battery JEEP WRANGLER 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER, Model: JEEP WRANGLER 2020Pages: 276, PDF Size: 4.47 MB

Page 148 of 276

HAZARD WARNING

FLASHERS

The Hazard Warning flasher switch is located

on the instrument panel below the climate

controls.

Push the switch to turn on the

Hazard Warning flasher. When the

switch is activated, all directionalturn signals will flash on and off to warn

oncoming traffic of an emergency. Push the

switch a second time to turn off the Hazard

Warning flashers.

This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled

and it is creating a safety hazard for other

motorists.When you must leave the vehicle to seek

assistance, the Hazard Warning flashers will

continue to operate even though the ignition

is placed in the OFF position.

NOTE:

With extended use the Hazard Warning flash-

ers may wear down your battery.

BULB REPLACEMENT

Replacement Bulbs

Interior Lights

Bulb Type

Bulb Number

Automatic Transmission Indicator Lamp 658

Courtesy Lights, Under Dash (1)906

Heater Control Lamps (2)194

Rocker Switch Indicator Lamp (Rear Window Defogger) **

Soundbar Dome Lamp912

** Bulbs only available from authorized dealer.

IN CASE OF EMERGENCY

146

Page 152 of 276

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

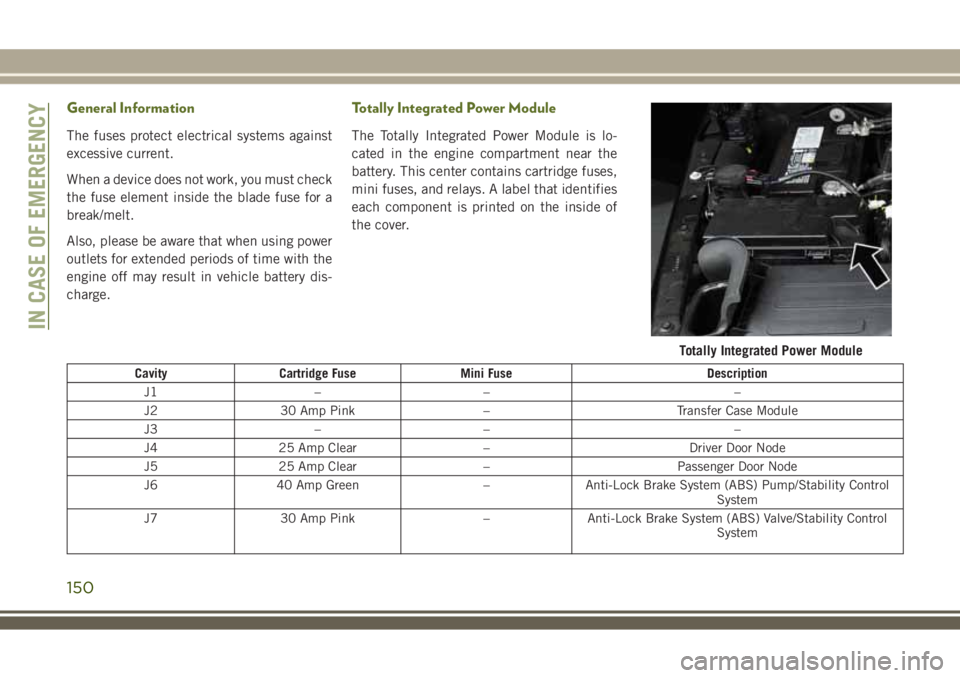

Totally Integrated Power Module

The Totally Integrated Power Module is lo-

cated in the engine compartment near the

battery. This center contains cartridge fuses,

mini fuses, and relays. A label that identifies

each component is printed on the inside of

the cover.

Cavity Cartridge Fuse Mini Fuse Description

J1 – – –

J2 30 Amp Pink – Transfer Case Module

J3 – – –

J4 25 Amp Clear – Driver Door Node

J5 25 Amp Clear – Passenger Door Node

J6 40 Amp Green – Anti-Lock Brake System (ABS) Pump/Stability Control

System

J7 30 Amp Pink – Anti-Lock Brake System (ABS) Valve/Stability Control

System

Totally Integrated Power Module

IN CASE OF EMERGENCY

150

Page 162 of 276

Jack Usage Precautions

To complete the Use and Maintenance Hand-

book to which this supplement is attached,

given below are some instructions on the

proper use of the jack.

WARNING!

When using the crank, make sure it turns

freely without the risk of scraping hands

against the ground.

