spare tire JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 445 of 1803

front of the vehicle. In certain markets where

required, a headlamp leveling actuator motor is

included on each headlamp.

²Park Lamps- The park lamps include the front

park lamps and front side marker lamps that are

integral to the front lamp units mounted at each end

of the bumper fascia at the front of the vehicle, as

well as the rear park lamps and rear side marker

lamps that are integral to the rear lamp units

mounted to the back of the quarter panel on each

side of the tailgate at the rear of the vehicle. The

park lamps include a license plate lamp or lamps,

depending upon the requirements of the market for

which the vehicle is manufactured. Vehicles with a

license plate tub located near the left end of the rear

bumper fascia have a single lamp, while vehicles

with a license plate module located on the spare tire

carrier have two license plate lamps. In certain mar-

kets where required, a front position lamp that is

integral to each headlamp unit is illuminated instead

of the front park lamps and front side marker lamps

in the park lamps circuit; and, a rectangular, red

reflector is located on the rear bumper fascia just

inboard and below each rear lamp unit.

²Rear Fog Lamps- Rear fog lamps are avail-

able only in certain markets where they are required

equipment. The rear fog lamps are integral to the

rear lamp units mounted to the back of the quarter

panel on each side of the tailgate at the rear of the

vehicle.

²Turn Signal Lamps- The turn signal lamps

include the front turn signal and front side marker

lamps that are integral to the front lamp units

mounted at each end of the bumper fascia at the

front of the vehicle, as well as rear turn signal lamps

that are integral to the rear lamp units mounted to

the back of the quarter panel on each side of the tail-

gate at the rear of the vehicle. In certain markets

where required, a repeater lamp unit mounted to

each front fender just behind the front wheel opening

is illuminated instead of the front side marker lamp

in each turn signal lamp circuit.

Other components of the exterior lighting system

for this model include:

²Combination Flasher- An electronic combina-

tion flasher is integral to the hazard warning switch

in the center of the instrument panel.

²Backup Lamp Switch- Vehicles equipped with

a manual transmission have a plunger-type backup

lamp switch located on the transmission housing. ATransmission Range Sensor (TRS) integral to the

solenoid pack on the valve body of the optional elec-

tronic automatic transmission performs the backup

lamp switch function on models that are so equipped.

²Brake Lamp Switch- A plunger-type brake

lamp switch is located on the steering column sup-

port bracket under the instrument panel and actu-

ated by the brake pedal arm.

²Body Control Module- The Body Control

Module (BCM) is located on the Junction Block (JB)

under the driver side outboard end of the instrument

panel. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/BODY CONTROL MODULE

- DESCRIPTION).

²Daytime Running Lamp Relay- Vehicles

manufactured for sale in Canada use a solid state

Daytime Running Lamps (DRL) relay installed in the

Junction Block (JB) instead of the conventional high

beam relay.

²Front Fog Lamp Relay- Vehicles equipped

with the optional front fog lamps have a front fog

lamp relay located in the Junction Block (JB).

²Hazard Switch- The hazard switch is located

near the center of the instrument panel and includes

the integral electronic combination flasher circuitry

for the hazard warning system and the turn signal

system.

²Headlamp Leveling Motor- A headlamp lev-

eling actuator motor is located on the back of each

headlamp housing of vehicles manufactured for cer-

tain markets where this equipment is required.

²Headlamp Leveling Switch- A thumbwheel

actuated headlamp leveling switch is mounted in the

driver side inboard instrument panel trim bezel of

vehicles manufactured for certain markets where this

equipment is required.

²High Beam Relay- A high beam relay is

located in the Junction Block (JB) of all vehicles

except those that are manufactured for sale in Can-

ada. Canadian vehicles have a solid state Daytime

Running Lamps (DRL) relay in the JB instead of the

high beam relay.

²Low Beam Relay- A low beam relay is located

in the Junction Block (JB) of all vehicles.

²Multi-Function Switch- The multi-function

switch is located on the top of the steering column,

just below the steering wheel. The multi-function

switch includes a left (lighting) control stalk and a

right (wiper) control stalk. The left control stalk is

dedicated to providing almost all of the driver con-

1 - HEADLAMP UNIT (2)

2 - REPEATER LAMP UNIT (2)

3 - FRONT POSITION LAMP (2)

4 - FRONT LAMP UNIT (2)

5 - FRONT FOG LAMP (2)6 - CENTER HIGH MOUNTED STOP LAMP UNIT

7 - REAR LAMP UNIT

8 - LICENSE PLATE LAMP UNIT

8L - 4 LAMPS/LIGHTING - EXTERIORKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 485 of 1803

