light JEEP WRANGLER 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WRANGLER, Model: JEEP WRANGLER 2023Pages: 396, PDF Size: 25.15 MB

Page 339 of 396

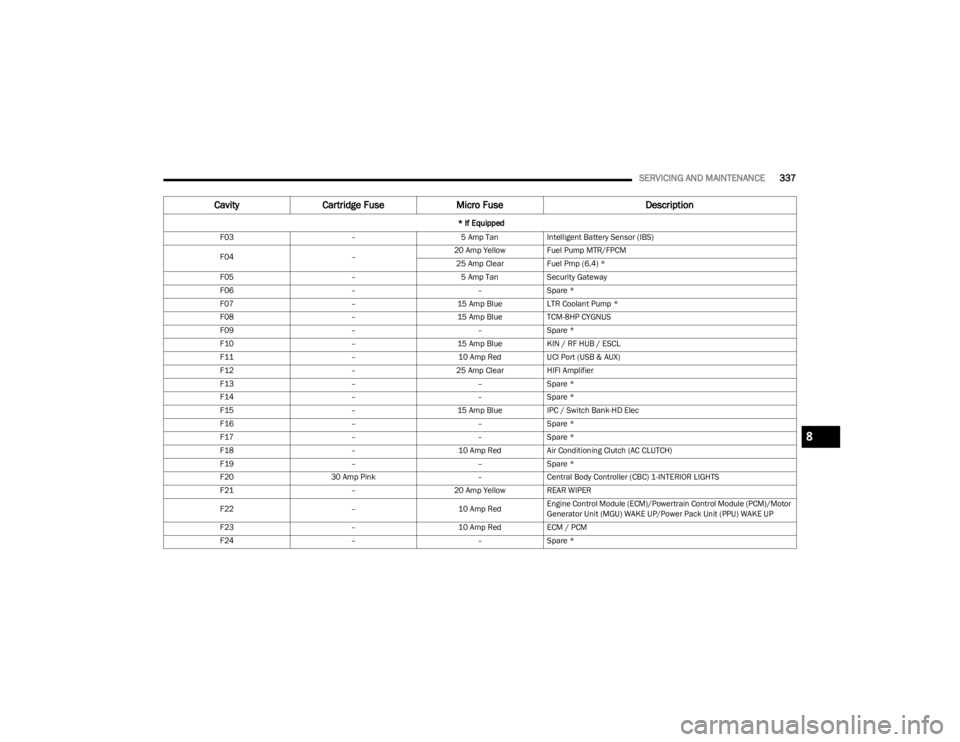

SERVICING AND MAINTENANCE337

F03 –5 Amp TanIntelligent Battery Sensor (IBS)

F04 –20 Amp Yellow Fuel Pump MTR/FPCM

25 Amp Clear Fuel Pmp (6.4) *

F05 –5 Amp TanSecurity Gateway

F06 ––Spare *

F07 –15 Amp BlueLTR Coolant Pump *

F08 –15 Amp BlueTCM-8HP CYGNUS

F09 ––Spare *

F10 –15 Amp BlueKIN / RF HUB / ESCL

F11 –10 Amp RedUCI Port (USB & AUX)

F12 –25 Amp ClearHIFI Amplifier

F13 ––Spare *

F14 ––Spare *

F15 –15 Amp BlueIPC / Switch Bank-HD Elec

F16 ––Spare *

F17 ––Spare *

F18 –10 Amp RedAir Conditioning Clutch (AC CLUTCH)

