flat tire JEEP RENEGADE 2015 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: RENEGADE, Model: JEEP RENEGADE 2015 1.GPages: 220, PDF Size: 34.11 MB

Page 84 of 220

Built-In Features (Uconnect® 6.5A/6.5AN)

CAUTION!

• Ignoring the light/LED on the 9-1-1 button in the overhead console could meanyou may not have 9-1-1 Call service if needed. If the light/LED on the 9-1-1button in the overhead console is illuminated, have an authorized dealerservice the 9-1-1 Call system immediately.

• The Occupant Restraint Controller (ORC) turns on the Air Bag Warning Light onthe instrument panel if a malfunction is detected in any part of the air bagsystem. If the Air Bag Warning Light is illuminated, the air bag system may notbe working properly and the 9-1-1 system may not be able to send a signal toa 9-1-1 operator. If the Air Bag Warning Light is illuminated, have anauthorized dealer service your vehicle immediately.

• If anyone in the vehicle could be in danger (e.g., fire or smoke is visible,dangerous road conditions or location), do not wait for voice contact from a9-1-1 operator. All occupants should exit the vehicle immediately and move toa safe location.

• Do not add any aftermarket electrical equipment to the vehicle’s electricalsystem. This may prevent your vehicle from sending a signal to initiate anemergency call. To avoid interference that can cause the 9-1-1 Call system tofail, never add aftermarket equipment (e.g., two-way mobile radio, CB radio,data recorder, etc.) to your vehicle’s electrical system or modify the antennason your vehicle. IF YOUR VEHICLE LOSES BATTERY POWER FOR ANYREASON (INCLUDING DURING OR AFTER AN ACCIDENT), THEUCONNECT®FEATURES, APPS AND SERVICES, AMONG OTHERS, WILLNOT OPERATE.