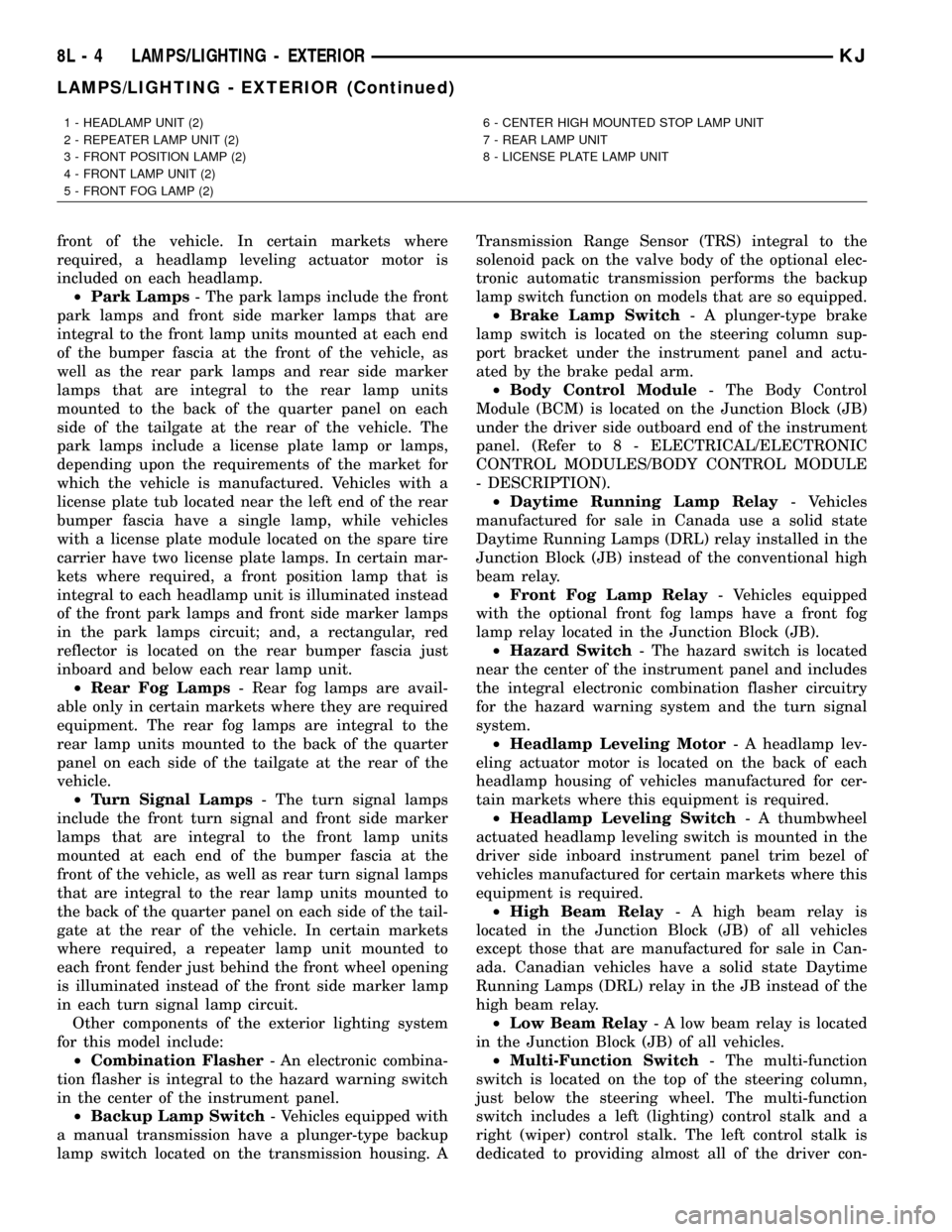

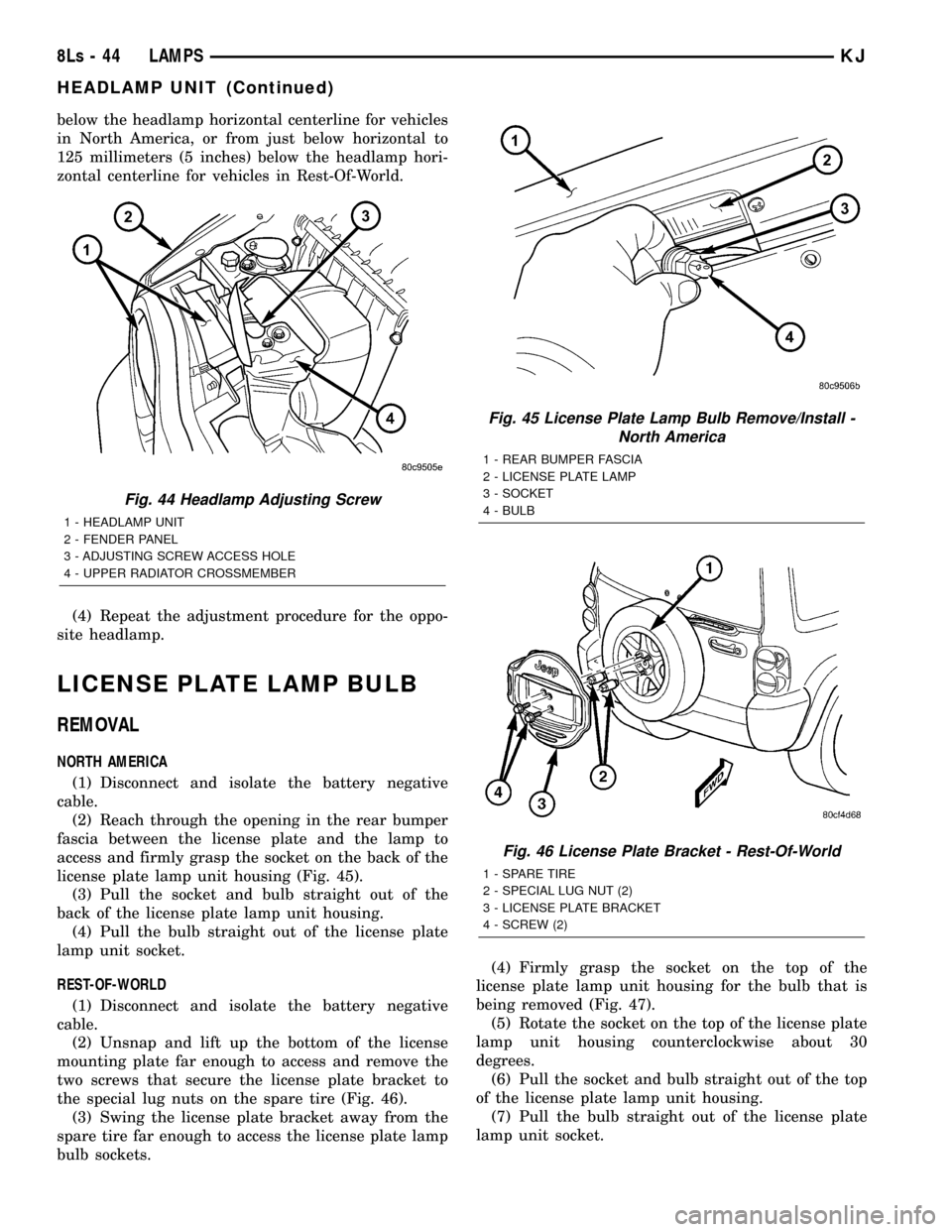

(3) Turn the adjusting screw (Fig. 44) until the top

edge of the beam intensity pattern is positioned from

just below horizontal to 75 millimeters (3 inches)

below the headlamp horizontal centerline for vehicles

in North America, or from just below horizontal to

125 millimeters (5 inches) below the headlamp hori-

zontal centerline for vehicles in Rest-Of-World.

(4) Repeat the adjustment procedure for the oppo-

site headlamp.

LICENSE PLATE LAMP BULB

REMOVAL

NORTH AMERICA

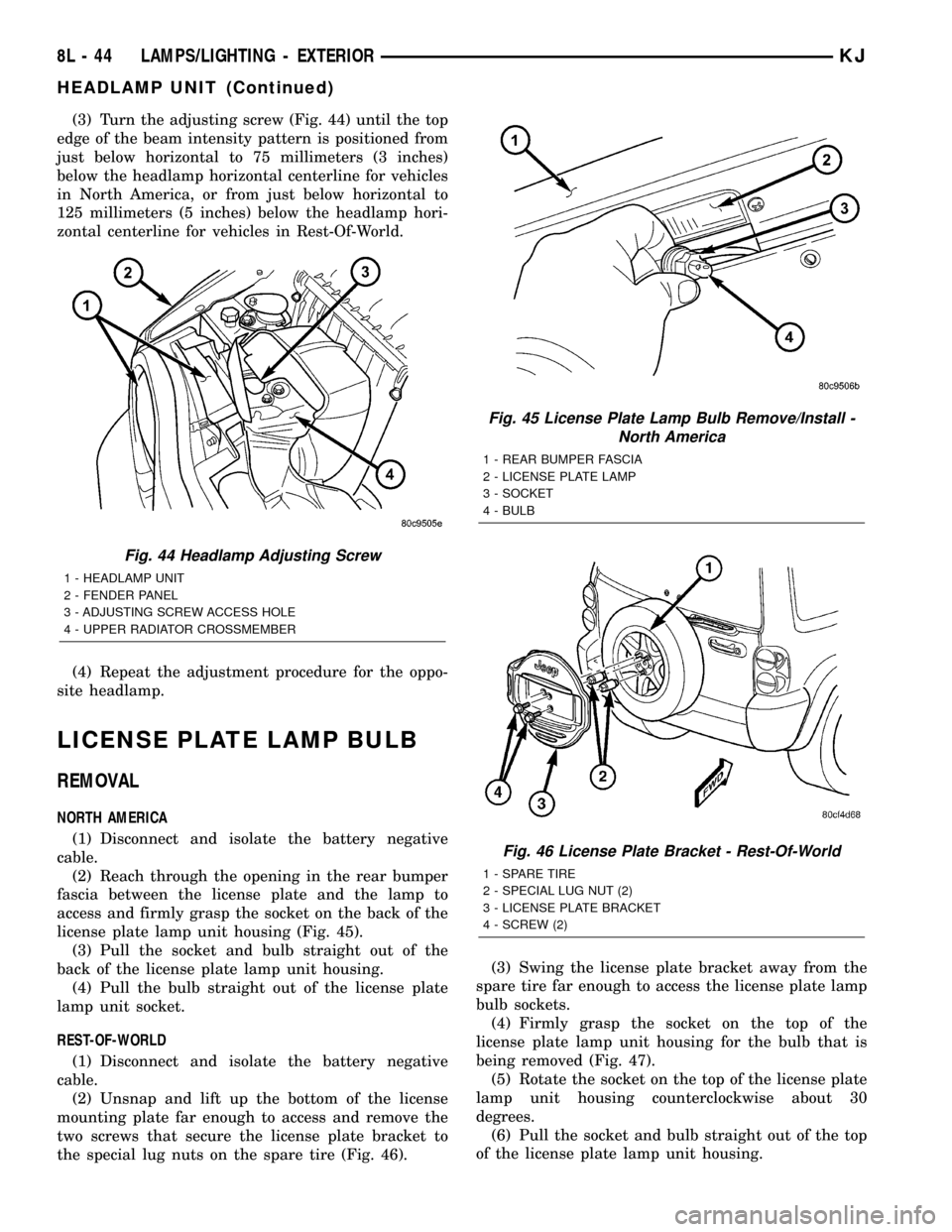

(1) Disconnect and isolate the battery negative

cable.

