technical specifications JEEP WRANGLER 2021 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2021, Model line: WRANGLER, Model: JEEP WRANGLER 2021Pages: 276, PDF Size: 4.47 MB

Page 7 of 276

GRAPHICAL TABLE OF CONTENTS

GETTING TO KNOW YOUR VEHICLE

GETTING TO KNOW YOUR INSTRUMENT PANEL

SAFETY

STARTING AND OPERATING

IN CASE OF EMERGENCY

SERVICING AND MAINTENANCE

TECHNICAL SPECIFICATIONS

MULTIMEDIA

CUSTOMER ASSISTANCE

INDEX

Page 159 of 276

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.9. Finish tightening the lug nuts. Push down

on the wrench while tightening for in-

creased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

10. Remove the jack assembly and wheel

blocks.

11. Secure the tire, jack, and tools in their

proper locations.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

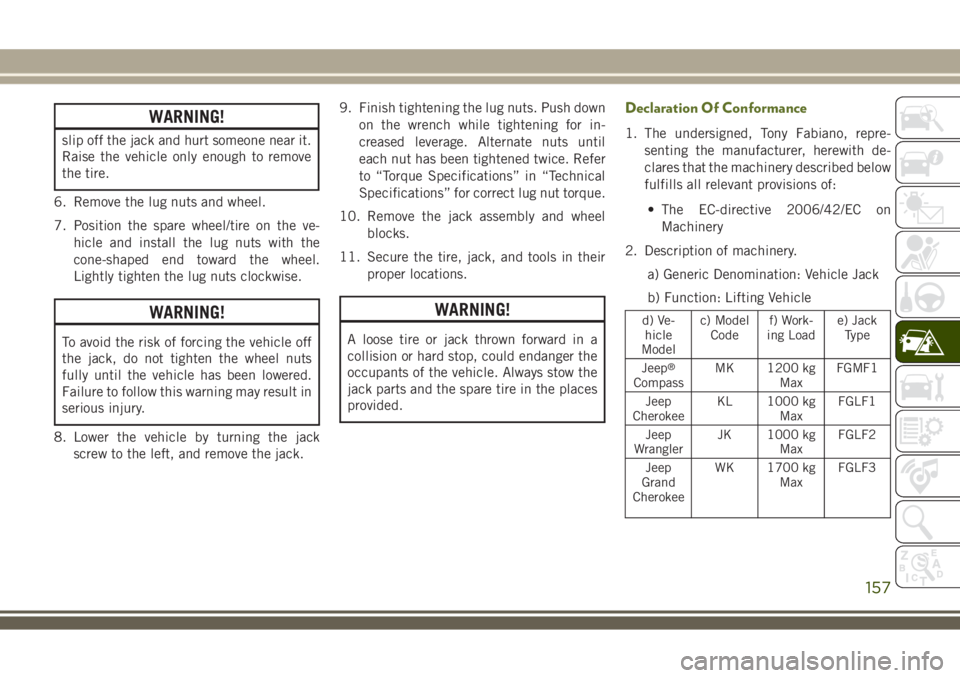

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described below

fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

157

Page 186 of 276

WARNING!

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

WARNING!

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

• Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

Manual Transmission

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 of an inch (4.76 mm) below the

bottom of the hole.

Add fluid, if necessary, to maintain the

proper level.

Automatic Transmission

Fluid Level Check — Gasoline Engine

It is best to check the fluid level when the

transmission is at normal operating tempera-

ture (approximately 180°F/82°C). This oc-

curs after at least 15 miles (25 km) of driv-

ing. At normal operating temperature, the

fluid cannot be held comfortably between the

fingertips.

Use the following procedure to check the

transmission fluid level properly:

1. Park the vehicle on level ground.

2. Remove the engine cover by pulling it up

off the mounting studs (two in the front

and two in the rear).

3. Run the engine at normal idle speed for at

least 60 seconds, and leave the engine

running for the rest of this procedure.

4. Fully apply the parking brake, and press

the brake pedal.

SERVICING AND MAINTENANCE

184

Page 187 of 276

5. Place the gear selector momentarily into

each gear position (allowing time for the

transmission to fully engage in each posi-

tion), ending with the transmission in

PARK.

