light JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 7 of 1803

FASTENER USAGE

DESCRIPTION

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

INTERNATIONAL SYMBOLS

DESCRIPTION

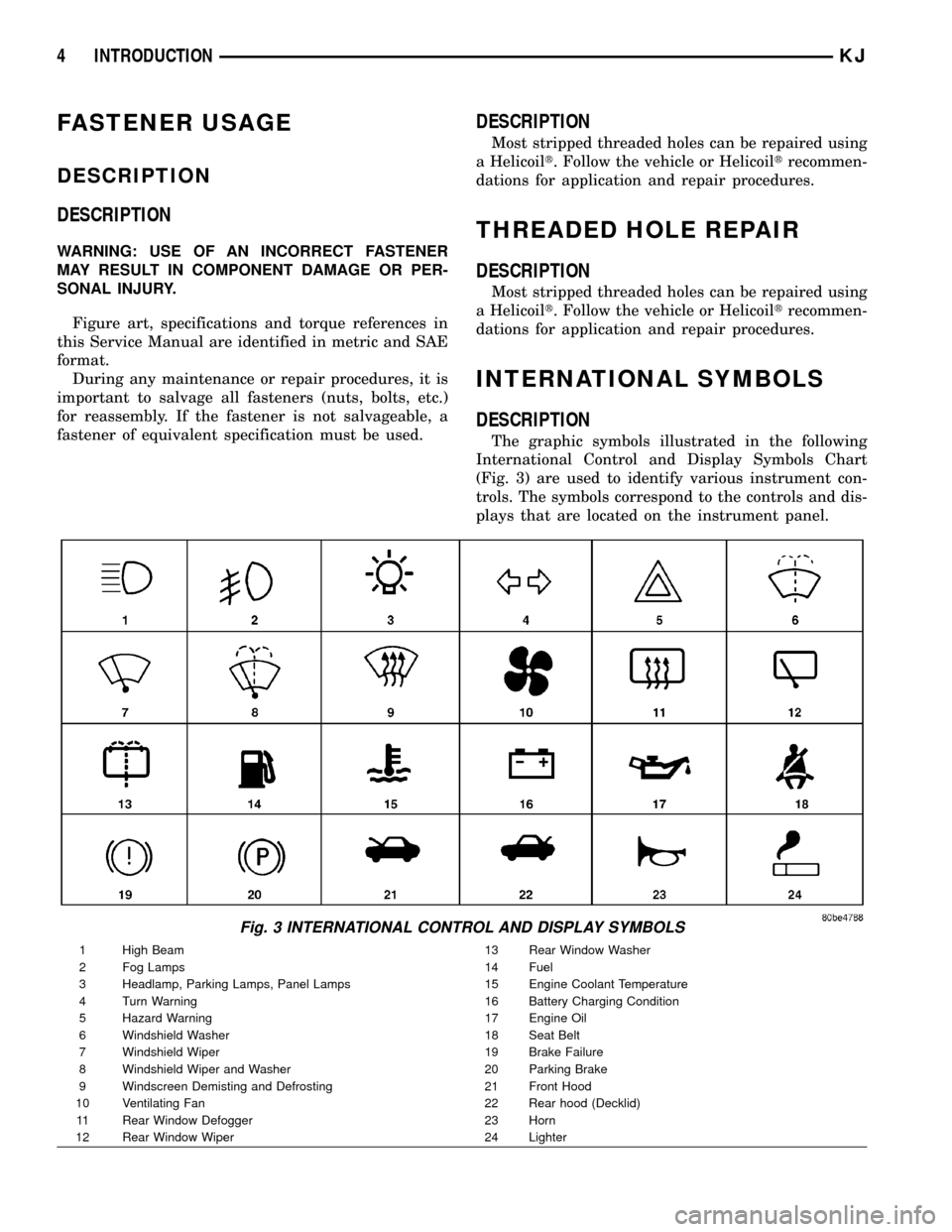

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 3) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 3 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