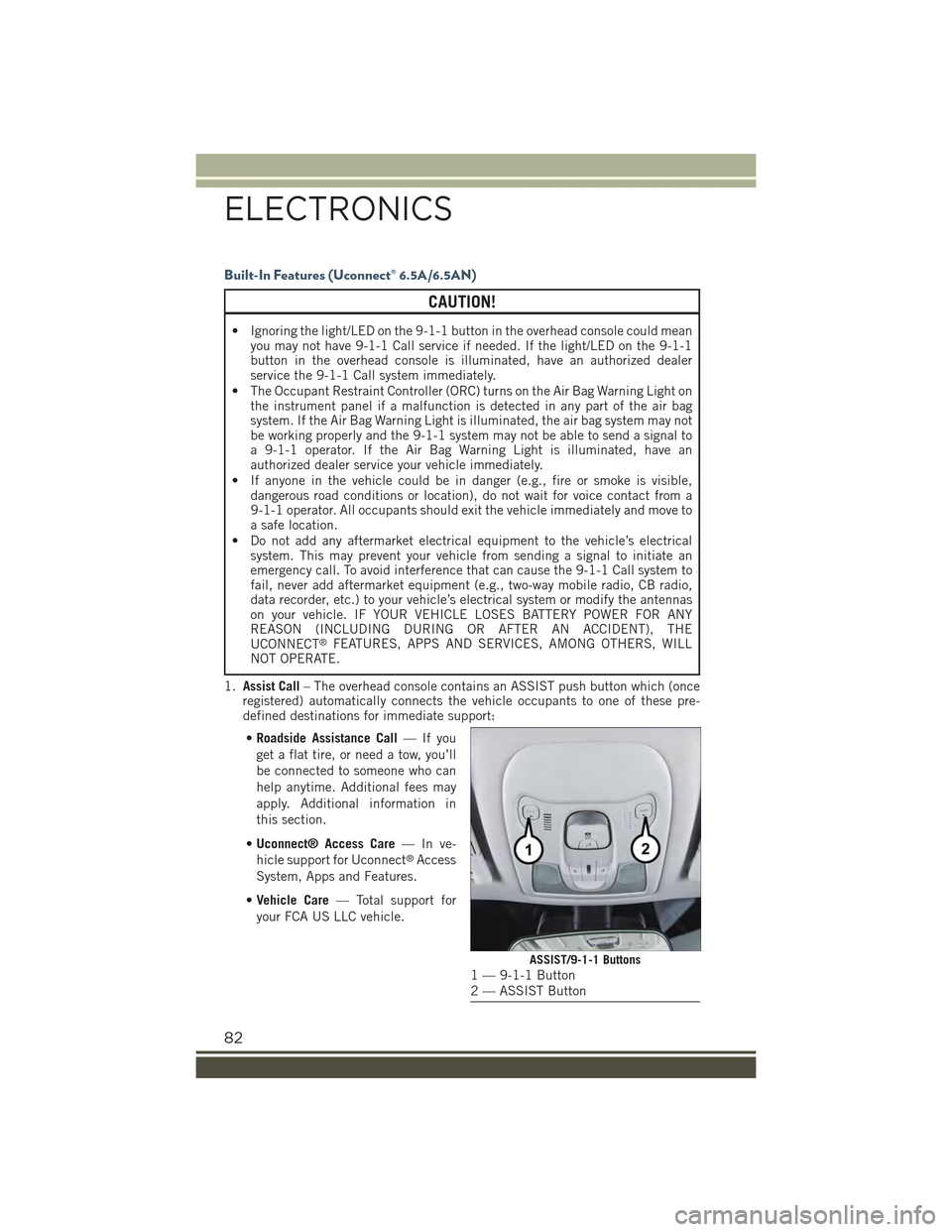

1.Assist Call– The overhead console contains an ASSIST push button which (onceregistered) automatically connects the vehicle occupants to one of these pre-defined destinations for immediate support:

•Roadside Assistance Call—Ifyou

get a flat tire, or need a tow, you’ll

be connected to someone who can

help anytime. Additional fees may

apply. Additional information in

this section.

•Uconnect® Access Care—Inve-

hicle support for Uconnect®Access

System, Apps and Features.

•Vehicle Care— Total support for

your FCA US LLC vehicle.

ASSIST/9-1-1 Buttons1 — 9-1-1 Button2 — ASSIST Button

ELECTRONICS

82

Page 155 of 220

CARGO AREA FEATURES

Cargo Load Floor

The vehicle is equipped with a load floor that can be adjusted as needed.

Position 1 (Floor Flush):

This position allows you to make the load floor flat for ease of loading/unloading

objects from the cargo area. This position also makes it possible to use the space

below as another compartment for storing fragile or smaller objects.

Position 2 (Elevated Position):

When the rear seatbacks and front passenger seat is folded flat, it will allow for

loading objects of long dimensions. It is recommended to use this position only

during the actual transporting of the objects.

Table Tilt Load

In addition to the two positions described above, the load floor can also be placed in

a tilted position (slanted toward the rear seatbacks as to ease the access to the

underlying zone of the luggage compartment (e.g. to pick up the spare tire or the Tire

Service Kit).

Place the load floor in a way that it rests at the supports 1 and 2 on the sides of the

cargo area.

The load floor provides securing of any cargo inside this position, so that the cargo

will slide in the case of sudden braking.

