brake fluid JEEP PATRIOT 2007 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2007, Model line: PATRIOT, Model: JEEP PATRIOT 2007 1.GPages: 440, PDF Size: 7.26 MB

Page 72 of 440

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield.

Periodic Safety Checks You Should Make Outside

The Vehicle

Tires

Examine tires for excessive tread wear or uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread. Inspect tread and sidewall for cuts or

cracks. Check wheel nuts for tightness, and tires (includ-

ing spare) for proper pressure.

Lights

Have someone observe the operation of exterior lights

while you work the controls. Check turn signal and high

beam indicator lights on the instrument panel.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

engine coolant, oil or other fluid leaks. Also, if gasoline

fumes are detected or fuel, power steering fluid, trans-

mission fluid or brake fluid leaks are suspected, the cause

should be located and corrected immediately.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 71

2

Page 76 of 440

NWindshield Wiper Operation.............125

NIntermittent Wiper System...............125

NAdding Washer Fluid..................126

mTilt Steering Column....................126

mElectronic Speed Control Ð If Equipped......127

NTo Activate..........................127

NTo Set At A Desired Speed...............128

NTo Deactivate........................128

NTo Resume Speed.....................128

NTo Vary The Speed Setting...............128

NManual Transaxle.....................129

NTo Accelerate For Passing...............129

mGarage Door Opener Ð If Equipped.........130NProgramming The Universal Transceiver.....131

NªRolling Codeº Programming............133

NCanadian Programming/Gate Programming . . 135

NOperation...........................135

NReprogramming A Single Button..........135

NSecurity............................136

mAnti-Lock Brake System (ABS) ± If Equipped . . . 136

mElectronic Brake Control System ±

ABS/TCS/BAS/ERM/HDC/ESP...........137

NAnti-Lock Brake System ± ABS............137

NTraction Control System (TCS)............138

NBrake Assist System (BAS)...............138

NElectronic Roll Mitigation (ERM)..........139

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 75

3

Page 173 of 440

will sound 10 times. After the chime turns off, the engine

will still be critically hot until the light goes out.

14. Brake System Warning Light

This light monitors various brake functions, in-

cluding brake fluid level and parking brake appli-

cation. If the brake light turns on, it may indicate that the

parking brake is applied, there is a low brake fluid level

or there is a problem with the anti-lock brake system.

The dual brake system provides a reserve braking capac-

ity in the event of a failure to a portion of the hydraulic

system. Failure of either half of the dual brake system is

indicated by the Brake Warning Light which will turn on

when the brake fluid level in the master cylinder has

dropped below a specified level.

The light will remain on until the cause is corrected.NOTE:The light may flash momentarily during sharp

cornering maneuvers which change fluid level condi-

tions. The vehicle should have service performed, and

the brake fluid level checked.

If brake failure is indicated, immediate repair is neces-

sary.

WARNING!

Driving a vehicle with the brake light on is danger-

ous. Part of the brake system may have failed. It will

take longer to stop the vehicle. You could have an

accident. Have the vehicle checked immediately.

Vehicles equipped with Anti-Lock brakes (ABS), are also

equipped with Electronic Brake Force Distribution (EBD).

172 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 264 of 440

avoid damage to the environment. You should know

your vehicles abilities and be able to recover it if some-

thing goes wrong. You should never stop or shut a

vehicle off when crossing deep water unless you ingested

water into the engine air intake. If the engine stalls do not

attempt to restart it. Determine if it has ingested water

first. The key to any crossing is low and slow. You want

to use low (L Off-Road) with the 4WD Lock engaged and

proceed very slowly with a constant slow speed {3-5 mph

(5±8 km/h) maximum} and light throttle. Keep the ve-

hicle moving; do not try to accelerate through the cross-

ing. After crossing any water higher than the bottom of

the axle differentials, you should inspect all of the vehicle

fluids for signs of water ingestion.CAUTION!

Water ingestion into the axles, transmission, transfer

case, engine or vehicle interior can occur if you drive

too fast or through too deep of water. Water can cause

permanent damage to engine, driveline or other

vehicle components and your brakes will be less

effective once wet and/or muddy.