4 INTRODUCTIONKJ

Page 25 of 1803

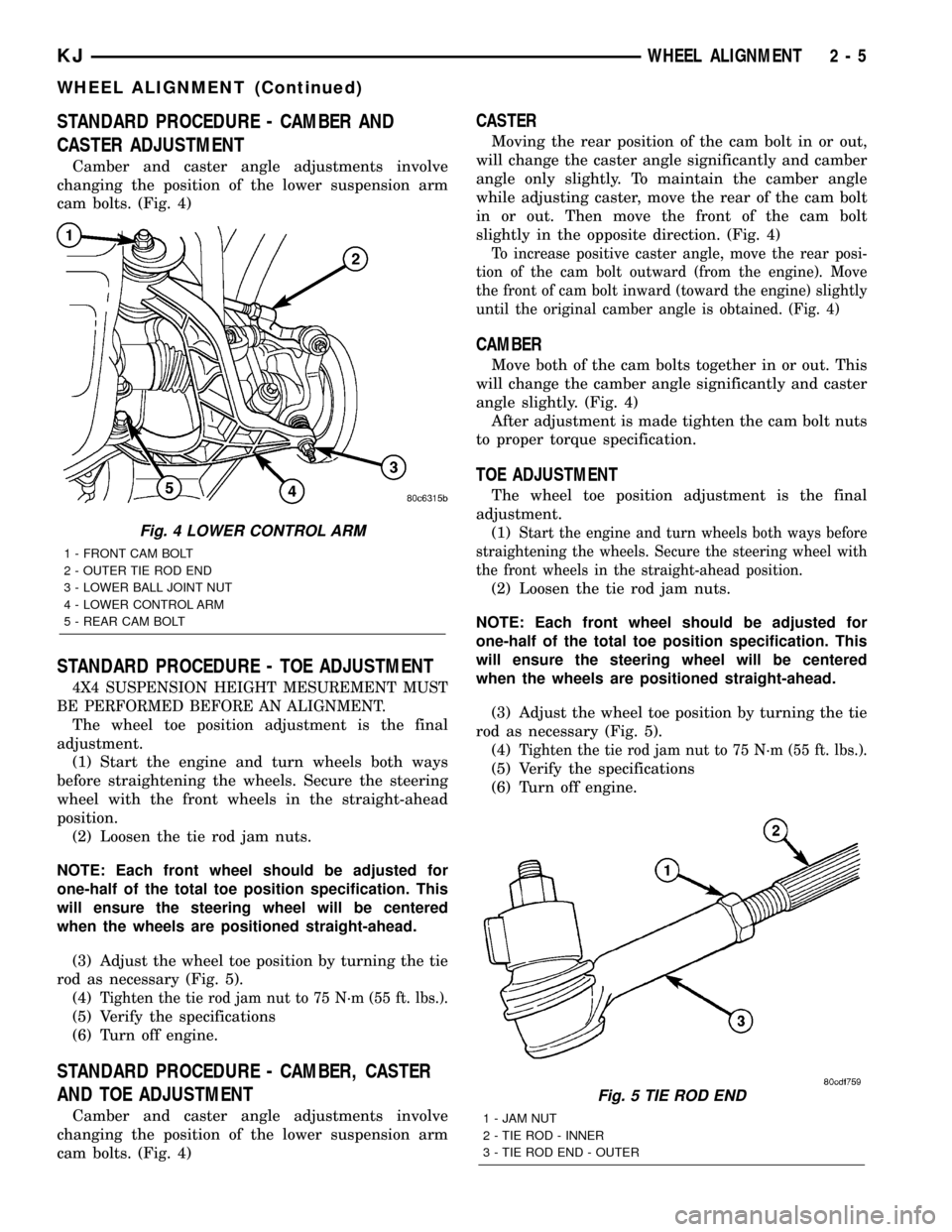

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT

Camber and caster angle adjustments involve

changing the position of the lower suspension arm

cam bolts. (Fig. 4)

STANDARD PROCEDURE - TOE ADJUSTMENT

4X4 SUSPENSION HEIGHT MESUREMENT MUST

BE PERFORMED BEFORE AN ALIGNMENT.

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod as necessary (Fig. 5).

(4)

Tighten the tie rod jam nut to 75 N´m (55 ft. lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - CAMBER, CASTER

AND TOE ADJUSTMENT

Camber and caster angle adjustments involve

changing the position of the lower suspension arm

cam bolts. (Fig. 4)

CASTER

Moving the rear position of the cam bolt in or out,

will change the caster angle significantly and camber

angle only slightly. To maintain the camber angle

while adjusting caster, move the rear of the cam bolt

in or out. Then move the front of the cam bolt

slightly in the opposite direction. (Fig. 4)

To increase positive caster angle, move the rear posi-

tion of the cam bolt outward (from the engine). Move

the front of cam bolt inward (toward the engine) slightly

until the original camber angle is obtained. (Fig. 4)

CAMBER

Move both of the cam bolts together in or out. This

will change the camber angle significantly and caster

angle slightly. (Fig. 4)

After adjustment is made tighten the cam bolt nuts

to proper torque specification.

TOE ADJUSTMENT

The wheel toe position adjustment is the final

adjustment.

(1)

Start the engine and turn wheels both ways before

straightening the wheels. Secure the steering wheel with

the front wheels in the straight-ahead position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod as necessary (Fig. 5).

(4)

Tighten the tie rod jam nut to 75 N´m (55 ft. lbs.).

(5) Verify the specifications

(6) Turn off engine.

Fig. 5 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

Fig. 4 LOWER CONTROL ARM

1 - FRONT CAM BOLT

2 - OUTER TIE ROD END

3 - LOWER BALL JOINT NUT

4 - LOWER CONTROL ARM

5 - REAR CAM BOLT

KJWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 41 of 1803

INSTALLATION

(1) Position the upper suspension arm in the

frame rail brackets (Fig. 8).

(2) Install the mounting bolts and tighten to 100

N´m (74 ft. lbs.).

(3) Retighten the heat shield back into place.

(4) Pull the arm down on the differential housing

bracket and install the pinch bolt and nut. Tighten

the nut to 95 N´m (70 ft. lbs.) (Fig. 7).

(5) Remove the supports and lower the vehicle.

