brake JEEP WRANGLER 2014 JK / 3.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2014, Model line: WRANGLER, Model: JEEP WRANGLER 2014 JK / 3.GPages: 148, PDF Size: 12.93 MB

Page 113 of 148

JUMP-STARTING

• If your vehicle has a discharged bat-tery it can be jump-started using a set

of jumper cables and a battery in an-

other vehicle or by using a portable

battery booster pack.

• Jump-starting can be dangerous if done improperly so please follow the

procedures in this section carefully.

NOTE:

When using a portable battery booster

pack follow the manufacturer’s operating

instructions and precautions.

Preparations For Jump-Start

• The battery in your vehicle is located in the right rear of the engine compartment.

1. Set the parking brake, shift the automatic transmission into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electrical accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

Jump-Starting Procedure

1. Connect the positive (+)end of the jumper cable to the positive (+)post of the

vehicle with the discharged battery.

2. Connect the opposite end of the positive (+)jumper cable to the positive (+)post

of the booster battery.

3. Connect the negative (-)end of the jumper cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged vehicle’s engine) away from the battery and

the fuel injection system.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

WHAT TO DO IN EMERGENCIES

111

Page 116 of 148

SHIFT LEVER OVERRIDE

If a malfunction occurs and the shift lever

cannot be moved out of the PARK position,

you can use the following procedure to

temporarily move the shift lever:

1. To access the shift lever override, re-move the override cover located on

the shift lever bezel, next to the shift

lever.

2. Firmly set the parking brake.

3. Turn the ignition switch to the ACC or ON position without starting the en-

gine.

4. Press and maintain firm pressure on the brake pedal.

5. Using a screwdriver or similar tool, press and hold the override tab through the access port on the center console.

6. Move the shift lever into the NEUTRAL position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the override cover.

TOWING A DISABLED VEHICLE

• The manufacturer requires towing your vehicle with all four wheels OFFthe ground

using a flatbed.

CAUTION!

Towing this vehicle using any other method could result in extensive damage to the

transfer case and/or transmission.

WHAT TO DO IN EMERGENCIES

114

Page 118 of 148

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an Event Data Recorder (EDR). The main purpose of an

EDR is to record, in certain crash or near crash-like situations, such as an air bag

deployment or hitting a road obstacle, data that will assist in understanding how a

vehicle’s systems performed. The EDR is designed to record data related to vehicle

dynamics and safety systems for a short period of time, typically 30 seconds or less.

The EDR in this vehicle is designed to record such data as:

• How various systems in your vehicle were operating.

• Whether or not the driver and passenger safety belts were buckled/fastened.

• How far (if at all) the driver was depressing the accelerator and/or brake pedal.

• How fast the vehicle was traveling.

These data can help provide a better understanding of the circumstances in which

crashes and injuries occur.

NOTE:

EDR data is recorded by your vehicle only if a non-trivial crash situation occurs; no

data is recorded by the EDR under normal driving conditions and no personal data

(e.g. name, gender, age, and crash location) is recorded. However, other parties, such

as law enforcement, could combine the EDR data with the type of personally

identifying data routinely acquired during a crash investigation.

To read data recorded by an EDR, special equipment is required, and access to the

vehicle or the EDR is needed. In addition to the vehicle manufacturer, other parties

such as law enforcement, that have the special equipment, can read the information

if they have access to the vehicle or the EDR.

