steering column JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 19 of 1803

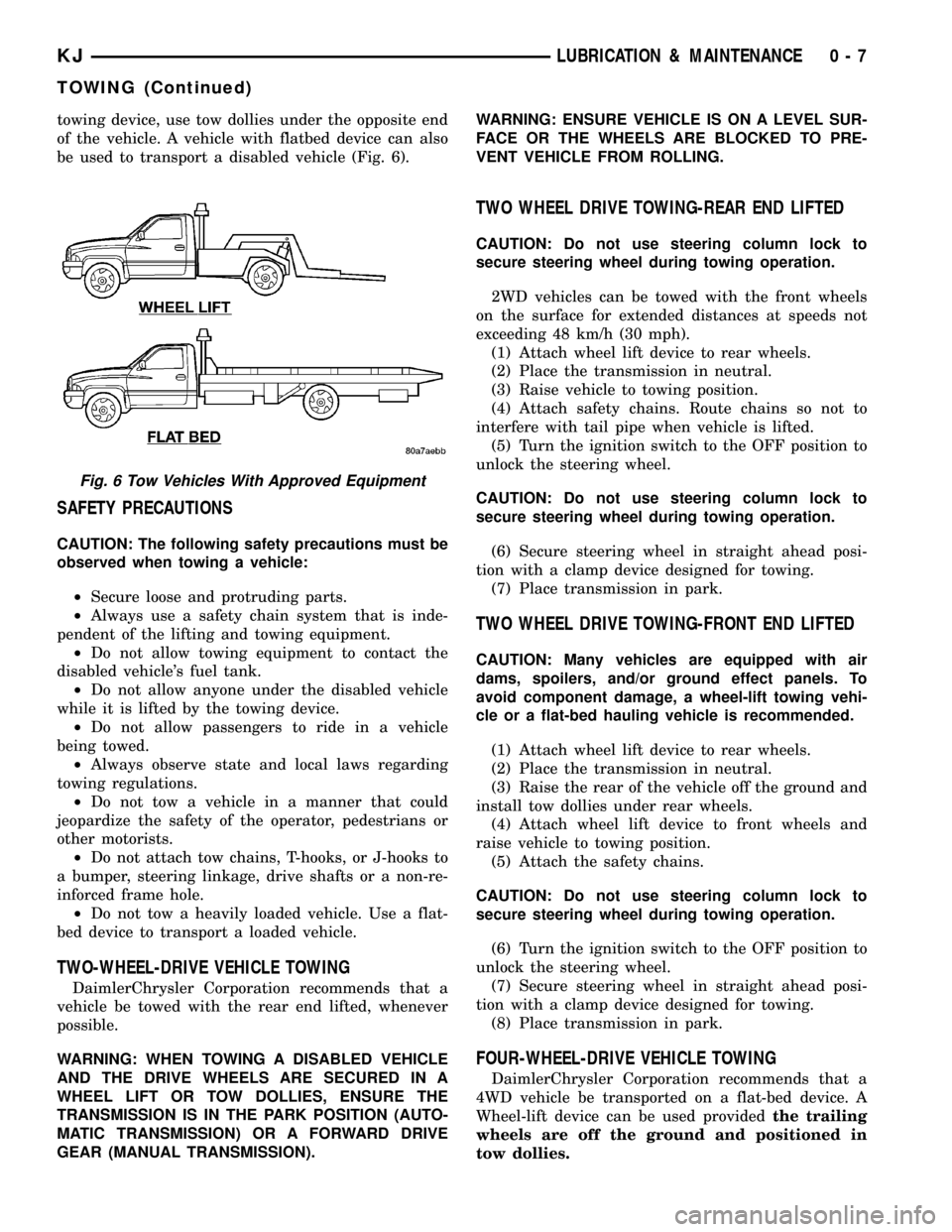

towing device, use tow dollies under the opposite end

of the vehicle. A vehicle with flatbed device can also

be used to transport a disabled vehicle (Fig. 6).

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, or J-hooks to

a bumper, steering linkage, drive shafts or a non-re-

inforced frame hole.

²Do not tow a heavily loaded vehicle. Use a flat-

bed device to transport a loaded vehicle.

TWO-WHEEL-DRIVE VEHICLE TOWING

DaimlerChrysler Corporation recommends that a

vehicle be towed with the rear end lifted, whenever

possible.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

TWO WHEEL DRIVE TOWING-REAR END LIFTED

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

2WD vehicles can be towed with the front wheels

on the surface for extended distances at speeds not

exceeding 48 km/h (30 mph).

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise vehicle to towing position.

(4) Attach safety chains. Route chains so not to

interfere with tail pipe when vehicle is lifted.

(5) Turn the ignition switch to the OFF position to

unlock the steering wheel.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(7) Place transmission in park.

TWO WHEEL DRIVE TOWING-FRONT END LIFTED

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise the rear of the vehicle off the ground and

install tow dollies under rear wheels.

(4) Attach wheel lift device to front wheels and

raise vehicle to towing position.

(5) Attach the safety chains.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

FOUR-WHEEL-DRIVE VEHICLE TOWING

DaimlerChrysler Corporation recommends that a

4WD vehicle be transported on a flat-bed device. A

Wheel-lift device can be used providedthe trailing

wheels are off the ground and positioned in

tow dollies.

Fig. 6 Tow Vehicles With Approved Equipment

KJLUBRICATION & MAINTENANCE 0 - 7

TOWING (Continued)

Page 20 of 1803

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION.

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

FOUR WHEEL DRIVE TOWINGÐREAR END LIFTED

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

(1) Attach wheel lift device to front wheels.

(2) Place the transmission in neutral.

(3) Raise the front of the vehicle off the ground

and install tow dollies under front wheels.

(4) Attach wheel lift device to rear wheels and

raise vehicle to towing position.

(5) Attach safety chains. Route chains so not to

interfere with tail pipe when vehicle is lifted.

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

FOUR WHEEL DRIVE TOWINGÐFRONT END

LIFTED

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise the rear of the vehicle off the ground and

install tow dollies under rear wheels.