TRAILER TOWING

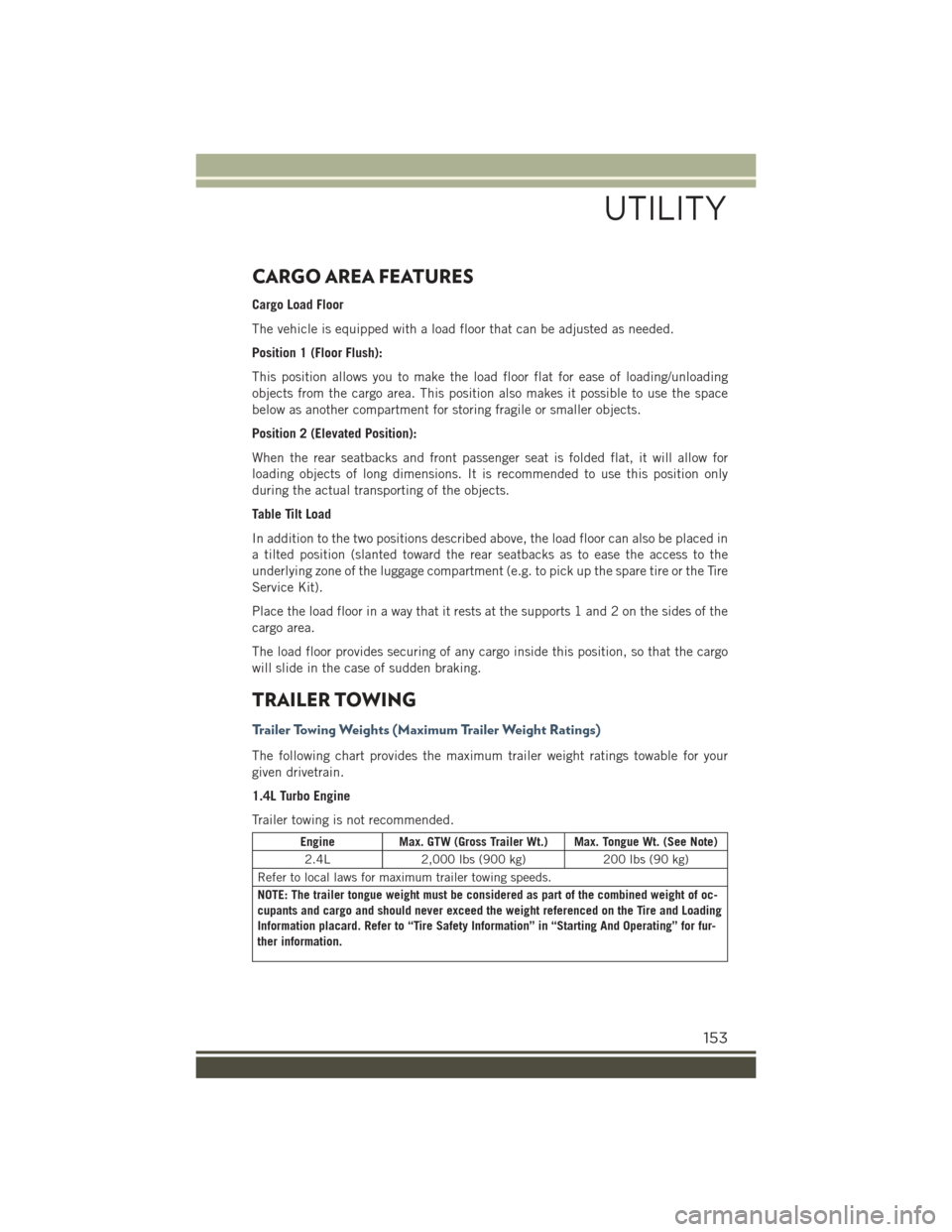

Tr a i l e r To w i n g W e i g h t s ( M a x i m u m Tr a i l e r W e i g h t R a t i n g s )

The following chart provides the maximum trailer weight ratings towable for your

given drivetrain.

1.4L Turbo Engine

Trailer towing is not recommended.

EngineMax. GTW (Gross Trailer Wt.) Max. Tongue Wt. (See Note)

2.4L2,000 lbs (900 kg)200 lbs (90 kg)

Refer to local laws for maximum trailer towing speeds.

NOTE: The trailer tongue weight must be considered as part of the combined weight of oc-cupants and cargo and should never exceed the weight referenced on the Tire and LoadingInformation placard. Refer to “Tire Safety Information” in “Starting And Operating” for fur-ther information.

UTILITY

153

Page 159 of 220

If the ABS light is on, the brake system should be serviced as soon as possible to

restore the benefits of Anti-Lock brakes. If the ABS light does not turn on when the

ignition switch is turned to the MAR/RUN position, have the light inspected by an

authorized dealer.

- Air Bag Warning Light

This light will turn on for four to eight seconds as a bulb check when the ignition

switch is first turned to the MAR/RUN position. If the light is either not on during

starting, stays on, or turns on while driving, have the system inspected at an

authorized dealer as soon as possible. Refer to “Occupant Restraints” in “Safety” in

your Owner’s Manual on the DVD for further information.

NOTE:

The Air Bag System is designed to be maintenance free.

- Electronic Throttle Control (ETC) Light

This light informs you of a problem with the Electronic Throttle Control (ETC) system.

If a problem is detected, the light will come on while the engine is running. Cycle the

ignition key when the vehicle has completely stopped and the shift lever/gear selector

is placed in the PARK position; the light should turn off.

If the light remains lit with the engine running, your vehicle will usually be drivable.

However, see an authorized service center immediately. If the light is flashing when

the engine is running, immediate service is required and you may experience reduced

performance, an elevated/rough idle or engine stall and your vehicle may require

towing.

-TirePressureMonitoringSystem(TPMS)Light

Each tire, including the spare (if provided), should be checked monthly, when cold

and inflated to the inflation pressure recommended by the vehicle manufacturer on

the vehicle placard or tire inflation pressure label. (If your vehicle has tires of a

different size than the size indicated on the vehicle placard or tire inflation pressure

label, you should determine the proper tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been equipped with a Tire Pressure

Monitoring System (TPMS) which display in the Electronic Vehicle Information

Center (EVIC) or Driver Information Display (DID) when one or more of your tires is

significantly under-inflated. Accordingly, when the low tire pressure EVIC or DID

display illuminates, you should stop and check your tires as soon as possible, and

inflate them to the proper pressure. Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to tire failure. Under-inflation also reduces

fuel efficiency and tire tread life, and may affect the vehicle’s handling and stopping

ability.