WHAT TO DO IN EMERGENCIES

116

Page 122 of 148

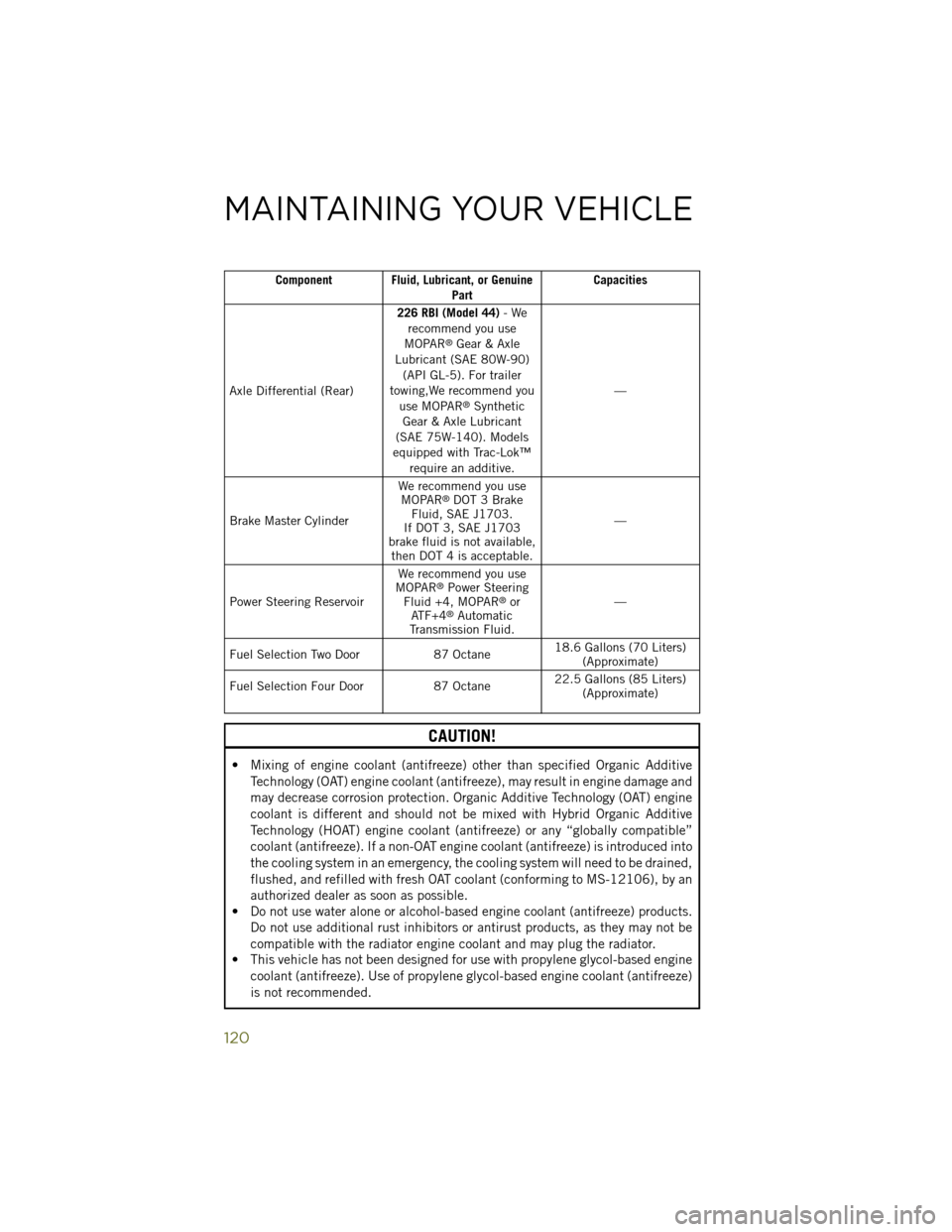

Component Fluid, Lubricant, or GenuinePartCapacities

Axle Differential (Rear) 226 RBI (Model 44)

-We

recommend you use

MOPAR

®Gear & Axle

Lubricant (SAE 80W-90) (API GL-5). For trailer

towing,We recommend you use MOPAR

®Synthetic

Gear & Axle Lubricant

(SAE 75W-140). Models

equipped with Trac-Lok™ require an additive. —

Brake Master Cylinder We recommend you use

MOPAR

®DOT 3 Brake

Fluid, SAE J1703.

If DOT 3, SAE J1703

brake fluid is not available, then DOT 4 is acceptable. —

Power Steering Reservoir We recommend you use

MOPAR

®Power Steering

Fluid +4, MOPAR®or

ATF+4®Automatic

Transmission Fluid. —

Fuel Selection Two Door 87 Octane 18.6 Gallons (70 Liters)

(Approximate)

Fuel Selection Four Door 87 Octane22.5 Gallons (85 Liters)

(Approximate)

CAUTION!

• Mixing of engine coolant (antifreeze) other than specified Organic Additive

Technology (OAT) engine coolant (antifreeze), may result in engine damage and

may decrease corrosion protection. Organic Additive Technology (OAT) engine

coolant is different and should not be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (antifreeze) or any “globally compatible”

coolant (antifreeze). If a non-OAT engine coolant (antifreeze) is introduced into

the cooling system in an emergency, the cooling system will need to be drained,

flushed, and refilled with fresh OAT coolant (conforming to MS-12106), by an

authorized dealer as soon as possible.

• Do not use water alone or alcohol-based engine coolant (antifreeze) products.

Do not use additional rust inhibitors or antirust products, as they may not be

compatible with the radiator engine coolant and may plug the radiator.

• This vehicle has not been designed for use with propylene glycol-based engine

coolant (antifreeze). Use of propylene glycol-based engine coolant (antifreeze)

is not recommended.

