hub bearing JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 27 of 1803

FRONT

TABLE OF CONTENTS

page page

FRONT

DESCRIPTION..........................7

WARNING.............................7

SPECIFICATIONS

TORQUE CHART......................8

SPECIAL TOOLS

FRONT SUSPENSION...................8

BUSHINGS

REMOVAL - STABILIZER BAR BUSHINGS.....9

INSTALLATION - STABILIZER BAR BUSHINGS . . 9

HUB / BEARING

REMOVAL.............................9

INSTALLATION..........................9

KNUCKLE

REMOVAL.............................9

INSTALLATION..........................9

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT..............................10

LOWER CONTROL ARM

REMOVAL.............................10

INSTALLATION.........................10

SHOCK

REMOVAL

REMOVAL - LEFT SIDE.................11REMOVAL - RIGHT SIDE................11

INSTALLATION

INSTALLATION - LEFT SIDE.............12

INSTALLATION - RIGHT SIDE............12

SPRING

REMOVAL.............................13

INSTALLATION.........................13

CLEVIS BRACKET

REMOVAL.............................13

INSTALLATION.........................13

STABILIZER BAR

REMOVAL.............................14

INSTALLATION.........................14

STABILIZER LINK

REMOVAL.............................14

INSTALLATION.........................14

UPPER CONTROL ARM

REMOVAL

REMOVAL - RIGHT SIDE................14

REMOVAL - LEFT SIDE.................15

INSTALLATION

INSTALLATION - RIGHT SIDE............15

INSTALLATION - LEFT SIDE.............15

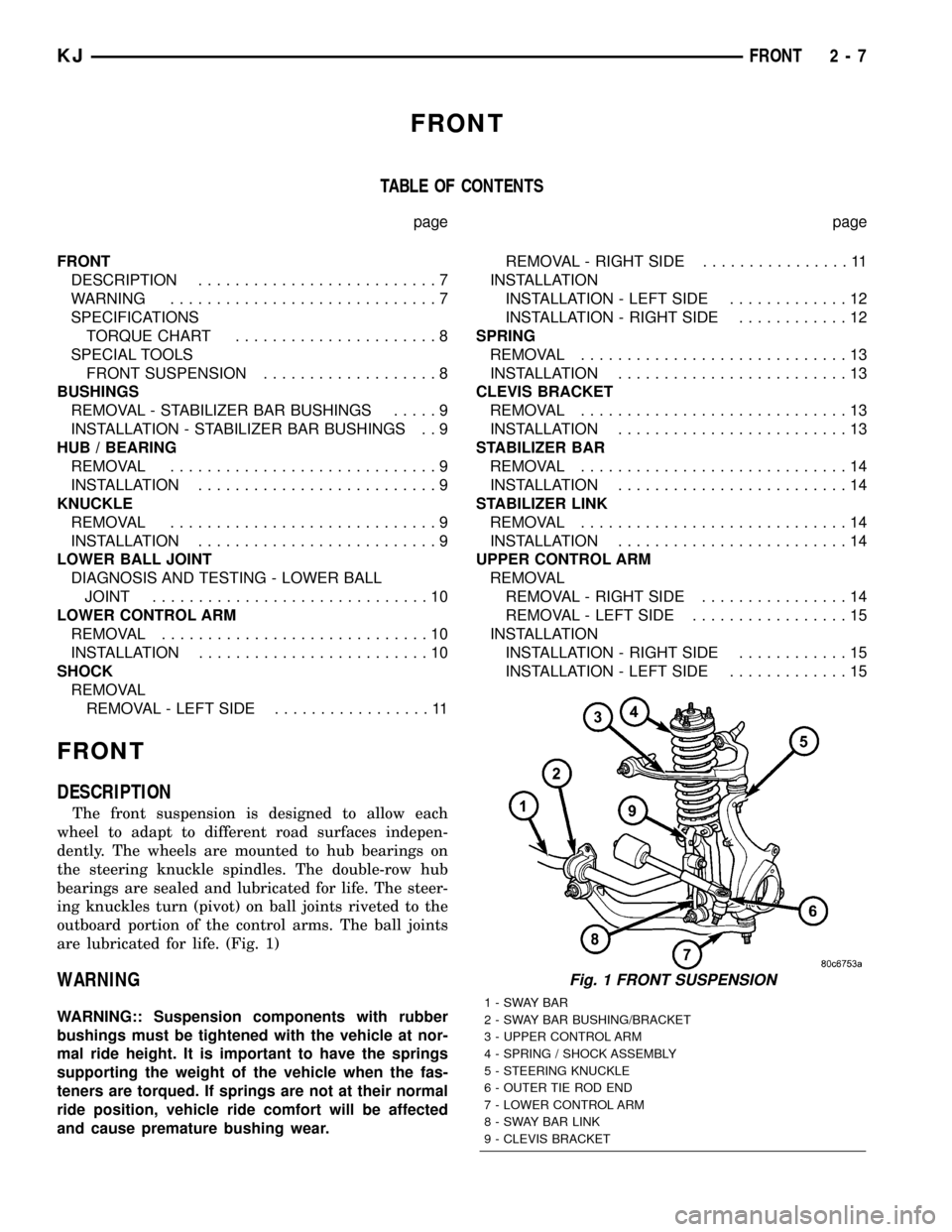

FRONT

DESCRIPTION

The front suspension is designed to allow each

wheel to adapt to different road surfaces indepen-

dently. The wheels are mounted to hub bearings on

the steering knuckle spindles. The double-row hub

bearings are sealed and lubricated for life. The steer-

ing knuckles turn (pivot) on ball joints riveted to the

outboard portion of the control arms. The ball joints

are lubricated for life. (Fig. 1)