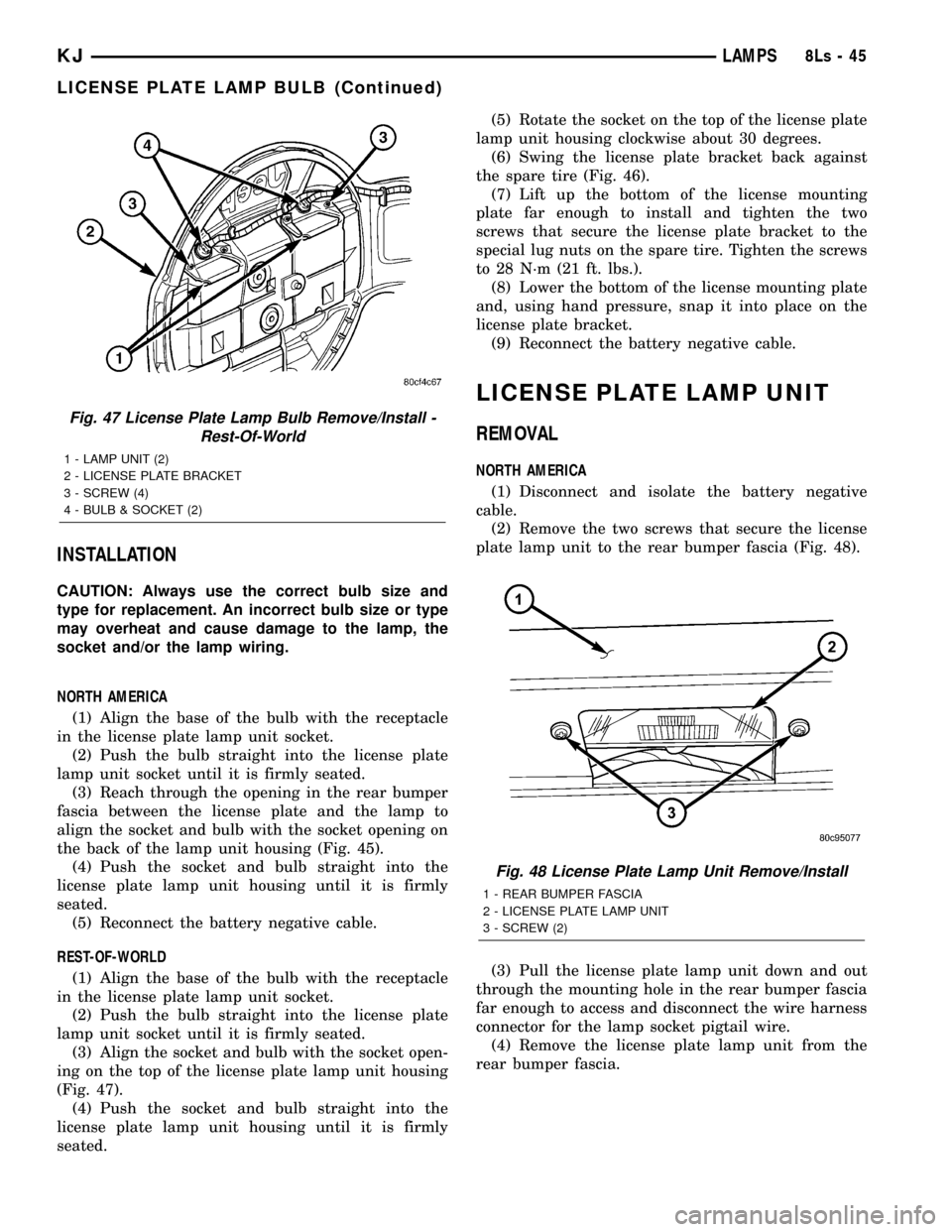

(2) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

access and firmly grasp the socket on the back of the

license plate lamp unit housing (Fig. 45).

(3) Pull the socket and bulb straight out of the

back of the license plate lamp unit housing.

(4) Pull the bulb straight out of the license plate

lamp unit socket.

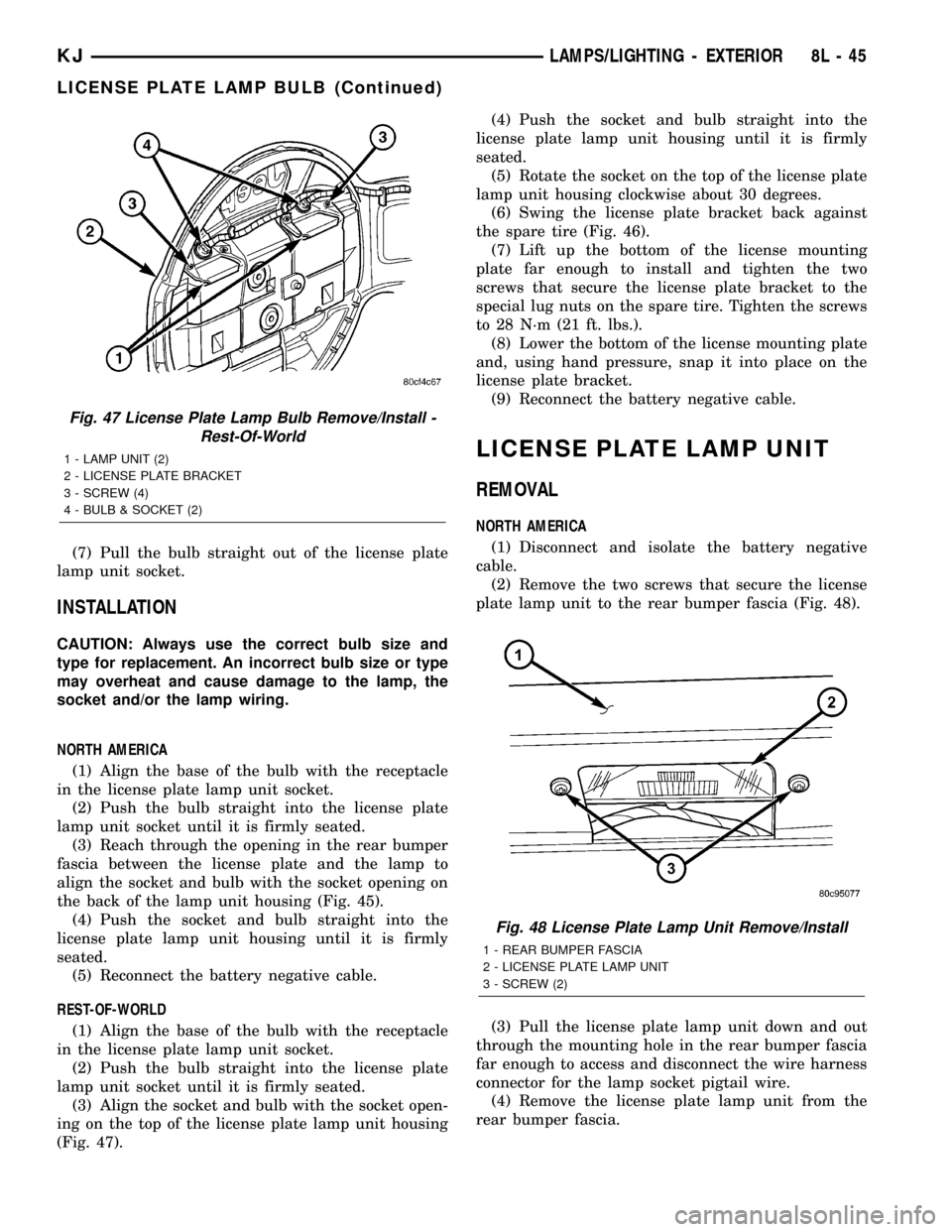

REST-OF-WORLD

(1) Disconnect and isolate the battery negative

cable.