(4) Attach wheel lift device to front wheels and

raise vehicle to towing position.

(5) Attach the safety chains.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

0 - 8 LUBRICATION & MAINTENANCEKJ

TOWING (Continued)

Page 21 of 1803

SUSPENSION

TABLE OF CONTENTS

page page

SUSPENSION

DIAGNOSIS AND TESTING - SUSPENSION

AND STEERING SYSTEM................1WHEEL ALIGNMENT......................3

FRONT.................................7

REAR.................................16

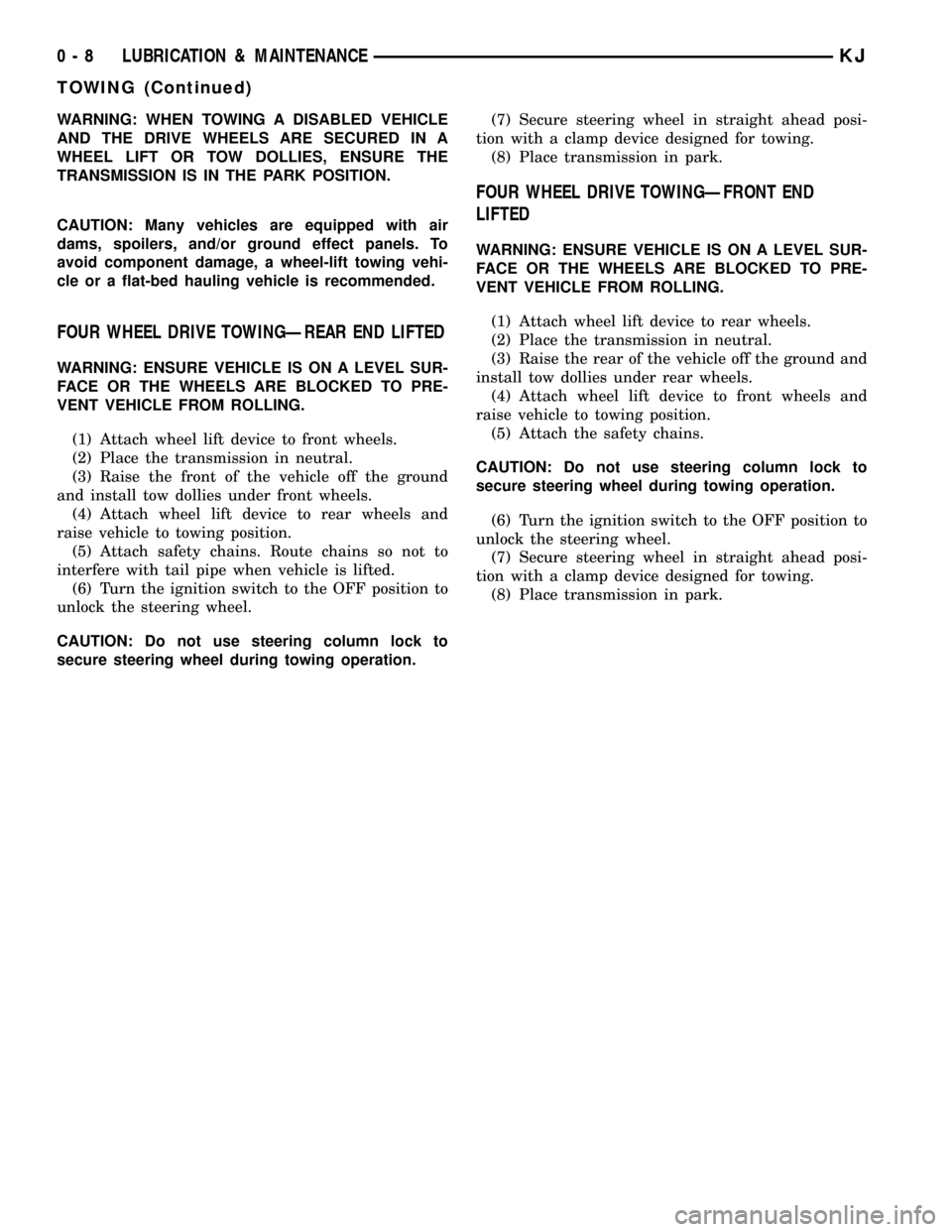

SUSPENSION

DIAGNOSIS AND TESTING - SUSPENSION AND

STEERING SYSTEM

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering gear. 3. Adjust or replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Adjust or replace steering gear.

2. Power steering fluid low. 2. Add fluid and repair leak.

3. Column coupler binding. 3. Replace coupler.

4. Tire pressure. 4. Adjust tire pressure.

5. Alignment. 5. Align vehicle to specifications.

VEHICLE PULLS TO ONE

SIDE DURING BRAKING1. Uneven tire pressure. 1. Adjust tire pressure.