WARNING

WARNING:: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

Fig. 1 FRONT SUSPENSION

1-SWAYBAR

2 - SWAY BAR BUSHING/BRACKET

3 - UPPER CONTROL ARM

4 - SPRING / SHOCK ASSEMBLY

5 - STEERING KNUCKLE

6 - OUTER TIE ROD END

7 - LOWER CONTROL ARM

8 - SWAY BAR LINK

9 - CLEVIS BRACKET

KJFRONT 2 - 7

Page 28 of 1803

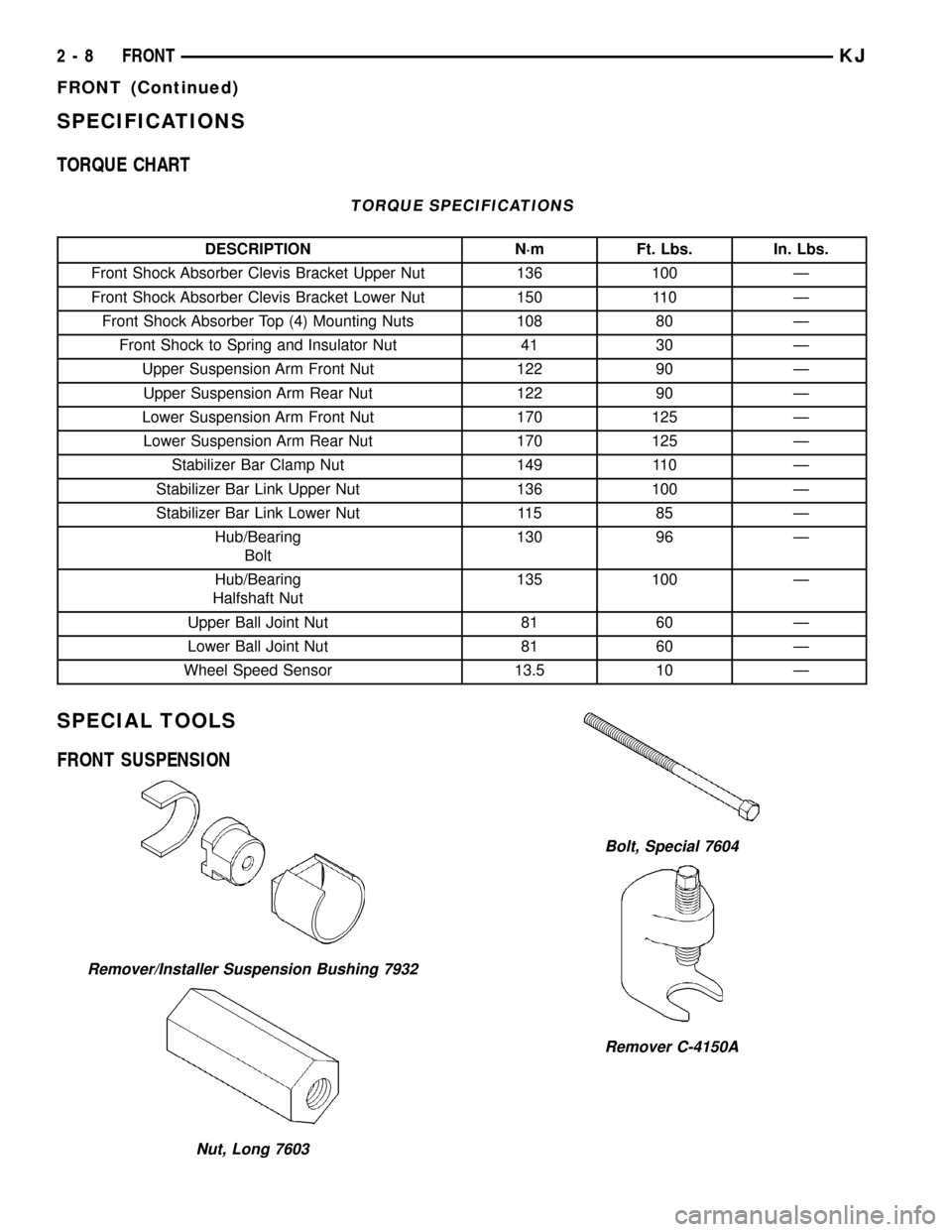

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front Shock Absorber Clevis Bracket Upper Nut 136 100 Ð

Front Shock Absorber Clevis Bracket Lower Nut 150 110 Ð

Front Shock Absorber Top (4) Mounting Nuts 108 80 Ð

Front Shock to Spring and Insulator Nut 41 30 Ð

Upper Suspension Arm Front Nut 122 90 Ð

Upper Suspension Arm Rear Nut 122 90 Ð

Lower Suspension Arm Front Nut 170 125 Ð

Lower Suspension Arm Rear Nut 170 125 Ð

Stabilizer Bar Clamp Nut 149 110 Ð

Stabilizer Bar Link Upper Nut 136 100 Ð

Stabilizer Bar Link Lower Nut 115 85 Ð

Hub/Bearing

Bolt130 96 Ð

Hub/Bearing

Halfshaft Nut135 100 Ð

Upper Ball Joint Nut 81 60 Ð

Lower Ball Joint Nut 81 60 Ð

Wheel Speed Sensor 13.5 10 Ð

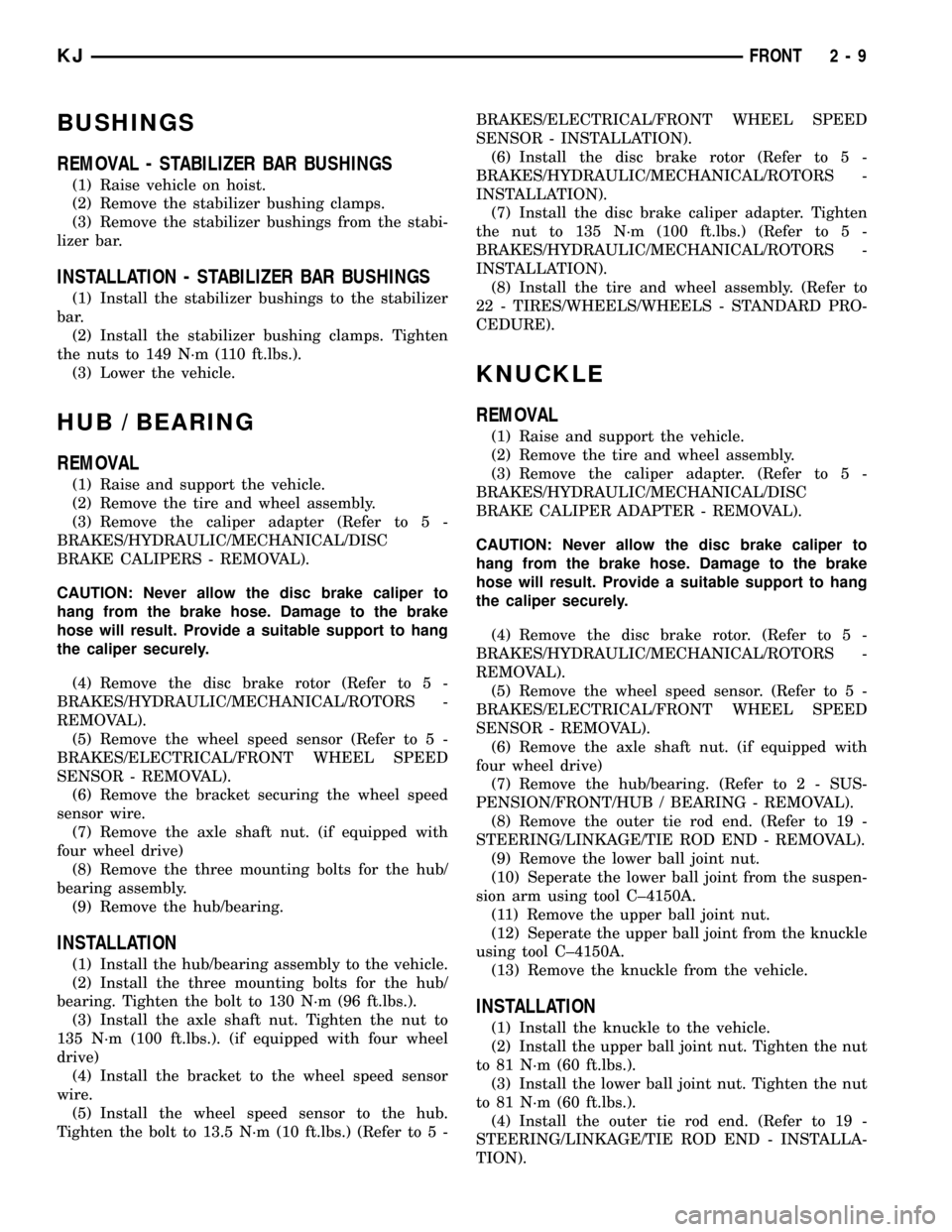

SPECIAL TOOLS

FRONT SUSPENSION

Remover/Installer Suspension Bushing 7932

Nut, Long 7603

Bolt, Special 7604

Remover C-4150A

2 - 8 FRONTKJ

FRONT (Continued)

Page 29 of 1803

BUSHINGS

REMOVAL - STABILIZER BAR BUSHINGS

(1) Raise vehicle on hoist.

