tire pressure JEEP WRANGLER 2016 JK / 3.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2016, Model line: WRANGLER, Model: JEEP WRANGLER 2016 JK / 3.GPages: 705, PDF Size: 5.5 MB

Page 544 of 705

rear axle systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable load

weight a truck can carry, including the weight of the

driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the front

and rear axles. The load must be distributed in the cargo

area so that the GAWR of each axle is not exceeded.

Each axle GAWR is determined by the components in the

system with the lowest load carrying capacity (axle,

springs, tires or wheels). Heavier axles or suspension

components sometimes specified by purchasers for in-

creased durability does not necessarily increase the vehi-

cle’s GVWR.

Tire Size

The tire size on the Vehicle Certification Label represents

the actual tire size on your vehicle. Replacement tires

must be equal to the load capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire size

listed.

Inflation Pressure

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb weight

542 STARTING AND OPERATING

Page 560 of 705

Towing Requirements — Tires

•Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle. Refer to

“Tires – General Information” in “Starting And Oper-

ating” for proper tire inflation procedures.

• Check the trailer tires for proper tire inflation pres-

sures before trailer usage.

• Check for signs of tire wear or visible tire damage

before towing a trailer. Refer to “Tires – General

Information” in “Starting And Operating” for proper

inspection procedure.

• When replacing tires, refer to “Tires – General Infor-

mation” in “Starting And Operating” for proper tire

replacement procedures. Replacing tires with a higher

load carrying capacity will not increase the vehicle’s

GVWR and GAWR limits.

Towing Requirements — Trailer Brakes

• Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury.

• An electronically actuated trailer brake controller is

required when towing a trailer with electronically

actuated brakes. When towing a trailer equipped with

a hydraulic surge actuated brake system, an electronic

brake controller is not required.

• Trailer brakes are recommended for trailers over

1,000 lbs (453 kg) and required for trailers in excess of

2,000 lbs (907 kg).

558 STARTING AND OPERATING

Page 573 of 705

NOTE:There are steps that you can take to slow down

an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C

system adds heat to the engine cooling system and

turning the A/C off can help remove this heat.

• You can also turn the temperature control to maximum

heat, the mode control to floor and the blower control

to high. This allows the heater core to act as a

supplement to the radiator and aids in removing heat

from the engine cooling system.WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If

you see or hear steam coming from under the hood,

do not open the hood until the radiator has had time

to cool. Never try to open a cooling system pressure

cap when the radiator or coolant bottle is hot.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure

that the wheel is properly mounted to the vehicle. Any

time a wheel has been removed and reinstalled on the

vehicle the lug nuts/bolts should be torqued using a

properly calibrated torque wrench.

6

WHAT TO DO IN EMERGENCIES 571

Page 627 of 705

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts, and tightness of the connection at

the coolant recovery bottle and radiator. Inspect the

entire system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

If the cap is sealing properly, the engine coolant (anti-

freeze) will begin to drain from the coolant recovery

bottle. DO NOT REMOVE THE COOLANT PRESSURE

CAP WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead

to severe internal engine damage. If any coolant is

needed to be added to the system please contact your

local authorized dealer. If the engine coolant (antifreeze) is dirty or contains

visible sediment, have an authorized dealer clean and

flush with OAT coolant (antifreeze) (conforming to

MS.90032).

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Selection Of Coolant

Refer to “Fluids, Lubricants, And Genuine Parts” in

“Maintaining Your Vehicle” for further information.

CAUTION!

•

Mixing of engine coolant (antifreeze) other than

specified Organic Additive Technology (OAT) en-

gine coolant (antifreeze), may result in engine

damage and may decrease corrosion protection.

(Continued)

7

MAINTAINING YOUR VEHICLE 625

Page 647 of 705

•Be especially careful when washing the windows by

following the directions for “Care of Fabric Top Win-

dows.”

Washing – Use MOPAR Car Wash or equivalent, or mild

soap suds, lukewarm water, and a brush with soft

bristles. If extra cleaning is required, use MOPAR Con-

vertible Cloth Top Cleaner or equivalent, or a mild

foaming cleaner on the entire top, but support the top

from underneath.

Rinsing – Be sure to remove all traces of cleaner by

rinsing the top thoroughly with clean water. Remember

to allow the top to dry before lowering it.CAUTION!

Failure to follow these cautions may cause interior

water damage, stains or mildew on the top material:

• Avoid high-pressure car washes, as they can dam-

age the top material. Also, increased water pressure

may force past the weather strips.

• It is recommended that the top be free of water

prior to opening it. Operating the top, opening a

door or lowering a window while the top is wet

may allow water to drip into the vehicle’s interior.

