check engine light JEEP WRANGLER 2004 TJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2004, Model line: WRANGLER, Model: JEEP WRANGLER 2004 TJ / 2.GPages: 299, PDF Size: 6.82 MB

Page 12 of 299

Key-In-Ignition Reminder

Opening the driver's door when the key is in the ignition,

sounds a signal to remind you to remove the key.

CAUTION!

Always remove the key from the ignition, and lock

all doors when leaving the vehicle unattended.

SENTRY KEY IMMOBILIZER SYSTEM Ð IF

EQUIPPED

The Sentry Key Immobilizer System (SKIS) prevents

unauthorized operation of the vehicle by disabling the

engine. The system will shut the engine down after 2

seconds of running if an invalid key is used to start the

vehicle. This system utilizes ignition keys which have an

electronic chip (transponder) embedded into them. Only

keys that have been programmed to the vehicle can be

used to start and operate the vehicle for longer than the

2 second validation time period.

The Sentry Key Immobilizer System does not need to be

armed or activated. Operation of the system is automaticregardless of whether or not the vehicle is locked or

unlocked. During normal operation, the SKIS indicator

light will come on for 3 seconds immediately after the

ignition switch is turned on for a bulb check. Afterwards,

if the bulb remains on, this indicates a malfunction in the

electronics. If the bulb begins to flash immediately after

the ignition switch is turned on, this indicates that an

invalid key is being used to start the vehicle. Both of

these conditions will result in the engine being shut

down after 2 seconds of running. Keep in mind that a key

which has not been programmed is also considered an

invalid key even if it is cut to fit the ignition for that

vehicle.

If the SKIS indicator light comes on during normal

vehicle operation (it has been running for longer than 10

seconds) a fault has been detected in the electronics and

the vehicle should be serviced as soon as possible.

NOTE:

²

The Sentry Key Immobilizer System is not compatible

with remote starting systems. Use of these systems

may result in vehicle starting problems and loss of

security protection.

12 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 58 of 299

Front Fog Lights Ð If Equipped

The front fog light switch is in the multi-function

control lever. To activate the front fog lights, turn

on the parking or low beam headlights and pull

out the end of the lever.

NOTE:The fog lights will only operate with the park-

ing lights or the headlights on low beam. Selecting high

beam headlights will turn off the fog lights.

Turn Signals

Move the multi-function control lever up or down and

the arrows on each side of the instrument cluster flash to

show proper operation of the front and rear turn signal

lights. You can signal a lane change by moving the lever

partially up or down without moving beyond the detent.

If either light remains on and does not flash, or there is a

very fast flash rate, check for a defective outside light

bulb. If an indicator fails to light when the lever is

moved, it would suggest that the fuse or indicator bulb is

defective.

NOTE:A tone will chime if the turn signals are left on

for more than 1 mile (2 km).

Daytime Running Lights Ð Canada Only

The headlights come on at a low intensity level after the

vehicle has been driven approximately 3 feet (1 meter).

They will turn off when the vehicle is turned off or when

the headlights are switched on.

WINDSHIELD WIPERS AND WASHERS

CAUTION!

In cold weather, always turn off the wiper switch

and allow the wipers to return to the park position

before turning off the engine. If the wiper switch is

left on and the wipers freeze to the windshield,

damage to the wiper motor may occur when the

vehicle is restarted.

Intermittent Wiper System

Use the intermittent wiper when weather conditions

make a single wiping cycle, with a variable pause be-

tween cycles, desirable. Move the lever to the DELAY

position, then select the delay interval by turning the end

58 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 118 of 299

15. Coolant Temperature Gauge

Indicates engine coolant temperature. The red

zone to the far right indicates possible overheat-

ing. Seek authorized service immediately if the

gauge operates in the red zone. In U.S. vehicles,

temperature is indicated in degrees fahrenheit; in

Canadian vehicles in degrees centigrade.

16. Airbag Warning Light

This indicator lights and remains lit for 6 to

8 seconds when the ignition is first turned

on. If the light does not come on for 6 to 8

seconds, stays on or comes on while driving,

have the airbag system checked by an authorized

dealer.