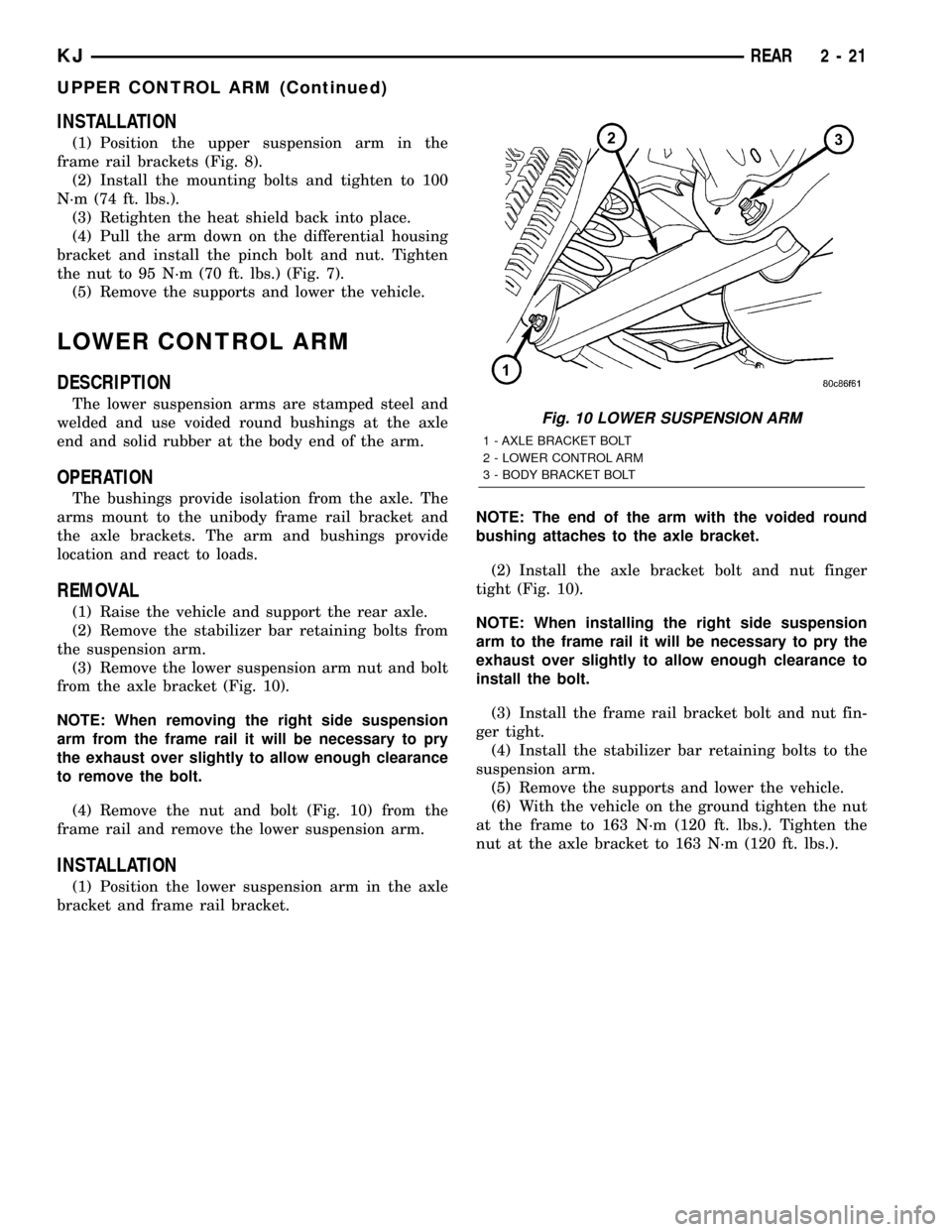

LOWER CONTROL ARM

DESCRIPTION

The lower suspension arms are stamped steel and

welded and use voided round bushings at the axle

end and solid rubber at the body end of the arm.

OPERATION

The bushings provide isolation from the axle. The

arms mount to the unibody frame rail bracket and

the axle brackets. The arm and bushings provide

location and react to loads.

REMOVAL

(1) Raise the vehicle and support the rear axle.

(2) Remove the stabilizer bar retaining bolts from

the suspension arm.

(3) Remove the lower suspension arm nut and bolt

from the axle bracket (Fig. 10).

NOTE: When removing the right side suspension

arm from the frame rail it will be necessary to pry

the exhaust over slightly to allow enough clearance

to remove the bolt.

(4) Remove the nut and bolt (Fig. 10) from the

frame rail and remove the lower suspension arm.

INSTALLATION

(1) Position the lower suspension arm in the axle

bracket and frame rail bracket.NOTE: The end of the arm with the voided round

bushing attaches to the axle bracket.

(2) Install the axle bracket bolt and nut finger

tight (Fig. 10).

NOTE: When installing the right side suspension

arm to the frame rail it will be necessary to pry the

exhaust over slightly to allow enough clearance to

install the bolt.

(3) Install the frame rail bracket bolt and nut fin-

ger tight.

(4) Install the stabilizer bar retaining bolts to the

suspension arm.

(5) Remove the supports and lower the vehicle.

(6) With the vehicle on the ground tighten the nut

at the frame to 163 N´m (120 ft. lbs.). Tighten the

nut at the axle bracket to 163 N´m (120 ft. lbs.).

Fig. 10 LOWER SUSPENSION ARM

1 - AXLE BRACKET BOLT

2 - LOWER CONTROL ARM

3 - BODY BRACKET BOLT

KJREAR 2 - 21

UPPER CONTROL ARM (Continued)

