ECU JEEP PATRIOT 2008 1.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: PATRIOT, Model: JEEP PATRIOT 2008 1.GPages: 438, PDF Size: 6.71 MB

Page 338 of 438

Jacking InstructionsWARNING!

Carefully follow these tire changing warnings to help prevent

personal injury or damage to your vehicle:

•Always park on a firm, level surface as far from the edge of

the roadway as possible before raising the vehicle.

•Block the wheel diagonally opposite the wheel to be raised.

•Set the parking brake firmly and set an automatic transmis-

sion in park; a manual transmission in reverse.

•Never start or run the engine with the vehicle on a jack.

•Do not let anyone sit in the vehicle when it is on a jack.

•Do not get under the vehicle when it is on a jack.

•Only use the jack in the positions indicated and for lifting

this vehicle during a tire change.

•If working on or near a roadway, be extremely careful of

motor traffic.

•To assure that spare tires, flat or inflated are securely stowed,

spares must be stowed with the valve stem facing the ground.

•Turn on the Hazard warning flasher.

Jack Warning Label

336 WHAT TO DO IN EMERGENCIES

Page 340 of 438

3. There are two front jacking locations and two rear

jacking locations on each side of the body. The front

locations are outlined by two triangular cutouts, the rear

ones by two rectangular cutouts. For vehicles equipped

with plastic trim, the plastic has been cut away to expose

the jacking locations in the body.

Do not raise the vehicle until you are sure the jack is

securely engaged.

4. Turn the jack screw to the left until the jack can be

placed under the jacking location. Once the jack is

positioned, turn the jack screw to the right until the jack

head is properly engaged with the lift area closest to the

wheel to be changed. Do not raise the vehicle until you

are sure the jack is securely engaged.WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

5. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

6. Remove the wheel nuts and pull the wheel (and

bolt-on center cap if equipped) off the hub. Install the

spare wheel and wheel nuts with the cone shaped end of

the nuts toward the wheel. Lightly tighten the nuts. To

avoid the risk of forcing the vehicle off the jack, do not

tighten the nuts fully until the vehicle has been lowered.

338 WHAT TO DO IN EMERGENCIES

Page 341 of 438

7. Lower the vehicle by turning the jack screw to the left.

8. Finish tightening the nuts. Push down on the wrench

while tightening the wheel nuts. Alternate nuts until each

nut has been tightened twice. Correct wheel nut torque is

100 ft lbs (135 N·m). If you doubt that you have tightened

the nuts correctly, have them checked with a torque

wrench by your authorized dealer or at a service station.

9. Remove the wheel blocks and lower the jack until it is

free. Reassemble the lug wrench to the jack assembly and

stow it in the spare tire area. Secure the assembly using

the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.10. Place the deflated (flat) tire in the cargo area.Have

the tire repaired or replaced as soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard

stop could injure the occupants in the vehicle. Have

the deflated (flat) tire repaired or replaced

immediately.

11. Check the tire pressure as soon as possible. Correct

pressure as required.

WHAT TO DO IN EMERGENCIES 339

6

Page 346 of 438

2All Transaxles

CAUTION!

If the vehicle being towed requires steering, the

ignition switch must be in the ACC position, not in

the LOCK position.

Do not attempt to use sling type equipment when

towing. When securing the vehicle to a flat bed truck,

do not attach to front or rear suspension components.

Damage to your vehicle may result from improper

towing.

If it is necessary to use the accessories while being towed

(wipers, defrosters, etc.), the key must be in the ON

position, not the ACC position. Make certain the trans-

mission remains in NEUTRAL.

Without The Ignition Key

Special care must be taken when the vehicle is towed

with the ignition in the LOCK position. A dolly should be

used under the front wheels if the rear wheels are raised.

Proper towing equipment is necessary to prevent dam-

age to the vehicle.

Battery power is required to release the brake/

transmission interlock system. There is a removable plug

in the right side of the shift lever housing that allows you

to insert your finger to override the system. The ignition

key must be in the ON position to use the override lever.

Towing this Vehicle Behind Another Vehicle (Flat

Towing with All Four Wheels on the Ground)

CAUTION!

DO NOT flat tow this vehicle. Damage to the driv-

etrain will result.