17. Check Gauges Warning Light

This light monitors the engine coolant tem-

perature, engine oil pressure, and voltage

gauges. If it detects an extreme condition a

chime will sound and the light will come on. If the

light comes on, check the operation of these gauges for

a malfunction condition.18. Malfunction Indicator Light

This light is a part of an Onboard Diagnostic

System called OBD II that monitors engine,

and automatic transmission control systems.

The light will illuminate when the ignition is in the

ON position before engine start. If the bulb does not

come on when turning the key from OFF to ON, have

the condition checked promptly.

Certain conditions such as a loose or missing gas cap,

poor quality fuel, etc. may illuminate the light after

engine start. The vehicle should be serviced if the light

stays on through several typical driving styles. In most

situations, the vehicle will drive normally and will not

require towing.

When the engine is running, the ªMalfunction Indicator

Lightº may flash to alert serious conditions that could

lead to immediate loss of power or severe catalytic

converter damage. The vehicle should be serviced as

soon as possible if this occurs.

118 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 120 of 299

If the parking brake is applied and the vehicle is in

motion, the red BRAKE warning light will ªflashº and a

chime will sound.

The operation of the BRAKE warning light can be

checked by turning the ignition switch from the OFF

position to the ON position. The light should illuminate

for approximately two seconds. The light should then

turn off unless the parking brake is applied or a brake

fault is detected. If the light does not illuminate, have the

light inspected by an authorized dealer.

23. Low Fuel Warning Light

When the fuel level reaches approximately 2 U.S.

Gallons (7.6L) this light will come on and remain

on until fuel is added. The ªLow Fuel Warning

Lightº may turn on and off again, especially during

and after hard braking, accelerations, or turns. This

occurs due to the shifting of the fuel in the tank.

24. Fuel Cap Indicator

This symbol indicates the side of the vehicle

where the fuel cap is located.25. Fuel Gauge

The pointer shows the level of fuel in the fuel tank. When

the fuel gauge pointer initially moves to E, for your

safety, approximately 2 U.S. Gallons (7.6L) of fuel remain.

NOTE:When the ignition switch is turned to OFF, the

fuel gauge, voltmeter, oil pressure and temperature

gauges may not show accurate readings. When the

engine is not running, turn the ignition switch to ON to

obtain accurate readings.

ELECTRONIC DIGITAL CLOCK

The clock and radio each use the display panel built into

the radio. A digital readout shows the time in hours and

minutes whenever the ignition switch is in the ON or

ACC position and the time button is pressed.

When the ignition switch is in the OFF position, or when

the radio frequency is being displayed, time keeping is

accurately maintained.

120 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 179 of 299

WARNING!

To help avoid personal injury, follow these tips:

²Never reach through the steering wheel to operate

steering column controls. Injury to your hands or

loss of vehicle control may result.

²If the engine stalls or power assist fails due to a

malfunction, vehicle steering and braking will

require greater effort.

ANTI-LOCK BRAKE SYSTEM Ð IF EQUIPPED

The Anti-Lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lock-up and help avoid skidding on slippery surfaces.

All vehicle wheels and tires must be the same size and

type and tires must be properly inflated to produce

accurate signals for the computer.

WARNING!

Significant over or under-inflation of tires, or mixing

sizes of tires or wheels on the vehicle can lead to loss

of braking effectiveness.

The Anti-Lock Brake System conducts a low speed self-

test at about 12 mph (20 km/h). If for any reason, your

foot is on the brake when the vehicle reaches 12 mph (20

km/h), this check will be delayed until 25 mph (40

km/h).

The Anti-Lock Brake System pump motor runs during

the self-test and during an ABS stop to provide the

regulated hydraulic pressure. The motor pump makes a

low humming noise during operation, this is normal.

During off-road use, loss of traction can temporarily

defeat the system and cause the warning light to illumi-

nate. Turn the ignition OFF and ON again to restore

Anti-Lock Brake System function.