6. Remove the dipstick, wipe it clean and

reinsert it until seated.

7. Remove the dipstick again and note the

fluid level on both sides. The fluid level

reading is only valid if there is a solid

coating of oil on both sides of the dipstick.

Note that the holes in the dipstick will be

full of fluid if the actual level is at or above

the hole. The fluid level should be be-

tween the HOT (upper) reference holes on

the dipstick at normal operating tempera-

ture. If the fluid level is low, add fluid

through the dipstick tube to bring it to the

proper level.Do not overfill.Use ONLY the

specified fluid (refer to "Fluids And Lubri-

cants" under “Technical Specifications”

for fluid specifications). After adding any

quantity of oil through the dipstick tube,

wait a minimum of two minutes for the oil

to fully drain into the transmission before

rechecking the fluid level.NOTE:

• The holes in the dipstick will be full of

fluid if the actual level is at or above the

hole.

• If it is necessary to check the transmis-

sion below the operating temperature,

the fluid level should be between the

two COLD (lower) holes on the dipstick

with the fluid at approximately 80°F

(27°C). If the fluid level is correctly

established at 80° F (27°C), it should

be between the HOT (upper) reference

holes when the transmission reaches

180° F (82°C). Remember it is best to

check the level at the normal operating

temperature.

CAUTION!

If the fluid temperature is below 50°F

(10°C) it may not register on the dipstick.

Do not add fluid until the temperature is

elevated enough to produce an accurate

reading. Run the engine at idle, in PARK,

to warm the fluid.8. Reinstall the engine cover and snap it

down securely onto the four mounting

studs.

9. Check for leaks. Release the parking

brake.

NOTE:

To prevent dirt and water from entering the

transmission after checking or replenishing

fluid, make sure that the dipstick cap is

properly reseated. It is normal for the dipstick

cap to spring back slightly from its fully

seated position, as long as its seal remains

engaged in the dipstick tube.

Fluid Level Check — 2.8L Turbo Diesel

Engine

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required, therefore the trans-

mission filler tube is capped and no dipstick

is provided. An authorized dealer can check

your transmission fluid level using a special

service dipstick.

185

Page 209 of 276

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION

NUMBER.................208

WHEEL AND TIRE TORQUE

SPECIFICATIONS...........208

Torque Specifications............208

FUEL REQUIREMENTS — GASOLINE

ENGINES.................209

Ethanol....................209

FUEL REQUIREMENTS — DIESEL

ENGINES.................209

FLUID CAPACITIES..........210

FLUIDS AND LUBRICANTS.....210

Engine.....................210

Chassis....................211

MOPAR ACCESSORIES........212

Authentic Accessories And Jeep

Performance Parts By Mopar.......212

TECHNICAL SPECIFICATIONS

207

Page 210 of 276

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN) is

found on the left front corner of the instru-

ment panel pad, visible from outside of the

vehicle through the windshield. This number

also appears underbody, on the right side of

the frame rail near the center of the vehicle,

as well as on the Automobile Information

Disclosure Label affixed to a window on your

vehicle. Save this label for a convenient re-

cord of your vehicle identification number

and optional equipment.

The VIN is also stamped on either right or left

hand side of the engine block.NOTE:

It is illegal to remove or alter the VIN plate.

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lugnuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m)1/2” x 20 19 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

