tow JEEP WRANGLER 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER, Model: JEEP WRANGLER 2020Pages: 276, PDF Size: 4.47 MB

Page 66 of 276

— 4WD Indicator Light — If Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive mode, and the front

and rear driveshafts are mechanically locked

together forcing the front and rear wheels to

rotate at the same speed.

— Sway Bar Indicator Light — If

Equipped

This indicator will illuminate when the front

sway bar is disconnected.

Green Indicator Lights

— Front Fog Indicator Light — If

Equipped

This indicator will illuminate when the front

fog lights are on.

— Turn Signal Indicator Lights

When the left or right turn signal is activated,

the turn signal indicator will flash indepen-

dently and the corresponding exterior turn

signal lamps will flash. Turn signals can be

activated when the multifunction lever is

moved down (left) or up (right).NOTE:

• A continuous chime will sound if the ve-

hicle is driven more than 1 mile (1.6 km)

with either turn signal on.

• Check for an inoperative outside light bulb

if either indicator flashes at a rapid rate.

White Indicator Lights

CRUISE— Cruise Indicator

This indicator shows that the Speed Control

System is ON.

— Hill Descent Control (HDC) Indicator

Light — If Equipped

This indicator shows when the Hill Descent

Control (HDC) feature is turned on. The lamp

will be on solid when HDC is armed. HDC can

only be armed when the transfer case is in the

“4WD LOW” position and the vehicle speed

is less then 30 mph (48 km/h). If these

conditions are not met while attempting to

use the HDC feature, the HDC indicator light

will flash on/off.

Blue Indicator Lights

— High Beam Indicator Light

This indicator shows that the high beam

headlights are on. With the low beams acti-

vated, push the multifunction lever forward

(toward the front of the vehicle) to turn on the

high beams. Pull the multifunction lever rear-

ward (toward the rear of the vehicle) to turn

off the high beams. If the high beams are off,

pull the lever toward you for a temporary high

beam on, "flash to pass" scenario.

ONBOARD DIAGNOSTIC

SYSTEM — OBD II

Your vehicle is equipped with a sophisticated

Onboard Diagnostic system called OBD II.

This system monitors the performance of the

emissions, engine, and automatic transmis-

sion control systems. When these systems are

operating properly, your vehicle will provide

excellent performance and fuel economy, as

well as engine emissions well within current

government regulations.

GETTING TO KNOW YOUR INSTRUMENT PANEL

64

Page 67 of 276

If any of these systems require service, the

OBD II system will turn on the Malfunction

Indicator Light (MIL). It will also store diag-

nostic codes and other information to assist

your service technician in making repairs.

Although your vehicle will usually be drivable

and not need towing, see your authorized

dealer for service as soon as possible.

CAUTION!

• Prolonged driving with the MIL on could

cause further damage to the emission

control system. It could also affect fuel

economy and driveability. The vehicle

must be serviced before any emissions

tests can be performed.

• If the MIL is flashing while the vehicle is

running, severe catalytic converter dam-

age and power loss will soon occur. Im-

mediate service is required.

Onboard Diagnostic System (OBD II)

Cybersecurity

Your vehicle is required to have an Onboard

Diagnostic system (OBD II) and a connection

port to allow access to information related tothe performance of your emissions controls.

Authorized service technicians may need to

access this information to assist with the

diagnosis and service of your vehicle and

emissions system.

WARNING!

• ONLY an authorized service technician

should connect equipment to the OBD II

connection port in order to diagnose or

service your vehicle.

• If unauthorized equipment is connected

to the OBD II connection port, such as a

driver-behavior tracking device, it may:

• Be possible that vehicle systems,

including safety related systems,

could be impaired or a loss of ve-

hicle control could occur that may

result in an accident involving seri-

ous injury or death.

• Access, or allow others to access,

information stored in your vehicle

systems, including personal infor-

mation.For further information, refer to “Cybersecu-

rity” in “Multimedia” in your Owner's

Manual.