STARTING AND OPERATING 179

5

Page 238 of 299

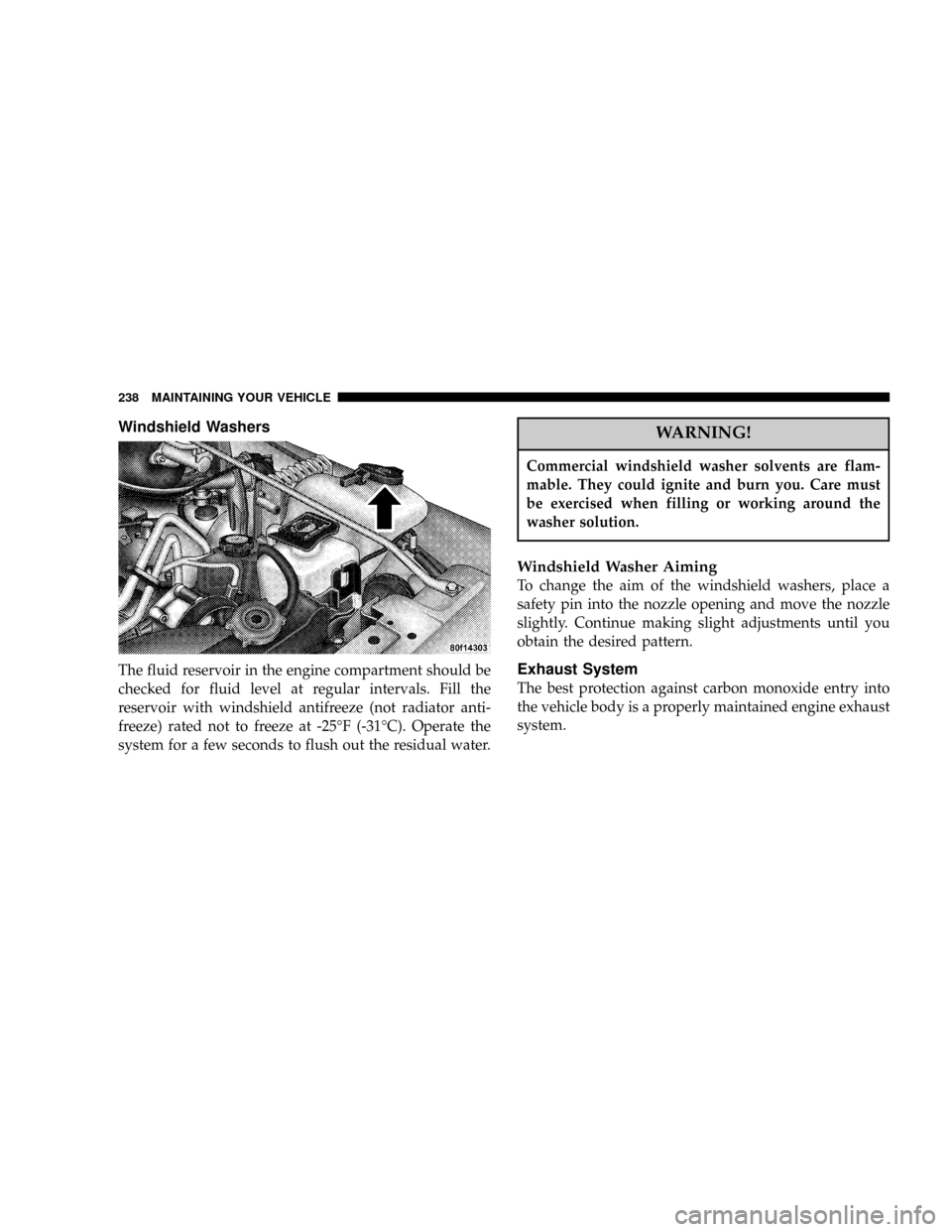

Windshield Washers

The fluid reservoir in the engine compartment should be

checked for fluid level at regular intervals. Fill the

reservoir with windshield antifreeze (not radiator anti-

freeze) rated not to freeze at -25ÉF (-31ÉC). Operate the

system for a few seconds to flush out the residual water.

WARNING!

Commercial windshield washer solvents are flam-

mable. They could ignite and burn you. Care must

be exercised when filling or working around the

washer solution.