Even the moving parts of the jack, the

“worm screw” and joints can cause inju-

ries: avoid contact with them. Clean it

thoroughly if dirtied with grease.

CAUTION!

The jack is a tool designed exclusively for

changing a wheel, in case of a puncture or

damage to a tire of the vehicle on which it

is fitted or on vehicles of the same model.

Any other use, e.g. to jack up other vehicle

models or different things, is strictly pro-

hibited. Never use it to carry out mainte-

nance or repairs under the vehicle or to

CAUTION!

change summer/winter wheels and vice

versa. Never go under the raised vehicle. If

any work under the vehicle is necessary,

contact the Fiat Service Network. Incor-

rect placing of the jack can cause the

vehicle to drop: use it only in the positions

indicated. Do not use the jack for loads

higher than that specified on the label.

Never start the engine with vehicle raised.

If the vehicle is raised more than neces-

sary, everything can become more un-

stable, with the risk of the vehicle drop-

ping violently. Therefore raise the vehicle

only as much as necessary for the wheel/

spare.

Maintenance

• Make sure grime does not build up on the

“worm screw.”

• Keep the “worm screw” lubricated.

• Never modify the jack.

Conditions Of Non-Use:

• Temperatures below −40°C.

• On sandy or muddy ground.• On uneven ground.

• On steep roads.

• In extreme weather conditions: thunder-

storms, typhoons, hurricanes, blizzards,

storms, etc.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

IN CASE OF EMERGENCY

160

Page 163 of 276

CAUTION!

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc-

tions and precautions.

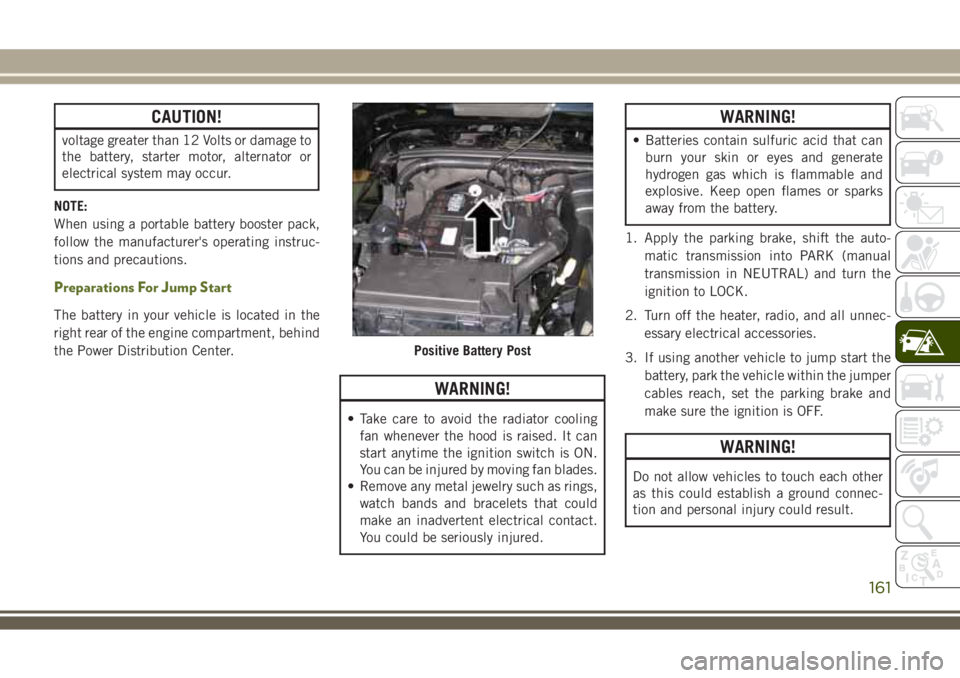

Preparations For Jump Start

The battery in your vehicle is located in the

right rear of the engine compartment, behind

the Power Distribution Center.

WARNING!

• Take care to avoid the radiator cooling

fan whenever the hood is raised. It can

start anytime the ignition switch is ON.

You can be injured by moving fan blades.

• Remove any metal jewelry such as rings,

watch bands and bracelets that could

make an inadvertent electrical contact.

You could be seriously injured.

WARNING!

• Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

1. Apply the parking brake, shift the auto-

matic transmission into PARK (manual

transmission in NEUTRAL) and turn the

ignition to LOCK.

2. Turn off the heater, radio, and all unnec-

essary electrical accessories.

3. If using another vehicle to jump start the

battery, park the vehicle within the jumper

cables reach, set the parking brake and

make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other

as this could establish a ground connec-

tion and personal injury could result.