WHAT TO DO IN EMERGENCIES

157

Page 160 of 220

IF THE LIGHT STARTS FLASHING INDICATING A LOW TIRE PRESSURE, ADJUST THE AIR

PRESSURE IN THE LOW TIRE TO THE AIR PRESSURE SHOWN ON THE VEHICLE PLACARD OR

TIRE INFLATION PRESSURE LABEL LOCATED ON THE DRIVER'S DOOR.

NOTE:

After inflation, the vehicle may need to be driven for 20 minutes before the flashing light

will turn off.

Please note that the TPMS is not a substitute for proper tire maintenance, and it is

the driver’s responsibility to maintain correct tire pressure, even if under-inflation has

not reached the level to trigger illumination of the TPMS low EVIC or DID display.

Your vehicle has also been equipped with a TPMS malfunction indicator to indicate

when the system is not operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the system detects a malfunction,

the telltale will flash for approximately one minute and then remain continuously

illuminated. This sequence will continue each time the vehicle is restarted as long as

the malfunction exists.

When the malfunction indicator is illuminated, the system may not be able to detect

or signal low tire pressure as intended. TPMS malfunctions may occur for a variety of

reasons, including the installation of replacement or alternate tires or wheels on the

vehicle that prevent the TPMS from functioning properly. Always check the TPMS

malfunction telltale after replacing one or more tires or wheels on your vehicle, to

ensure that the replacement or alternate tires and wheels allow the TPMS to continue

to function properly.

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air

temperature change. Keep this in mind when checking tire pressure inside a garage,

especially in the Winter. Example: If garage temperature is 68°F (20°C) and the

outside temperature is 32°F (0°C), then the cold tire inflation pressure should be

increased by 3 psi (21 kPa), which equals 1 psi (7 kPa) for every 12°F (7°C) for this

outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your

vehicle. Undesirable system operation or sensor damage may result when using

replacement equipment that is not of the same size, type, and/or style. Aftermar-

ket wheels can cause sensor damage. Do not use tire sealant from a can, or

balance beads if your vehicle is equipped with a TPMS, as damage to the sensors

may result.

WHAT TO DO IN EMERGENCIES

158

Page 168 of 220

WARNING!

• Do not attempt to seal a tire on the side of the vehicle closest to traffic. Pull far

enough off the road to avoid the danger of being hit when using the Tire Service

Kit.

• Do not use Tire Service Kit or drive the vehicle under the following circum-

stances:

• If the puncture in the tire tread is approximately 1/4” (6 mm) or larger.

• If the tire has any sidewall damage.

• If the tire has any damage from driving with extremely low tire pressure.

• If the tire has any damage from driving on a flat tire.

• If the wheel has any damage.

• If you are unsure of the condition of the tire or the wheel.

• Keep Tire Service Kit away from open flames or heat source.

• A loose Tire Service Kit thrown forward in a collision or hard stop could

endanger the occupants of the vehicle. Always stow the Tire Service Kit in the

place provided. Failure to follow these warnings can result in injuries that are

serious or fatal to you, your passengers, and others around you.

• Take care not to allow the contents of Tire Service Kit to come in contact with

hair, eyes, or clothing. Tire Service Kit sealant is harmful if inhaled, swallowed,

or absorbed through the skin. It causes skin, eye, and respiratory irritation.

Flush immediately with plenty of water if there is any contact with eyes or skin.

Change clothing as soon as possible, if there is any contact with clothing.

• Tire Service Kit Sealant solution contains latex. In case of an allergic reaction

or rash, consult a physician immediately. Keep Tire Service Kit out of reach of

children. If swallowed, rinse mouth immediately with plenty of water and drink

plenty of water. Do not induce vomiting! Consult a physician immediately.

Insert the power plug into the vehicle power outlet socket. Start the vehicle engine.

Push the Tire Service Kit power button to the “I” position. The electric compressor

will be turned on, sealant and air will inflate the tire.

Minimum 26 psi (1.8 bar) of pressure should be reached within 20 minutes. If the

pressure has not been reached turn off and remove the Tire Service Kit, drive the

vehicle 30 feet (10 meters) back and forth, to better distribute the sealant inside the

tire.

Attach the clear flexible filling tube of the compressor directly to the tire valve and

repeat the inflation process.

When the correct pressure has been reached, start driving the vehicle to uniformly

distribute the sealant inside the tire. After 10 minutes, stop and check the tire

pressure. If the pressure is below 19 psi (1.3 bar), do not drive the vehicle, as the tire

is too damaged, contact the nearest Authorized Dealer.

WHAT TO DO IN EMERGENCIES

166

Page 169 of 220

WARNING!

Tire Service Kit is not a permanent flat tire repair. Have the tire inspected and

repaired or replaced after using Tire Service Kit. Do not exceed 65 mph

(110 km/h) until the tire is repaired or replaced. Failure to follow this warning can

result in injuries that are serious or fatal to you, your passengers, and others

around you. Have the tire checked as soon as possible at an Authorized Dealer.