(2) Remove the stabilizer bushing clamps.

(3) Remove the stabilizer bushings from the stabi-

lizer bar.

INSTALLATION - STABILIZER BAR BUSHINGS

(1) Install the stabilizer bushings to the stabilizer

bar.

(2) Install the stabilizer bushing clamps. Tighten

the nuts to 149 N´m (110 ft.lbs.).

(3) Lower the vehicle.

HUB / BEARING

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(4) Remove the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Remove the wheel speed sensor (Refer to 5 -

BRAKES/ELECTRICAL/FRONT WHEEL SPEED

SENSOR - REMOVAL).

(6) Remove the bracket securing the wheel speed

sensor wire.

(7) Remove the axle shaft nut. (if equipped with

four wheel drive)

(8) Remove the three mounting bolts for the hub/

bearing assembly.

(9) Remove the hub/bearing.

INSTALLATION

(1) Install the hub/bearing assembly to the vehicle.

(2) Install the three mounting bolts for the hub/

bearing. Tighten the bolt to 130 N´m (96 ft.lbs.).

(3) Install the axle shaft nut. Tighten the nut to

135 N´m (100 ft.lbs.). (if equipped with four wheel

drive)

(4) Install the bracket to the wheel speed sensor

wire.

(5) Install the wheel speed sensor to the hub.

Tighten the bolt to 13.5 N´m (10 ft.lbs.) (Refer to 5 -BRAKES/ELECTRICAL/FRONT WHEEL SPEED

SENSOR - INSTALLATION).

(6) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(7) Install the disc brake caliper adapter. Tighten

the nut to 135 N´m (100 ft.lbs.) (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(8) Install the tire and wheel assembly. (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

KNUCKLE

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the caliper adapter. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(4) Remove the disc brake rotor. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Remove the wheel speed sensor. (Refer to 5 -

BRAKES/ELECTRICAL/FRONT WHEEL SPEED

SENSOR - REMOVAL).

(6) Remove the axle shaft nut. (if equipped with

four wheel drive)

(7) Remove the hub/bearing. (Refer to 2 - SUS-

PENSION/FRONT/HUB / BEARING - REMOVAL).

(8) Remove the outer tie rod end. (Refer to 19 -

STEERING/LINKAGE/TIE ROD END - REMOVAL).

(9) Remove the lower ball joint nut.

(10) Seperate the lower ball joint from the suspen-

sion arm using tool C±4150A.

(11) Remove the upper ball joint nut.

(12) Seperate the upper ball joint from the knuckle

using tool C±4150A.

(13) Remove the knuckle from the vehicle.

INSTALLATION

(1) Install the knuckle to the vehicle.

(2) Install the upper ball joint nut. Tighten the nut

to 81 N´m (60 ft.lbs.).

(3) Install the lower ball joint nut. Tighten the nut

to 81 N´m (60 ft.lbs.).

(4) Install the outer tie rod end. (Refer to 19 -

STEERING/LINKAGE/TIE ROD END - INSTALLA-

TION).

KJFRONT 2 - 9

Page 30 of 1803

(5) Install the hub/bearing. (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - INSTALLATION).

(6) Install the axle shaft nut. Tighten the nut to

135 N´m (96 ft.lbs.).(if equipped with four wheel

drive).

(7) Install the wheel speed sensor. (Refer to 5 -

BRAKES/ELECTRICAL/FRONT WHEEL SPEED

SENSOR - INSTALLATION).

(8) Install the disc brake rotor. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(9) Install the caliper adapter. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(10) Install the tire and wheel assembly. (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(11) Perform the set toe procedure (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