Positive Battery Post

161

Page 164 of 276

Jump Starting Procedure

WARNING!

Failure to follow this jump starting proce-

dure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged ve-

hicle.

NOTE:

Make sure at all times that unused ends of

jumper cables are not contacting each other

or either vehicle while making connections.

Connecting The Jumper Cables

1. Connect the positive(+)end of the jumper

cable to the remote positive(+)post of the

discharged vehicle.

2. Connect the opposite end of the positive

(+)jumper cable to the positive(+)post of

the booster battery.3. Connect the negative end(-)of the jumper

cable to the negative(-)post of the

booster battery.

4. Connect the opposite end of the negative

(-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicle’s engine) away from the battery

and the fuel injection system.WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts.

5. Start the engine in the vehicle that has

the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery.

CAUTION!

Do not run the booster vehicle engine

above 2000 rpm since it provides no

charging benefit, wastes fuel and can

damage booster vehicle engine.

6. Once the engine is started, remove the

jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative(-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the nega-

tive(-)jumper cable from the negative(-)

post of the booster battery.

3. Disconnect the positive(+)end of the

jumper cable from the positive(+)post of

the booster battery.

4. Disconnect the opposite end of the posi-

tive(+)jumper cable from the remote

positive(+)post of the discharged

vehicle.

IN CASE OF EMERGENCY

162

Page 165 of 276

5. Reinstall the protective cover over the

remote positive(+)post of the discharged

vehicle.

If frequent jump starting is required to start

your vehicle you should have the battery and

charging system tested at an authorized

dealer.

CAUTION!

Accessories plugged into the vehicle

power outlets draw power from the vehi-

cle’s battery, even when not in use (i.e.,

cellular devices, etc.). Eventually, if

plugged in long enough without engine

operation, the vehicle’s battery will dis-

charge sufficiently to degrade battery life

and/or prevent the engine from starting.

IF YOUR ENGINE

OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

• On the highways — slow down.

• In city traffic — while stopped, shift trans-

mission into NEUTRAL, but do not increase

engine idle speed.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop

the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer

drops back into the normal range. If the

pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.NOTE:

There are steps that you can take to slow

down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off.

The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

• You can also turn the temperature control to

maximum heat, the mode control to floor

and the blower control to high. This allows

the heater core to act as a supplement to

the radiator and aids in removing heat from

the engine cooling system.WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

pressure cap when the radiator or coolant

bottle is hot.

163

Page 168 of 276

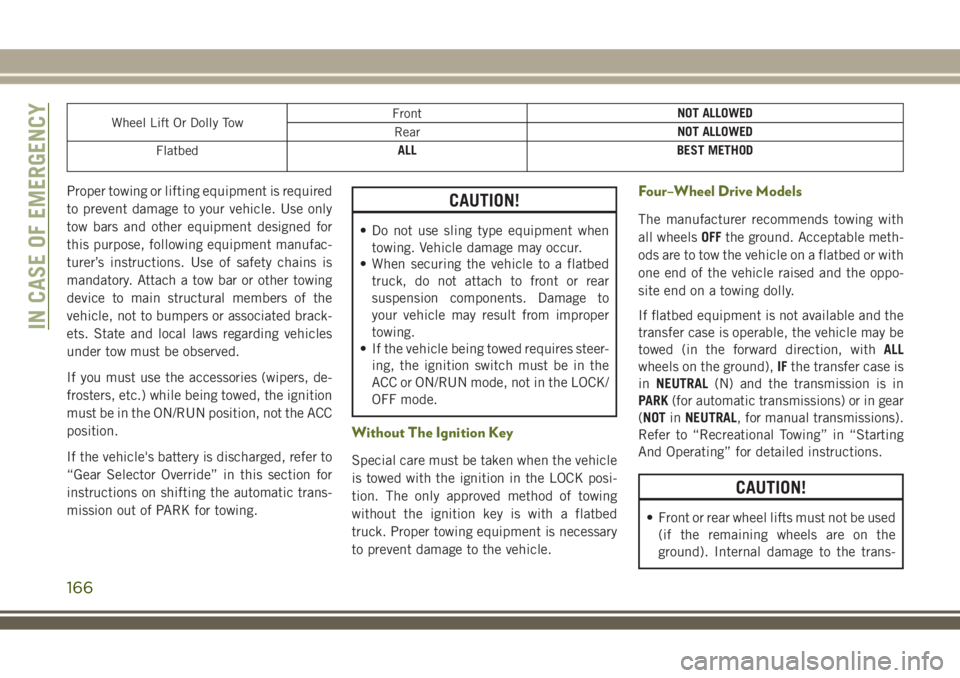

Wheel Lift Or Dolly TowFrontNOT ALLOWED

RearNOT ALLOWED

FlatbedALL BEST METHOD

Proper towing or lifting equipment is required

to prevent damage to your vehicle. Use only

tow bars and other equipment designed for

this purpose, following equipment manufac-

turer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing

device to main structural members of the

vehicle, not to bumpers or associated brack-

ets. State and local laws regarding vehicles

under tow must be observed.