MAINTAINING YOUR VEHICLE

120

Page 124 of 148

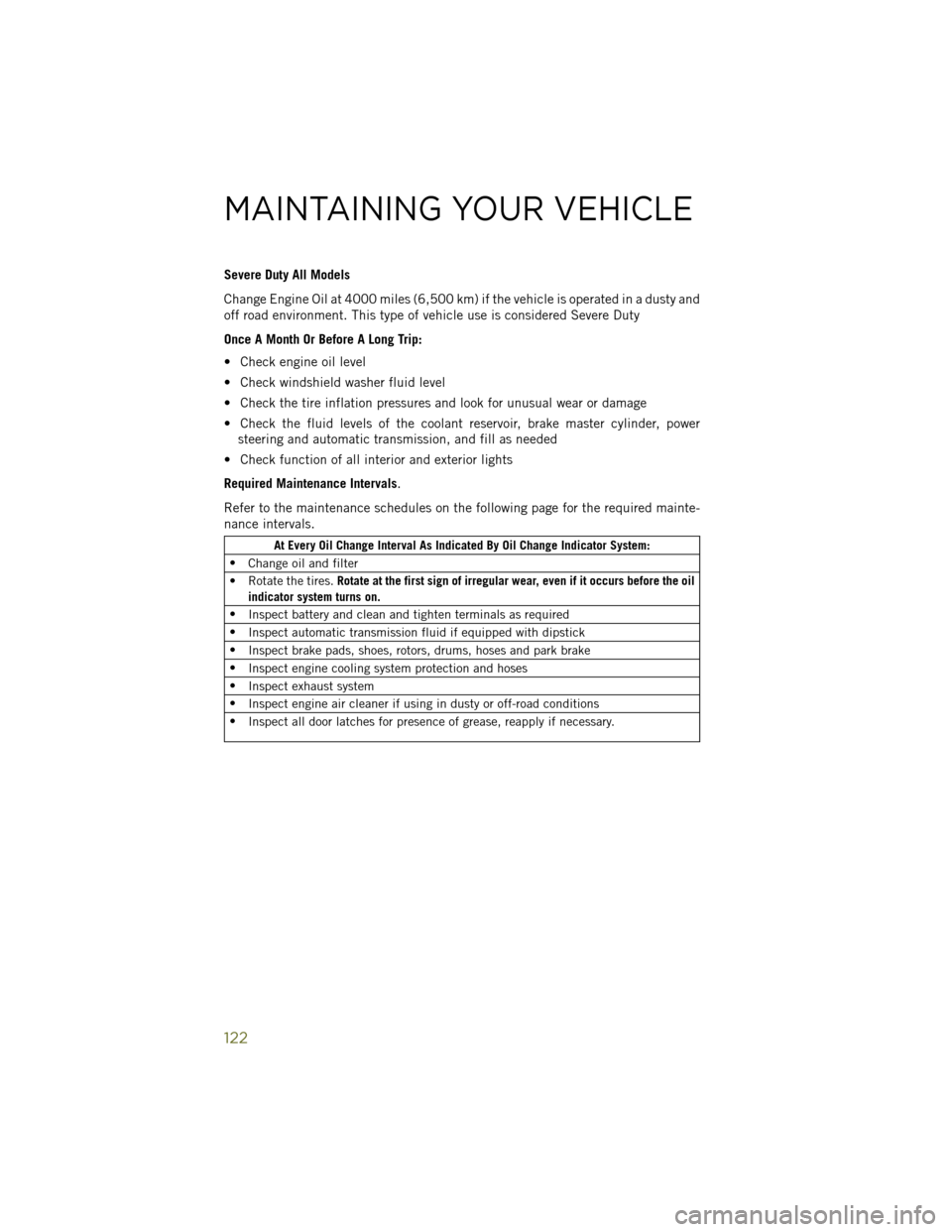

Severe Duty All Models

Change Engine Oil at 4000 miles (6,500 km) if the vehicle is operated in a dusty and

off road environment. This type of vehicle use is considered Severe Duty

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual wear or damage

• Check the fluid levels of the coolant reservoir, brake master cylinder, powersteering and automatic transmission, and fill as needed

• Check function of all interior and exterior lights

Required Maintenance Intervals.

Refer to the maintenance schedules on the following page for the required mainte-

nance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Change oil and filter

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten terminals as required

• Inspect automatic transmission fluid if equipped with dipstick

• Inspect brake pads, shoes, rotors, drums, hoses and park brake

• Inspect engine cooling system protection and hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or off-road conditions

• Inspect all door latches for presence of grease, reapply if necessary.