F19 ––Spare *

F20 30 Amp Pink –Central Body Controller (CBC) 1-INTERIOR LIGHTS

F21 –20 Amp Yellow REAR WIPER

F22 –10 Amp RedEngine Control Module (ECM)/Powertrain Control Module (PCM)/Motor

Generator Unit (MGU) WAKE UP/Power Pack Unit (PPU) WAKE UP

F23 –10 Amp RedECM / PCM

F24 ––Spare *

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

8

23_JL_OM_EN_USC_t.book Page 337

Page 340 of 396

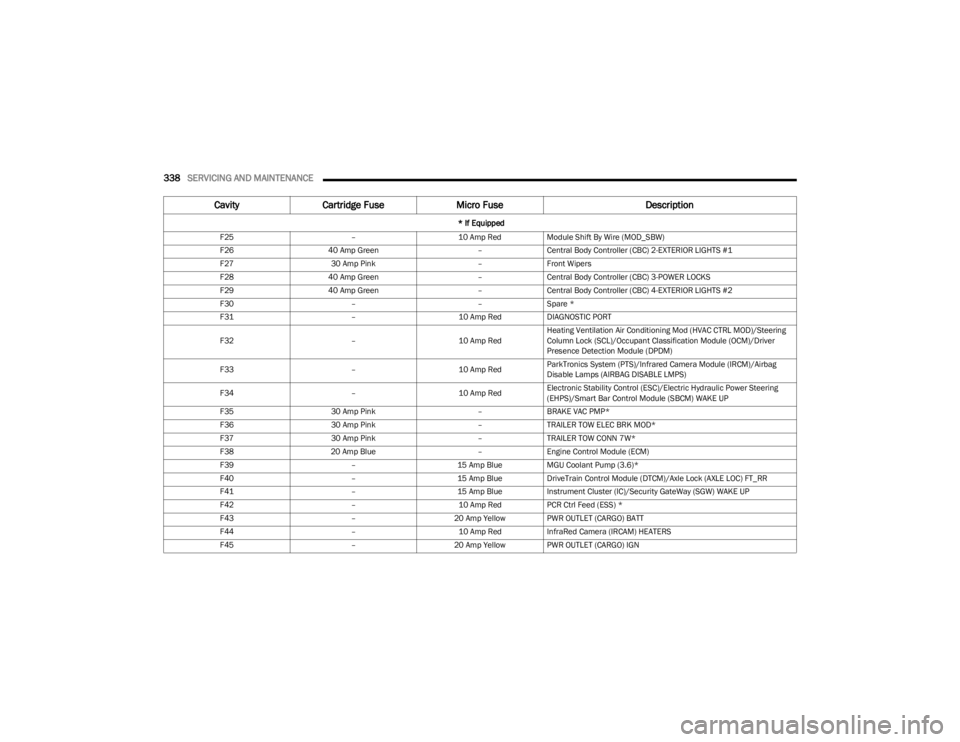

338SERVICING AND MAINTENANCE

F25 –10 Amp RedModule Shift By Wire (MOD_SBW)

F26 40 Amp Green –Central Body Controller (CBC) 2-EXTERIOR LIGHTS #1

F27 30 Amp Pink –Front Wipers

F28 40 Amp Green –Central Body Controller (CBC) 3-POWER LOCKS

F29 40 Amp Green –Central Body Controller (CBC) 4-EXTERIOR LIGHTS #2

F30 ––Spare *

F31 –10 Amp RedDIAGNOSTIC PORT

F32 –10 Amp RedHeating Ventilation Air Conditioning Mod (HVAC CTRL MOD)/Steering

Column Lock (SCL)/Occupant Classification Module (OCM)/Driver

Presence Detection Module (DPDM)

F33 –10 Amp RedParkTronics System (PTS)/Infrared Camera Module (IRCM)/Airbag

Disable Lamps (AIRBAG DISABLE LMPS)

F34 –10 Amp RedElectronic Stability Control (ESC)/Electric Hydraulic Power Steering

(EHPS)/Smart Bar Control Module (SBCM) WAKE UP

F35 30 Amp Pink –BRAKE VAC PMP*

F36 30 Amp Pink –TRAILER TOW ELEC BRK MOD*

F37 30 Amp Pink –TRAILER TOW CONN 7W*

F38 20 Amp Blue –Engine Control Module (ECM)