2. Worn brake components. 2. Repair brakes as necessary.

3. Air in brake line. 3. Repair as necessary.

KJSUSPENSION 2 - 1

Page 184 of 1803

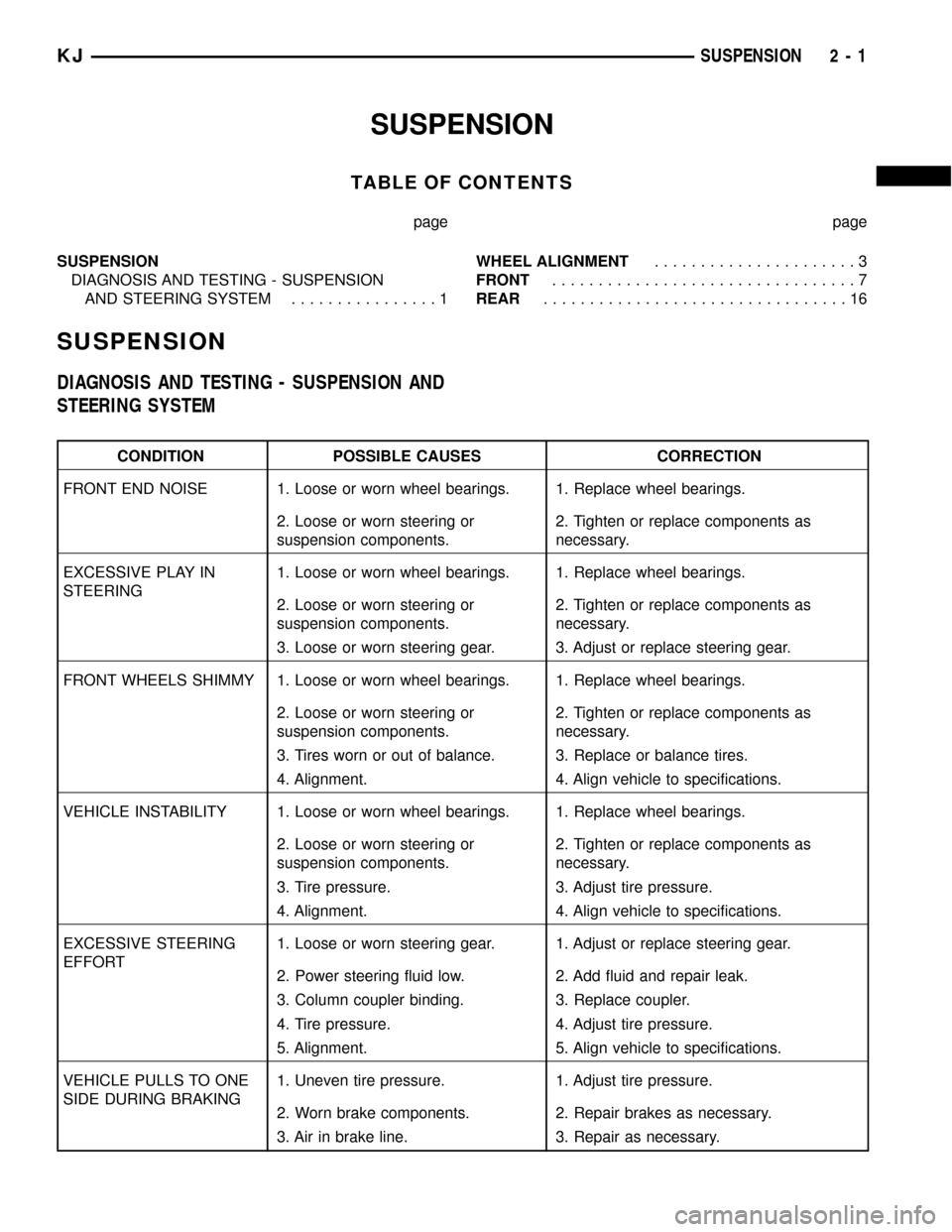

JUNCTION BLOCK

DESCRIPTION

The junction block and a rear brake proportioning

valve. The valve is not repairable and must be

replaced as an assembly if diagnosis indicates this is

necessary.

OPERATION

PROPORTIONING VALVE

The proportioning valve is used to balance front-

rear brake action at high decelerations. The valve

allows normal fluid flow during moderate braking.

The valve only controls fluid flow during high decel-

erations brake stops. If the primary brake hydraulic

circuit cannot build pressure a by-pass feature is

activated allowing full flow and pressure to the rear

brakes.

DIAGNOSIS AND TESTING - PROPORTIONING

VALVE

The valve controls fluid flow. If fluid enters the

valve and does not exit the valve the combination

valve must be replaced.

REMOVAL

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the brake lines from the junction

block.

(3) Remove mounting nuts and bolt and remove

the junction block (Fig. 31).

INSTALLATION

(1) Install the junction block on the mounting

studs.

(2) Install mounting nuts and bolt. Tighten to 14

N´m (125 in. lbs.).

(3) Install brake lines to the junction block and

tighten to 20 N´m (180 in. lbs.).

(4) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

PEDAL

DESCRIPTION

A suspended-type brake pedal is used, the pedal

pivots on a shaft mounted in the steering coloumn

support bracket. The bracket is attached to the dash

panel. The unit is serviced as an assembly, except for

the pedal pad.

OPERATION

The brake pedal is attached to the booster push

rod. When the pedal is depressed, the primary

booster push rod is depressed which move the booster

secondary rod. The booster secondary rod depress the

master cylinder piston.

REMOVAL

(1) Remove the knee blocker under the steering

column,(Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - REMOVAL).

(2) Remove the retainer clip securing the booster

push rod to pedal (Fig. 32).

(3) Remove the brake lamp switch,(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(4) Remove the nuts securing the pedal to the col-

umn bracket.

(5) Remove the pedal from the vehicle.

INSTALLATION

(1) Install the pedal into the vehicle.

(2) Install the nuts securing the pedal to the col-

umn bracket.

(3) Tighten the nuts to 22.6 N´m (200 in. lbs.).

(4) Lubricate the brake pedal pin and bushings

with Mopar multi-mileage grease.

(5) Install the booster push rod on the pedal pin

and install a new retainer clip (Fig. 32).

(6) Install the brake lamp switch,(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION).