Loose Fuel Filler Cap Message

After fuel is added, the vehicle diagnostic

system can determine if the fuel filler cap is

possibly loose, improperly installed, or dam-

aged. A “gASCAP” message will be displayed

in the odometer. Tighten the gas cap until a

"clicking" sound is heard. This is an indica-

tion that the gas cap is properly tightened.

Push the odometer reset button to turn the

message off. If the problem persists, the

message will appear the next time the vehicle

is started. This might indicate a damaged

cap. If the problem is detected twice in a row,

the system will turn on the MIL. Resolving the

problem will turn the MIL off.

65

Page 78 of 276

WARNING!

Many factors, such as vehicle loading,

road conditions and driving conditions,

influence the chance that wheel lift or

rollover may occur. ERM cannot prevent

all wheel lift or roll overs, especially those

that involve leaving the roadway or striking

objects or other vehicles. The capabilities

of an ERM-equipped vehicle must never

be exploited in a reckless or dangerous

manner which could jeopardize the user's

safety or the safety of others.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize

an excessively swaying trailer and will take

the appropriate actions to attempt to stop the

sway. TSC will become active automatically

once an excessively swaying trailer is recog-

nized.NOTE:

TSC cannot stop all trailers from swaying.

Always use caution when towing a trailer and

follow the trailer tongue weight recommenda-

tions. Refer to “Trailer Towing” in “Starting

And Operating” for further information.

When TSC is functioning, the “ESC

Activation/Malfunction Indicator Light” will

flash, the engine power may be reduced and

you may feel the brakes being applied to

individual wheels to attempt to stop the

trailer from swaying. TSC is disabled when

the ESC system is in the “Partial Off” or “Full

Off” modes.WARNING!

If TSC activates while driving, slow the

vehicle down, stop at the nearest safe

location, and adjust the trailer load to

eliminate trailer sway.

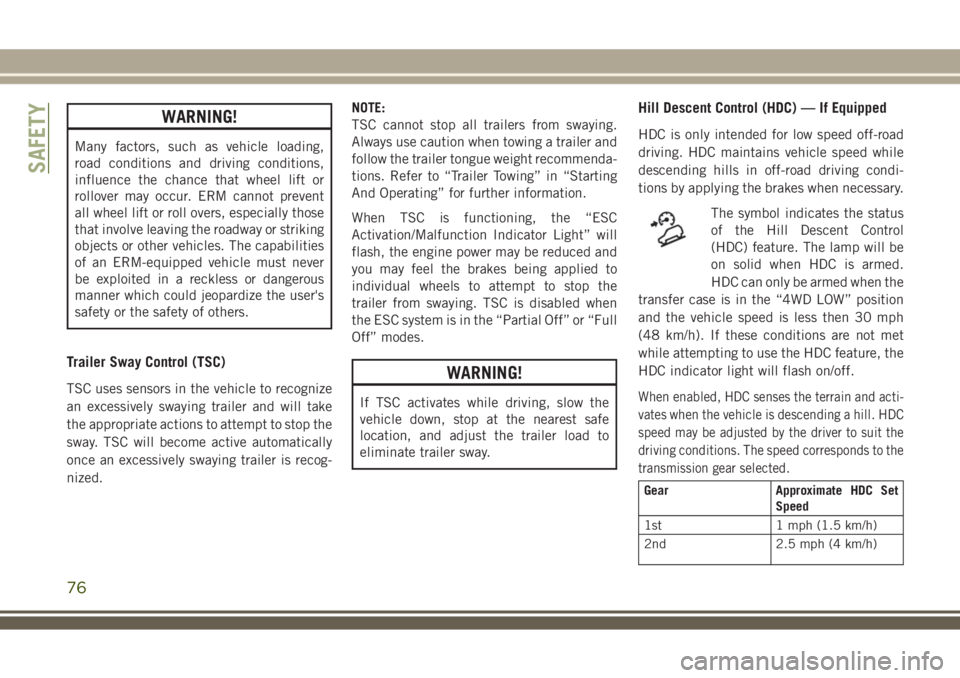

Hill Descent Control (HDC) — If Equipped

HDC is only intended for low speed off-road

driving. HDC maintains vehicle speed while

descending hills in off-road driving condi-

tions by applying the brakes when necessary.

