fog lamp indicator on or off.

When the front fog lamp relay is energized, it pro-

vides battery current from a fused B(+) fuse in the

JB to the front fog lamps through the front fog lamp

relay output circuit. The BCM provides a battery

saver (load shedding) feature for the front fog lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position. In certain markets where

required, the front fog lamps are also turned off by

the BCM whenever the headlamp high beams are

selected. Each front fog lamp includes an integral

adjustment screw to be used for static aiming the fog

lamp beams.

HAZARD WARNING LAMPS

With the hazard switch in the On position, the

hazard warning system is activated causing the haz-

ard switch button illumination lamp, the right and

left turn signal indicators, and the right and left turn

signal lamps to flash on and off. When the hazard

warning system is activated, the circuitry within the

hazard switch and electronic combination flasher

unit will repeatedly energize and de-energize two

internal relays that switch battery current from a

fused B(+) fuse in the Junction Block (JB) to the

right side and left side turn signal indicators, and

turn signal lamps through the right and left turn sig-

nal circuits. The flashing of the hazard switch button

illumination lamp is performed internally by the haz-

ard switch and combination flasher unit circuit

board. The hazard warning lamps can also be ener-

gized by the Body Control Module (BCM) through a

hazard lamp control circuit input to the hazard

switch and combination flasher unit.HEADLAMPS

The headlamp system includes the Body Control

Module (BCM), a low beam relay installed in the

Junction Block (JB), a high beam relay installed in

the JB (except Canada), a solid state Daytime Run-

ning Lamps (DRL) relay installed in the JB (Canada

only), and the exterior lighting (headlamp and dim-

mer) switches integral to the left (lighting) control

stalk of the multi-function switch. The headlamp

bulbs have a path to ground at all times through

their connection to the grille opening reinforcement

wire harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The BCM

controls the headlamp operation by monitoring the

exterior lighting switch inputs from the multi-func-

tion switch, then energizing or de-energizing the con-

trol coils of the low beam relay, the high beam relay,

or the solid state circuitry of the DRL relay; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the high

beam indicator on or off. When each respective relay

is energized, it provides battery current from a fused

B(+) fuse in the Power Distribution Center (PDC)

through a relay (low beam, high beam, or DRL) out-

put circuit and four separate fuses in the JB through

individual fused right and left, low and high beam

output circuits to the appropriate headlamp bulb fil-

aments. The BCM provides a battery saver (load

shedding) feature for the headlamps, which will turn

these lamps off if they are left on for more than

about eight minutes with the ignition switch in the

Off position; and, a headlamp delay feature with a

DRBIIItscan tool programmable delay interval.

Each headlamp includes an integral adjustment

screw to be used for static aiming of the headlamp

beams.

HEADLAMP LEVELING

In certain markets where required, a headlamp

leveling system is provided on the vehicle. The head-

lamp leveling system includes unique headlamp units

equipped with a headlamp leveling actuator motor,

and a rotary thumbwheel actuated headlamp leveling

switch on the instrument panel. The headlamp level-

ing system allows the headlamp beams to be

adjusted to one of four vertical positions to compen-

sate for changes in inclination caused by the loading

of the vehicle suspension. The actuator motors are

mechanically connected through an integral pushrod

to an adjustable headlamp reflector. The headlamp

leveling switch is a resistor multiplexed unit that

provides one of four voltage outputs to the headlamp

leveling motors. The headlamp leveling motors will

8Ls - 6 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)