(7) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

Fig. 31 JUNCTION BLOCK

1 - JUNCTION BLOCK

2 - MOUNTING NUT

5 - 20 BRAKES - BASEKJ

Page 214 of 1803

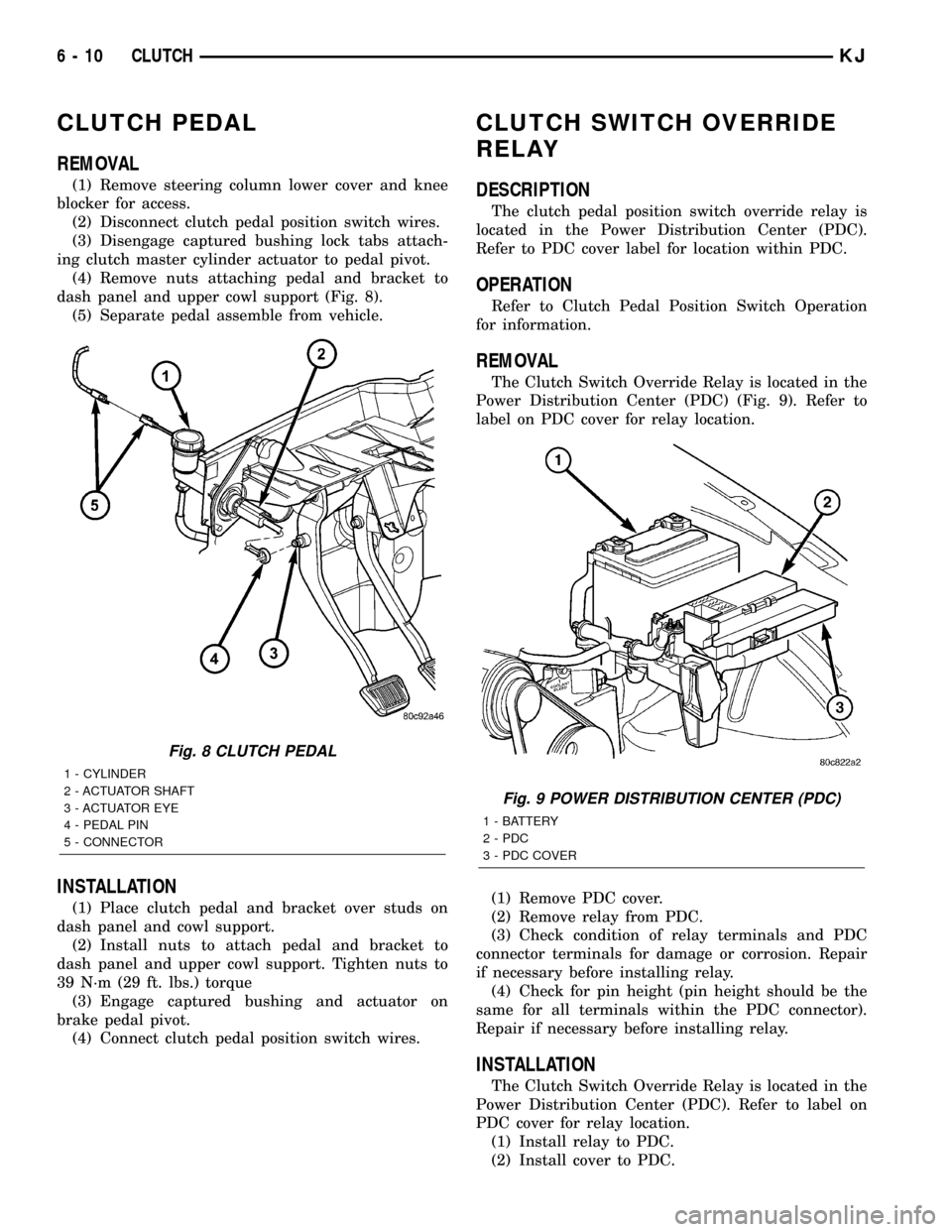

CLUTCH PEDAL

REMOVAL

(1) Remove steering column lower cover and knee

blocker for access.

(2) Disconnect clutch pedal position switch wires.

(3) Disengage captured bushing lock tabs attach-

ing clutch master cylinder actuator to pedal pivot.

(4) Remove nuts attaching pedal and bracket to

dash panel and upper cowl support (Fig. 8).

(5) Separate pedal assemble from vehicle.

INSTALLATION

(1) Place clutch pedal and bracket over studs on

dash panel and cowl support.

(2) Install nuts to attach pedal and bracket to

dash panel and upper cowl support. Tighten nuts to

39 N´m (29 ft. lbs.) torque

(3) Engage captured bushing and actuator on

brake pedal pivot.

(4) Connect clutch pedal position switch wires.