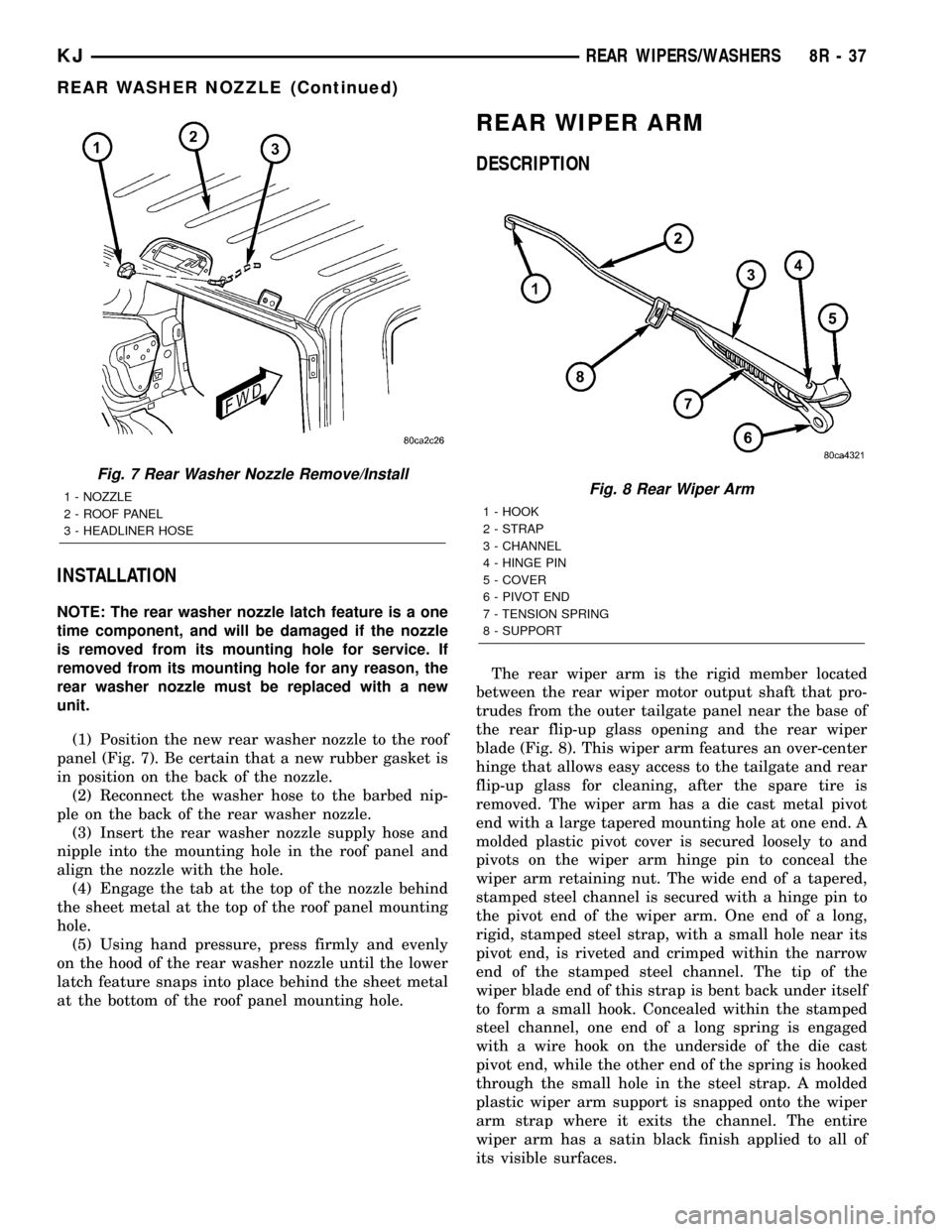

(2) Unsnap and lift up the bottom of the license

mounting plate far enough to access and remove the

two screws that secure the license plate bracket to

the special lug nuts on the spare tire (Fig. 46).(3) Swing the license plate bracket away from the

spare tire far enough to access the license plate lamp

bulb sockets.

(4) Firmly grasp the socket on the top of the

license plate lamp unit housing for the bulb that is

being removed (Fig. 47).

(5) Rotate the socket on the top of the license plate

lamp unit housing counterclockwise about 30

degrees.

(6) Pull the socket and bulb straight out of the top

of the license plate lamp unit housing.

Fig. 44 Headlamp Adjusting Screw

1 - HEADLAMP UNIT

2 - FENDER PANEL

3 - ADJUSTING SCREW ACCESS HOLE

4 - UPPER RADIATOR CROSSMEMBER

Fig. 45 License Plate Lamp Bulb Remove/Install -

North America

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP

3 - SOCKET

4 - BULB

Fig. 46 License Plate Bracket - Rest-Of-World

1 - SPARE TIRE

2 - SPECIAL LUG NUT (2)

3 - LICENSE PLATE BRACKET

4 - SCREW (2)

8L - 44 LAMPS/LIGHTING - EXTERIORKJ

HEADLAMP UNIT (Continued)

Page 486 of 1803

(7) Pull the bulb straight out of the license plate

lamp unit socket.

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

NORTH AMERICA

(1) Align the base of the bulb with the receptacle

in the license plate lamp unit socket.

(2) Push the bulb straight into the license plate

lamp unit socket until it is firmly seated.

(3) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

align the socket and bulb with the socket opening on

the back of the lamp unit housing (Fig. 45).

(4) Push the socket and bulb straight into the

license plate lamp unit housing until it is firmly

seated.

(5) Reconnect the battery negative cable.

REST-OF-WORLD

(1) Align the base of the bulb with the receptacle

in the license plate lamp unit socket.

(2) Push the bulb straight into the license plate

lamp unit socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing on the top of the license plate lamp unit housing

(Fig. 47).(4) Push the socket and bulb straight into the

license plate lamp unit housing until it is firmly

seated.

(5) Rotate the socket on the top of the license plate

lamp unit housing clockwise about 30 degrees.

(6) Swing the license plate bracket back against

the spare tire (Fig. 46).

(7) Lift up the bottom of the license mounting

plate far enough to install and tighten the two

screws that secure the license plate bracket to the

special lug nuts on the spare tire. Tighten the screws

to 28 N´m (21 ft. lbs.).

(8) Lower the bottom of the license mounting plate

and, using hand pressure, snap it into place on the

license plate bracket.

(9) Reconnect the battery negative cable.