Page 60 of 1803

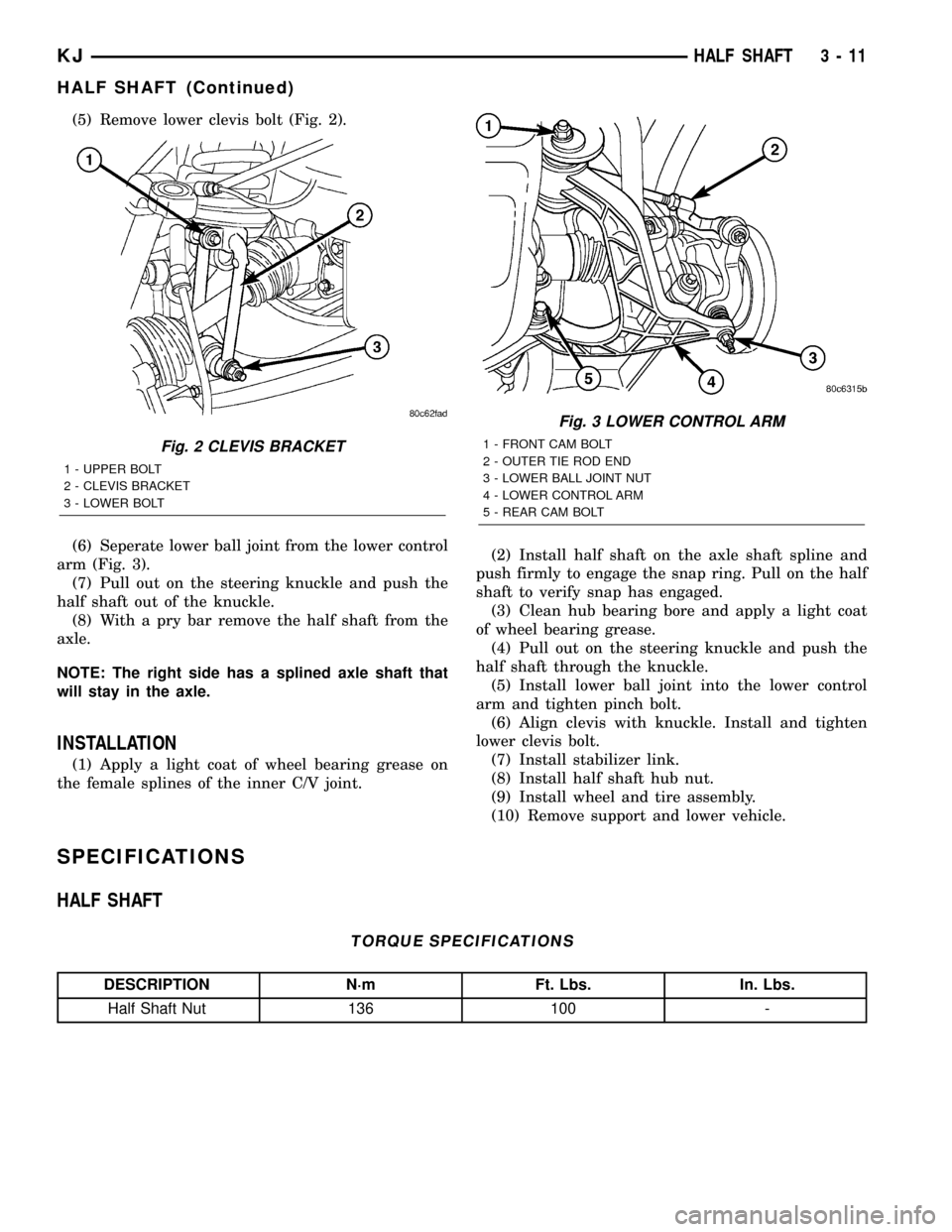

(5) Remove lower clevis bolt (Fig. 2).

(6) Seperate lower ball joint from the lower control

arm (Fig. 3).

(7) Pull out on the steering knuckle and push the

half shaft out of the knuckle.

(8) With a pry bar remove the half shaft from the

axle.

NOTE: The right side has a splined axle shaft that

will stay in the axle.

INSTALLATION

(1) Apply a light coat of wheel bearing grease on

the female splines of the inner C/V joint.(2) Install half shaft on the axle shaft spline and

push firmly to engage the snap ring. Pull on the half

shaft to verify snap has engaged.

(3) Clean hub bearing bore and apply a light coat

of wheel bearing grease.

(4) Pull out on the steering knuckle and push the

half shaft through the knuckle.

(5) Install lower ball joint into the lower control

arm and tighten pinch bolt.

(6) Align clevis with knuckle. Install and tighten

lower clevis bolt.

(7) Install stabilizer link.

(8) Install half shaft hub nut.

(9) Install wheel and tire assembly.

(10) Remove support and lower vehicle.

SPECIFICATIONS

HALF SHAFT

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Half Shaft Nut 136 100 -

Fig. 3 LOWER CONTROL ARM

1 - FRONT CAM BOLT

2 - OUTER TIE ROD END

3 - LOWER BALL JOINT NUT

4 - LOWER CONTROL ARM

5 - REAR CAM BOLTFig. 2 CLEVIS BRACKET

1 - UPPER BOLT

2 - CLEVIS BRACKET

3 - LOWER BOLT

KJHALF SHAFT 3 - 11

HALF SHAFT (Continued)