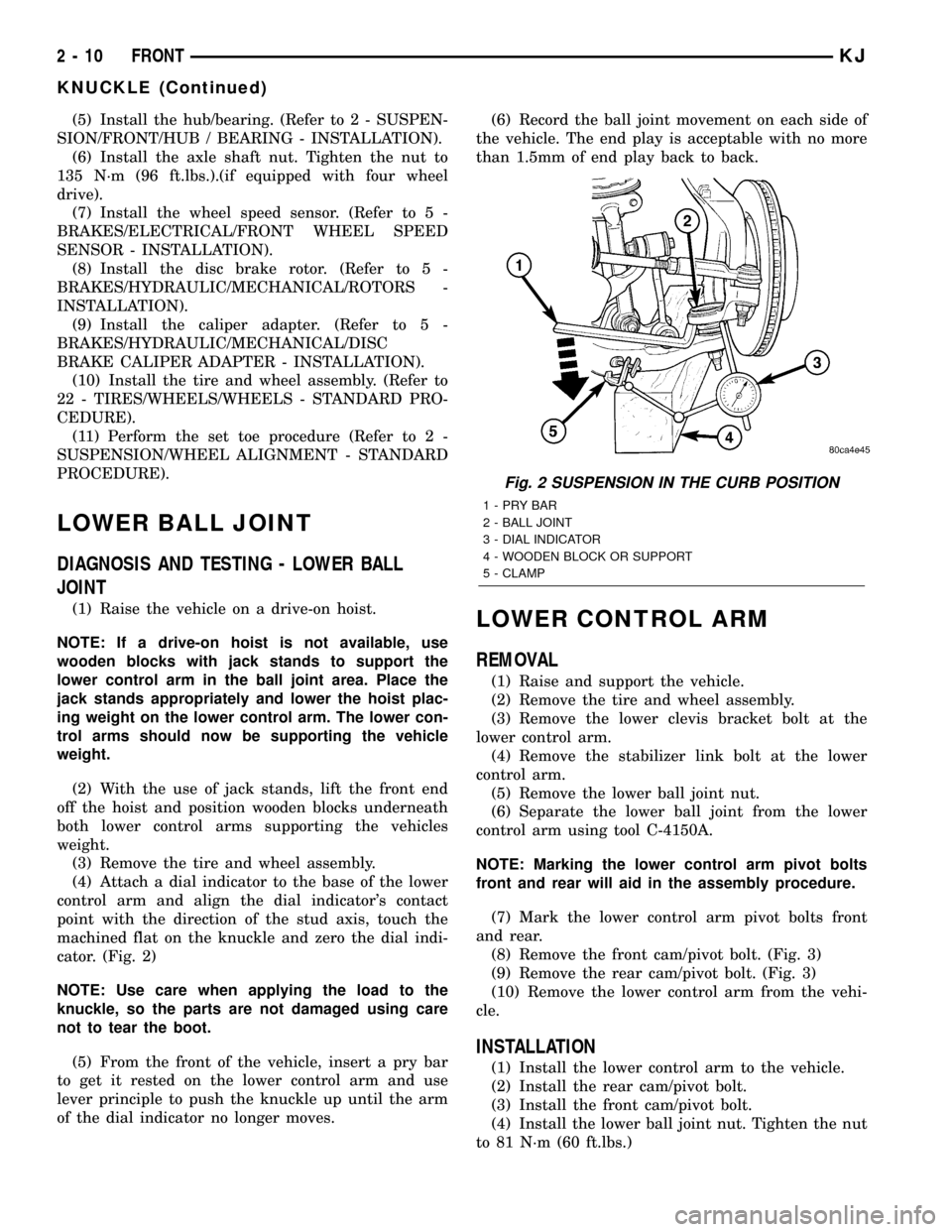

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT

(1) Raise the vehicle on a drive-on hoist.

NOTE: If a drive-on hoist is not available, use

wooden blocks with jack stands to support the

lower control arm in the ball joint area. Place the

jack stands appropriately and lower the hoist plac-

ing weight on the lower control arm. The lower con-

trol arms should now be supporting the vehicle

weight.

(2) With the use of jack stands, lift the front end

off the hoist and position wooden blocks underneath

both lower control arms supporting the vehicles

weight.

(3) Remove the tire and wheel assembly.

(4) Attach a dial indicator to the base of the lower

control arm and align the dial indicator's contact

point with the direction of the stud axis, touch the

machined flat on the knuckle and zero the dial indi-

cator. (Fig. 2)

NOTE: Use care when applying the load to the

knuckle, so the parts are not damaged using care

not to tear the boot.

(5) From the front of the vehicle, insert a pry bar

to get it rested on the lower control arm and use

lever principle to push the knuckle up until the arm

of the dial indicator no longer moves.(6) Record the ball joint movement on each side of

the vehicle. The end play is acceptable with no more

than 1.5mm of end play back to back.LOWER CONTROL ARM

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the lower clevis bracket bolt at the

lower control arm.

(4) Remove the stabilizer link bolt at the lower

control arm.

(5) Remove the lower ball joint nut.

(6) Separate the lower ball joint from the lower

control arm using tool C-4150A.

NOTE: Marking the lower control arm pivot bolts

front and rear will aid in the assembly procedure.

(7) Mark the lower control arm pivot bolts front

and rear.

(8) Remove the front cam/pivot bolt. (Fig. 3)

(9) Remove the rear cam/pivot bolt. (Fig. 3)

(10) Remove the lower control arm from the vehi-

cle.

INSTALLATION

(1) Install the lower control arm to the vehicle.

(2) Install the rear cam/pivot bolt.

(3) Install the front cam/pivot bolt.

(4) Install the lower ball joint nut. Tighten the nut

to 81 N´m (60 ft.lbs.)

Fig. 2 SUSPENSION IN THE CURB POSITION

1-PRYBAR

2 - BALL JOINT

3 - DIAL INDICATOR

4 - WOODEN BLOCK OR SUPPORT

5 - CLAMP

2 - 10 FRONTKJ

KNUCKLE (Continued)

Page 60 of 1803

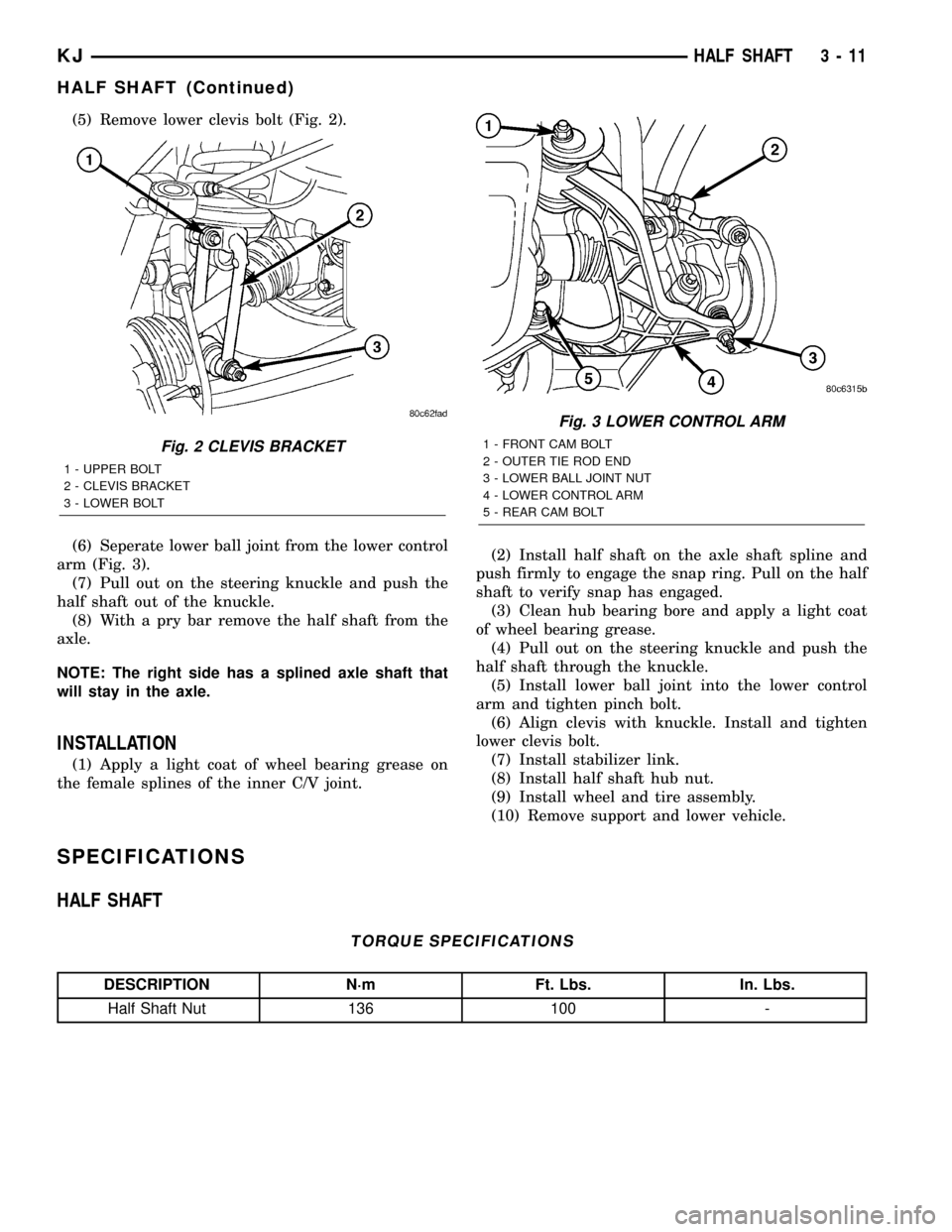

(5) Remove lower clevis bolt (Fig. 2).