The symbol indicates the status

of the Hill Descent Control

(HDC) feature. The lamp will be

on solid when HDC is armed.

HDC can only be armed when the

transfer case is in the “4WD LOW” position

and the vehicle speed is less then 30 mph

(48 km/h). If these conditions are not met

while attempting to use the HDC feature, the

HDC indicator light will flash on/off.

When enabled, HDC senses the terrain and acti-

vates when the vehicle is descending a hill. HDC

speed may be adjusted by the driver to suit the

driving conditions. The speed corresponds to the

transmission gear selected.

Gear Approximate HDC Set

Speed

1st 1 mph (1.5 km/h)

2nd 2.5 mph (4 km/h)

SAFETY

76

Page 81 of 276

• Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces

fuel efficiency and tire tread life, and may

affect the vehicle’s handling and stopping

ability.

• The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s respon-

sibility to maintain correct tire pressure,

even if under-inflation has not reached the

level to trigger illumination of the “Tire

Pressure Monitoring Telltale Light.”

• Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor

the actual tire pressure in the tire.

Base System

The Tire Pressure Monitor System (TPMS)

uses wireless technology with wheel rim-

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the Receiver Module.NOTE:

It is particularly important for you to check

the tire pressure in all of your tires regularly

and to maintain the proper pressure.

The Tire Pressure Monitor System (TPMS)

consists of the following components:

• Receiver Module

• Four Tire Pressure Monitoring Sensors

• Tire Pressure Monitoring Telltale Light

A tire pressure monitoring sensor is located in

the spare wheel if the vehicle is equipped

with a matching full size spare wheel and tire

assembly. The matching full size spare tire

can be used in place of any of the four road

tires. A low spare tire will not cause the “Tire

Pressure Monitoring Telltale Light” to illumi-

nate or the chime to sound while stowed in

the spare location.

The “Tire Pressure Monitoring Tell-

tale Light” will illuminate in the in-

strument cluster, a “LOW TIRE

PRESSURE” message will display in the in-

strument cluster, and an audible chime will

be activated when one or more of the four

active road tire pressures are low. Should thisoccur, you should stop as soon as possible,

check the inflation pressure of each tire on

your vehicle, and inflate each tire to the

vehicle's recommended cold placard pres-

sure value. The system will automatically

update and the “Tire Pressure Monitoring

Telltale Light” will extinguish once the up-

dated tire pressures have been received. The

vehicle may need to be driven for up to

10 minutes above 15 mph (24 km/h) to

receive this information

The “Tire Pressure Monitoring Telltale Light”

will flash on and off for 75 seconds, and will

remain on solid when a system fault is de-

tected. The system fault will also sound a

chime. If the ignition key is cycled, this

sequence will repeat, providing the system

fault still exists. The “Tire Pressure Monitor-

ing Telltale Light” will turn off when the fault

condition no longer exists. A system fault can

occur by any of the following scenarios:

1. Jamming due to electronic devices or driv-

ing next to facilities emitting the same

Radio Frequencies as the TPM sensors.

79

Page 88 of 276

Belt Reminder Light will remain on until the

seat belts are buckled. The BeltAlert warning

sequence may repeat based on vehicle speed

until the driver and occupied outboard front

seat passenger seat belts are buckled. The

driver should instruct all occupants to buckle

their seat belts.

Change of Status

If the driver or outboard front seat passenger

(if equipped with outboard front passenger

seat BeltAlert) unbuckles their seat belt

while the vehicle is traveling, the BeltAlert

warning sequence will begin until the seat

belts are buckled again.