344 WHAT TO DO IN EMERGENCIES

Page 372 of 438

•Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

Ensure nylon tubing in these areas has not melted or

collapsed.Inspect all hose connections such as clamps and cou-

plings, to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.Fuel System Connections

Electronic Fuel Injection high pressure fuel systems are

designed with tubes and special connects, connections

and clamps which have unique material characteristics to

provide adequate sealing and resist attack by deterio-

rated gasoline.

You are urged to use only the manufacturer’s-specified

tubes, connections and clamps, or their equivalent in

material and specification, in any fuel system servicing.

370 MAINTAINING YOUR VEHICLE

Page 373 of 438

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to “Maintenance Schedule” under Section 8.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

Brake And Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling suggest deterioration of the rubber. Particu-

lar attention should be made to examining those hose

surfaces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Ensure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

MAINTAINING YOUR VEHICLE 371

7

Page 384 of 438

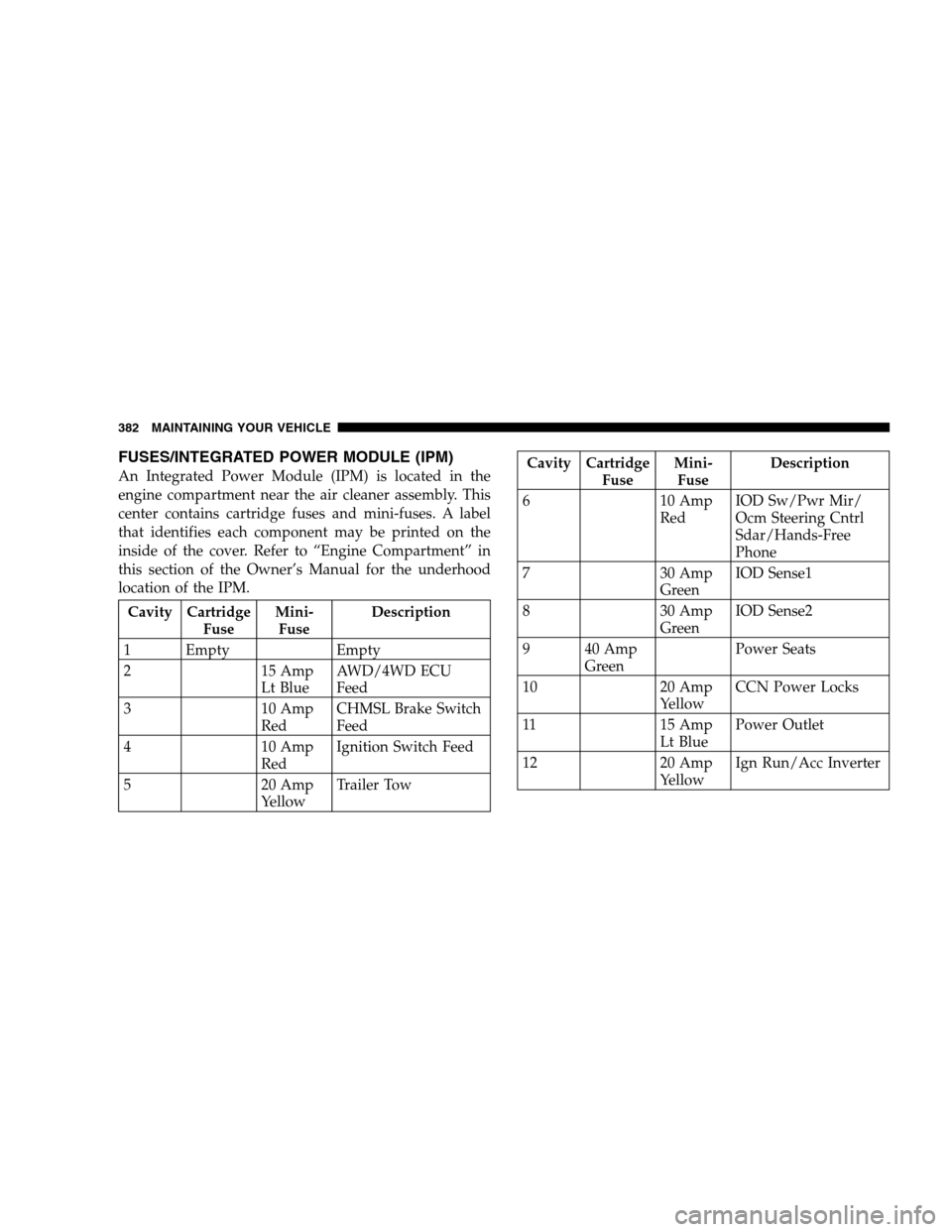

FUSES/INTEGRATED POWER MODULE (IPM)

An Integrated Power Module (IPM) is located in the

engine compartment near the air cleaner assembly. This

center contains cartridge fuses and mini-fuses. A label

that identifies each component may be printed on the

inside of the cover. Refer to “Engine Compartment” in

this section of the Owner’s Manual for the underhood

location of the IPM.