STARTING AND OPERATING 263

5

Page 273 of 440

BRAKE SYSTEM

Your vehicle is equipped with power assisted brakes as

standard equipment. In the event power assist is lost for

any reason (for example, repeated brake applications

with the engine off), the brakes will still function. How-

ever, the effort required to brake the vehicle will be much

greater than that required with the power system oper-

ating.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.If either of the two hydraulic systems lose normal capa-

bility, the remaining system will still function with some

loss of overall braking effectiveness. This will be evident

by increased pedal travel during application and greater

pedal force required to slow or stop. In addition, if the

malfunction is caused by an internal leak, as the brake

fluid in the master cylinder drops, the brake warning

indicator will light.

WARNING!

Driving a vehicle with the brake light on is danger-

ous. A significant decrease in braking performance or

vehicle stability during braking may occur. It will

take you longer to stop the vehicle or will make your

vehicle harder to control. You could have an accident.

Have the vehicle checked immediately.

272 STARTING AND OPERATING

Page 367 of 440

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling suggest deterioration of the rubber. Particu-

lar attention should be made to examining those hose

surfaces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

366 MAINTAINING YOUR VEHICLE

Page 368 of 440

NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and at every engine oil

change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brakefluid reservoir. Fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

NOTE:If your vehicle is equipped with aManual

Transaxle, the Brake Fluid Reservoir supplies fluid to

both the Brake System and the Clutch Release System.

The two systems are separated in the reservoir and a leak

in one system will not affect the other system. The

Manual TransaxleClutch Release System should not

require fluid replacement during the life of the vehicle. If

the Brake Fluid Reservoir is low, and the brake system

does not indicate any leaks or other problems, it may be

a result of a leak in the Hydraulic Clutch Release System.

See your local authorized dealer for service.

Use only manufacturers recommended brake fluid, refer

to Fluids, Lubricants and Genuine Parts for correct fluid

type.

MAINTAINING YOUR VEHICLE 367

7

Page 369 of 440

WARNING!

Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification, may

result in sudden brake failure during hard prolonged

braking. You could have an accident.

CAUTION!

Use of improper brake fluids will affect overall

clutch system performance. Improper brake fluids

may damage the clutch system resulting in loss of

clutch function and the ability to shift the transaxle.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum based fluid to contaminate the

brake fluid as seal damage will result!

Automatic Transaxle (CVT)

Selection Of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only the manufacturer's recommended transmission