Page 62 of 1803

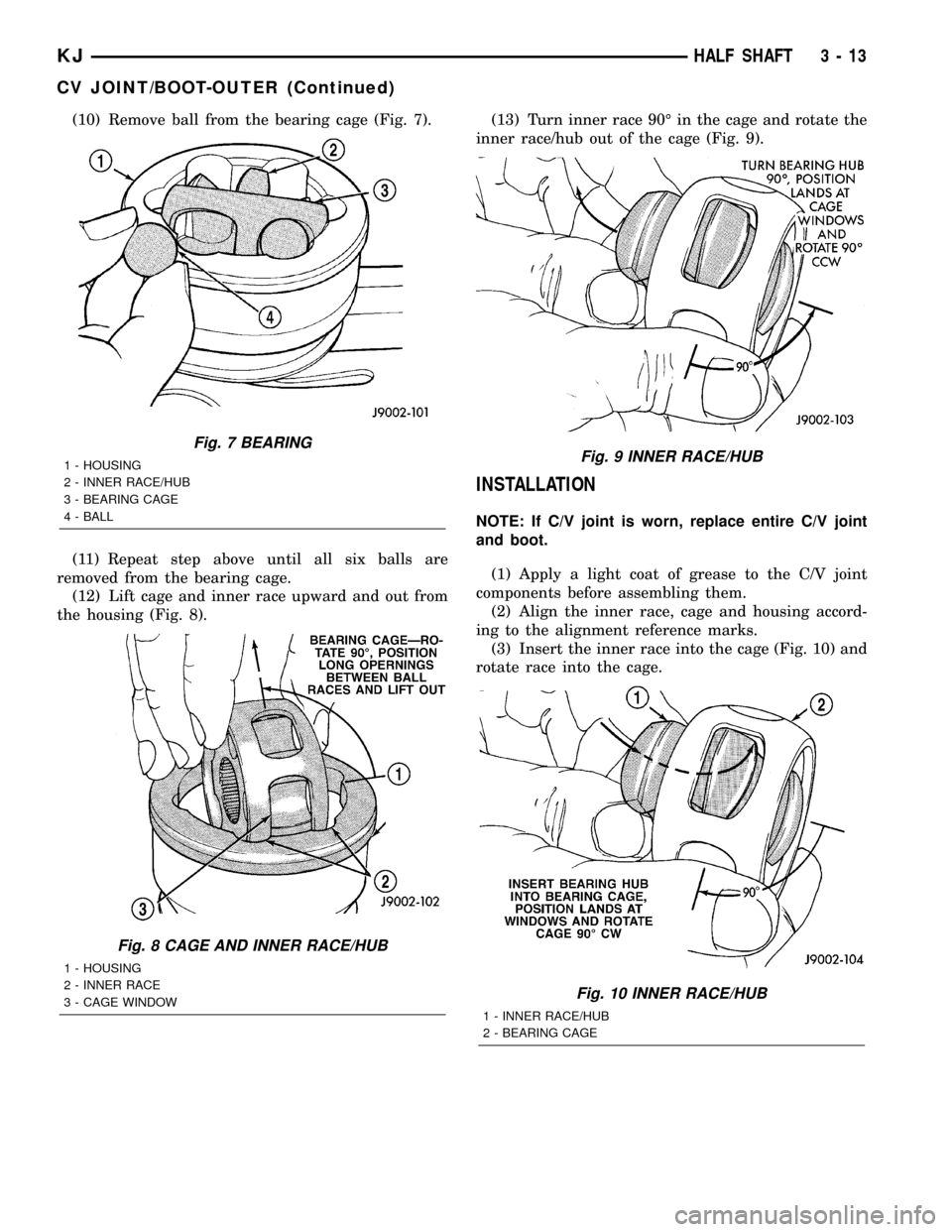

(10) Remove ball from the bearing cage (Fig. 7).

(11) Repeat step above until all six balls are

removed from the bearing cage.

(12) Lift cage and inner race upward and out from

the housing (Fig. 8).(13) Turn inner race 90É in the cage and rotate the

inner race/hub out of the cage (Fig. 9).

INSTALLATION

NOTE: If C/V joint is worn, replace entire C/V joint

and boot.

(1) Apply a light coat of grease to the C/V joint

components before assembling them.

(2) Align the inner race, cage and housing accord-

ing to the alignment reference marks.

(3) Insert the inner race into the cage (Fig. 10) and

rotate race into the cage.

Fig. 7 BEARING

1 - HOUSING

2 - INNER RACE/HUB

3 - BEARING CAGE

4 - BALL

Fig. 8 CAGE AND INNER RACE/HUB

1 - HOUSING

2 - INNER RACE

3 - CAGE WINDOW

Fig. 9 INNER RACE/HUB

Fig. 10 INNER RACE/HUB

1 - INNER RACE/HUB

2 - BEARING CAGE

KJHALF SHAFT 3 - 13

CV JOINT/BOOT-OUTER (Continued)