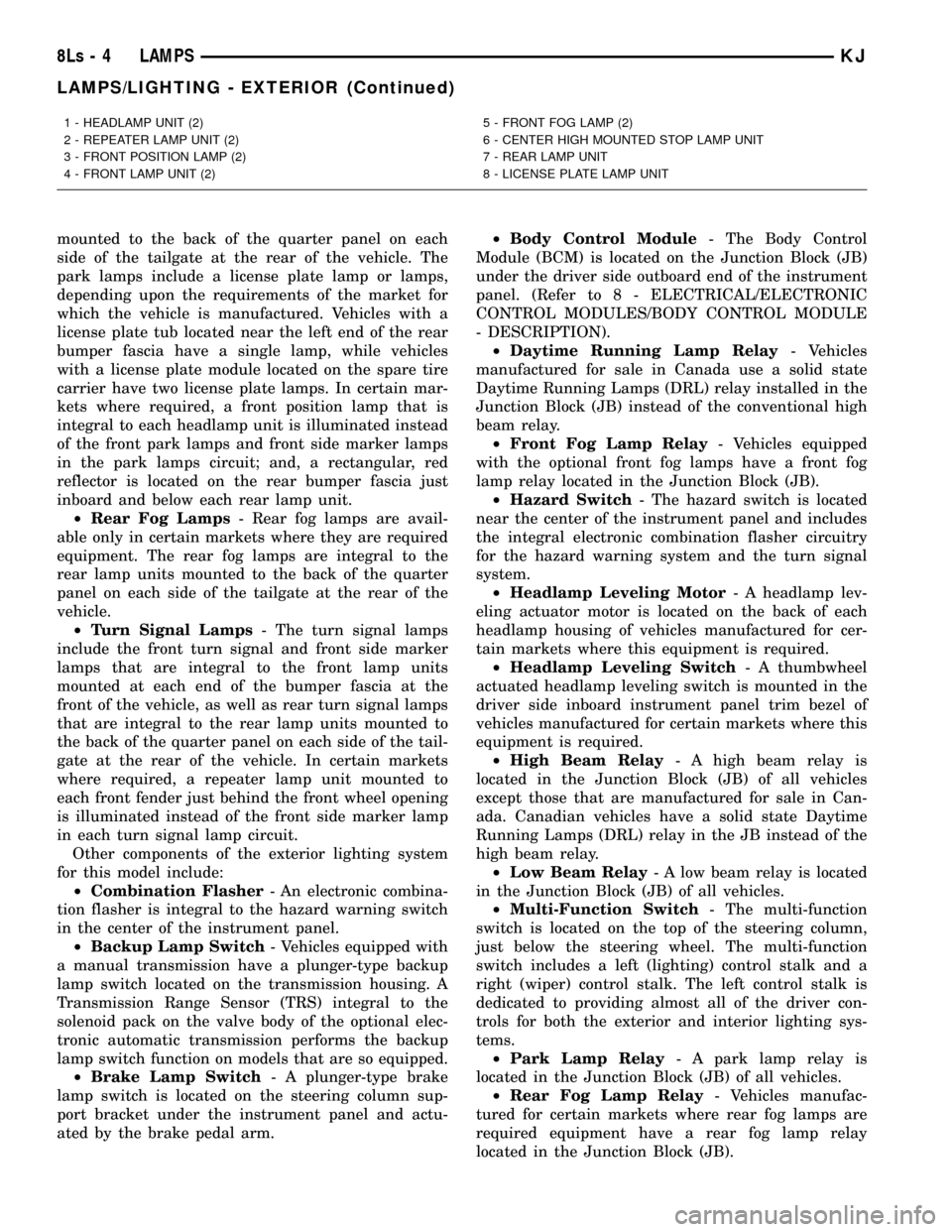

LICENSE PLATE LAMP UNIT

REMOVAL

NORTH AMERICA

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the license

plate lamp unit to the rear bumper fascia (Fig. 48).

(3) Pull the license plate lamp unit down and out

through the mounting hole in the rear bumper fascia

far enough to access and disconnect the wire harness

connector for the lamp socket pigtail wire.

(4) Remove the license plate lamp unit from the

rear bumper fascia.

Fig. 47 License Plate Lamp Bulb Remove/Install -

Rest-Of-World

1 - LAMP UNIT (2)

2 - LICENSE PLATE BRACKET

3 - SCREW (4)

4 - BULB & SOCKET (2)

Fig. 48 License Plate Lamp Unit Remove/Install

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP UNIT

3 - SCREW (2)

KJLAMPS/LIGHTING - EXTERIOR 8L - 45

LICENSE PLATE LAMP BULB (Continued)

Page 529 of 1803

mounted to the back of the quarter panel on each

side of the tailgate at the rear of the vehicle. The

park lamps include a license plate lamp or lamps,

depending upon the requirements of the market for

which the vehicle is manufactured. Vehicles with a

license plate tub located near the left end of the rear

bumper fascia have a single lamp, while vehicles

with a license plate module located on the spare tire

carrier have two license plate lamps. In certain mar-

kets where required, a front position lamp that is

integral to each headlamp unit is illuminated instead

of the front park lamps and front side marker lamps

in the park lamps circuit; and, a rectangular, red

reflector is located on the rear bumper fascia just

inboard and below each rear lamp unit.

²Rear Fog Lamps- Rear fog lamps are avail-

able only in certain markets where they are required

equipment. The rear fog lamps are integral to the

rear lamp units mounted to the back of the quarter

panel on each side of the tailgate at the rear of the

vehicle.

²Turn Signal Lamps- The turn signal lamps

include the front turn signal and front side marker

lamps that are integral to the front lamp units

mounted at each end of the bumper fascia at the

front of the vehicle, as well as rear turn signal lamps

that are integral to the rear lamp units mounted to

the back of the quarter panel on each side of the tail-

gate at the rear of the vehicle. In certain markets

where required, a repeater lamp unit mounted to

each front fender just behind the front wheel opening

is illuminated instead of the front side marker lamp

in each turn signal lamp circuit.

Other components of the exterior lighting system

for this model include:

²Combination Flasher- An electronic combina-

tion flasher is integral to the hazard warning switch

in the center of the instrument panel.

²Backup Lamp Switch- Vehicles equipped with

a manual transmission have a plunger-type backup

lamp switch located on the transmission housing. A

Transmission Range Sensor (TRS) integral to the

solenoid pack on the valve body of the optional elec-

tronic automatic transmission performs the backup

lamp switch function on models that are so equipped.

²Brake Lamp Switch- A plunger-type brake

lamp switch is located on the steering column sup-

port bracket under the instrument panel and actu-

ated by the brake pedal arm.²Body Control Module- The Body Control

Module (BCM) is located on the Junction Block (JB)

under the driver side outboard end of the instrument

panel. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/BODY CONTROL MODULE

- DESCRIPTION).

²Daytime Running Lamp Relay- Vehicles

manufactured for sale in Canada use a solid state

Daytime Running Lamps (DRL) relay installed in the

Junction Block (JB) instead of the conventional high

beam relay.

²Front Fog Lamp Relay- Vehicles equipped

with the optional front fog lamps have a front fog

lamp relay located in the Junction Block (JB).

²Hazard Switch- The hazard switch is located

near the center of the instrument panel and includes

the integral electronic combination flasher circuitry

for the hazard warning system and the turn signal

system.

²Headlamp Leveling Motor- A headlamp lev-

eling actuator motor is located on the back of each

headlamp housing of vehicles manufactured for cer-

tain markets where this equipment is required.

²Headlamp Leveling Switch- A thumbwheel

actuated headlamp leveling switch is mounted in the

driver side inboard instrument panel trim bezel of

vehicles manufactured for certain markets where this

equipment is required.

²High Beam Relay- A high beam relay is

located in the Junction Block (JB) of all vehicles

except those that are manufactured for sale in Can-

ada. Canadian vehicles have a solid state Daytime

Running Lamps (DRL) relay in the JB instead of the

high beam relay.

²Low Beam Relay- A low beam relay is located

in the Junction Block (JB) of all vehicles.

²Multi-Function Switch- The multi-function

switch is located on the top of the steering column,

just below the steering wheel. The multi-function

switch includes a left (lighting) control stalk and a

right (wiper) control stalk. The left control stalk is

dedicated to providing almost all of the driver con-

trols for both the exterior and interior lighting sys-

tems.

²Park Lamp Relay- A park lamp relay is

located in the Junction Block (JB) of all vehicles.

²Rear Fog Lamp Relay- Vehicles manufac-

tured for certain markets where rear fog lamps are

required equipment have a rear fog lamp relay

located in the Junction Block (JB).