MAINTAINING YOUR VEHICLE

122

Page 125 of 148

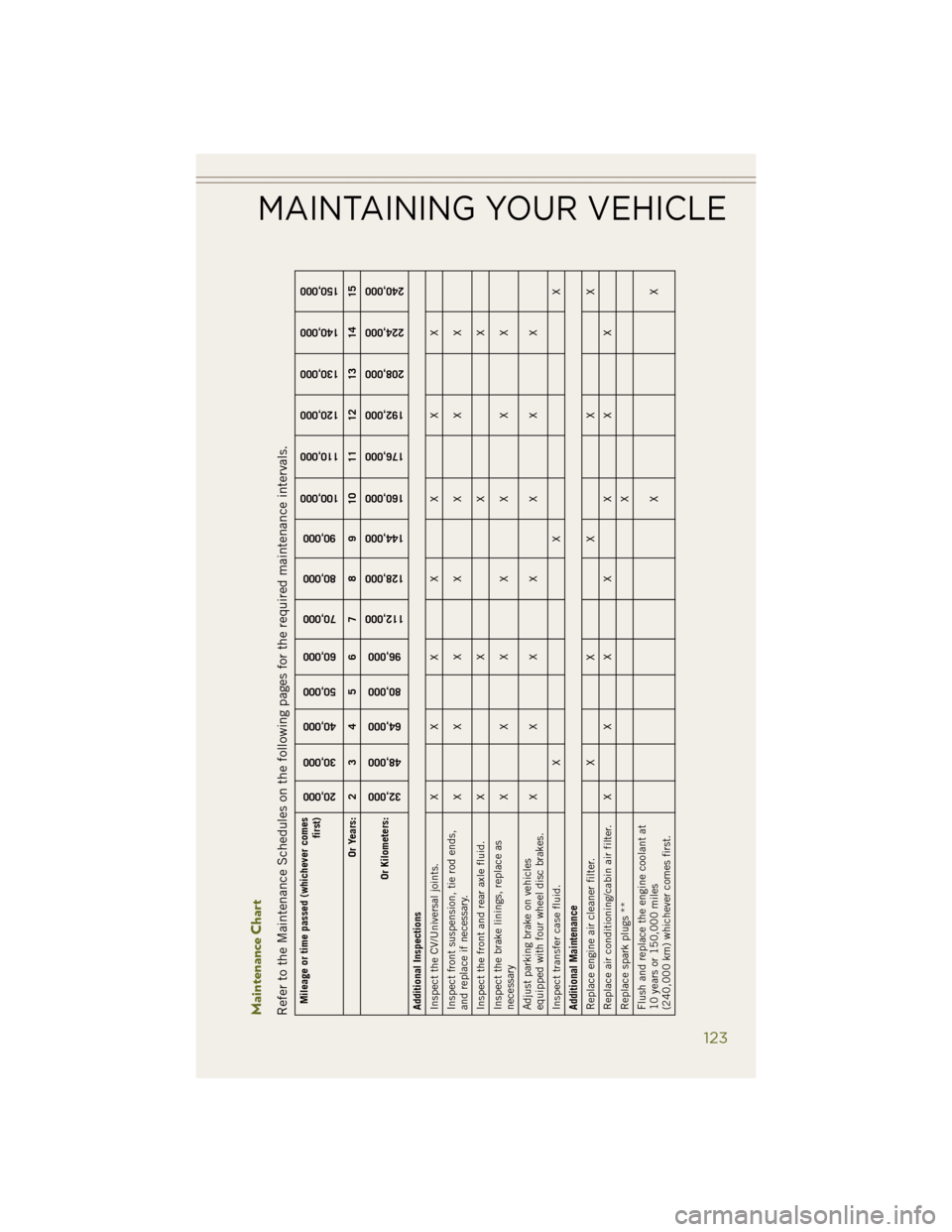

Maintenance ChartRefer to the Maintenance Schedules on the following pages for the required maintenance intervals.Mileage or time passed (whichever comesfirst)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X