If the pressure is at 19 psi (1.3 bar) or above repeat the inflation process to reach the

correct tire pressure and continue driving.

Peel off the warning label from the bottle and place it on the dashboard as a reminder

to the driver that the tire has been treated with Tire Service Kit.

WARNING!

The metal end fitting from Power Plug may get hot after use, so it should be

handled carefully.

NOTE:

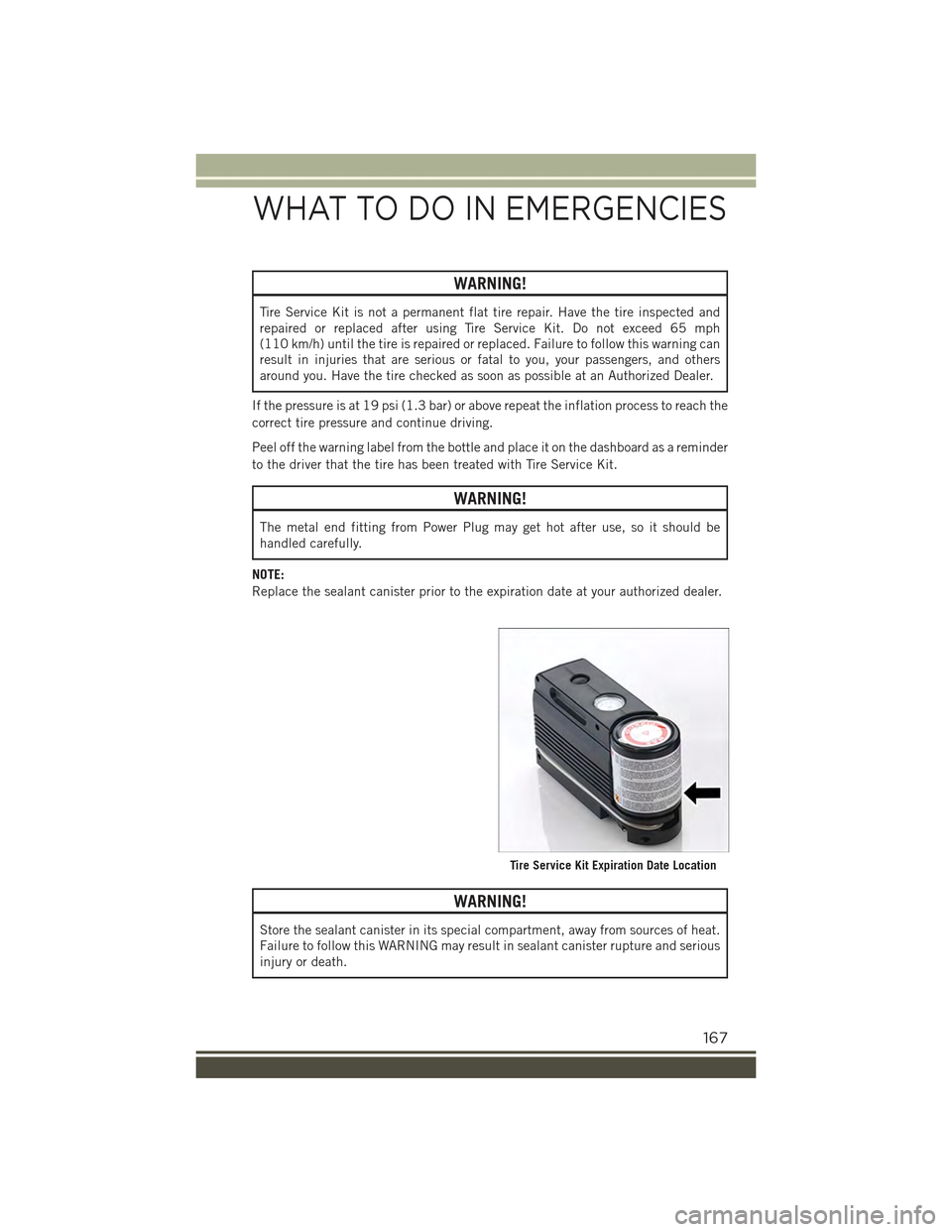

Replace the sealant canister prior to the expiration date at your authorized dealer.

WARNING!

Store the sealant canister in its special compartment, away from sources of heat.

Failure to follow this WARNING may result in sealant canister rupture and serious

injury or death.

Tire Service Kit Expiration Date Location

WHAT TO DO IN EMERGENCIES

167

Page 170 of 220

JACKING AND TIRE CHANGING

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving

traffic. Pull far enough off the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get under a raised vehicle, take

it to a service center where it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack

should not be used to lift the vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or slippery areas.