1 - HEADLAMP UNIT (2)

2 - REPEATER LAMP UNIT (2)

3 - FRONT POSITION LAMP (2)

4 - FRONT LAMP UNIT (2)5 - FRONT FOG LAMP (2)

6 - CENTER HIGH MOUNTED STOP LAMP UNIT

7 - REAR LAMP UNIT

8 - LICENSE PLATE LAMP UNIT

8Ls - 4 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 569 of 1803

below the headlamp horizontal centerline for vehicles

in North America, or from just below horizontal to

125 millimeters (5 inches) below the headlamp hori-

zontal centerline for vehicles in Rest-Of-World.

(4) Repeat the adjustment procedure for the oppo-

site headlamp.

LICENSE PLATE LAMP BULB

REMOVAL

NORTH AMERICA

(1) Disconnect and isolate the battery negative

cable.

(2) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

access and firmly grasp the socket on the back of the

license plate lamp unit housing (Fig. 45).

(3) Pull the socket and bulb straight out of the

back of the license plate lamp unit housing.

(4) Pull the bulb straight out of the license plate

lamp unit socket.

REST-OF-WORLD

(1) Disconnect and isolate the battery negative

cable.

(2) Unsnap and lift up the bottom of the license

mounting plate far enough to access and remove the

two screws that secure the license plate bracket to

the special lug nuts on the spare tire (Fig. 46).

(3) Swing the license plate bracket away from the

spare tire far enough to access the license plate lamp

bulb sockets.(4) Firmly grasp the socket on the top of the

license plate lamp unit housing for the bulb that is

being removed (Fig. 47).

(5) Rotate the socket on the top of the license plate

lamp unit housing counterclockwise about 30

degrees.

(6) Pull the socket and bulb straight out of the top

of the license plate lamp unit housing.

(7) Pull the bulb straight out of the license plate

lamp unit socket.

Fig. 44 Headlamp Adjusting Screw

1 - HEADLAMP UNIT

2 - FENDER PANEL

3 - ADJUSTING SCREW ACCESS HOLE

4 - UPPER RADIATOR CROSSMEMBER

Fig. 45 License Plate Lamp Bulb Remove/Install -

North America

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP

3 - SOCKET

4 - BULB

Fig. 46 License Plate Bracket - Rest-Of-World

1 - SPARE TIRE

2 - SPECIAL LUG NUT (2)

3 - LICENSE PLATE BRACKET

4 - SCREW (2)

8Ls - 44 LAMPSKJ

HEADLAMP UNIT (Continued)

Page 570 of 1803

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

NORTH AMERICA

(1) Align the base of the bulb with the receptacle

in the license plate lamp unit socket.

(2) Push the bulb straight into the license plate

lamp unit socket until it is firmly seated.

(3) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

align the socket and bulb with the socket opening on

the back of the lamp unit housing (Fig. 45).

(4) Push the socket and bulb straight into the

license plate lamp unit housing until it is firmly

seated.

(5) Reconnect the battery negative cable.

REST-OF-WORLD

(1) Align the base of the bulb with the receptacle

in the license plate lamp unit socket.

(2) Push the bulb straight into the license plate

lamp unit socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing on the top of the license plate lamp unit housing

(Fig. 47).

(4) Push the socket and bulb straight into the

license plate lamp unit housing until it is firmly

seated.(5) Rotate the socket on the top of the license plate

lamp unit housing clockwise about 30 degrees.

(6) Swing the license plate bracket back against

the spare tire (Fig. 46).

(7) Lift up the bottom of the license mounting

plate far enough to install and tighten the two

screws that secure the license plate bracket to the

special lug nuts on the spare tire. Tighten the screws

to 28 N´m (21 ft. lbs.).

(8) Lower the bottom of the license mounting plate

and, using hand pressure, snap it into place on the

license plate bracket.

(9) Reconnect the battery negative cable.

LICENSE PLATE LAMP UNIT

REMOVAL

NORTH AMERICA

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the license

plate lamp unit to the rear bumper fascia (Fig. 48).

(3) Pull the license plate lamp unit down and out

through the mounting hole in the rear bumper fascia

far enough to access and disconnect the wire harness

connector for the lamp socket pigtail wire.

(4) Remove the license plate lamp unit from the

rear bumper fascia.

Fig. 47 License Plate Lamp Bulb Remove/Install -

Rest-Of-World

1 - LAMP UNIT (2)

2 - LICENSE PLATE BRACKET

3 - SCREW (4)

4 - BULB & SOCKET (2)

Fig. 48 License Plate Lamp Unit Remove/Install

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP UNIT

3 - SCREW (2)

KJLAMPS8Ls-45

LICENSE PLATE LAMP BULB (Continued)

Page 738 of 1803

INSTALLATION

NOTE: The rear washer nozzle latch feature is a one

time component, and will be damaged if the nozzle

is removed from its mounting hole for service. If

removed from its mounting hole for any reason, the

rear washer nozzle must be replaced with a new

unit.

(1) Position the new rear washer nozzle to the roof

panel (Fig. 7). Be certain that a new rubber gasket is

in position on the back of the nozzle.

(2) Reconnect the washer hose to the barbed nip-

ple on the back of the rear washer nozzle.

(3) Insert the rear washer nozzle supply hose and

nipple into the mounting hole in the roof panel and

align the nozzle with the hole.

(4) Engage the tab at the top of the nozzle behind

the sheet metal at the top of the roof panel mounting

hole.

(5) Using hand pressure, press firmly and evenly

on the hood of the rear washer nozzle until the lower

latch feature snaps into place behind the sheet metal

at the bottom of the roof panel mounting hole.