Inspect front suspension, tie rod ends,

and replace if necessary. XXX X X X X

Inspect the front and rear axle fluid. X X X X

Inspect the brake linings, replace as

necessary XXX X X X X

Adjust parking brake on vehicles

equipped with four wheel disc brakes. XXX X X X X

Inspect transfer case fluid. X X X

Additional Maintenance

Replace engine air cleaner filter. X X X X X

Replace air conditioning/cabin air filter. X X X X X X X

Replace spark plugs ** X

Flush and replace the engine coolant at

10 years or 150,000 miles

(240,000 km) whichever comes first. XX

MAINTAINING YOUR VEHICLE

123

Page 129 of 148

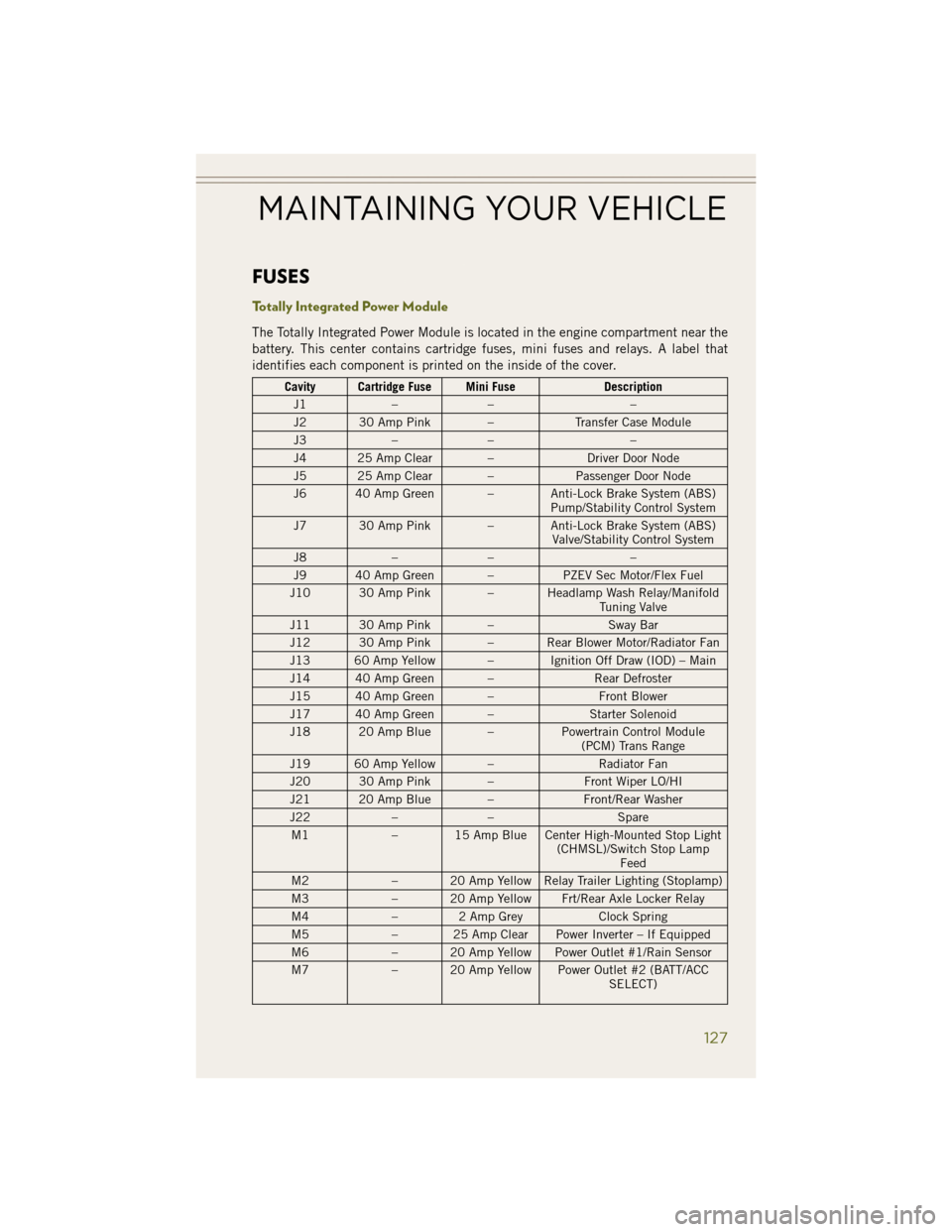

FUSES

Totally Integrated Power Module

The Totally Integrated Power Module is located in the engine compartment near the

battery. This center contains cartridge fuses, mini fuses and relays. A label that

identifies each component is printed on the inside of the cover.

Cavity Cartridge Fuse Mini FuseDescription

J1 –– –

J2 30 Amp Pink – Transfer Case Module

J3 –– –

J4 25 Amp Clear – Driver Door Node

J5 25 Amp Clear – Passenger Door Node

J6 40 Amp Green – Anti-Lock Brake System (ABS) Pump/Stability Control System

J7 30 Amp Pink – Anti-Lock Brake System (ABS) Valve/Stability Control System

J8 –– –

J9 40 Amp Green – PZEV Sec Motor/Flex Fuel

J10 30 Amp Pink – Headlamp Wash Relay/Manifold Tuning Valve

J11 30 Amp Pink – Sway Bar

J12 30 Amp Pink – Rear Blower Motor/Radiator Fan

J13 60 Amp Yellow – Ignition Off Draw (IOD) – Main

J14 40 Amp Green – Rear Defroster

J15 40 Amp Green – Front Blower

J17 40 Amp Green – Starter Solenoid

J18 20 Amp Blue – Powertrain Control Module

(PCM) Trans Range

J19 60 Amp Yellow – Radiator Fan

J20 30 Amp Pink – Front Wiper LO/HI

J21 20 Amp Blue – Front/Rear Washer

J22 –– Spare

M1 – 15 Amp Blue Center High-Mounted Stop Light

(CHMSL)/Switch Stop LampFeed

M2 – 20 Amp Yellow Relay Trailer Lighting (Stoplamp)

M3 – 20 Amp Yellow Frt/Rear Axle Locker Relay

M4 – 2 Amp Grey Clock Spring

M5 – 25 Amp Clear Power Inverter – If Equipped

M6 – 20 Amp Yellow Power Outlet #1/Rain Sensor

M7 – 20 Amp Yellow Power Outlet #2 (BATT/ACC

SELECT)

