wheel torque JEEP WRANGLER 2015 JK / 3.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: WRANGLER, Model: JEEP WRANGLER 2015 JK / 3.GPages: 156, PDF Size: 23.54 MB

Page 115 of 156

Jacking Instructions

1. Remove the spare tire, jack and tools

from the stored location.

2. Loosen (but do not remove) the wheel

lug nuts by turning them to the left

one turn while the wheel is still on the

ground.

3. Assemble the jack and jacking tools.

Connect the jack handle driver to the

extension, then to the lug wrench.

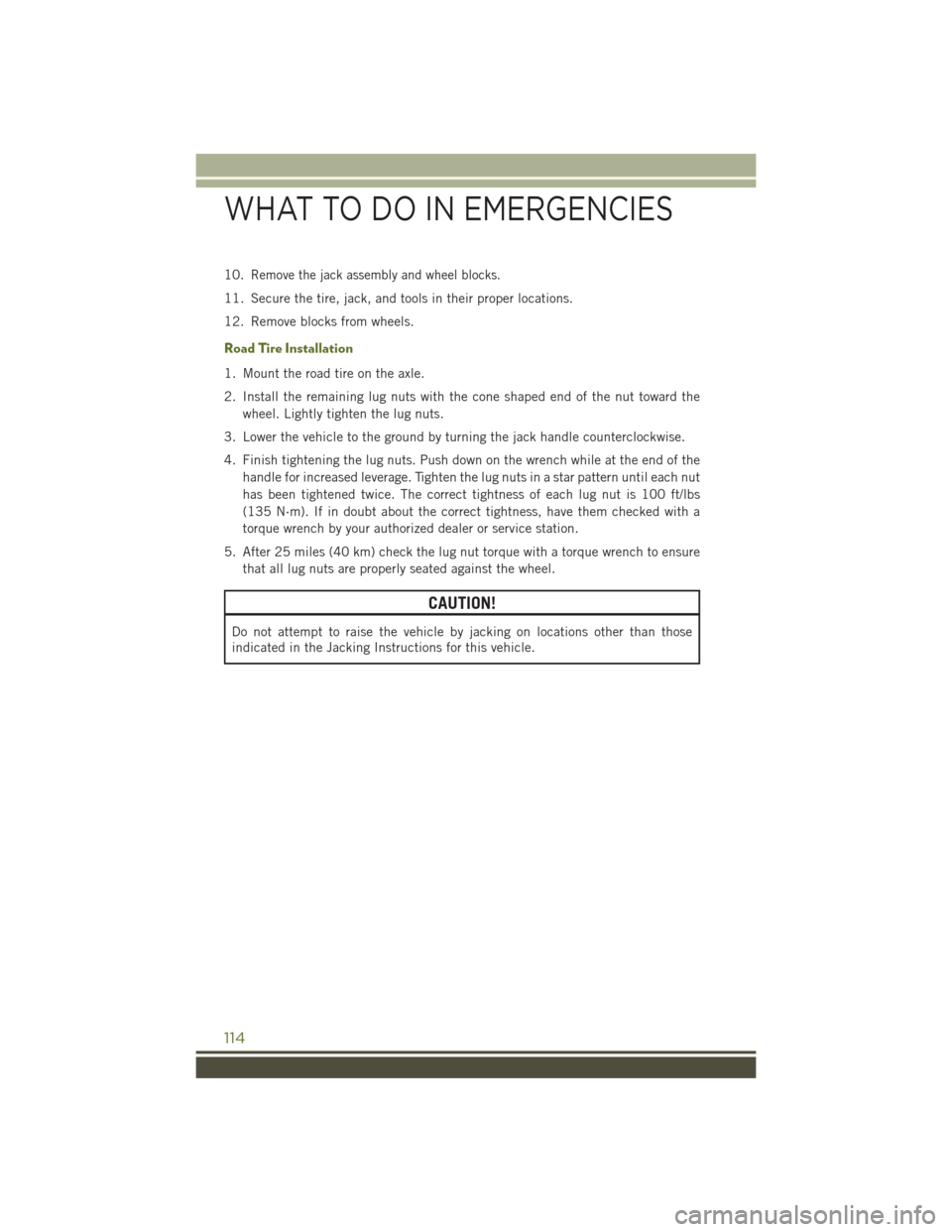

4. Operate the jack from the front or the

rear of the vehicle. Place the jack

under the axle tube, as shown.Do not

raise the vehicle until you are sure the

jack is fully engaged.

5.Raise the vehicle by turning the jack

screw to the right. Raise the vehicle

only until the tire just clears the surface

and enough clearance is obtained to

install the spare tire. Minimum tire lift

provides maximum stability.

6. Remove the lug nuts and wheel.

7.Position the spare wheel/tire on the

vehicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.

9. Finish tightening the lug nuts. Push

down on the wrench while tightening

for increased leverage. Alternate nuts

until each nut has been tightened

twice. The correct wheel nut tightness

is 100 ft lbs (135 N·m). If in doubt

about the correct tightness, have

them checked with a torque wrench

by your authorized dealer or at a ser-

vice station.

Warning Label

Front Jack Engagement Location

Rear Jack Engagement Location

WHAT TO DO IN EMERGENCIES

113

Page 116 of 156

10.Remove the jack assembly and wheel blocks.

11. Secure the tire, jack, and tools in their proper locations.

12. Remove blocks from wheels.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure

that all lug nuts are properly seated against the wheel.

CAUTION!

Do not attempt to raise the vehicle by jacking on locations other than those

indicated in the Jacking Instructions for this vehicle.

WHAT TO DO IN EMERGENCIES

114