REAR WIPER ARM

DESCRIPTION

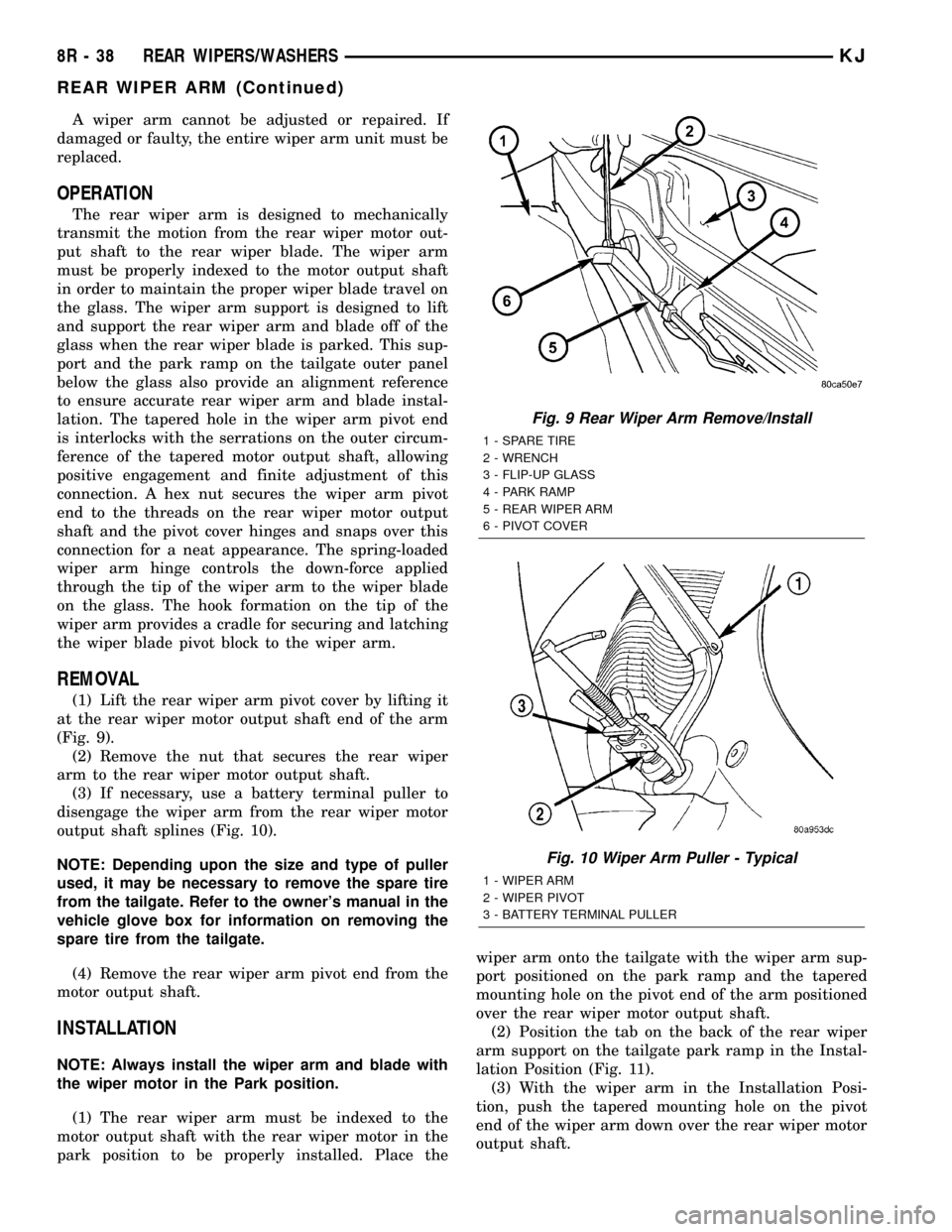

The rear wiper arm is the rigid member located

between the rear wiper motor output shaft that pro-

trudes from the outer tailgate panel near the base of

the rear flip-up glass opening and the rear wiper

blade (Fig. 8). This wiper arm features an over-center

hinge that allows easy access to the tailgate and rear

flip-up glass for cleaning, after the spare tire is

removed. The wiper arm has a die cast metal pivot

end with a large tapered mounting hole at one end. A

molded plastic pivot cover is secured loosely to and

pivots on the wiper arm hinge pin to conceal the

wiper arm retaining nut. The wide end of a tapered,

stamped steel channel is secured with a hinge pin to

the pivot end of the wiper arm. One end of a long,

rigid, stamped steel strap, with a small hole near its

pivot end, is riveted and crimped within the narrow

end of the stamped steel channel. The tip of the

wiper blade end of this strap is bent back under itself

to form a small hook. Concealed within the stamped

steel channel, one end of a long spring is engaged

with a wire hook on the underside of the die cast

pivot end, while the other end of the spring is hooked

through the small hole in the steel strap. A molded

plastic wiper arm support is snapped onto the wiper

arm strap where it exits the channel. The entire

wiper arm has a satin black finish applied to all of

its visible surfaces.

Fig. 7 Rear Washer Nozzle Remove/Install

1 - NOZZLE

2 - ROOF PANEL

3 - HEADLINER HOSEFig. 8 Rear Wiper Arm

1 - HOOK

2 - STRAP

3 - CHANNEL

4 - HINGE PIN

5 - COVER

6 - PIVOT END

7 - TENSION SPRING

8 - SUPPORT

KJREAR WIPERS/WASHERS 8R - 37

REAR WASHER NOZZLE (Continued)

Page 739 of 1803

A wiper arm cannot be adjusted or repaired. If

damaged or faulty, the entire wiper arm unit must be

replaced.

OPERATION

The rear wiper arm is designed to mechanically

transmit the motion from the rear wiper motor out-

put shaft to the rear wiper blade. The wiper arm

must be properly indexed to the motor output shaft

in order to maintain the proper wiper blade travel on

the glass. The wiper arm support is designed to lift

and support the rear wiper arm and blade off of the

glass when the rear wiper blade is parked. This sup-

port and the park ramp on the tailgate outer panel

below the glass also provide an alignment reference

to ensure accurate rear wiper arm and blade instal-

lation. The tapered hole in the wiper arm pivot end

is interlocks with the serrations on the outer circum-

ference of the tapered motor output shaft, allowing

positive engagement and finite adjustment of this

connection. A hex nut secures the wiper arm pivot

end to the threads on the rear wiper motor output

shaft and the pivot cover hinges and snaps over this

connection for a neat appearance. The spring-loaded

wiper arm hinge controls the down-force applied

through the tip of the wiper arm to the wiper blade

on the glass. The hook formation on the tip of the

wiper arm provides a cradle for securing and latching

the wiper blade pivot block to the wiper arm.

REMOVAL

(1) Lift the rear wiper arm pivot cover by lifting it

at the rear wiper motor output shaft end of the arm

(Fig. 9).

(2) Remove the nut that secures the rear wiper

arm to the rear wiper motor output shaft.

(3) If necessary, use a battery terminal puller to

disengage the wiper arm from the rear wiper motor

output shaft splines (Fig. 10).

NOTE: Depending upon the size and type of puller

used, it may be necessary to remove the spare tire

from the tailgate. Refer to the owner's manual in the

vehicle glove box for information on removing the

spare tire from the tailgate.

(4) Remove the rear wiper arm pivot end from the

motor output shaft.

INSTALLATION

NOTE: Always install the wiper arm and blade with

the wiper motor in the Park position.

(1) The rear wiper arm must be indexed to the

motor output shaft with the rear wiper motor in the

park position to be properly installed. Place thewiper arm onto the tailgate with the wiper arm sup-

port positioned on the park ramp and the tapered

mounting hole on the pivot end of the arm positioned

over the rear wiper motor output shaft.

(2) Position the tab on the back of the rear wiper

arm support on the tailgate park ramp in the Instal-

lation Position (Fig. 11).

(3) With the wiper arm in the Installation Posi-

tion, push the tapered mounting hole on the pivot

end of the wiper arm down over the rear wiper motor

output shaft.

Fig. 9 Rear Wiper Arm Remove/Install

1 - SPARE TIRE

2 - WRENCH

3 - FLIP-UP GLASS

4 - PARK RAMP

5 - REAR WIPER ARM

6 - PIVOT COVER

Fig. 10 Wiper Arm Puller - Typical

1 - WIPER ARM

2 - WIPER PIVOT

3 - BATTERY TERMINAL PULLER

8R - 38 REAR WIPERS/WASHERSKJ

REAR WIPER ARM (Continued)

Page 1455 of 1803

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRES AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE ROTATION . 2

STANDARD PROCEDURE - MATCH

MOUNTING...........................3

STANDARD PROCEDURE - WHEEL

BALANCING..........................4

TIRES

DESCRIPTION

DESCRIPTION - TIRES..................6

DESCRIPTION - RADIAL-PLY TIRES........6

DESCRIPTION - SPARE TIRE

&TEMPORARY........................6

DESCRIPTION - REPLACEMENT TIRES.....7

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE

INFLATION...........................7

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................8

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................8DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................8