• Use care when washing the vehicle, water pressure

directed at the weather strip seals may cause water

to leak into the vehicle’s interior.

• Careless handling and storage of the removable

roof panels may damage the seals, causing water to

leak into the vehicle’s interior.

(Continued)

7

MAINTAINING YOUR VEHICLE 645

Page 653 of 705

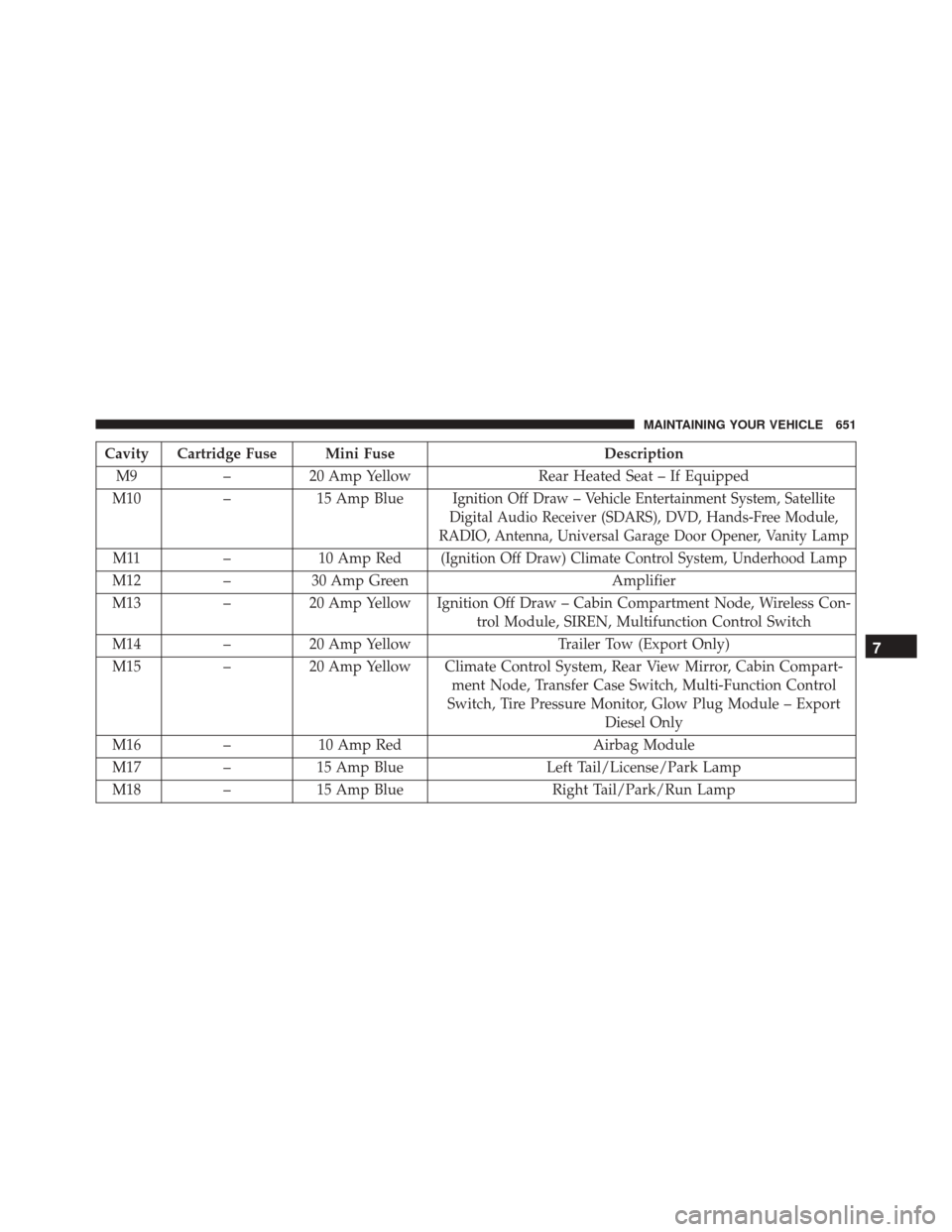

Cavity Cartridge Fuse Mini FuseDescription

M9 –20 Amp Yellow Rear Heated Seat – If Equipped

M10 –15 Amp Blue

Ignition Off Draw – Vehicle Entertainment System, Satellite

Digital Audio Receiver (SDARS), DVD, Hands-Free Module,

RADIO, Antenna, Universal Garage Door Opener, Vanity Lamp

M11 –10 Amp Red(Ignition Off Draw) Climate Control System, Underhood Lamp

M12 –30 Amp Green Amplifier

M13 –20 Amp Yellow Ignition Off Draw – Cabin Compartment Node, Wireless Con-

trol Module, SIREN, Multifunction Control Switch

M14 –20 Amp Yellow Trailer Tow (Export Only)