MAINTAINING YOUR VEHICLE

127

Page 131 of 148

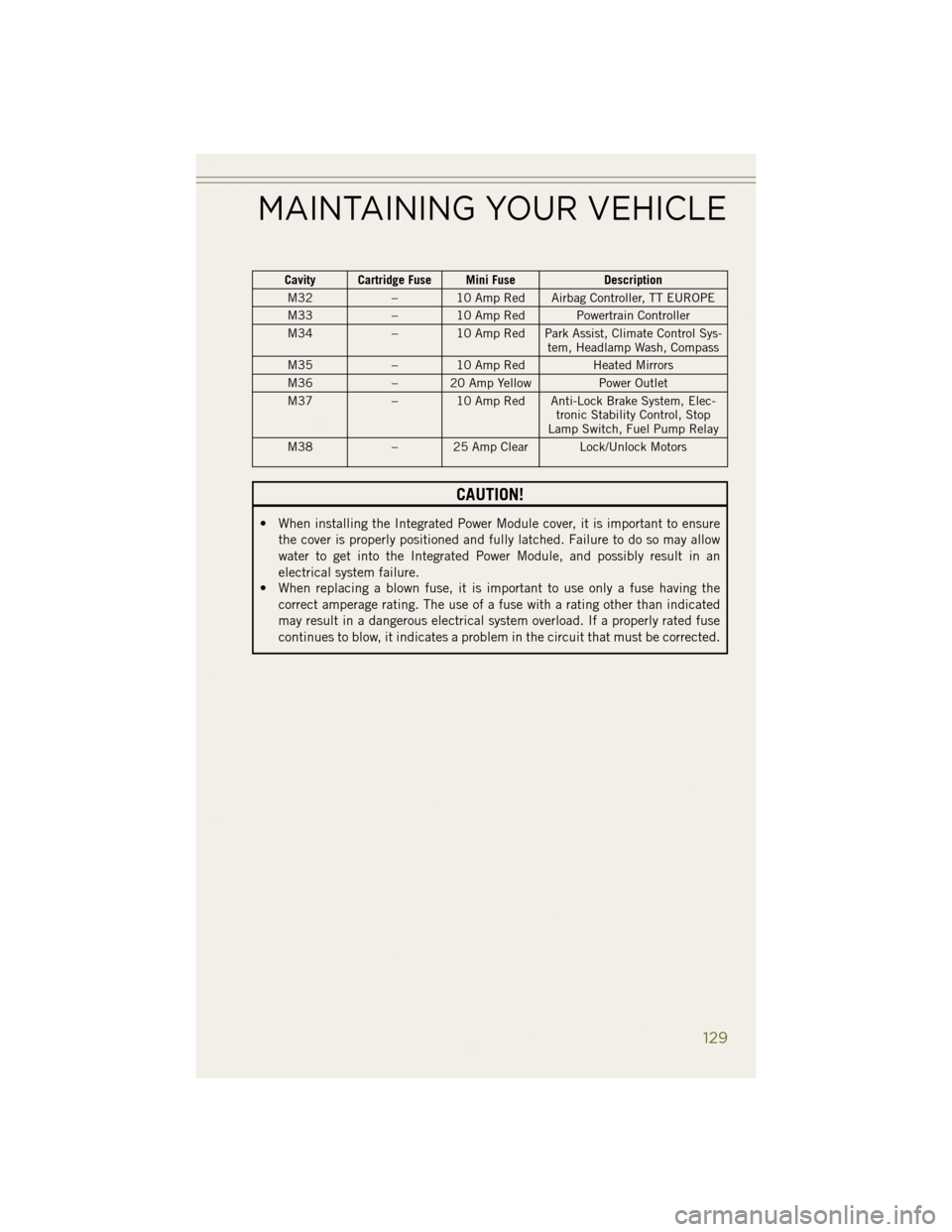

Cavity Cartridge Fuse Mini FuseDescription

M32 – 10 Amp Red Airbag Controller, TT EUROPE

M33 – 10 Amp Red Powertrain Controller

M34 – 10 Amp Red Park Assist, Climate Control Sys-

tem, Headlamp Wash, Compass

M35 – 10 Amp Red Heated Mirrors

M36 – 20 Amp Yellow Power Outlet

M37 – 10 Amp Red Anti-Lock Brake System, Elec-

tronic Stability Control, Stop

Lamp Switch, Fuel Pump Relay

M38 – 25 Amp Clear Lock/Unlock Motors

CAUTION!

• When installing the Integrated Power Module cover, it is important to ensure

the cover is properly positioned and fully latched. Failure to do so may allow

water to get into the Integrated Power Module, and possibly result in an

electrical system failure.

• When replacing a blown fuse, it is important to use only a fuse having the

correct amperage rating. The use of a fuse with a rating other than indicated

may result in a dangerous electrical system overload. If a properly rated fuse

continues to blow, it indicates a problem in the circuit that must be corrected.