(6) Seperate lower ball joint from the lower control

arm (Fig. 3).

(7) Pull out on the steering knuckle and push the

half shaft out of the knuckle.

(8) With a pry bar remove the half shaft from the

axle.

NOTE: The right side has a splined axle shaft that

will stay in the axle.

INSTALLATION

(1) Apply a light coat of wheel bearing grease on

the female splines of the inner C/V joint.(2) Install half shaft on the axle shaft spline and

push firmly to engage the snap ring. Pull on the half

shaft to verify snap has engaged.

(3) Clean hub bearing bore and apply a light coat

of wheel bearing grease.

(4) Pull out on the steering knuckle and push the

half shaft through the knuckle.

(5) Install lower ball joint into the lower control

arm and tighten pinch bolt.

(6) Align clevis with knuckle. Install and tighten

lower clevis bolt.

(7) Install stabilizer link.

(8) Install half shaft hub nut.

(9) Install wheel and tire assembly.

(10) Remove support and lower vehicle.

SPECIFICATIONS

HALF SHAFT

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Half Shaft Nut 136 100 -

Fig. 3 LOWER CONTROL ARM

1 - FRONT CAM BOLT

2 - OUTER TIE ROD END

3 - LOWER BALL JOINT NUT

4 - LOWER CONTROL ARM

5 - REAR CAM BOLTFig. 2 CLEVIS BRACKET

1 - UPPER BOLT

2 - CLEVIS BRACKET

3 - LOWER BOLT

KJHALF SHAFT 3 - 11

HALF SHAFT (Continued)

Page 61 of 1803

SPECIAL TOOLS

CV JOINT/BOOT-OUTER

REMOVAL

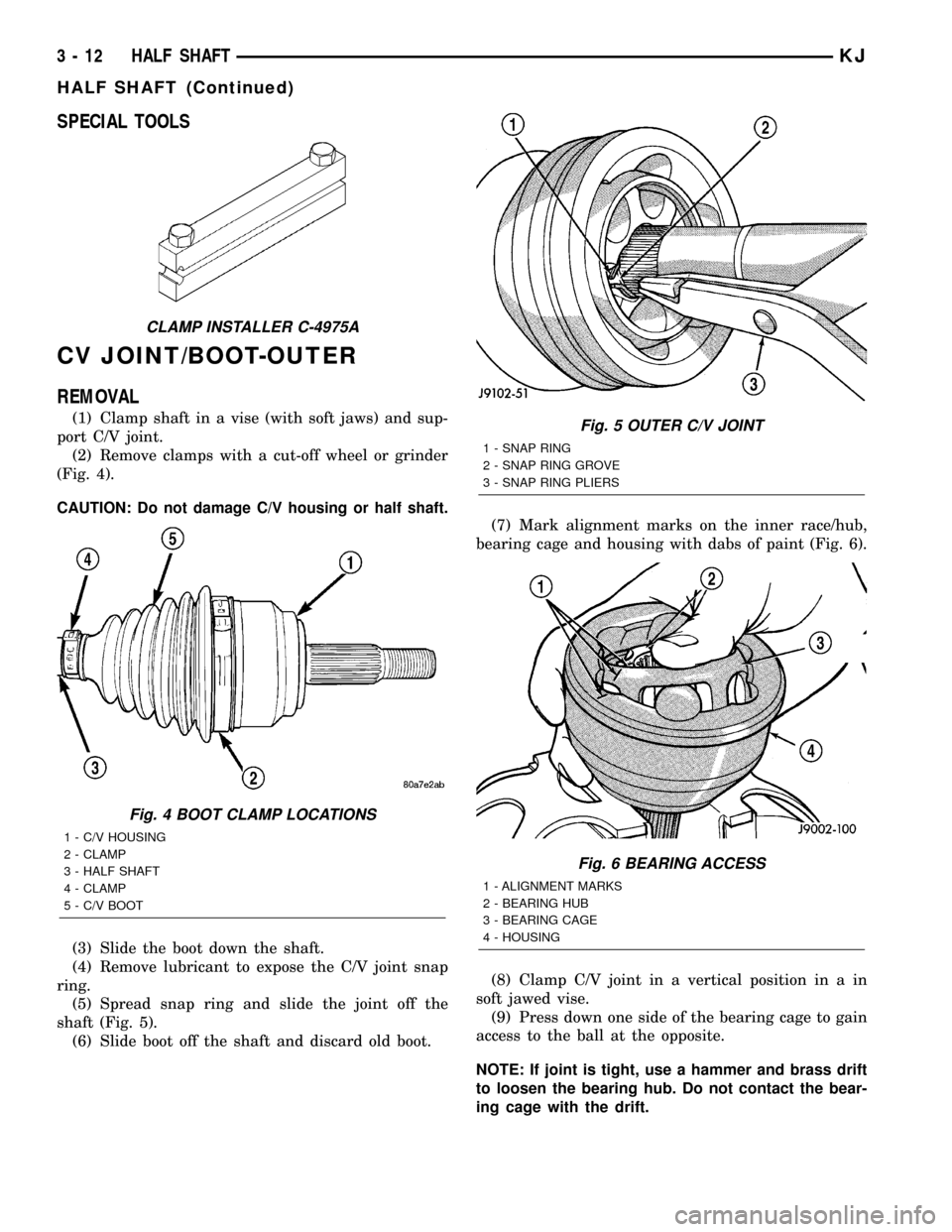

(1) Clamp shaft in a vise (with soft jaws) and sup-

port C/V joint.

(2) Remove clamps with a cut-off wheel or grinder

(Fig. 4).

CAUTION: Do not damage C/V housing or half shaft.

(3) Slide the boot down the shaft.

(4) Remove lubricant to expose the C/V joint snap

ring.

(5) Spread snap ring and slide the joint off the

shaft (Fig. 5).

(6) Slide boot off the shaft and discard old boot.(7) Mark alignment marks on the inner race/hub,

bearing cage and housing with dabs of paint (Fig. 6).

(8) Clamp C/V joint in a vertical position in a in

soft jawed vise.

(9) Press down one side of the bearing cage to gain

access to the ball at the opposite.

NOTE: If joint is tight, use a hammer and brass drift

to loosen the bearing hub. Do not contact the bear-

ing cage with the drift.