Windshield Washer Aiming

To change the aim of the windshield washers, place a

safety pin into the nozzle opening and move the nozzle

slightly. Continue making slight adjustments until you

obtain the desired pattern.

Exhaust System

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

238 MAINTAINING YOUR VEHICLE

Page 244 of 299

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

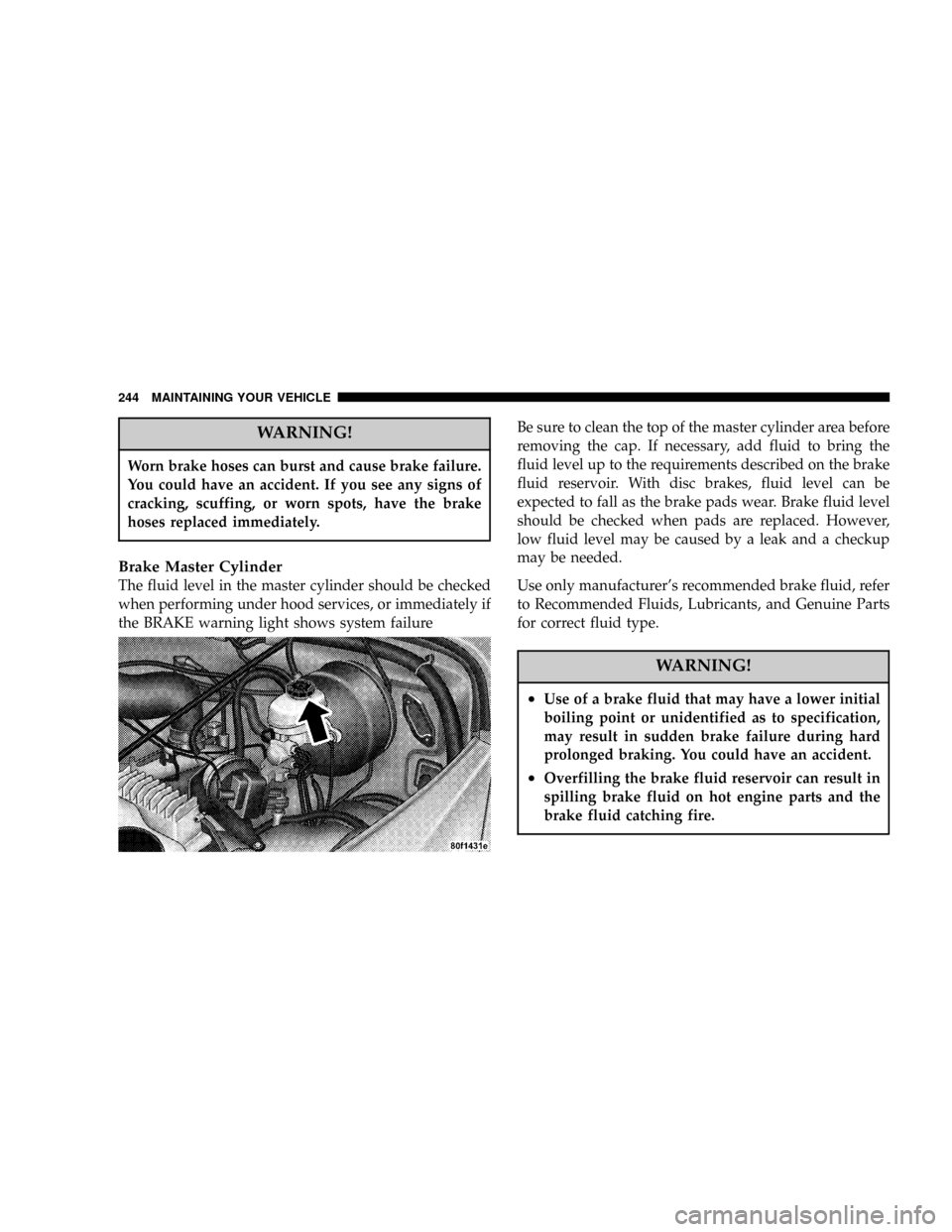

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the BRAKE warning light shows system failureBe sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. Brake fluid level

should be checked when pads are replaced. However,

low fluid level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended brake fluid, refer

to Recommended Fluids, Lubricants, and Genuine Parts

for correct fluid type.