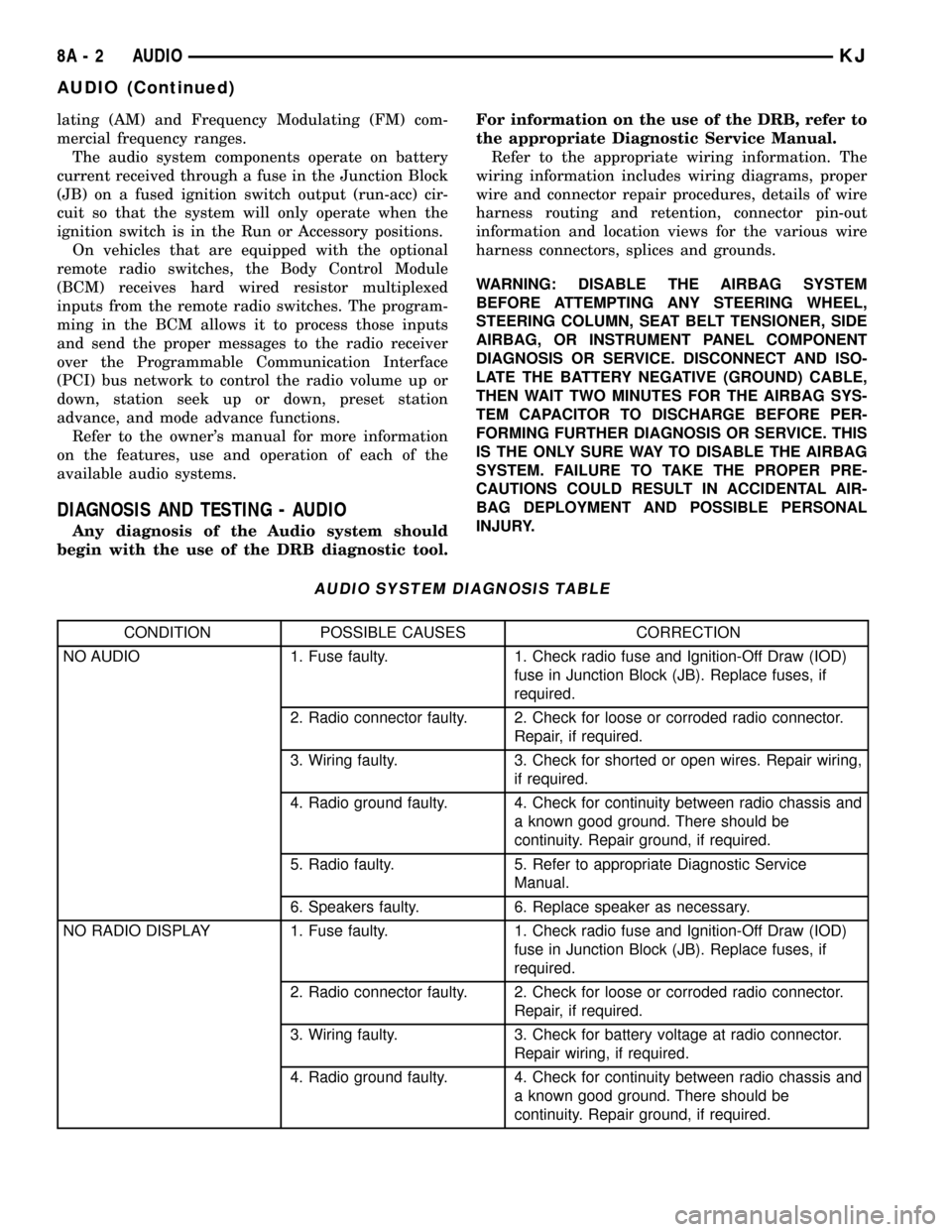

CLUTCH SWITCH OVERRIDE

RELAY

DESCRIPTION

The clutch pedal position switch override relay is

located in the Power Distribution Center (PDC).

Refer to PDC cover label for location within PDC.

OPERATION

Refer to Clutch Pedal Position Switch Operation

for information.

REMOVAL

The Clutch Switch Override Relay is located in the

Power Distribution Center (PDC) (Fig. 9). Refer to

label on PDC cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The Clutch Switch Override Relay is located in the

Power Distribution Center (PDC). Refer to label on

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

Fig. 8 CLUTCH PEDAL

1 - CYLINDER

2 - ACTUATOR SHAFT

3 - ACTUATOR EYE

4 - PEDAL PIN

5 - CONNECTOR

Fig. 9 POWER DISTRIBUTION CENTER (PDC)

1 - BATTERY

2 - PDC

3 - PDC COVER

6 - 10 CLUTCHKJ

Page 279 of 1803

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges.

The audio system components operate on battery

current received through a fuse in the Junction Block

(JB) on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the Run or Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the Body Control Module

(BCM) receives hard wired resistor multiplexed

inputs from the remote radio switches. The program-

ming in the BCM allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.

Refer to the owner's manual for more information

on the features, use and operation of each of the

available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB diagnostic tool.For information on the use of the DRB, refer to

the appropriate Diagnostic Service Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Junction Block (JB). Replace fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Junction Block (JB). Replace fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

8A - 2 AUDIOKJ

AUDIO (Continued)

Page 282 of 1803

OPERATION

The antenna body and cable connects the antenna

mast to the radio. The radio antenna is an electro-

magnetic circuit component used to capture radio fre-

quency signals that are broadcast by local

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

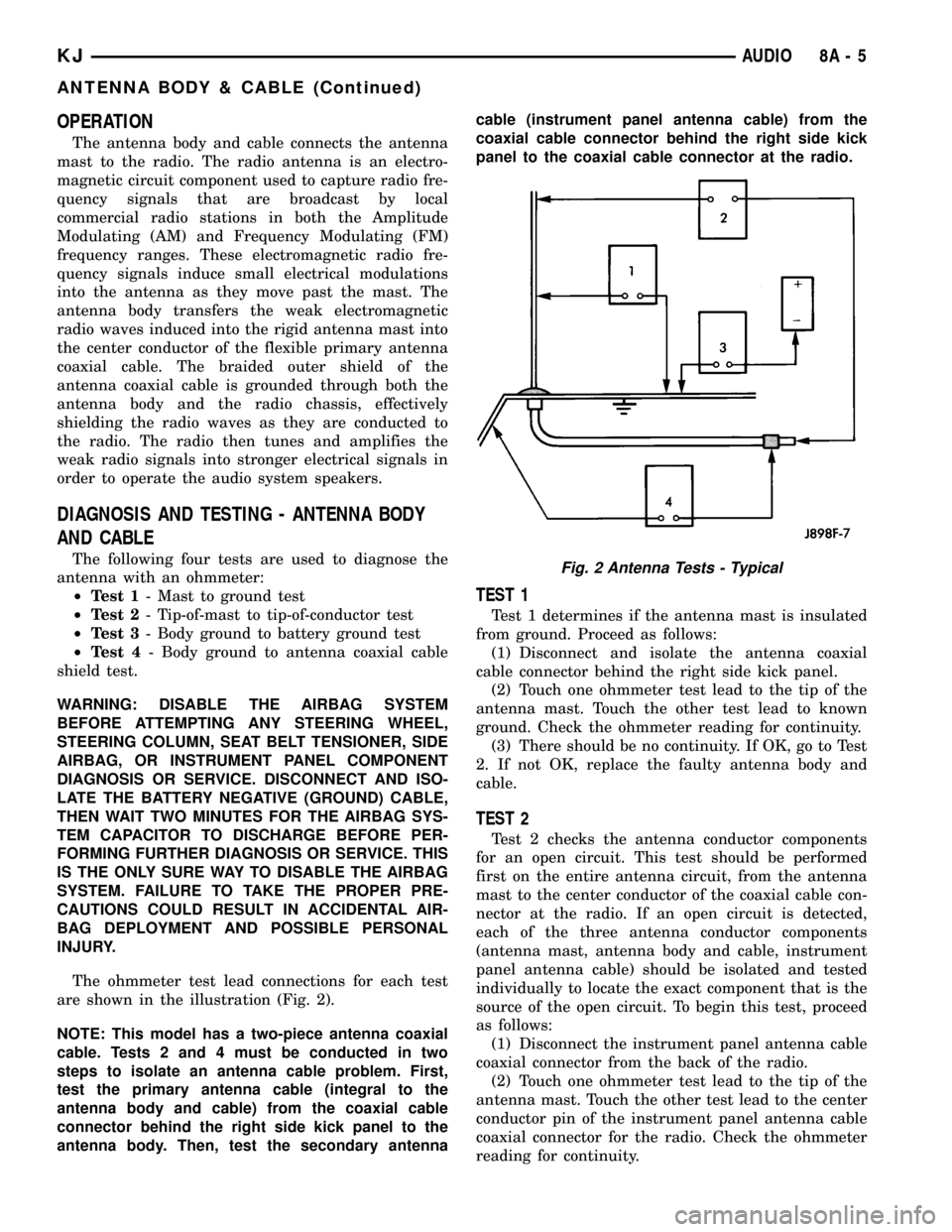

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to antenna coaxial cable

shield test.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The ohmmeter test lead connections for each test