Cavity Cartridge

FuseMini-

FuseDescription

1 Empty Empty

2 15 Amp

Lt BlueAWD/4WD ECU

Feed

3 10 Amp

RedCHMSL Brake Switch

Feed

4 10 Amp

RedIgnition Switch Feed

5 20 Amp

YellowTrailer Tow

Cavity Cartridge

FuseMini-

FuseDescription

6 10 Amp

RedIOD Sw/Pwr Mir/

Ocm Steering Cntrl

Sdar/Hands-Free

Phone

7 30 Amp

GreenIOD Sense1

8 30 Amp

GreenIOD Sense2

9 40 Amp

GreenPower Seats

10 20 Amp

YellowCCN Power Locks

11 15 Amp

Lt BluePower Outlet

12 20 Amp

YellowIgn Run/Acc Inverter

382 MAINTAINING YOUR VEHICLE

Page 395 of 438

Auxiliary Off-Road Light

1. Remove the three screws attaching the lens to the

housing.2. Unlatch the wire clasp securing the bulb into the

housing and rotate it into the position shown.

Lens Removal

Releasing The Bulb

MAINTAINING YOUR VEHICLE 393

7

Page 420 of 438

ABS (Anti-Lock Brake System).............. 279

Adding Engine Coolant (Antifreeze).......... 367

Adding Fuel........................... 314

Adding Washer Fluid..................... 163

Additives, Fuel......................... 313

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 358

Air Conditioner Maintenance............... 361

Air Conditioning Controls................. 227

Air Conditioning, Operating Tips............ 232

Air Conditioning Refrigerant.............361,362

Air Conditioning System................227,361

Air Pressure, Tires....................... 292

Airbag................................ 48

Airbag Deployment..................... 53,55

Airbag Light..................... 53,57,70,173

Airbag Maintenance....................... 57

Airbag, Side............................ 54

Airbag, Window (Side Curtain)............. 49,54

Alarm System (Security Alarm)............ 18,176Alignment and Balance................... 300

Alterations/Modifications, Vehicle............. 8

Antenna, Satellite Radio................... 223

Antifreeze (Engine Coolant)...........366,395,396

Capacities........................... 395

Disposal............................ 368

Anti-Lock Brake System (ABS)............133,279

Anti-Theft Security Alarm (Theft Alarm)........ 18

Appearance Care........................ 376

Assistance Towing........................ 95

Automatic Door Locks................... 27,29

Automatic Transaxle........... 13,239,244,333,373

Fluid Level Check...................... 374

Interlock System....................... 246

Overheating.......................... 333

Selection Of Lubricant................... 373

Shifting ............................. 246

Special Additives...................... 374

Autostick ............................. 249

418 INDEX

Page 428 of 438

Daytime Running...................... 122

Dimmer Switch, Headlight............... 121

Electronic Stability Program

(ESP) Indicator.......................139,142

Engine Temperature Warning.............. 175

Fog ..........................123,181,389

Headlight Switch...................... 121

Headlights........................... 121

High Beam Indicator.................... 173

Instrument Cluster..................... 121

License............................. 391

Lights On Reminder.................... 122

Low Fuel............................ 173

Malfunction Indicator (Check Engine)........ 181

Map Reading......................... 120

Off-Road............................ 125

Oil Pressure.......................... 173

Seat Belt Reminder..................... 174

Security Alarm (Theft Alarm).............. 18Theft Alarm (Security Alarm).............. 176

Traction Control....................... 139

Turn Signal..................121,123,173,389

Voltage............................. 172

Warning (Instrument Cluster Description)..... 172

Loading Vehicle......................... 317

Tires ............................... 287

Locks

Child Protection........................ 30

Door................................ 26

Power Door........................... 27

Lubrication, Body....................... 363

Luggage Rack (Roof Rack)................. 164

Lumbar Support........................ 111

Maintenance Free Battery.................. 359

Maintenance, General..................... 352

Maintenance Procedures................... 352

Maintenance Schedule.................... 400

426 INDEX