F39 –15 Amp BlueMGU Coolant Pump (3.6)*

F40 –15 Amp BlueDriveTrain Control Module (DTCM)/Axle Lock (AXLE LOC) FT_RR

F41 –15 Amp BlueInstrument Cluster (IC)/Security GateWay (SGW) WAKE UP

F42 –10 Amp RedPCR Ctrl Feed (ESS) *

F43 –20 Amp Yellow PWR OUTLET (CARGO) BATT

F44 –10 Amp RedInfraRed Camera (IRCAM) HEATERS

F45 –20 Amp Yellow PWR OUTLET (CARGO) IGN

CavityCartridge Fuse Micro Fuse Description

* If Equipped

23_JL_OM_EN_USC_t.book Page 338

Page 346 of 396

344SERVICING AND MAINTENANCE

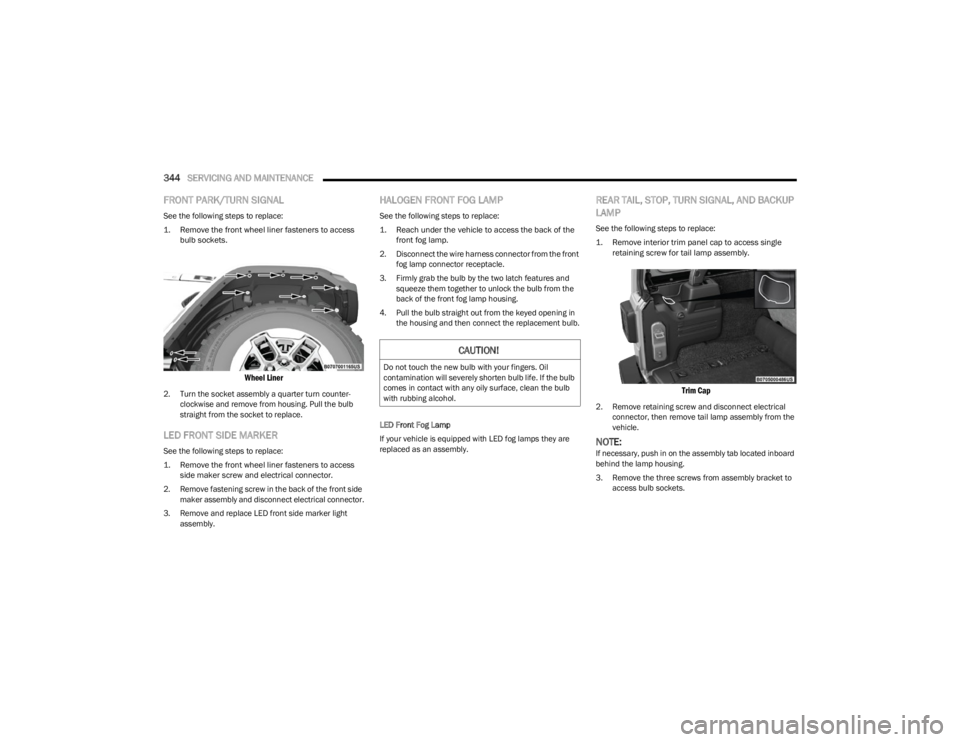

FRONT PARK/TURN SIGNAL

See the following steps to replace:

1. Remove the front wheel liner fasteners to access

bulb sockets.

Wheel Liner

2. Turn the socket assembly a quarter turn counter -

clockwise and remove from housing. Pull the bulb

straight from the socket to replace.

LED FRONT SIDE MARKER

See the following steps to replace:

1. Remove the front wheel liner fasteners to access side maker screw and electrical connector.

2. Remove fastening screw in the back of the front side maker assembly and disconnect electrical connector.

3. Remove and replace LED front side marker light assembly.

HALOGEN FRONT FOG LAMP

See the following steps to replace:

1. Reach under the vehicle to access the back of the front fog lamp.

2. Disconnect the wire harness connector from the front fog lamp connector receptacle.

3. Firmly grab the bulb by the two latch features and squeeze them together to unlock the bulb from the

back of the front fog lamp housing.

4. Pull the bulb straight out from the keyed opening in the housing and then connect the replacement bulb.

LED Front Fog Lamp

If your vehicle is equipped with LED fog lamps they are

replaced as an assembly.