CLAMP INSTALLER C-4975A

Fig. 4 BOOT CLAMP LOCATIONS

1 - C/V HOUSING

2 - CLAMP

3 - HALF SHAFT

4 - CLAMP

5 - C/V BOOT

Fig. 5 OUTER C/V JOINT

1 - SNAP RING

2 - SNAP RING GROVE

3 - SNAP RING PLIERS

Fig. 6 BEARING ACCESS

1 - ALIGNMENT MARKS

2 - BEARING HUB

3 - BEARING CAGE

4 - HOUSING

3 - 12 HALF SHAFTKJ

HALF SHAFT (Continued)

Page 62 of 1803

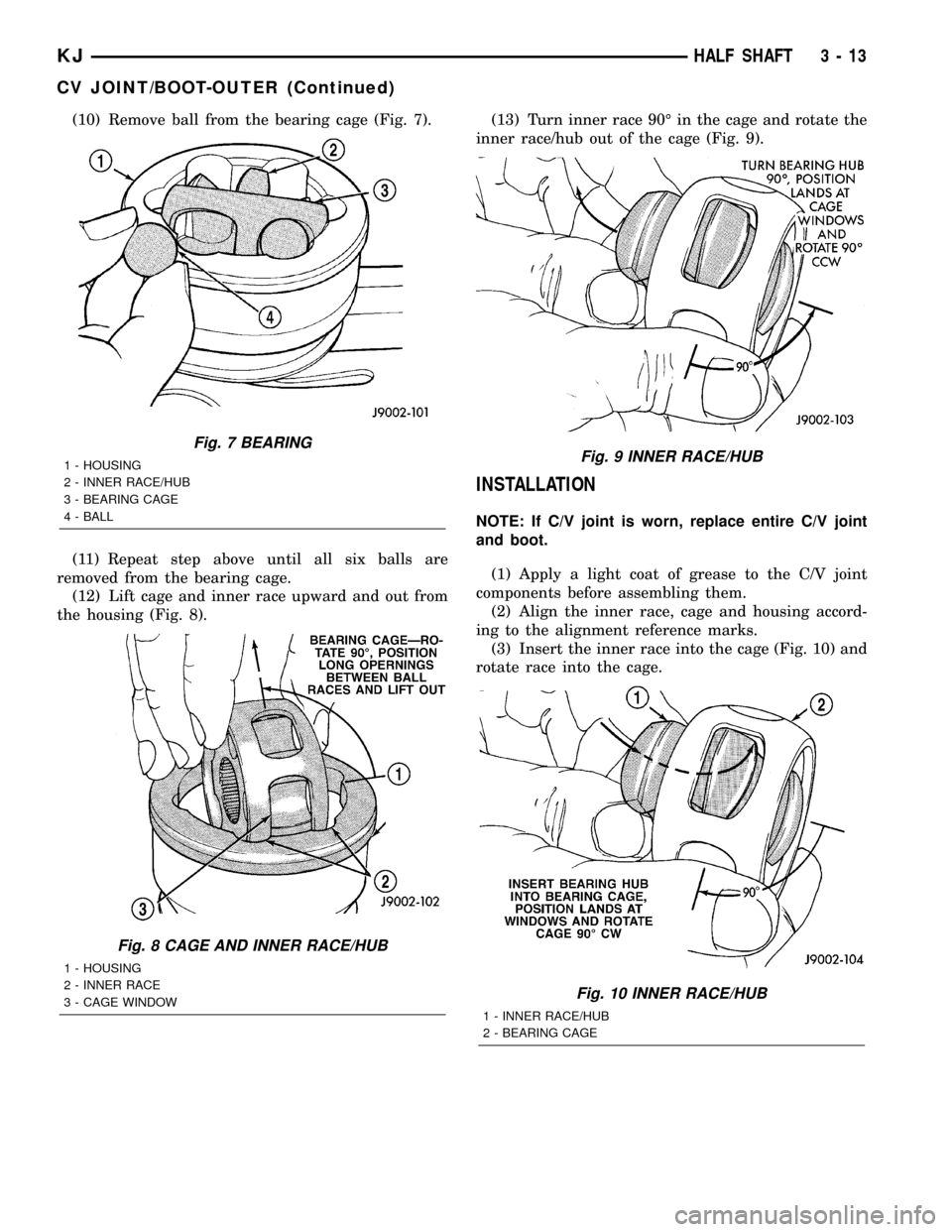

(10) Remove ball from the bearing cage (Fig. 7).

(11) Repeat step above until all six balls are

removed from the bearing cage.

(12) Lift cage and inner race upward and out from

the housing (Fig. 8).(13) Turn inner race 90É in the cage and rotate the

inner race/hub out of the cage (Fig. 9).

INSTALLATION

NOTE: If C/V joint is worn, replace entire C/V joint

and boot.

(1) Apply a light coat of grease to the C/V joint

components before assembling them.

(2) Align the inner race, cage and housing accord-

ing to the alignment reference marks.

(3) Insert the inner race into the cage (Fig. 10) and

rotate race into the cage.

Fig. 7 BEARING

1 - HOUSING

2 - INNER RACE/HUB

3 - BEARING CAGE

4 - BALL

Fig. 8 CAGE AND INNER RACE/HUB

1 - HOUSING

2 - INNER RACE

3 - CAGE WINDOW

Fig. 9 INNER RACE/HUB

Fig. 10 INNER RACE/HUB

1 - INNER RACE/HUB

2 - BEARING CAGE

KJHALF SHAFT 3 - 13

CV JOINT/BOOT-OUTER (Continued)