are shown in the illustration (Fig. 2).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate an antenna cable problem. First,

test the primary antenna cable (integral to the

antenna body and cable) from the coaxial cable

connector behind the right side kick panel to the

antenna body. Then, test the secondary antennacable (instrument panel antenna cable) from the

coaxial cable connector behind the right side kick

panel to the coaxial cable connector at the radio.

TEST 1

Test 1 determines if the antenna mast is insulated

from ground. Proceed as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector behind the right side kick panel.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to known

ground. Check the ohmmeter reading for continuity.

(3) There should be no continuity. If OK, go to Test

2. If not OK, replace the faulty antenna body and

cable.

TEST 2

Test 2 checks the antenna conductor components

for an open circuit. This test should be performed

first on the entire antenna circuit, from the antenna

mast to the center conductor of the coaxial cable con-

nector at the radio. If an open circuit is detected,

each of the three antenna conductor components

(antenna mast, antenna body and cable, instrument

panel antenna cable) should be isolated and tested

individually to locate the exact component that is the

source of the open circuit. To begin this test, proceed

as follows:

(1) Disconnect the instrument panel antenna cable

coaxial connector from the back of the radio.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to the center

conductor pin of the instrument panel antenna cable

coaxial connector for the radio. Check the ohmmeter

reading for continuity.

Fig. 2 Antenna Tests - Typical

KJAUDIO 8A - 5

ANTENNA BODY & CABLE (Continued)

Page 284 of 1803

(8) Install antenna mast.

(9) Tighten fender mounting bolts near door hinge

area.

(10) Install and tighten the upper fender mounting

bolts (Refer to 23 - BODY/EXTERIOR/FRONT

FENDER - INSTALLATION).

(11) Connect the battery negative cable.

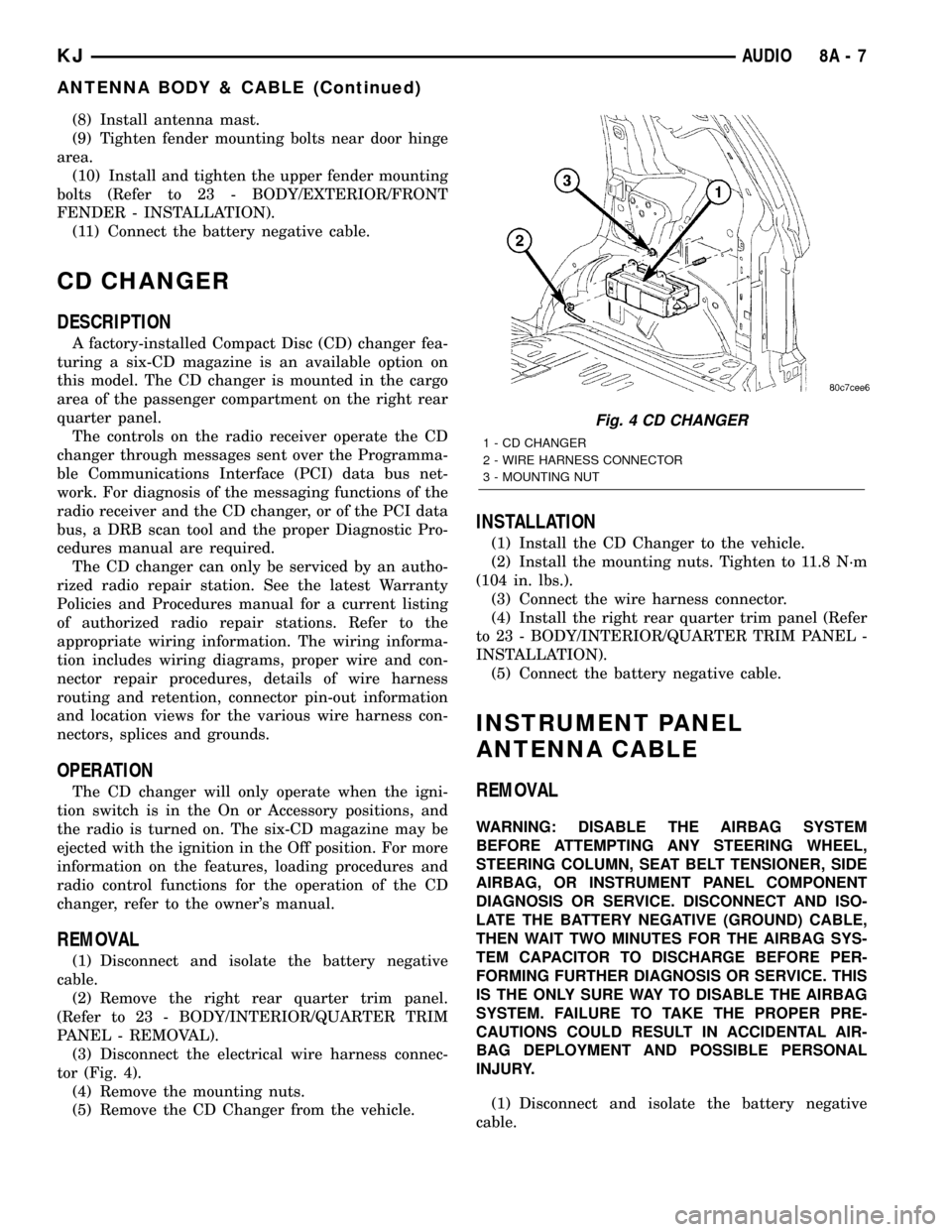

CD CHANGER

DESCRIPTION

A factory-installed Compact Disc (CD) changer fea-

turing a six-CD magazine is an available option on

this model. The CD changer is mounted in the cargo

area of the passenger compartment on the right rear

quarter panel.