Page 69 of 1803

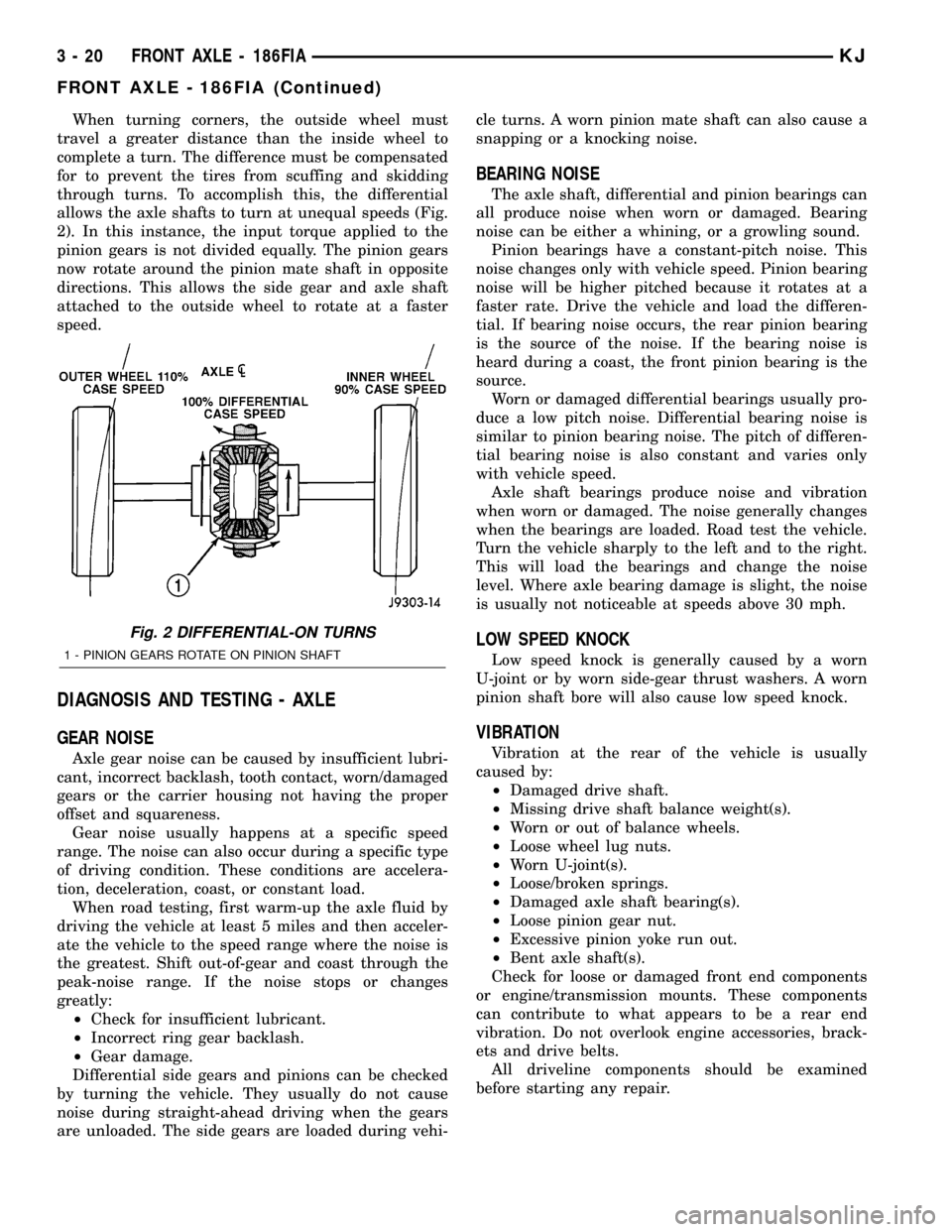

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

2). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

DIAGNOSIS AND TESTING - AXLE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

Fig. 2 DIFFERENTIAL-ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

3 - 20 FRONT AXLE - 186FIAKJ

FRONT AXLE - 186FIA (Continued)

Page 87 of 1803

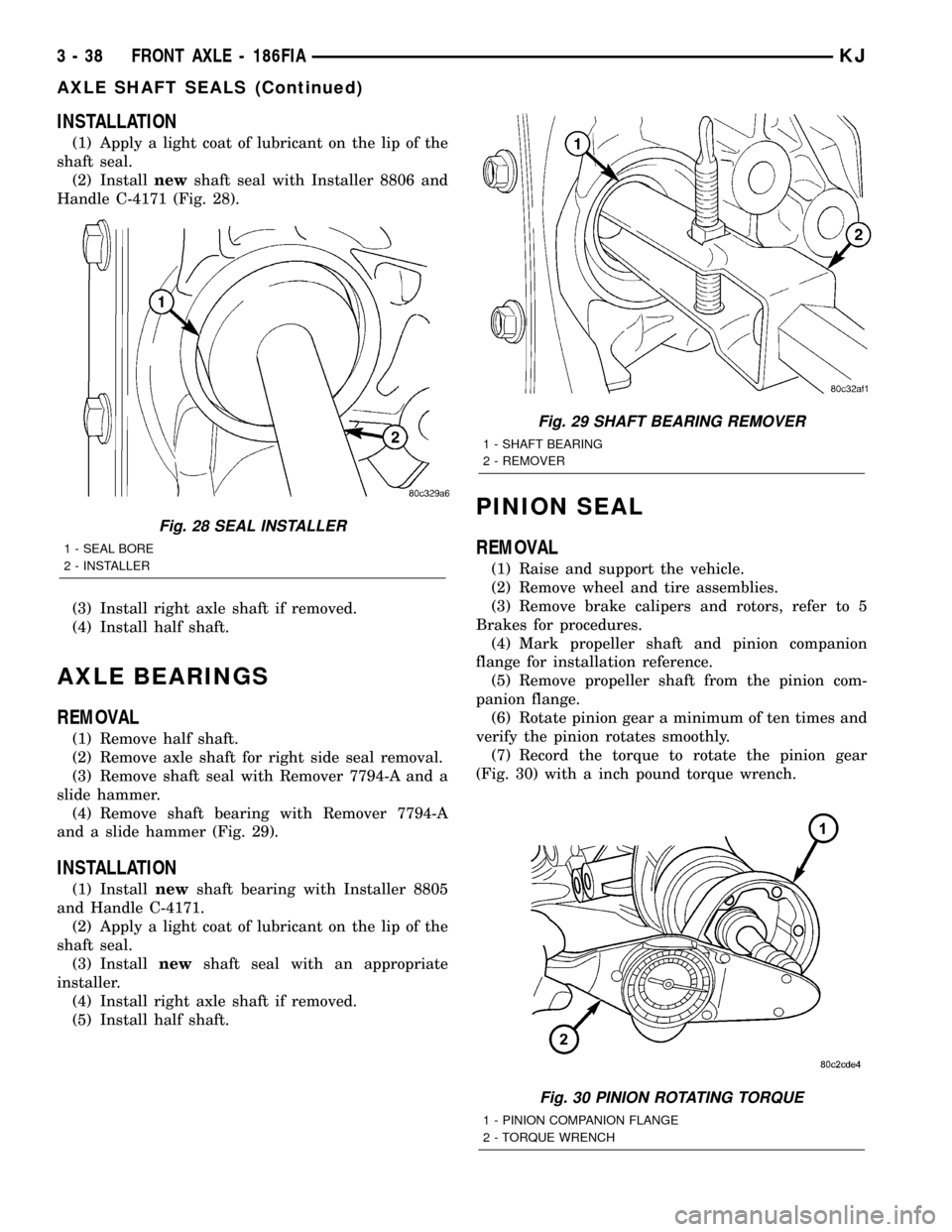

INSTALLATION

(1) Apply a light coat of lubricant on the lip of the

shaft seal.

(2) Installnewshaft seal with Installer 8806 and

Handle C-4171 (Fig. 28).

(3) Install right axle shaft if removed.

(4) Install half shaft.

AXLE BEARINGS

REMOVAL

(1) Remove half shaft.

(2) Remove axle shaft for right side seal removal.

(3) Remove shaft seal with Remover 7794-A and a

slide hammer.

(4) Remove shaft bearing with Remover 7794-A

and a slide hammer (Fig. 29).

INSTALLATION

(1) Installnewshaft bearing with Installer 8805

and Handle C-4171.

(2) Apply a light coat of lubricant on the lip of the

shaft seal.

(3) Installnewshaft seal with an appropriate

installer.

(4) Install right axle shaft if removed.

(5) Install half shaft.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove brake calipers and rotors, refer to 5

Brakes for procedures.

(4) Mark propeller shaft and pinion companion

flange for installation reference.