If you must use the accessories (wipers, de-

frosters, etc.) while being towed, the ignition

must be in the ON/RUN position, not the ACC

position.

If the vehicle's battery is discharged, refer to

“Gear Selector Override” in this section for

instructions on shifting the automatic trans-

mission out of PARK for towing.CAUTION!

• Do not use sling type equipment when

towing. Vehicle damage may occur.

• When securing the vehicle to a flatbed

truck, do not attach to front or rear

suspension components. Damage to

your vehicle may result from improper

towing.

• If the vehicle being towed requires steer-

ing, the ignition switch must be in the

ACC or ON/RUN mode, not in the LOCK/

OFF mode.

Without The Ignition Key

Special care must be taken when the vehicle

is towed with the ignition in the LOCK posi-

tion. The only approved method of towing

without the ignition key is with a flatbed

truck. Proper towing equipment is necessary

to prevent damage to the vehicle.

Four–Wheel Drive Models

The manufacturer recommends towing with

all wheelsOFFthe ground. Acceptable meth-

ods are to tow the vehicle on a flatbed or with

one end of the vehicle raised and the oppo-

site end on a towing dolly.

If flatbed equipment is not available and the

transfer case is operable, the vehicle may be

towed (in the forward direction, withALL

wheels on the ground),IFthe transfer case is

inNEUTRAL(N) and the transmission is in

PARK(for automatic transmissions) or in gear

(NOTinNEUTRAL, for manual transmissions).

Refer to “Recreational Towing” in “Starting

And Operating” for detailed instructions.

CAUTION!