WARNING!

²Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification,

may result in sudden brake failure during hard

prolonged braking. You could have an accident.

²Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

244 MAINTAINING YOUR VEHICLE

Page 263 of 299

NOTE:Most vehicles are operated under the conditions

listed for Schedule ªB.º

Second is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under Sched-

ule ªB.º

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent, add as required.

Once a Month

²

Check the tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of the coolant reservoir, brake

master cylinder, and transmission, and add as needed.

²Check all lights and all other electrical items for correct

operation.

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect brake hoses.

²Check the coolant level, hoses, and clamps.

²Inspect manual transmission fluid level Ð if

equipped.

MAINTENANCE SCHEDULES 263

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 288 of 299

About Your Brakes...................... 177

Add-A-Trunk........................... 65

Adding Washer Fluid.................... 155

Air Cleaner, Engine..................... 234

Air Conditioner Maintenance.............. 235

Air Conditioning....................... 151

Air Conditioning Controls................ 152

Air Conditioning, Operating Tips........... 154

Air Conditioning Refrigerant.............. 236

Air Filter............................. 234

Air Pressure, Tires...................... 192

Airbag................................ 22

Airbag Deployment...................... 27

Airbag Light........................29,118

Airbag Maintenance...................... 29

Airbag On/Off Switch.................... 26

Alignment and Balance.................. 195

Alterations/Modifications, Vehicle............ 8

Antenna, Satellite Radio.................. 147

Antifreeze (Engine Coolant)............... 258

Anti-Lock Brake System.................. 179

Anti-Lock Warning Light................. 119

Appearance Care....................... 248Ashtray............................... 62

Ashtrays and Lighter..................... 62

Automatic Dimming Mirror................ 46

Automatic Transmission...............165,245

Adding Fluid........................ 246

Fluid and Filter Changes................ 245

Fluid Level Check..................... 245

Fluid Type.......................... 245

Gear Ranges......................... 166

Shifting............................ 165

Special Additives..................... 246

Torque Converter..................... 170

Auxiliary Electrical Outlet................. 63

Auxiliary Power Outlet................... 63

Battery............................... 234

Emergency Starting.................... 216

Voltmeter........................... 116

Belts, Drive........................... 231

Belts, Seat............................. 17

Body Mechanism Lubrication.............. 237

Brake System.......................... 243

Anti-Lock........................... 179

288 INDEX

Page 289 of 299

Hoses.............................. 243

Master Cylinder...................... 244

Parking............................ 175

Warning Light....................... 119

Brakes............................... 177

Brake/Transmission Interlock.............. 166

Break-In Recommendations, New Vehicle...... 39

Bulb Replacement...................... 257

Calibration, Compass..................... 47

Capacities, Fluid....................... 258

Caps, Filler

Fuel............................... 200

Power Steering....................... 236

Car Washes........................... 249

Carpeting............................. 252

Cassette Tape and Player Maintenance....... 148

Cassette Tape Player.........126,130,132,140,142

Catalytic Converter..................... 232

Caution, Exhaust Gas..................... 40

CD Changer........................133,138

CD Player......................128,135,137

CD Player Maintenance.................. 149Cellular Phone......................... 149

Chains, Tire........................... 196

Changing A Flat Tire.................... 213

Chart, Tire Sizing....................... 185

Check Engine Light..................... 118

Child Restraint.....................29,33,36

Child Restraint Tether Anchors............. 33

Cigar Lighter........................... 62

Climate Control........................ 149

Clock................................ 120

Clutch Interlocking Ignition System......160,165

Compact Disc Maintenance............... 149

Compact Disc Player.................... 140

Compass.............................. 46

Compass Calibration..................... 47

Compass Variance....................... 48

Console............................... 65

Console, Floor.......................... 65

Contract, Service....................... 282

Converter, Catalytic..................... 232

Cooling System........................ 239

Adding Coolant (Antifreeze)............. 241

Coolant Capacity..................... 258

INDEX 289

10