(5) Remove propeller shaft from the pinion com-

panion flange.

(6) Rotate pinion gear a minimum of ten times and

verify the pinion rotates smoothly.

(7) Record the torque to rotate the pinion gear

(Fig. 30) with a inch pound torque wrench.

Fig. 28 SEAL INSTALLER

1 - SEAL BORE

2 - INSTALLER

Fig. 29 SHAFT BEARING REMOVER

1 - SHAFT BEARING

2 - REMOVER

Fig. 30 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

3 - 38 FRONT AXLE - 186FIAKJ

AXLE SHAFT SEALS (Continued)

Page 88 of 1803

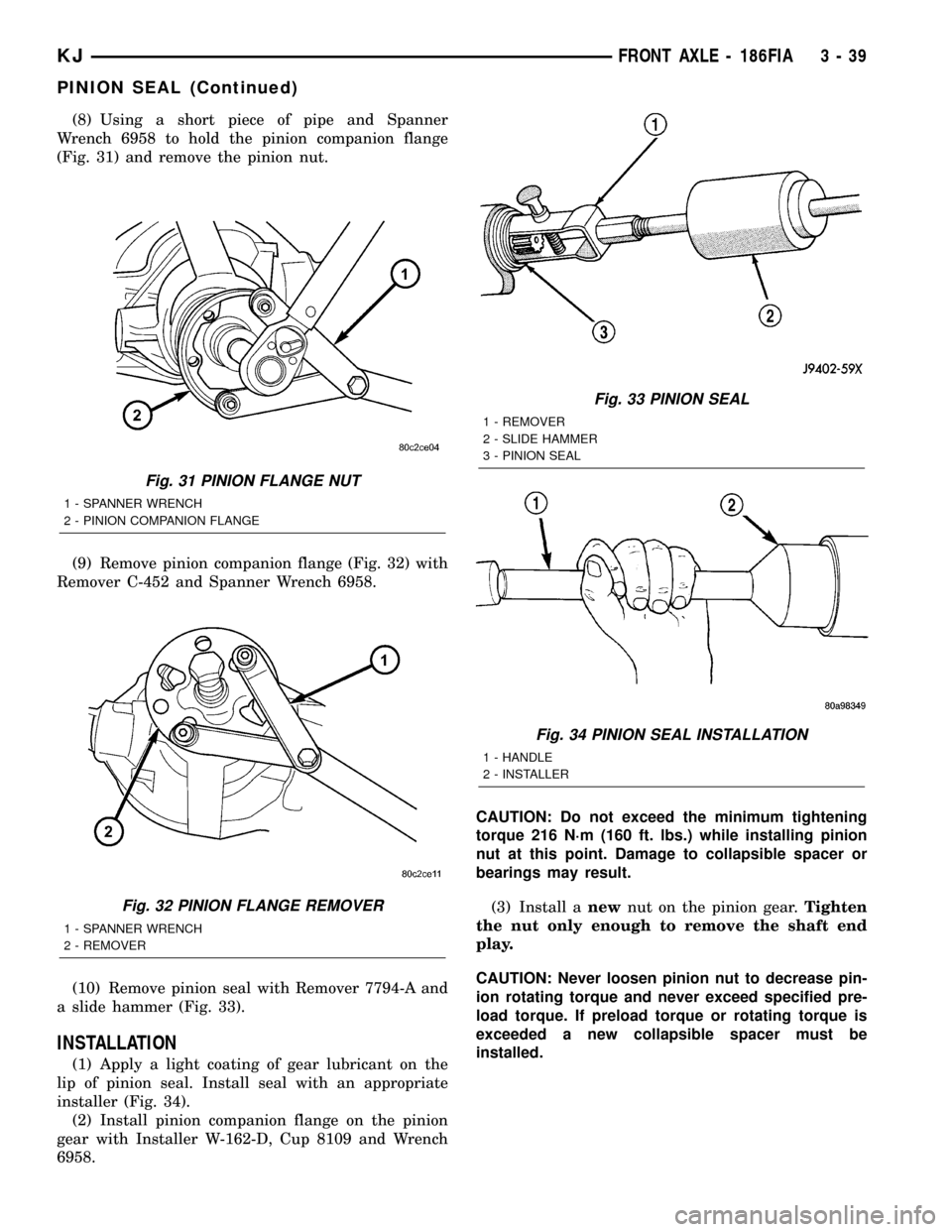

(8) Using a short piece of pipe and Spanner

Wrench 6958 to hold the pinion companion flange

(Fig. 31) and remove the pinion nut.

(9) Remove pinion companion flange (Fig. 32) with

Remover C-452 and Spanner Wrench 6958.

(10) Remove pinion seal with Remover 7794-A and

a slide hammer (Fig. 33).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with an appropriate

installer (Fig. 34).

(2) Install pinion companion flange on the pinion

gear with Installer W-162-D, Cup 8109 and Wrench

6958.CAUTION: Do not exceed the minimum tightening

torque 216 N´m (160 ft. lbs.) while installing pinion

nut at this point. Damage to collapsible spacer or

bearings may result.

(3) Install anewnut on the pinion gear.Tighten

the nut only enough to remove the shaft end

play.

CAUTION: Never loosen pinion nut to decrease pin-

ion rotating torque and never exceed specified pre-

load torque. If preload torque or rotating torque is

exceeded a new collapsible spacer must be

installed.