The outboard front passenger seat BeltAlert

is not active when the outboard front passen-

ger seat is unoccupied. BeltAlert may be

triggered when an animal or other items are

placed on the outboard front passenger seat

or when the seat is folded flat (if equipped). It

is recommended that pets be restrained in

the rear seat (if equipped) in pet harnesses or

pet carriers that are secured by seat belts,

and cargo is properly stowed.BeltAlert can be activated or deactivated by

your authorized dealer. FCA US LLC does not

recommend deactivating BeltAlert.

NOTE:

If BeltAlert has been deactivated and the

driver or outboard front seat passenger (if

equipped with outboard front passenger seat

BeltAlert) is unbuckled the Seat Belt Re-

minder Light will turn on and remain on until

the driver and outboard front seat passenger

seat belts are buckled.

Lap/Shoulder Belts

All seating positions in your vehicle are

equipped with lap/shoulder belts.

The seat belt webbing retractor will lock only

during very sudden stops or collisions. This

feature allows the shoulder part of the seat

belt to move freely with you under normal

conditions. However, in a collision the seat

belt will lock and reduce your risk of striking

the inside of the vehicle or being thrown out

of the vehicle.

WARNING!

• Relying on the air bags alone could lead

to more severe injuries in a collision. The

air bags work with your seat belt to

restrain you properly. In some collisions,

the air bags won’t deploy at all. Always

wear your seat belt even though you have

air bags.

• In a collision, you and your passengers

can suffer much greater injuries if you

are not properly buckled up. You can

strike the interior of your vehicle or other

passengers, or you can be thrown out of

the vehicle. Always be sure you and

others in your vehicle are buckled up

properly.

• It is dangerous to ride in a cargo area,

inside or outside of a vehicle. In a colli-

sion, people riding in these areas are

more likely to be seriously injured or

killed.

• Do not allow people to ride in any area of

your vehicle that is not equipped with

seats and seat belts.

SAFETY

86

Page 90 of 276

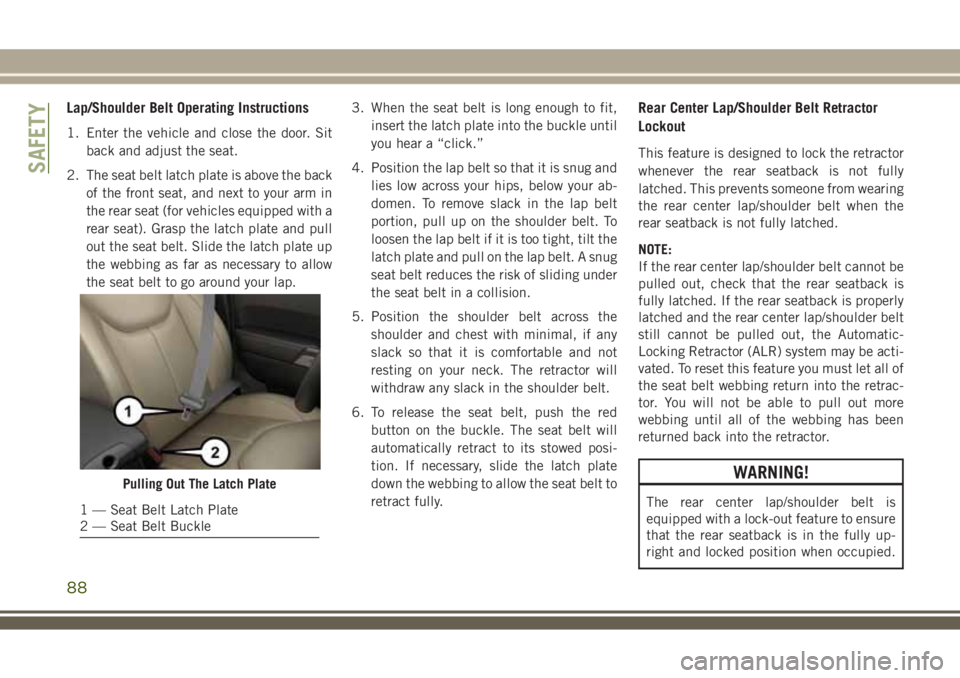

Lap/Shoulder Belt Operating Instructions

1. Enter the vehicle and close the door. Sit

back and adjust the seat.