M15 –20 Amp Yellow Climate Control System, Rear View Mirror, Cabin Compart-

ment Node, Transfer Case Switch, Multi-Function Control

Switch, Tire Pressure Monitor, Glow Plug Module – Export Diesel Only

M16 –10 Amp Red Airbag Module

M17 –15 Amp Blue Left Tail/License/Park Lamp

M18 –15 Amp Blue Right Tail/Park/Run Lamp

7

MAINTAINING YOUR VEHICLE 651

Page 667 of 705

NOTE:Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or

350 hours of engine run time, whichever comes first. The

350 hours of engine run or idle time is generally only a

concern for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) if the vehicle

is operated in a dusty and off road environment or is

operated predominately at idle or only very low engine

RPM’s. This type of vehicle use is considered Severe

Duty. Once A Month Or Before A Long Trip:

•

Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual

wear or damage

• Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering and automatic trans-

mission, and fill as needed

• Check function of all interior and exterior lights

8

MAINTENANCE SCHEDULES 665

Page 684 of 705

About Your Brakes....................... .480

Adding Engine Coolant (Antifreeze) ............626

Adding Fuel ............................ .539

Additives, Fuel .......................... .537

AirBag.................................63 Advance Front Air Bag ....................65

Air Bag Operation .......................66

Air Bag Warning Light ....................71

Enhanced Accident Response ................71

Event Data Recorder (EDR) .................74

FrontAirBag...........................63

If A Deployment Occurs ...................69

Knee Impact Bolsters .....................67

Maintaining Your Air Bag System ............73

Air Bag Deployment ........................63

Air Bag Light ..................... .71, 101, 320

Air Bag Maintenance .......................73

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . .603

Air Conditioner Maintenance .................610Air Conditioning

......................... .415

Air Conditioning Controls ...................415

Air Conditioning Filter ..................427, 612

Air Conditioning, Operating Tips ...........425, 428

Air Conditioning Refrigerant ..............610, 611

Air Conditioning System .............415, 419, 610

Air Pressure, Tires ........................ .510

Alarm (Security Alarm) ..................20, 322

Alterations/Modifications, Vehicle ...............9

Antenna, Satellite Radio .................380, 401

Antifreeze (Engine Coolant) ...............625, 659

Disposal ............................. .628

Anti-Lock Brake System (ABS) ................482

Anti-Lock Warning Light ....................325

Appearance Care ........................ .638

Arming System (Security Alarm) ...............20

Assistance Towing ........................ .129

Assist, Hill Start ......................... .484

Auto Down Power Windows ..................44

682 INDEX

Page 686 of 705

Caps, FillerFuel ................................ .539

Power Steering ........................ .477

Radiator (Coolant Pressure) ................628

Carbon Monoxide Warning ...............100, 538

Cargo Light ............................ .174