MAINTAINING YOUR VEHICLE

129

Page 133 of 148

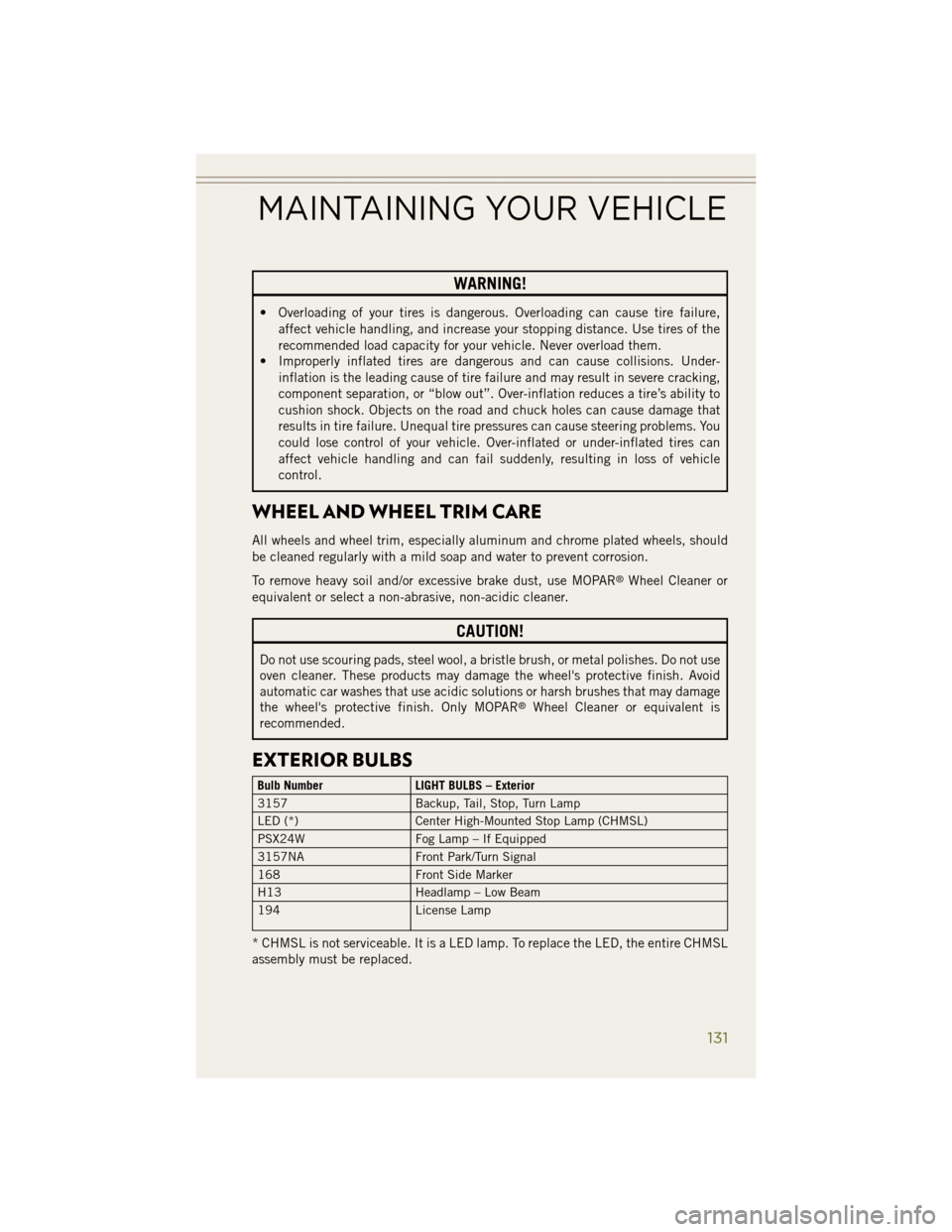

WARNING!

• Overloading of your tires is dangerous. Overloading can cause tire failure,affect vehicle handling, and increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never overload them.

• Improperly inflated tires are dangerous and can cause collisions. Under-

inflation is the leading cause of tire failure and may result in severe cracking,

component separation, or “blow out”. Over-inflation reduces a tire’s ability to

cushion shock. Objects on the road and chuck holes can cause damage that

results in tire failure. Unequal tire pressures can cause steering problems. You

could lose control of your vehicle. Over-inflated or under-inflated tires can

affect vehicle handling and can fail suddenly, resulting in loss of vehicle

control.

WHEEL AND WHEEL TRIM CARE

All wheels and wheel trim, especially aluminum and chrome plated wheels, should

be cleaned regularly with a mild soap and water to prevent corrosion.

To remove heavy soil and/or excessive brake dust, use MOPAR

®Wheel Cleaner or

equivalent or select a non-abrasive, non-acidic cleaner.

CAUTION!

Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Do not use

oven cleaner. These products may damage the wheel's protective finish. Avoid

automatic car washes that use acidic solutions or harsh brushes that may damage

the wheel's protective finish. Only MOPAR

®Wheel Cleaner or equivalent is

recommended.

EXTERIOR BULBS

Bulb Number LIGHT BULBS – Exterior

3157 Backup, Tail, Stop, Turn Lamp

LED (*) Center High-Mounted Stop Lamp (CHMSL)

PSX24W Fog Lamp – If Equipped

3157NA Front Park/Turn Signal

168 Front Side Marker

H13 Headlamp – Low Beam

194 License Lamp

* CHMSL is not serviceable. It is a LED lamp. To replace the LED, the entire CHMSL

assembly must be replaced.