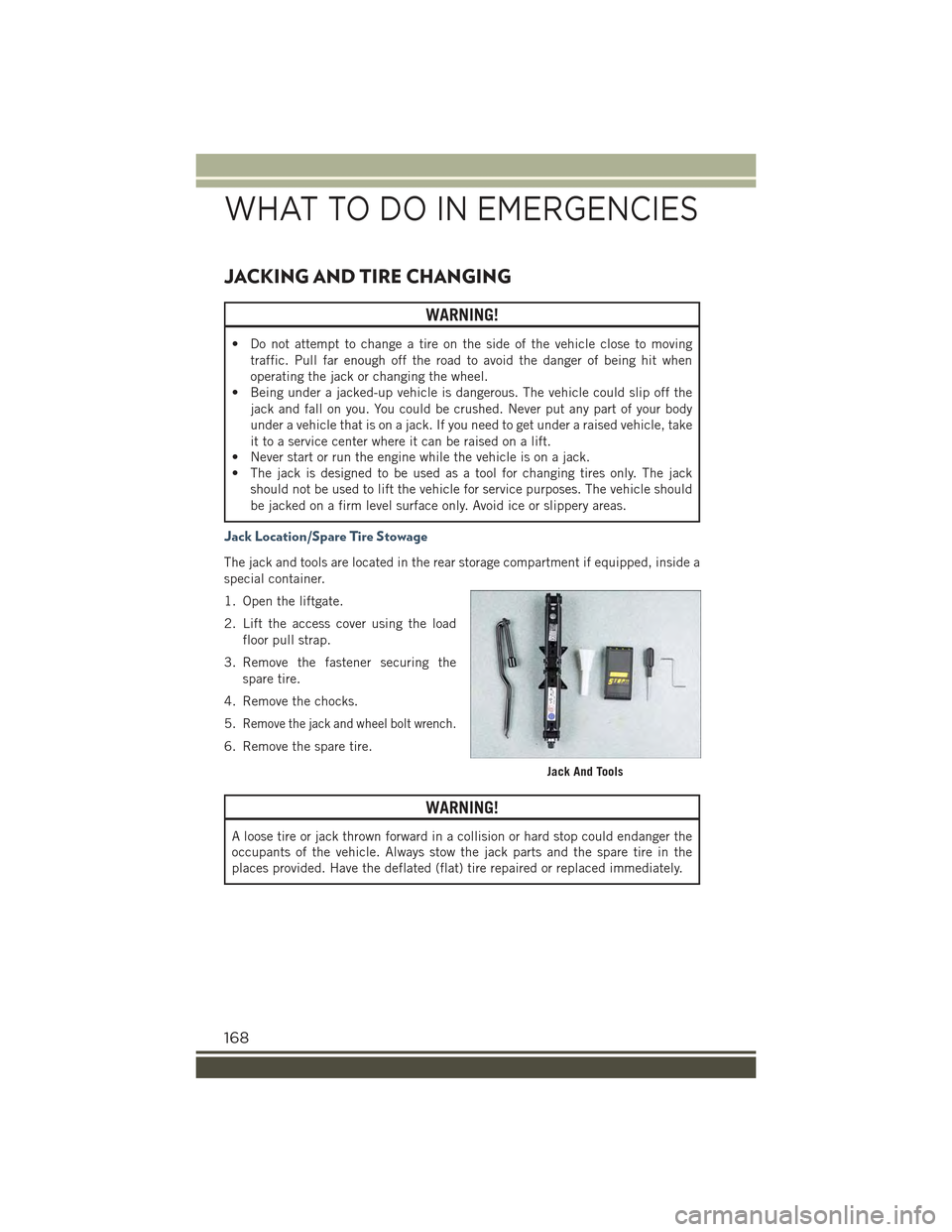

Jack Location/Spare Tire Stowage

The jack and tools are located in the rear storage compartment if equipped, inside a

special container.

1. Open the liftgate.

2. Lift the access cover using the load

floor pull strap.

3. Remove the fastener securing the

spare tire.

4. Remove the chocks.

5.Remove the jack and wheel bolt wrench.

6. Remove the spare tire.

WARNING!

A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or replaced immediately.

Jack And Tools

WHAT TO DO IN EMERGENCIES

168

Page 172 of 220

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Chock the wheel diagonally opposite the wheel to be raised.

• Apply the parking brake and place an automatic transmission in PARK.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack. If you need to get under a

raised vehicle, take it to a service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for lifting this vehicle during

a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on locations other than those

indicated in the Jacking Instructions for this vehicle.