The controls on the radio receiver operate the CD

changer through messages sent over the Programma-

ble Communications Interface (PCI) data bus net-

work. For diagnosis of the messaging functions of the

radio receiver and the CD changer, or of the PCI data

bus, a DRB scan tool and the proper Diagnostic Pro-

cedures manual are required.

The CD changer can only be serviced by an autho-

rized radio repair station. See the latest Warranty

Policies and Procedures manual for a current listing

of authorized radio repair stations. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

OPERATION

The CD changer will only operate when the igni-

tion switch is in the On or Accessory positions, and

the radio is turned on. The six-CD magazine may be

ejected with the ignition in the Off position. For more

information on the features, loading procedures and

radio control functions for the operation of the CD

changer, refer to the owner's manual.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right rear quarter trim panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Disconnect the electrical wire harness connec-

tor (Fig. 4).

(4) Remove the mounting nuts.

(5) Remove the CD Changer from the vehicle.

INSTALLATION

(1) Install the CD Changer to the vehicle.

(2) Install the mounting nuts. Tighten to 11.8 N´m

(104 in. lbs.).

(3) Connect the wire harness connector.

(4) Install the right rear quarter trim panel (Refer

to 23 - BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION).

(5) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

Fig. 4 CD CHANGER

1 - CD CHANGER

2 - WIRE HARNESS CONNECTOR

3 - MOUNTING NUT

KJAUDIO 8A - 7

ANTENNA BODY & CABLE (Continued)

Page 285 of 1803

(2) Remove the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

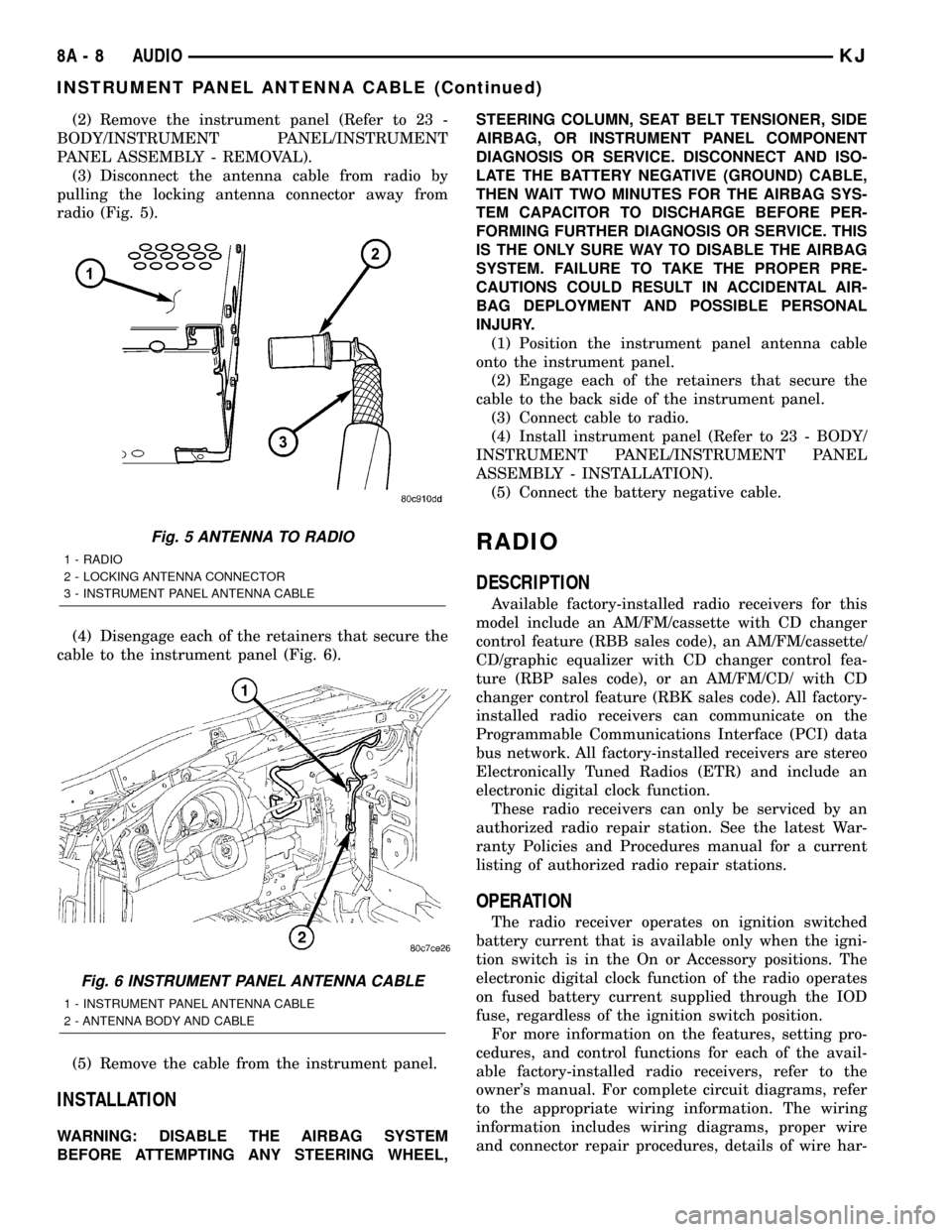

(3) Disconnect the antenna cable from radio by

pulling the locking antenna connector away from

radio (Fig. 5).

(4) Disengage each of the retainers that secure the

cable to the instrument panel (Fig. 6).

(5) Remove the cable from the instrument panel.

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the instrument panel antenna cable

onto the instrument panel.

(2) Engage each of the retainers that secure the

cable to the back side of the instrument panel.

(3) Connect cable to radio.

(4) Install instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

(5) Connect the battery negative cable.