• Front or rear wheel lifts must not be used

(if the remaining wheels are on the

ground). Internal damage to the trans-

IN CASE OF EMERGENCY

166

Page 171 of 276

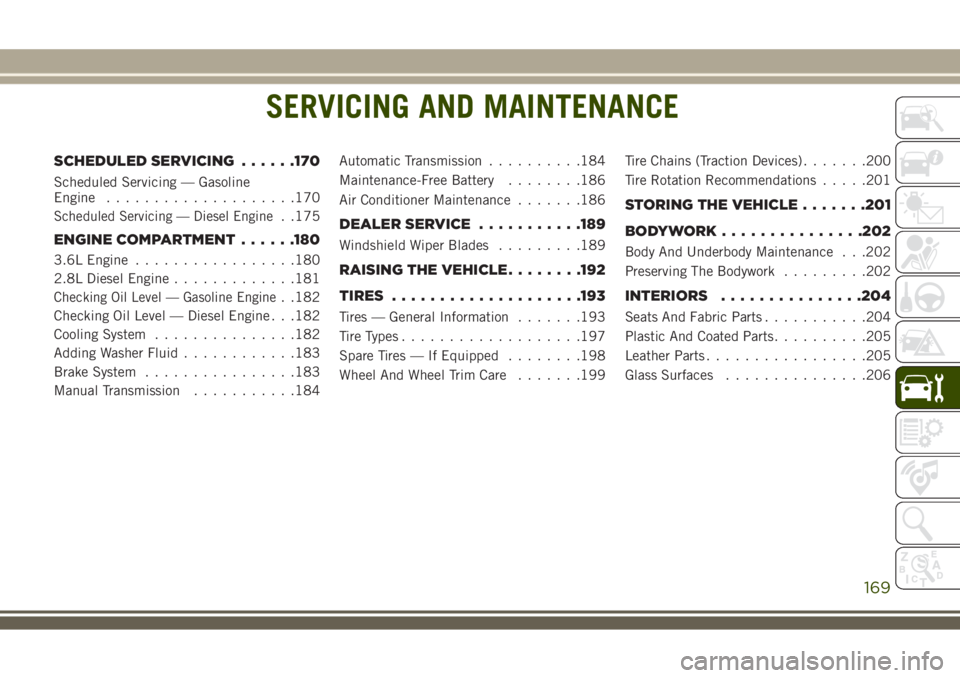

SERVICING AND MAINTENANCE

SCHEDULED SERVICING......170

Scheduled Servicing — Gasoline

Engine....................170

Scheduled Servicing — Diesel Engine. .175

ENGINE COMPARTMENT......180

3.6L Engine.................180

2.8L Diesel Engine.............181

Checking Oil Level — Gasoline Engine. .182

Checking Oil Level — Diesel Engine . . .182

Cooling System...............182

Adding Washer Fluid............183

Brake System................183

Manual Transmission...........184Automatic Transmission..........184

Maintenance-Free Battery........186

Air Conditioner Maintenance.......186

DEALER SERVICE...........189

Windshield Wiper Blades.........189

RAISING THE VEHICLE........192

TIRES....................193

Tires — General Information.......193

Tire Types...................197

Spare Tires — If Equipped........198

Wheel And Wheel Trim Care.......199Tire Chains (Traction Devices).......200

Tire Rotation Recommendations.....201

STORING THE VEHICLE.......201

BODYWORK...............202

Body And Underbody Maintenance . . .202

Preserving The Bodywork.........202

INTERIORS...............204

Seats And Fabric Parts...........204

Plastic And Coated Parts..........205

Leather Parts.................205

Glass Surfaces...............206

SERVICING AND MAINTENANCE

169

Page 172 of 276

SCHEDULED SERVICING

Scheduled Servicing — Gasoline Engine

The scheduled services listed in this manual

must be done at the times or mileages speci-

fied to protect your vehicle warranty and

ensure the best vehicle performance and re-

liability. More frequent maintenance may be

needed for vehicles in severe operating con-

ditions, such as dusty areas and very short

trip driving. Inspection and service should

also be done anytime a malfunction is sus-

pected.

The oil change indicator system will remind

you that it is time to take your vehicle in for

scheduled maintenance.

On non-instrument cluster display equipped

vehicles, “CHANgE OIL” will flash in the

instrument cluster odometer and a single

chime will sound, indicating that an oil

change is necessary.The oil change indicator message will illumi-

nate approximately 7,000 miles

(11,200 km) after the most recent oil change

was performed. Have your vehicle serviced as

soon as possible, within 500 miles (800 km).

However, an earlier oil change at 4,500 miles

(7,500 km) may be required if the vehicle is

operated under “Severe Duty Conditions”

later in this section.

NOTE:

• The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle's oil if it has been

6 months since your last oil change even if

the oil change indicator message is NOT

illuminated.

• Change your engine oil more often if you

drive your vehicle off-road for an extended

period of time.

• Under no circumstances should oil change

intervals exceed 7,500 miles (12,000 km)

or 6 months, whichever comes first.

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change.Once A Month Or Before A Long Trip

• Check the engine oil level about five min-

utes after a fully warmed engine is shut off.

Checking the oil level while the vehicle is

on level ground will improve the accuracy of

the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

• Check the windshield washer solvent and

add if required.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Inspect the battery and clean and tighten

the terminals as required.

• Check the fluid levels of coolant reservoir,

automatic transmission, brake master cyl-

inder and power steering and fill as needed.

• Check all lights and other electrical items

for correct operation.

SERVICING AND MAINTENANCE

170

Page 177 of 276

WARNING!

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

Severe Duty Conditions

†† Change the engine oil and engine oil filter

at every 4500 miles (7,500 km) or 6 months

if using your vehicle under any of the follow-

ing severe duty conditions:

• Stop and go driving.

• Driving in dusty conditions.

• Short trips of less than 10 miles (16 km).

• Trailer towing.

• Taxi, police, or delivery service (commercial

service).

• Off-road or desert operation.

Scheduled Servicing — Diesel Engine

At Each Stop for Fuel

• Check the engine oil level about five min-

utes after a fully warmed engine is shut off.

Checking the oil level while the vehicle is

on level ground will improve the accuracy of

the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

• Check the windshield washer solvent, add

as required.

Once a Month

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Inspect the battery; clean and tighten the

terminals as required.

• Check the fluid levels of engine coolant/

antifreeze deaeration bottle, and brake

master cylinder, add as needed.

• Check all lights and all other electrical

items for correct operation.At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect brake hoses.

• Check the engine coolant/antifreeze level,

hoses, and clamps.

• Inspect engine accessory drive belts. Re-

place as necessary.

• Inspect for the presence of water in the fuel

filter/water separator unit.

Inspection and service should be performed

anytime a malfunction is observed or sus-

pected. Retain all receipts.

175