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with wheels where the center cap covers the wheel bolts, use the

wheel bolt wrench to pry the center cap off carefully before raising the vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove,

the wheel bolts on the wheel with the flat tire. Turn the wheel bolts counterclock-

wise one turn while the wheel is still on the ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack

screw clockwise to firmly engage the jack saddle with the lift area of the sill

flange, centering the jack saddle inside the cutout in the sill cladding.

Jack Warning Label

WHAT TO DO IN EMERGENCIES

170

Page 173 of 220

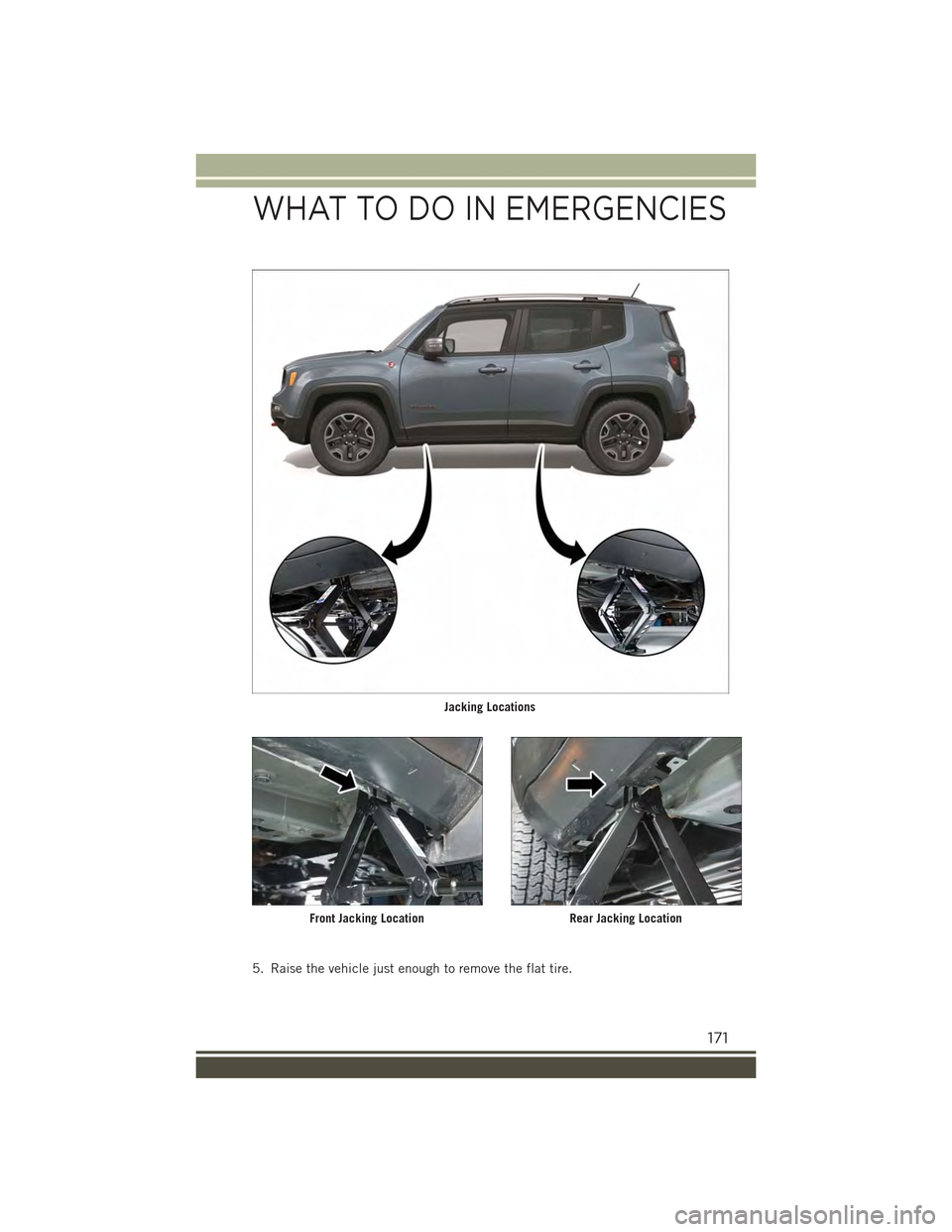

5. Raise the vehicle just enough to remove the flat tire.

Jacking Locations

Front Jacking LocationRear Jacking Location

WHAT TO DO IN EMERGENCIES

171

Page 175 of 220

9. Lower the vehicle to the ground by turning the jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. The correct torque specification for

the wheel bolts is 63 Ft-Lbs (86 Nm) for steel wheels and 89 Ft-Lbs (120 Nm)

for aluminum wheels. If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized dealer or at a service station.