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include an AM/FM/cassette with CD changer

control feature (RBB sales code), an AM/FM/cassette/

CD/graphic equalizer with CD changer control fea-

ture (RBP sales code), or an AM/FM/CD/ with CD

changer control feature (RBK sales code). All factory-

installed radio receivers can communicate on the

Programmable Communications Interface (PCI) data

bus network. All factory-installed receivers are stereo

Electronically Tuned Radios (ETR) and include an

electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory positions. The

electronic digital clock function of the radio operates

on fused battery current supplied through the IOD

fuse, regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

Fig. 5 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

Fig. 6 INSTRUMENT PANEL ANTENNA CABLE

1 - INSTRUMENT PANEL ANTENNA CABLE

2 - ANTENNA BODY AND CABLE

8A - 8 AUDIOKJ

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 289 of 1803

OPERATION

The six switches in the two remote radio switch units

are normally open, resistor multiplexed momentary

switches that are hard wired to the Body Control Mod-

ule (BCM) through the clockspring. The BCM sends a

five volt reference signal to both switch units on one

circuit, and senses the status of all of the switches by

reading the voltage drop on a second circuit.

When the BCM senses an input (voltage drop) from

any one of the remote radio switches, it sends the

proper switch status messages on the Programmable

Communication Interface (PCI) data bus network to

the radio receiver. The electronic circuitry within the

radio receiver is programmed to respond to these

remote radio switch status messages by adjusting the

radio settings as requested. For diagnosis of the

BCM or the PCI data bus, the use of a DRB scan tool

and the proper Diagnostic Procedures manual are

recommended.

For more information on the features and control

functions for each of the remote radio switches, refer

to the owner's manual.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB diagnostic tool.

For information on the use of the DRB, refer to

the appropriate Diagnostic Service Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

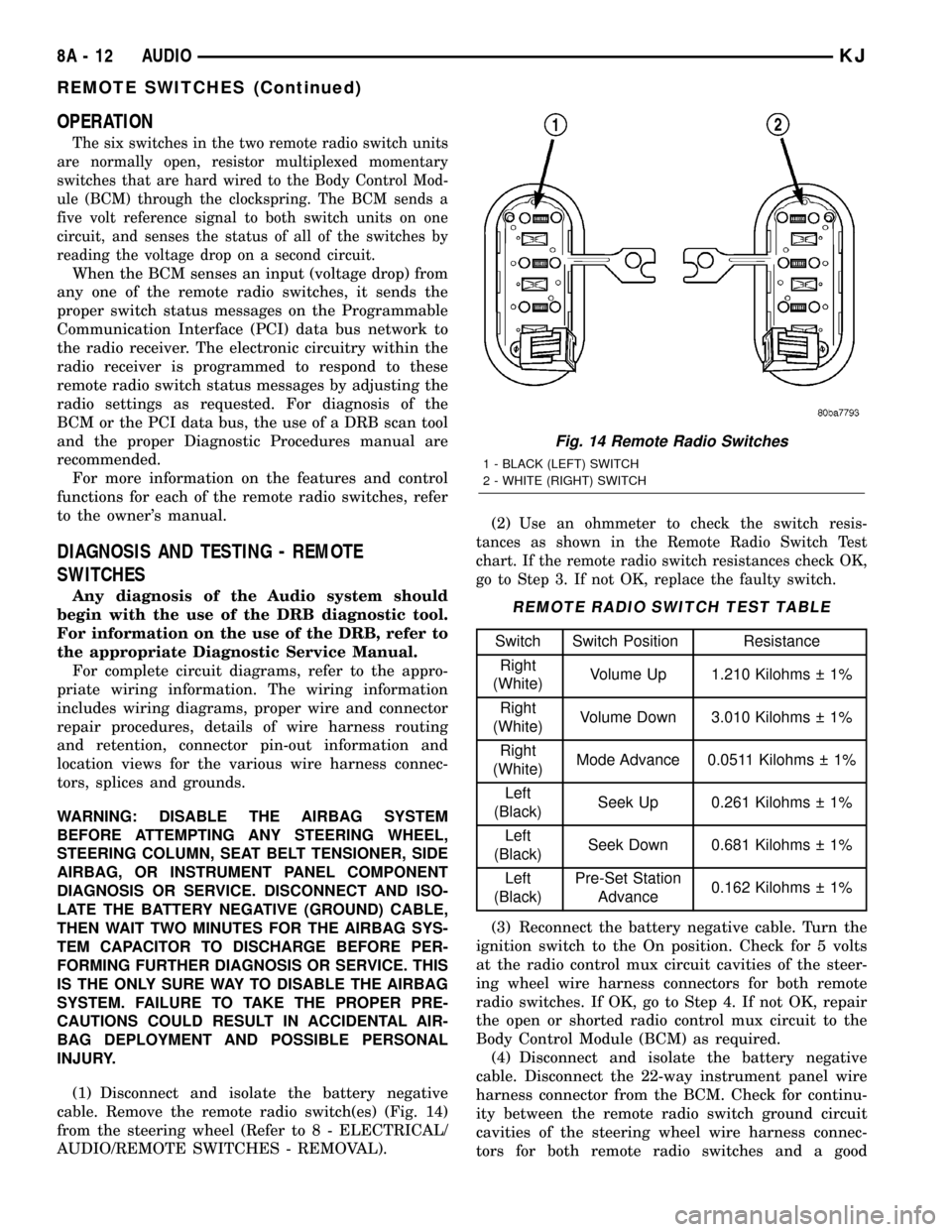

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 14)

from the steering wheel (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).(2)

Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check OK,

go to Step 3. If not OK, replace the faulty switch.

REMOTE RADIO SWITCH TEST TABLE

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms 1%

Right

(White)Volume Down 3.010 Kilohms 1%

Right

(White)Mode Advance 0.0511 Kilohms 1%

Left

(Black)Seek Up 0.261 Kilohms 1%

Left

(Black)Seek Down 0.681 Kilohms 1%

Left

(Black)Pre-Set Station

Advance0.162 Kilohms 1%

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Body Control Module (BCM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the BCM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

Fig. 14 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

8A - 12 AUDIOKJ

REMOTE SWITCHES (Continued)