Fig. 31 PINION FLANGE NUT

1 - SPANNER WRENCH

2 - PINION COMPANION FLANGE

Fig. 32 PINION FLANGE REMOVER

1 - SPANNER WRENCH

2 - REMOVER

Fig. 33 PINION SEAL

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

Fig. 34 PINION SEAL INSTALLATION

1 - HANDLE

2 - INSTALLER

KJFRONT AXLE - 186FIA 3 - 39

PINION SEAL (Continued)

Page 96 of 1803

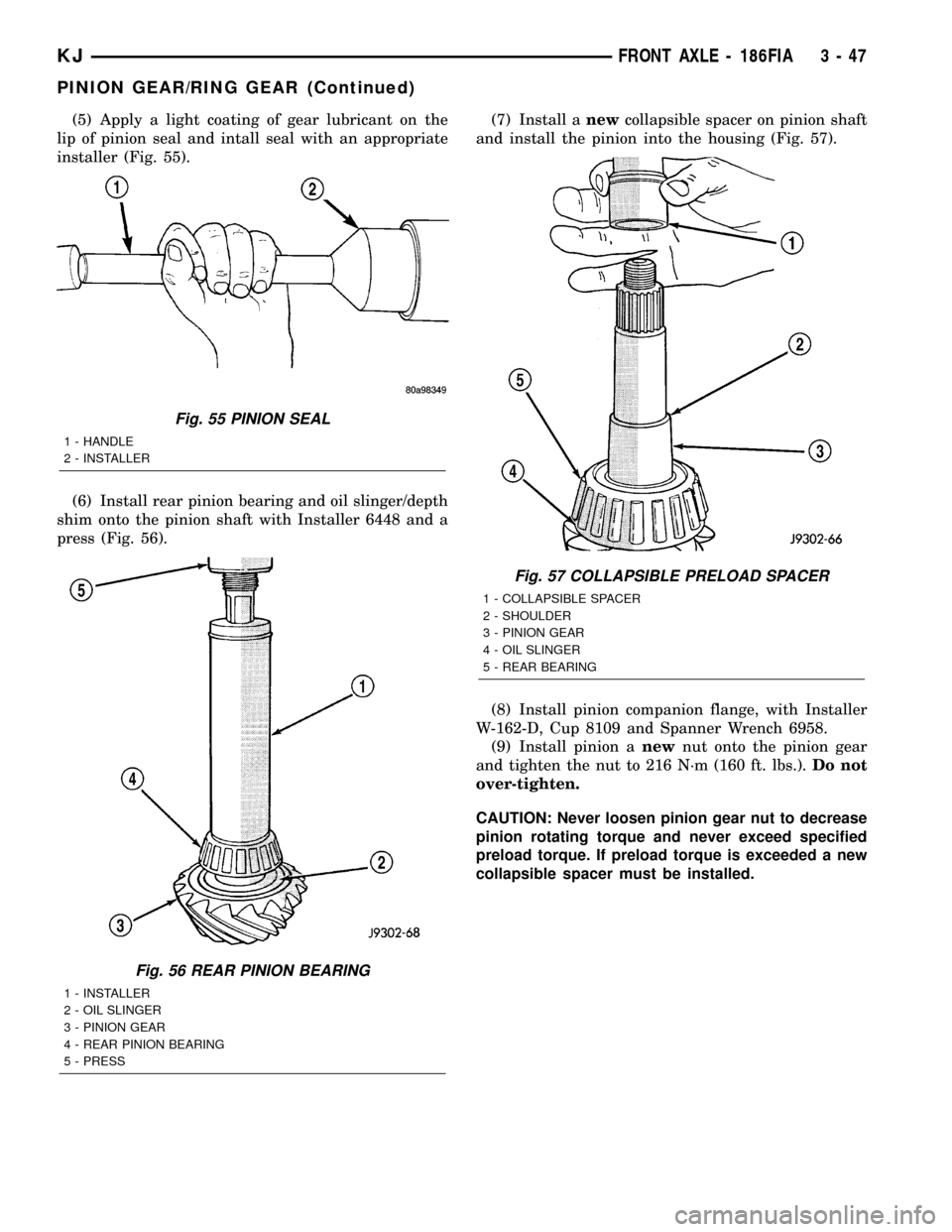

(5) Apply a light coating of gear lubricant on the

lip of pinion seal and intall seal with an appropriate

installer (Fig. 55).

(6) Install rear pinion bearing and oil slinger/depth

shim onto the pinion shaft with Installer 6448 and a

press (Fig. 56).(7) Install anewcollapsible spacer on pinion shaft

and install the pinion into the housing (Fig. 57).

(8) Install pinion companion flange, with Installer

W-162-D, Cup 8109 and Spanner Wrench 6958.

(9) Install pinion anewnut onto the pinion gear

and tighten the nut to 216 N´m (160 ft. lbs.).Do not

over-tighten.

CAUTION: Never loosen pinion gear nut to decrease

pinion rotating torque and never exceed specified

preload torque. If preload torque is exceeded a new

collapsible spacer must be installed.

Fig. 55 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 56 REAR PINION BEARING

1 - INSTALLER

2 - OIL SLINGER

3 - PINION GEAR

4 - REAR PINION BEARING

5 - PRESS

Fig. 57 COLLAPSIBLE PRELOAD SPACER

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - OIL SLINGER

5 - REAR BEARING

KJFRONT AXLE - 186FIA 3 - 47

PINION GEAR/RING GEAR (Continued)

Page 100 of 1803

The Trac-lokŸ design provides the differential

action needed for turning corners and for driving

straight ahead during periods of unequal traction.

When one wheel looses traction, the clutch packs

transfer additional torque to the wheel having the

most traction. Trac-lokŸ differentials resist wheel

spin on bumpy roads and provide more pulling power

when one wheel looses traction. Pulling power is pro-

vided continuously until both wheels loose traction. If

both wheels slip due to unequal traction, Trac-lokŸ

operation is normal. In extreme cases of differences

of traction, the wheel with the least traction may

spin.

DIAGNOSIS AND TESTING - AXLE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, tooth

contact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion shaft can also cause a snap-

ping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

KJREAR AXLE - 198RBI 3 - 51

REAR AXLE - 198RBI (Continued)