11. Securely stow the jack, tools, chocks and flat tire.

WARNING!

A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or replaced immediately.

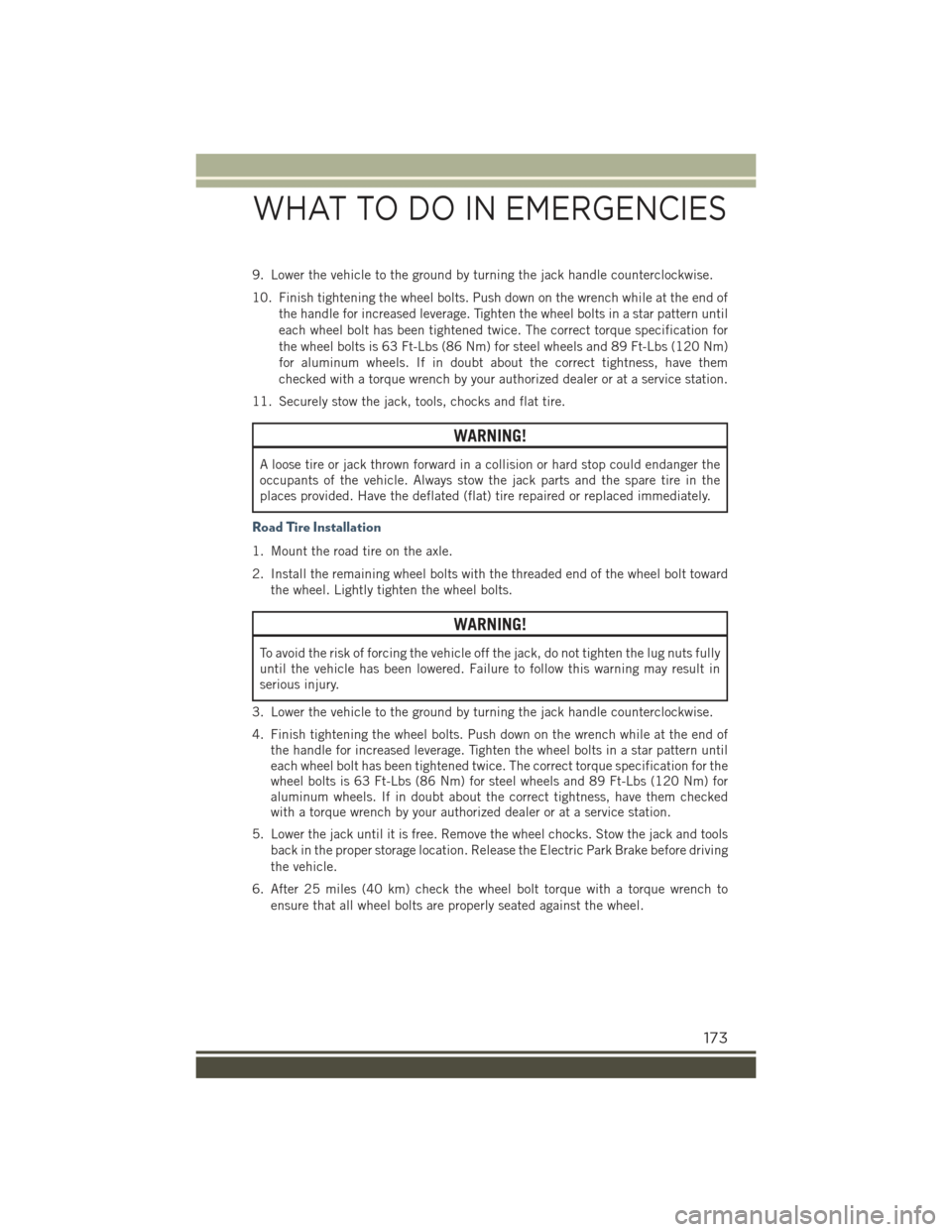

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded end of the wheel bolt toward

the wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end ofthe handle for increased leverage. Tighten the wheel bolts in a star pattern untileach wheel bolt has been tightened twice. The correct torque specification for thewheel bolts is 63 Ft-Lbs (86 Nm) for steel wheels and 89 Ft-Lbs (120 Nm) foraluminum wheels. If in doubt about the correct tightness, have them checkedwith a torque wrench by your authorized dealer or at a service station.

5. Lower the jack until it is free. Remove the wheel chocks. Stow the jack and tools

back in the proper storage location. Release the Electric Park Brake before driving

the vehicle.

6. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to

ensure that all wheel bolts are properly seated against the wheel.

WHAT TO DO IN EMERGENCIES

173