Page 63 of 1803

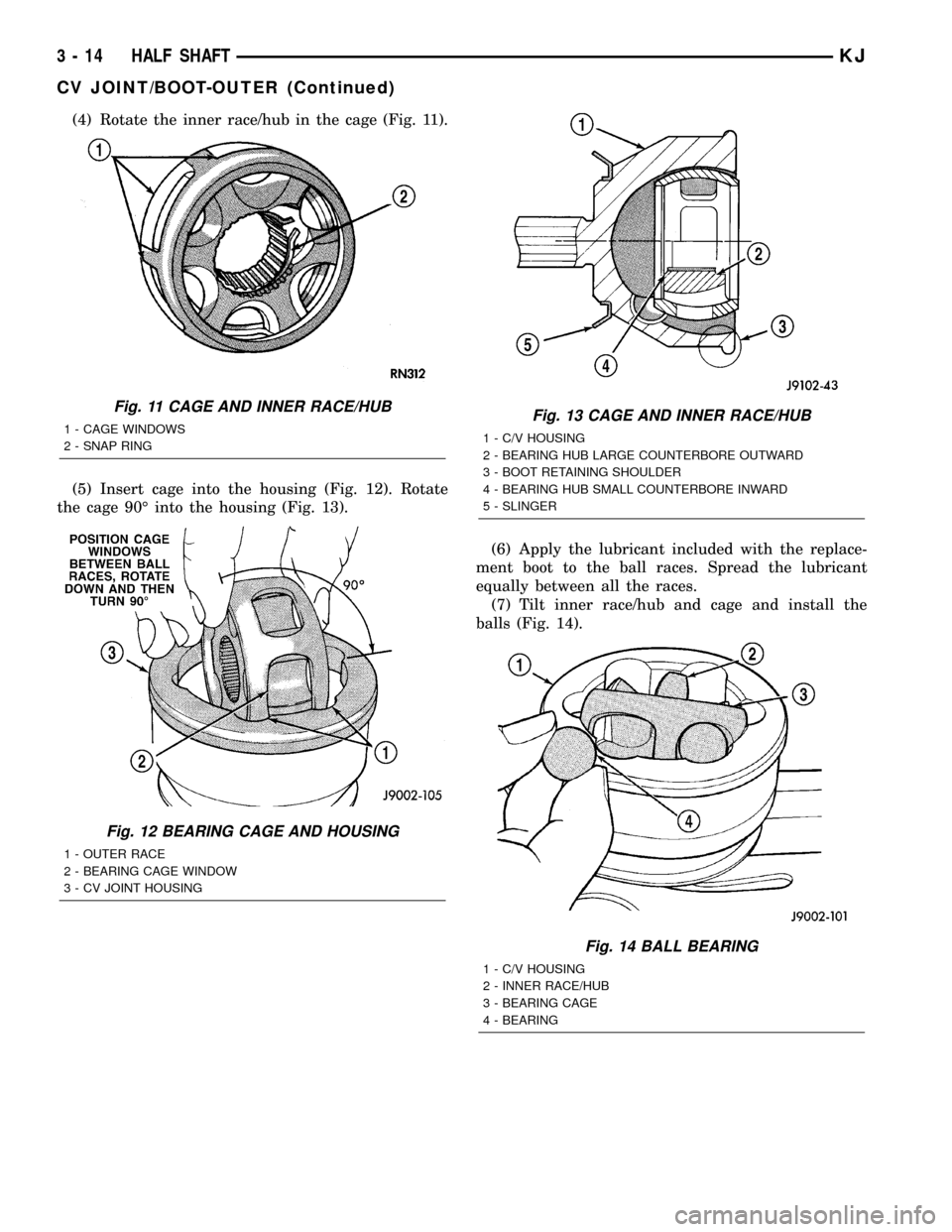

(4) Rotate the inner race/hub in the cage (Fig. 11).

(5) Insert cage into the housing (Fig. 12). Rotate

the cage 90É into the housing (Fig. 13).

(6) Apply the lubricant included with the replace-

ment boot to the ball races. Spread the lubricant

equally between all the races.

(7) Tilt inner race/hub and cage and install the

balls (Fig. 14).

Fig. 11 CAGE AND INNER RACE/HUB

1 - CAGE WINDOWS

2 - SNAP RING

Fig. 12 BEARING CAGE AND HOUSING

1 - OUTER RACE

2 - BEARING CAGE WINDOW

3 - CV JOINT HOUSING

Fig. 13 CAGE AND INNER RACE/HUB

1 - C/V HOUSING

2 - BEARING HUB LARGE COUNTERBORE OUTWARD

3 - BOOT RETAINING SHOULDER

4 - BEARING HUB SMALL COUNTERBORE INWARD

5 - SLINGER

Fig. 14 BALL BEARING

1 - C/V HOUSING

2 - INNER RACE/HUB

3 - BEARING CAGE

4 - BEARING

3 - 14 HALF SHAFTKJ

CV JOINT/BOOT-OUTER (Continued)

Page 64 of 1803

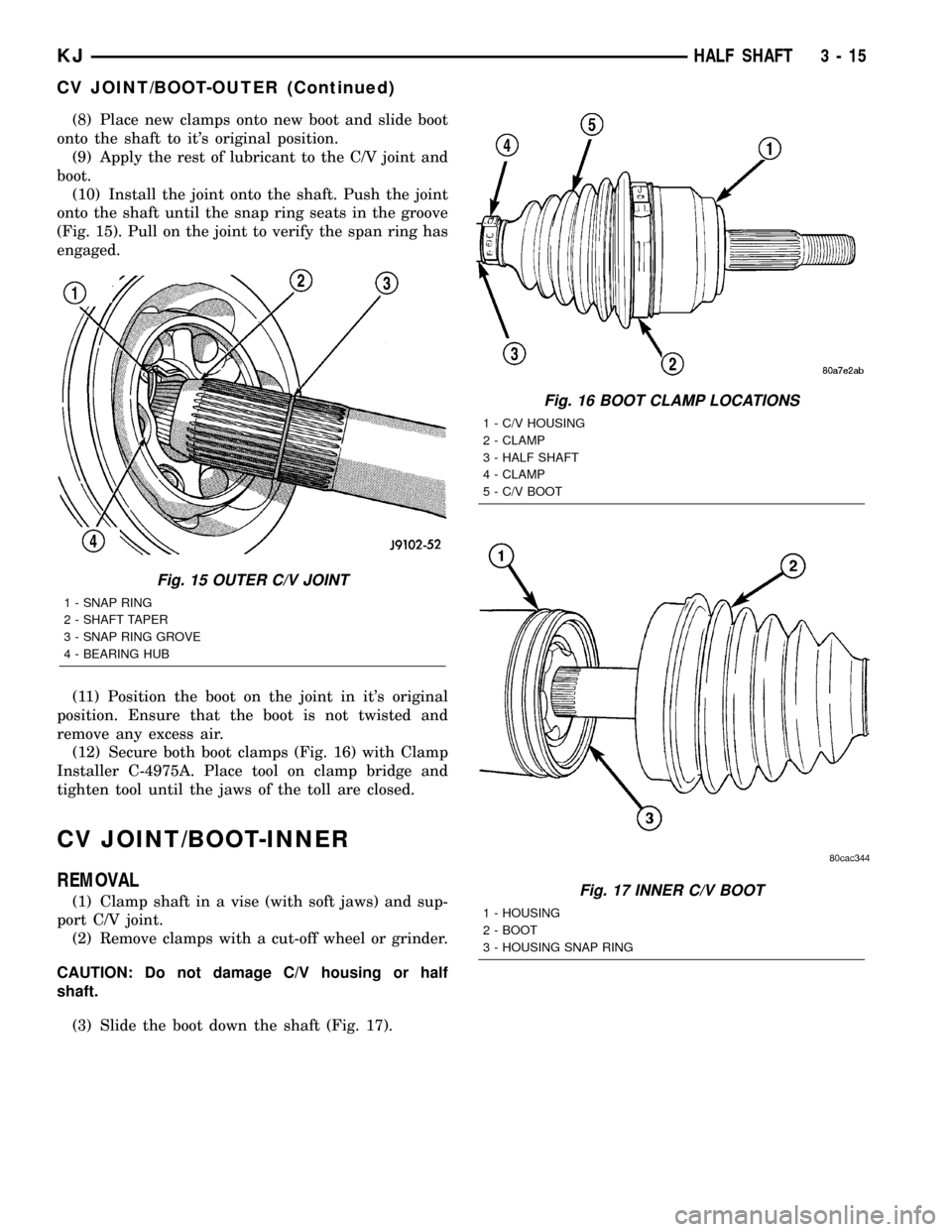

(8) Place new clamps onto new boot and slide boot

onto the shaft to it's original position.

(9) Apply the rest of lubricant to the C/V joint and

boot.

(10) Install the joint onto the shaft. Push the joint

onto the shaft until the snap ring seats in the groove

(Fig. 15). Pull on the joint to verify the span ring has

engaged.

(11) Position the boot on the joint in it's original

position. Ensure that the boot is not twisted and

remove any excess air.