fluid which has been formulated with special metal to

metal friction coefficient additives to provide the proper

368 MAINTAINING YOUR VEHICLE

Page 390 of 440

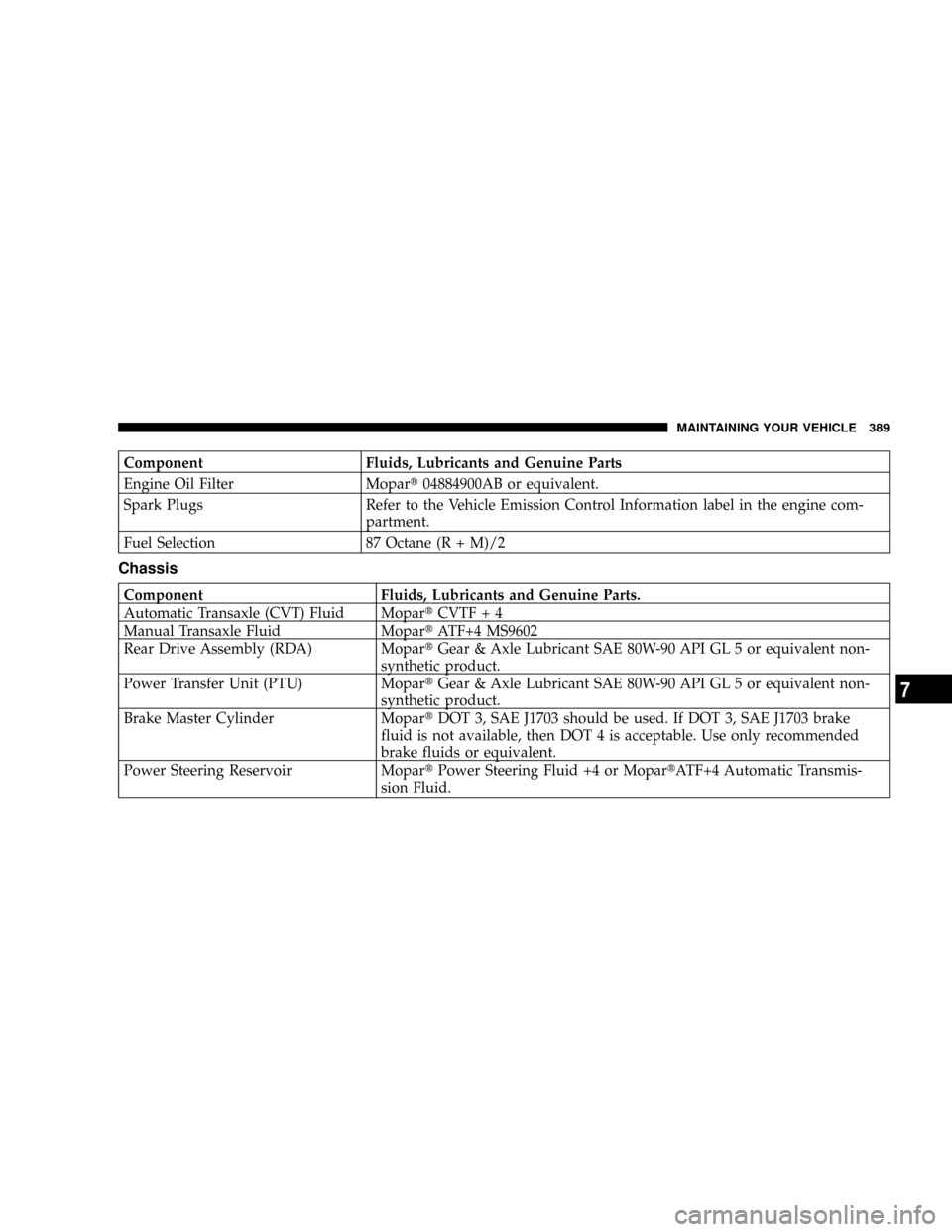

Component Fluids, Lubricants and Genuine Parts

Engine Oil Filter Mopart04884900AB or equivalent.

Spark Plugs Refer to the Vehicle Emission Control Information label in the engine com-

partment.

Fuel Selection 87 Octane (R + M)/2

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transaxle (CVT) Fluid MopartCVTF + 4

Manual Transaxle Fluid MopartATF+4 MS9602

Rear Drive Assembly (RDA) MopartGear & Axle Lubricant SAE 80W-90 API GL 5 or equivalent non-

synthetic product.

Power Transfer Unit (PTU) MopartGear & Axle Lubricant SAE 80W-90 API GL 5 or equivalent non-

synthetic product.

Brake Master Cylinder MopartDOT 3, SAE J1703 should be used. If DOT 3, SAE J1703 brake

fluid is not available, then DOT 4 is acceptable. Use only recommended

brake fluids or equivalent.

Power Steering Reservoir MopartPower Steering Fluid +4 or MopartATF+4 Automatic Transmis-

sion Fluid.

MAINTAINING YOUR VEHICLE 389

7

Page 395 of 440

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake/

clutch master cylinder, and manual transaxle and add

as needed.

²Check all lights and all other electrical items for correct

operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints (if equipped) and front suspen-

sion components.

²Check the manual transmission fluid level (if

equipped).

²Check the coolant level, hoses, and clamps.

CAUTION!

Do not check the automatic transaxle fluid. It must be

check by a trained service technician every 15,000

miles and if required only the recommended fluid be

added. Refer to the section ªFluids, Lubricants And

Genuine Partsº for the proper fluid.

394 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S