Car Washes ............................ .639

Cellular Phone ...........................115

Center High Mounted Stop Light ..............658

Certification Label ........................ .541

Chains, Tire ............................ .521

Changing A Flat Tire ...................... .573

Chart, Tire Sizing ........................ .500

Check Engine Light (Malfunction Indicator Light) . .597

Checking Your Vehicle For Safety ...............99

Checks, Safety ............................99

Child Restraint ............................75

Child Restraints Booster Seats ...........................79 Child Restraints

.........................75

Child Seat Installation .....................94

How To Stow An Unused ALR Seat Belt ........90

Infants And Child Restraints ................77

Install A LATCH-Compatible Child Restraint ....89

Installing Child Restraints Using The Vehicle Seat

Belt ..................................91

Locating The LATCH Anchorages ............86

Lower Anchors And Tethers For Children .......82

Older Children And Child Restraints ..........78

Seating Positions ........................81

Child Safety Locks .........................42

Clean Air Gasoline ....................... .535

Cleaning Wheels .............................. .641

Climate Control ......................... .415

Clock .......................... .359, 368, 385

Cold Weather Operation ....................435

Compact Disc (CD) Maintenance ..............412

684 INDEX

Page 687 of 705

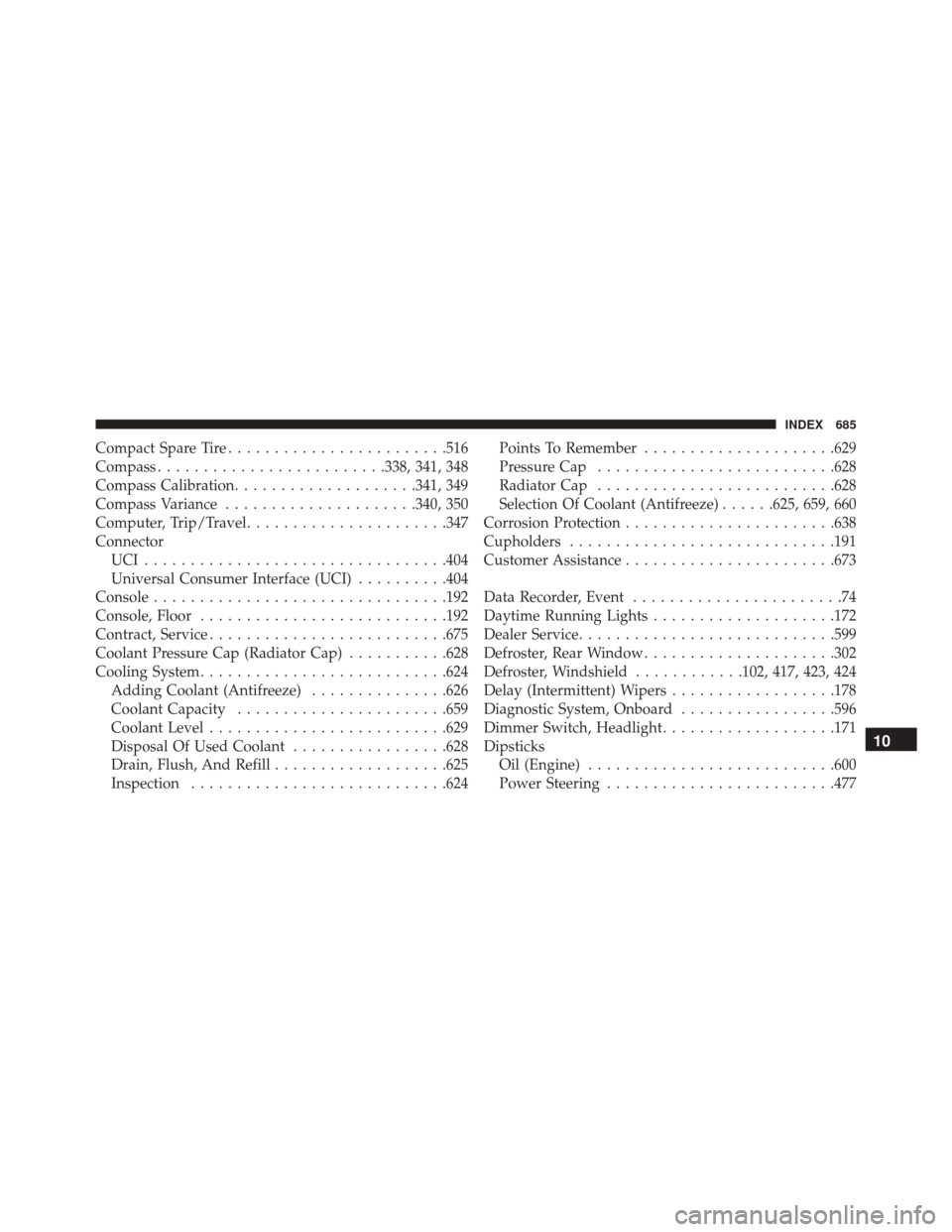

Compact Spare Tire....................... .516

Compass ........................ .338, 341, 348

Compass Calibration ....................341, 349

Compass Variance .....................340, 350

Computer, Trip/Travel ..................... .347

Connector UCI................................ .404

Universal Consumer Interface (UCI) ..........404

Console ............................... .192

Console, Floor .......................... .192

Contract, Service ......................... .675

Coolant Pressure Cap (Radiator Cap) ...........628

Cooling System .......................... .624

Adding Coolant (Antifreeze) ...............626

Coolant Capacity ...................... .659

Coolant Level ......................... .629

Disposal Of Used Coolant .................628

Drain, Flush, And Refill ...................625

Inspection ........................... .624Points To Remember

.....................629

Pressure Cap ......................... .628

Radiator Cap ......................... .628

Selection Of Coolant (Antifreeze) ......625, 659, 660

Corrosion Protection ...................... .638

Cupholders ............................ .191

Customer Assistance ...................... .673

Data Recorder, Event .......................74

Daytime Running Lights ....................172

Dealer Service ........................... .599

Defroster, Rear Window .....................302

Defroster, Windshield ............102, 417, 423, 424

Delay (Intermittent) Wipers ..................178

Diagnostic System, Onboard .................596

Dimmer Switch, Headlight ...................171

Dipsticks Oil (Engine) .......................... .600

Power

Steering ........................ .477

10

INDEX 685