(12) Secure both boot clamps (Fig. 16) with Clamp

Installer C-4975A. Place tool on clamp bridge and

tighten tool until the jaws of the toll are closed.

CV JOINT/BOOT-INNER

REMOVAL

(1) Clamp shaft in a vise (with soft jaws) and sup-

port C/V joint.

(2) Remove clamps with a cut-off wheel or grinder.

CAUTION: Do not damage C/V housing or half

shaft.

(3) Slide the boot down the shaft (Fig. 17).

Fig. 15 OUTER C/V JOINT

1 - SNAP RING

2 - SHAFT TAPER

3 - SNAP RING GROVE

4 - BEARING HUB

Fig. 16 BOOT CLAMP LOCATIONS

1 - C/V HOUSING

2 - CLAMP

3 - HALF SHAFT

4 - CLAMP

5 - C/V BOOT

Fig. 17 INNER C/V BOOT

1 - HOUSING

2 - BOOT

3 - HOUSING SNAP RING

KJHALF SHAFT 3 - 15

CV JOINT/BOOT-OUTER (Continued)

Page 68 of 1803

FRONT AXLE - 186FIA

TABLE OF CONTENTS

page page

FRONT AXLE - 186FIA

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - AXLE..........20

REMOVAL.............................24

INSTALLATION.........................24

ADJUSTMENTS........................25

SPECIFICATIONS - FRONT AXLE...........33

SPECIAL TOOLS

FRONT AXLE........................34

AXLE SHAFTS

REMOVAL.............................37

INSTALLATION.........................37

AXLE SHAFT SEALS

REMOVAL.............................37

INSTALLATION.........................38

AXLE BEARINGS

REMOVAL.............................38INSTALLATION.........................38

PINION SEAL

REMOVAL.............................38

INSTALLATION.........................39

DIFFERENTIAL

REMOVAL.............................40

DISASSEMBLY.........................41

ASSEMBLY............................41

INSTALLATION.........................42

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................43

INSTALLATION.........................44

PINION GEAR/RING GEAR

REMOVAL.............................44

INSTALLATION.........................46

FRONT AXLE - 186FIA

DESCRIPTION

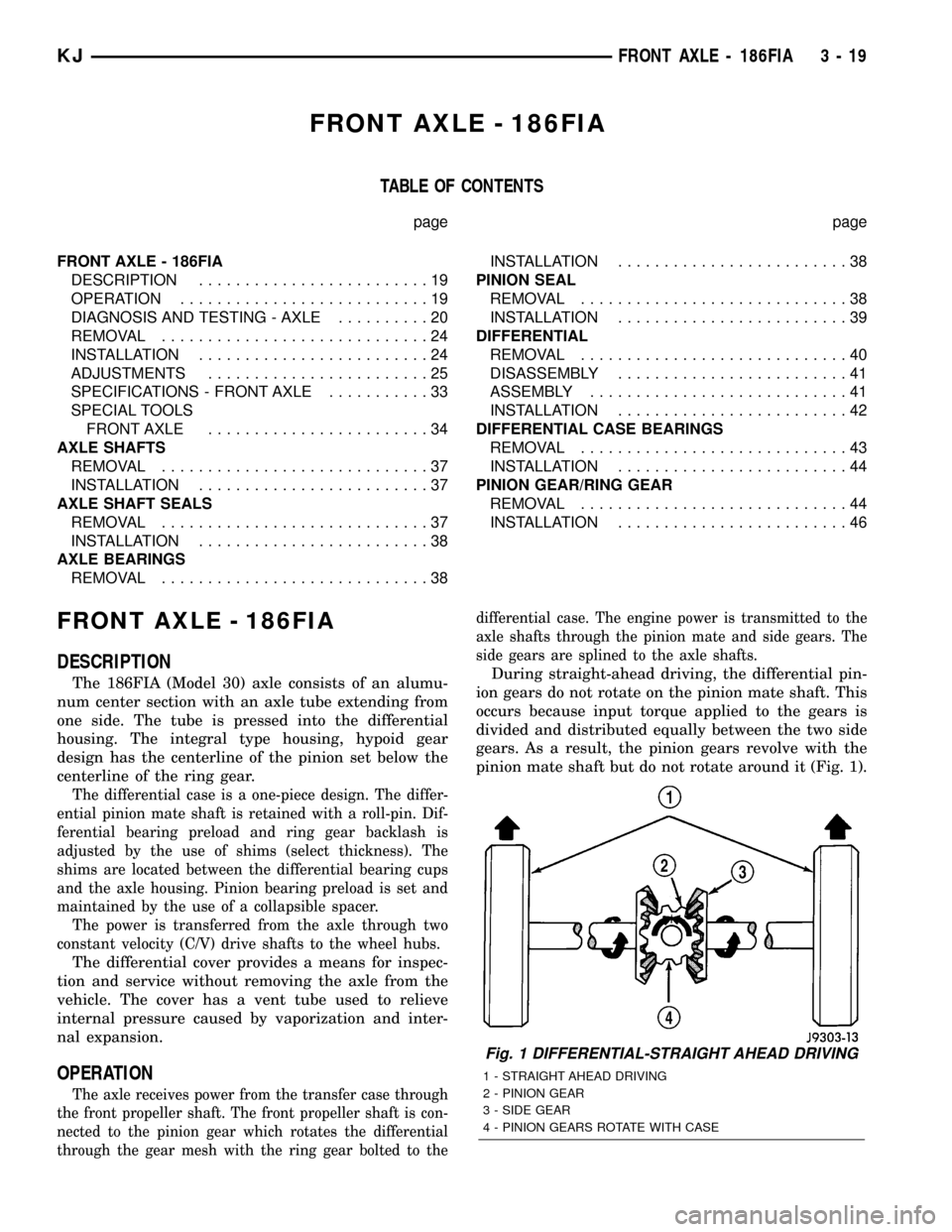

The 186FIA (Model 30) axle consists of an alumu-

num center section with an axle tube extending from

one side. The tube is pressed into the differential

housing. The integral type housing, hypoid gear

design has the centerline of the pinion set below the

centerline of the ring gear.

The differential case is a one-piece design. The differ-

ential pinion mate shaft is retained with a roll-pin. Dif-

ferential bearing preload and ring gear backlash is

adjusted by the use of shims (select thickness). The

shims are located between the differential bearing cups

and the axle housing. Pinion bearing preload is set and

maintained by the use of a collapsible spacer.

The power is transferred from the axle through two

constant velocity (C/V) drive shafts to the wheel hubs.

The differential cover provides a means for inspec-

tion and service without removing the axle from the

vehicle. The cover has a vent tube used to relieve

internal pressure caused by vaporization and inter-

nal expansion.

OPERATION

The axle receives power from the transfer case through

the front propeller shaft. The front propeller shaft is con-

nected to the pinion gear which rotates the differential

through the gear mesh with the ring gear bolted to thedifferential case. The engine power is transmitted to the

axle shafts through the pinion mate and side gears. The

side gears are splined to the axle shafts.

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).

Fig. 1 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - STRAIGHT AHEAD DRIVING

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

KJFRONT AXLE - 186FIA 3 - 19