Vehicle Identification NumberTECHNICAL SPECIFICATIONS

208

Page 212 of 276

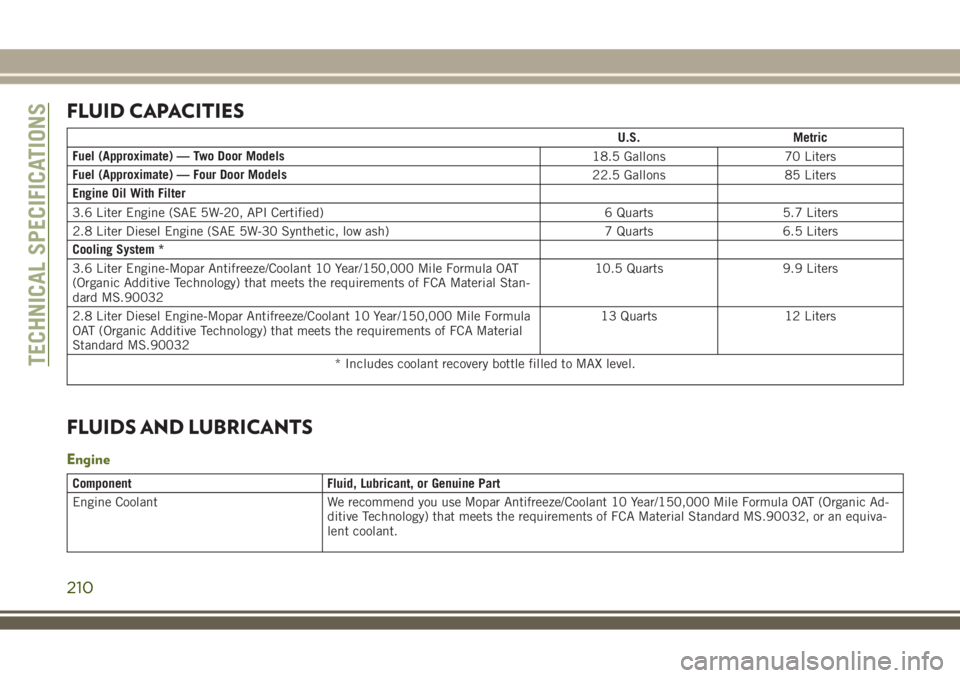

FLUID CAPACITIES

U.S. Metric

Fuel (Approximate) — Two Door Models

18.5 Gallons 70 Liters

Fuel (Approximate) — Four Door Models

22.5 Gallons 85 Liters

Engine Oil With Filter

3.6 Liter Engine (SAE 5W-20, API Certified) 6 Quarts 5.7 Liters

2.8 Liter Diesel Engine (SAE 5W-30 Synthetic, low ash) 7 Quarts 6.5 Liters

Cooling System *

3.6 Liter Engine-Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT

(Organic Additive Technology) that meets the requirements of FCA Material Stan-

dard MS.9003210.5 Quarts 9.9 Liters

2.8 Liter Diesel Engine-Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula

OAT (Organic Additive Technology) that meets the requirements of FCA Material

Standard MS.9003213 Quarts 12 Liters

* Includes coolant recovery bottle filled to MAX level.

FLUIDS AND LUBRICANTS

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT (Organic Ad-

ditive Technology) that meets the requirements of FCA Material Standard MS.90032, or an equiva-

lent coolant.

TECHNICAL SPECIFICATIONS

210

Page 214 of 276

Component Fluid, Lubricant, or Genuine Part

Brake Master Cylinder We recommend you use Mopar DOT 3 Brake Fluid, SAE J1703. If DOT 3,

SAE J1703 brake fluid is not available, then DOT 4 is acceptable.

If using DOT 4 brake fluid, the fluid must be changed every 24 months

regardless of millage.

Power Steering Reservoir We recommend you use Mopar Power Steering Fluid +4, Mopar ATF+4 Au-

tomatic Transmission Fluid.

MOPAR ACCESSORIES

Authentic Accessories And Jeep

Performance Parts By Mopar

• Mopar Accessories and Jeep performance

parts are developed with the same engi-

neering that went into your Wrangler.

Choose these products with confidenceknowing that they have passed the same

rigid standards for function, fit, durability

and performance as your Wrangler.

• For the full line of Authentic Jeep Accesso-

ries by Mopar, visit your local dealership or

online at mopar.com for U.S. residents and

mopar.ca for Canadian residents.NOTE:

All parts are subject to availability.

Chrome:

• Grille • Tubular Side Steps • Tubular Bumpers

• Exhaust Tip • Fuel Door • Tail Lamp Guards

Off Road & Performance:

• Bumpers • Rock Rails • Skid Plates

• Winches • Lift Kits • Lights

• Performance Axles • LED Lights • Tow Hooks

TECHNICAL SPECIFICATIONS

212