STANDARD PROCEDURE - REPAIRING

LEAKS...............................8

CLEANING.............................8

SPECIFICATIONS........................8

SPARE TIRE

REMOVAL.............................8

INSTALLATION..........................9

WHEELS

DESCRIPTION..........................9

DIAGNOSIS AND TESTING - WHEELS.......10

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................10

STANDARD PROCEDURE - WHEEL

MOUNTING..........................10

SPECIFICATIONS

SPECIFICATION......................11

STUDS

REMOVAL.............................11

INSTALLATION.........................11

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRES AND

WHEEL RUNOUT

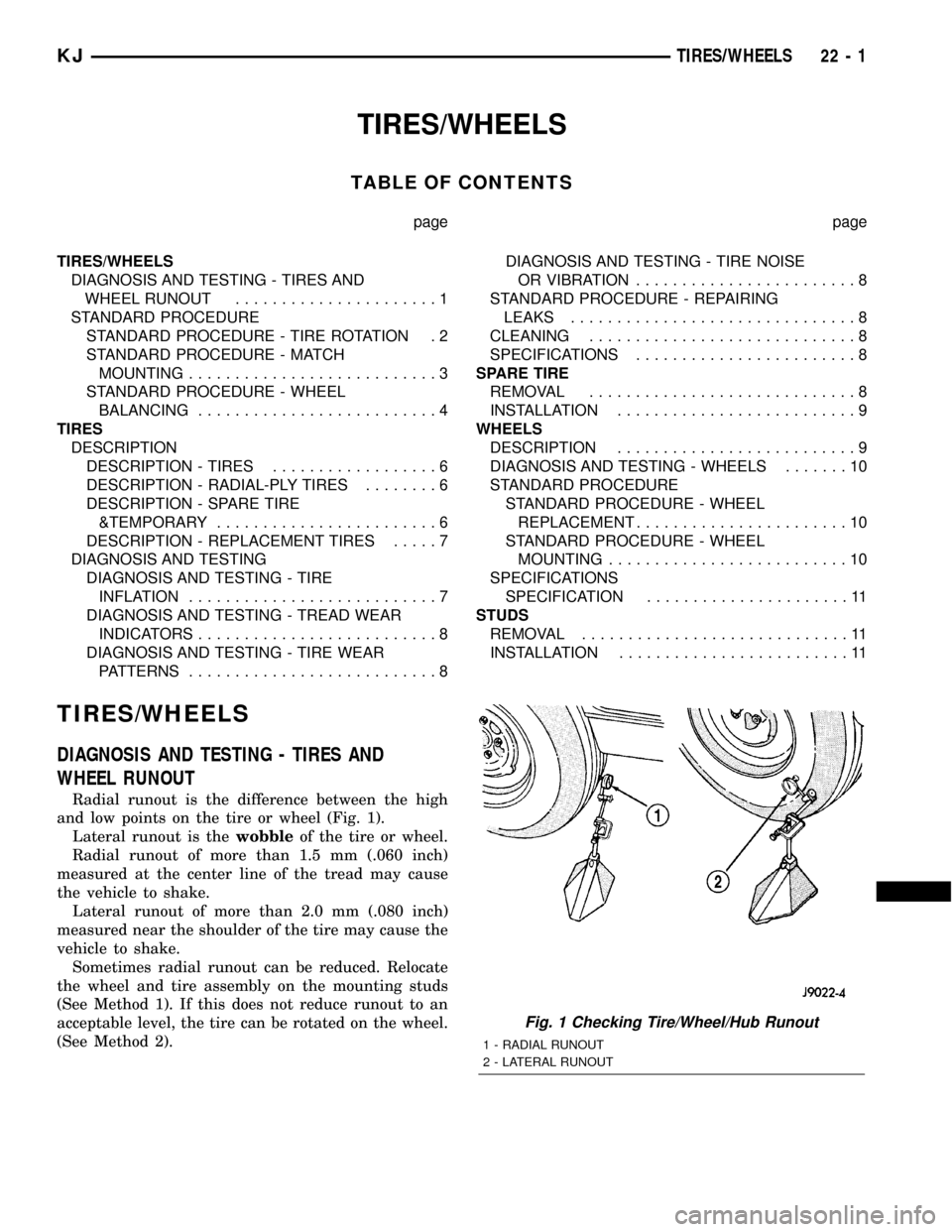

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

KJTIRES/WHEELS 22 - 1

Page 1460 of 1803

TIRES

DESCRIPTION

DESCRIPTION - TIRES

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe brake applications

²High speed driving

²Excessive speeds on turns

²Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val,(Refer to 22 - TIRES/WHEELS - STANDARD

PROCEDURE). This will help to achieve a greater

tread life.

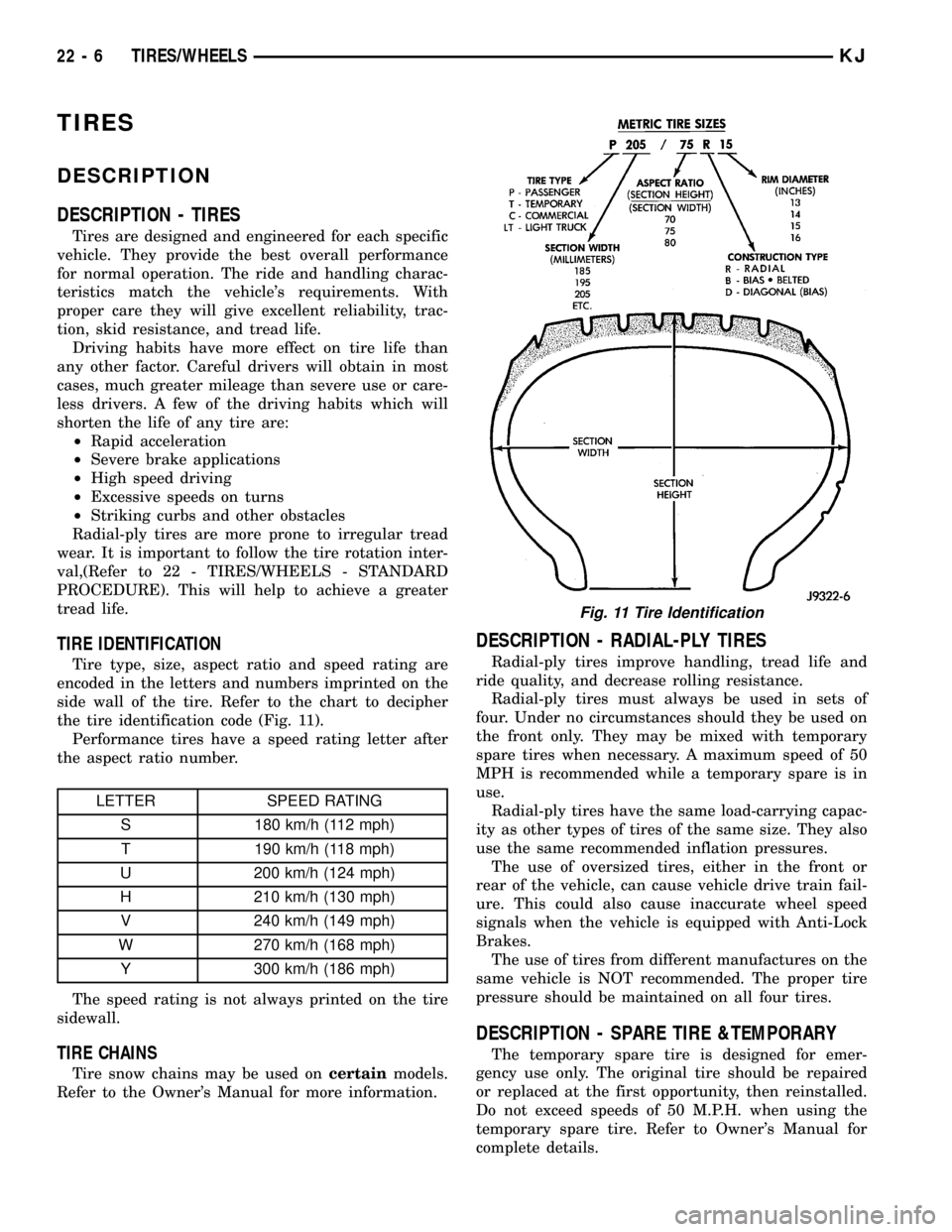

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 11).

Performance tires have a speed rating letter after

the aspect ratio number.

LETTER SPEED RATING

S 180 km/h (112 mph)

T 190 km/h (118 mph)

U 200 km/h (124 mph)

H 210 km/h (130 mph)

V 240 km/h (149 mph)

W 270 km/h (168 mph)

Y 300 km/h (186 mph)

The speed rating is not always printed on the tire

sidewall.

TIRE CHAINS

Tire snow chains may be used oncertainmodels.

Refer to the Owner's Manual for more information.

DESCRIPTION - RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

DESCRIPTION - SPARE TIRE &TEMPORARY

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

Fig. 11 Tire Identification

22 - 6 TIRES/WHEELSKJ