MAINTAINING YOUR VEHICLE

131

Page 139 of 148

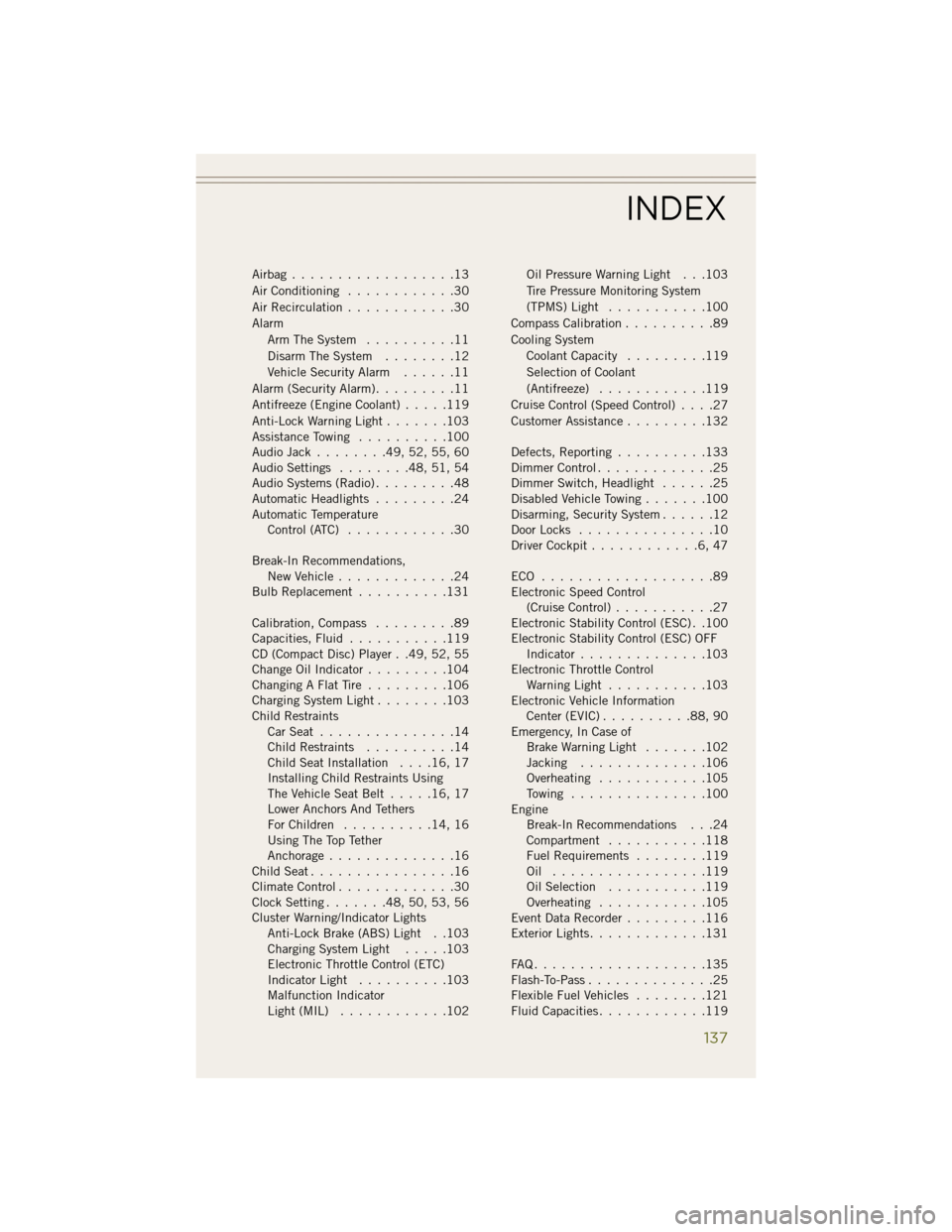

Airbag..................13

Air Conditioning ............30

Air Recirculation ............30

Alarm Arm The System ..........11

Disarm The System ........12

Vehicle Security Alarm ......11

Alarm (Security Alarm) .........11

Antifreeze (Engine Coolant) .....119

Anti-Lock Warning Light .......103

Assistance Towing ..........100

Audio Jack ........49, 52, 55, 60

Audio Settings ........48, 51, 54

Audio Systems (Radio) .........48

Automatic Headlights .........24

Automatic Temperature Control (ATC) ............30

Break-In Recommendations, New Vehicle .............24

Bulb Replacement ..........131

Calibration, Compass .........89

Capacities, Fluid ...........119

CD (Compact Disc) Player . .49, 52, 55

Change Oil Indicator .........104

Changing A Flat Tire .........106

Charging System Light ........103

Child Restraints Car Seat ...............14

Child Restraints ..........14

Child Seat Installation . . . .16, 17

Installing Child Restraints Using

The Vehicle Seat Belt .....16, 17

Lower Anchors And Tethers

For Children ..........14, 16

Using The Top Tether

Anchorage ..............16

Child Seat ................16

Climate Control .............30

Clock Setting .......48, 50, 53, 56

Cluster Warning/Indicator Lights Anti-Lock Brake (ABS) Light . .103

Charging System Light .....103

Electronic Throttle Control (ETC)

Indicator Light ..........103

Malfunction Indicator

Light (MIL) ............102 Oil Pressure Warning Light . . .103

Tire Pressure Monitoring System

(TPMS) Light

...........100

Compass Calibration ..........89

Cooling System Coolant Capacity .........119

Selection of Coolant

(Antifreeze) ........... .119

Cruise

Control (Speed Control) ....27

Customer Assistance .........132

Defects, Reporting ..........133

Dimmer Control .............25

Dimmer Switch, Headlight ......25

Disabled Vehicle Towing .......100

Disarming, Security System ......12

Door Locks ...............10

Driver Cockpit ............6,47

ECO ...................89

Electronic Speed Control (Cruise Control) ...........27

Electronic Stability Control (ESC) . .100

Electronic Stability Control (ESC) OFF Indicator ..............103

Electronic Throttle Control Warning Light ...........103

Electronic Vehicle Information Center (EVIC) ..........88, 90

Emergency, In Case of Brake Warning Light .......102

Jacking ..............106

Overheating ............105

Towing ...............100

Engine Break-In Recommendations . . .24

Compartment ...........118

Fuel Requirements ........119

Oil .................119

Oil Selection ...........119

Overheating ............105

Event Data Recorder .........116

Exterior Lights .............131

FAQ...................135

Flash-To-Pass ..............25

Flexible Fuel Vehicles ........121

Fluid Capacities ............119

INDEX

137