2. The seat belt latch plate is above the back

of the front seat, and next to your arm in

the rear seat (for vehicles equipped with a

rear seat). Grasp the latch plate and pull

out the seat belt. Slide the latch plate up

the webbing as far as necessary to allow

the seat belt to go around your lap.3. When the seat belt is long enough to fit,

insert the latch plate into the buckle until

you hear a “click.”

4. Position the lap belt so that it is snug and

lies low across your hips, below your ab-

domen. To remove slack in the lap belt

portion, pull up on the shoulder belt. To

loosen the lap belt if it is too tight, tilt the

latch plate and pull on the lap belt. A snug

seat belt reduces the risk of sliding under

the seat belt in a collision.

5. Position the shoulder belt across the

shoulder and chest with minimal, if any

slack so that it is comfortable and not

resting on your neck. The retractor will

withdraw any slack in the shoulder belt.

6. To release the seat belt, push the red

button on the buckle. The seat belt will

automatically retract to its stowed posi-

tion. If necessary, slide the latch plate

down the webbing to allow the seat belt to

retract fully.

Rear Center Lap/Shoulder Belt Retractor

Lockout

This feature is designed to lock the retractor

whenever the rear seatback is not fully

latched. This prevents someone from wearing

the rear center lap/shoulder belt when the

rear seatback is not fully latched.

NOTE:

If the rear center lap/shoulder belt cannot be

pulled out, check that the rear seatback is

fully latched. If the rear seatback is properly

latched and the rear center lap/shoulder belt

still cannot be pulled out, the Automatic-

Locking Retractor (ALR) system may be acti-

vated. To reset this feature you must let all of

the seat belt webbing return into the retrac-

tor. You will not be able to pull out more

webbing until all of the webbing has been

returned back into the retractor.

WARNING!

The rear center lap/shoulder belt is

equipped with a lock-out feature to ensure

that the rear seatback is in the fully up-

right and locked position when occupied.

Pulling Out The Latch Plate

1 — Seat Belt Latch Plate

2 — Seat Belt Buckle

SAFETY

88

Page 110 of 276

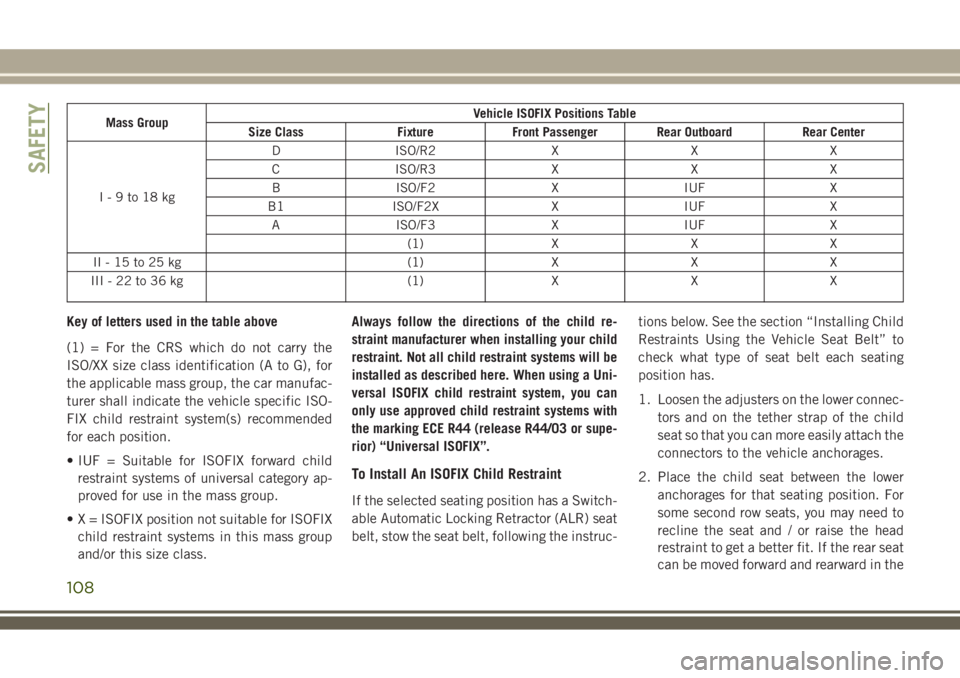

Mass GroupVehicle ISOFIX Positions Table

Size Class Fixture Front Passenger Rear Outboard Rear Center

I-9to18kgD ISO/R2 X X X

C ISO/R3 X X X

B ISO/F2 X IUF X

B1 ISO/F2X X IUF X

A ISO/F3 X IUF X

(1) X X X

II-15to25kg (1) X X X

III-22to36kg (1) X X X

Key of letters used in the table above

(1) = For the CRS which do not carry the

ISO/XX size class identification (A to G), for

the applicable mass group, the car manufac-

turer shall indicate the vehicle specific ISO-

FIX child restraint system(s) recommended

for each position.

• IUF = Suitable for ISOFIX forward child

restraint systems of universal category ap-

proved for use in the mass group.

• X = ISOFIX position not suitable for ISOFIX

child restraint systems in this mass group

and/or this size class.Always follow the directions of the child re-

straint manufacturer when installing your child

restraint. Not all child restraint systems will be

installed as described here. When using a Uni-

versal ISOFIX child restraint system, you can

only use approved child restraint systems with

the marking ECE R44 (release R44/03 or supe-

rior) “Universal ISOFIX”.

To Install An ISOFIX Child Restraint

If the selected seating position has a Switch-

able Automatic Locking Retractor (ALR) seat

belt, stow the seat belt, following the instruc-tions below. See the section “Installing Child

Restraints Using the Vehicle Seat Belt” to

check what type of seat belt each seating

position has.

1. Loosen the adjusters on the lower connec-

tors and on the tether strap of the child

seat so that you can more easily attach the

connectors to the vehicle anchorages.

2. Place the child seat between the lower

anchorages for that seating position. For

some second row seats, you may need to

recline the seat and / or raise the head

restraint to get a better fit. If the rear seat

can be moved forward and rearward in the

SAFETY

108

Page 112 of 276

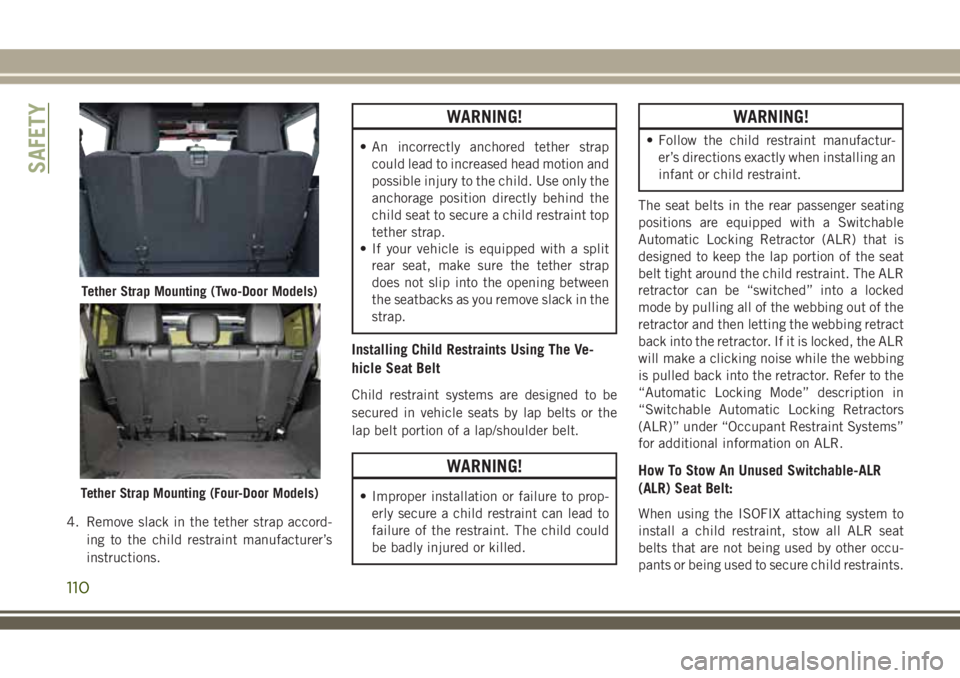

4. Remove slack in the tether strap accord-

ing to the child restraint manufacturer’s

instructions.

WARNING!

• An incorrectly anchored tether strap

could lead to increased head motion and

possible injury to the child. Use only the

anchorage position directly behind the

child seat to secure a child restraint top

tether strap.

• If your vehicle is equipped with a split

rear seat, make sure the tether strap

does not slip into the opening between

the seatbacks as you remove slack in the

strap.

Installing Child Restraints Using The Ve-

hicle Seat Belt

Child restraint systems are designed to be

secured in vehicle seats by lap belts or the

lap belt portion of a lap/shoulder belt.

WARNING!

• Improper installation or failure to prop-

erly secure a child restraint can lead to

failure of the restraint. The child could

be badly injured or killed.

WARNING!

• Follow the child restraint manufactur-

er’s directions exactly when installing an

infant or child restraint.

The seat belts in the rear passenger seating

positions are equipped with a Switchable

Automatic Locking Retractor (ALR) that is

designed to keep the lap portion of the seat

belt tight around the child restraint. The ALR

retractor can be “switched” into a locked

mode by pulling all of the webbing out of the

retractor and then letting the webbing retract

back into the retractor. If it is locked, the ALR

will make a clicking noise while the webbing

is pulled back into the retractor. Refer to the

“Automatic Locking Mode” description in

“Switchable Automatic Locking Retractors

(ALR)” under “Occupant Restraint Systems”

for additional information on ALR.

How To Stow An Unused Switchable-ALR

(ALR) Seat Belt:

When using the ISOFIX attaching system to

install a child restraint, stow all ALR seat

belts that are not being used by other occu-

pants or being used to secure child restraints.

Tether Strap Mounting (Two-Door Models)

Tether Strap Mounting (Four-Door Models)

SAFETY

110

Page 116 of 276

WARNING!

• ONLY use the driver’s side floor mat on

the driver’s side floor area. To check for

interference, with the vehicle properly

parked with the engine off, fully depress

the accelerator, the brake, and the

clutch pedal (if present) to check for

interference. If your floor mat interferes

with the operation of any pedal, or is not

secure to the floor, remove the floor mat

from the vehicle and place the floor mat

in your trunk.

• ONLY use the passenger’s side floor mat

on the passenger’s side floor area.

• ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator,

brake, or clutch pedals and could cause

a loss of vehicle control.

• NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference

WARNING!

with the accelerator, brake, or clutch

pedals.

• If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in thetread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel nuts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under vehicle after overnight

parking for fuel, coolant, oil, or other fluid

leaks. Also, if gasoline fumes are detected or

if fuel, or brake fluid leaks are suspected. The

cause should be located and corrected imme-

diately.

SAFETY

114

Page 118 of 276

TRAILER TOWING...........140

Trailer Towing Weights (Maximum Trailer

Weight Ratings)...............140

RECREATIONAL TOWING (BEHIND

MOTORHOME, ETC.).........142

Towing This Vehicle Behind Another

Vehicle....................142

Recreational Towing — Four-Wheel Drive

Models....................142

STARTING AND OPERATING

116