REAR TAIL, STOP, TURN SIGNAL, AND BACKUP

LAMP

See the following steps to replace:

1. Remove interior trim panel cap to access single retaining screw for tail lamp assembly.

Trim Cap

2. Remove retaining screw and disconnect electrical connector, then remove tail lamp assembly from the

vehicle.

NOTE:If necessary, push in on the assembly tab located inboard

behind the lamp housing.

3. Remove the three screws from assembly bracket to access bulb sockets.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the bulb

comes in contact with any oily surface, clean the bulb

with rubbing alcohol.

23_JL_OM_EN_USC_t.book Page 344

Page 348 of 396

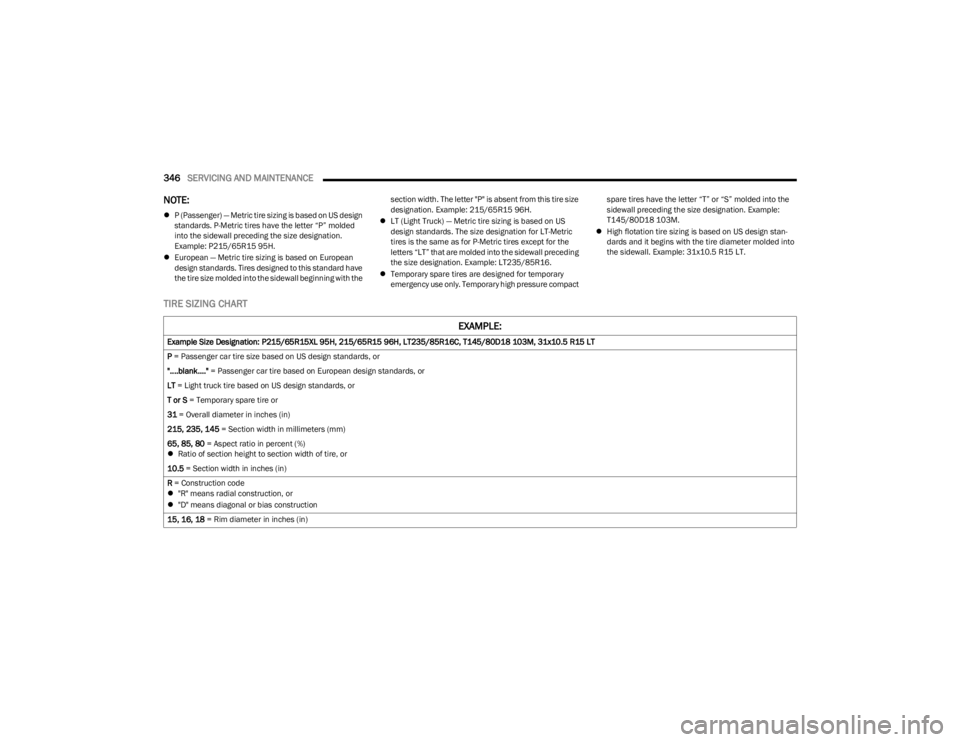

346SERVICING AND MAINTENANCE

NOTE:

P (Passenger) — Metric tire sizing is based on US design

standards. P-Metric tires have the letter “P” molded

into the sidewall preceding the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with the section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on US

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters “LT” that are molded into the sidewall preceding

the size designation. Example: LT235/85R16.

Temporary spare tires are designed for temporary

emergency use only. Temporary high pressure compact spare tires have the letter “T” or “S” molded into the

sidewall preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US design stan -

dards and it begins with the tire diameter molded into

the sidewall. Example: 31x10.5 R15 LT.

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

23_JL_OM_EN_USC_t.book Page 346

Page 349 of 396

SERVICING AND MAINTENANCE347

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls will have the full TIN, including the date code, located

on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as mounted on the vehicle. If the TIN is not found on the outboard side, then you will

find it on the inboard side of the tire.Service Description:

95

= Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and

posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

8

23_JL_OM_EN_USC_t.book Page 347

Page 356 of 396

354SERVICING AND MAINTENANCE

(Continued)

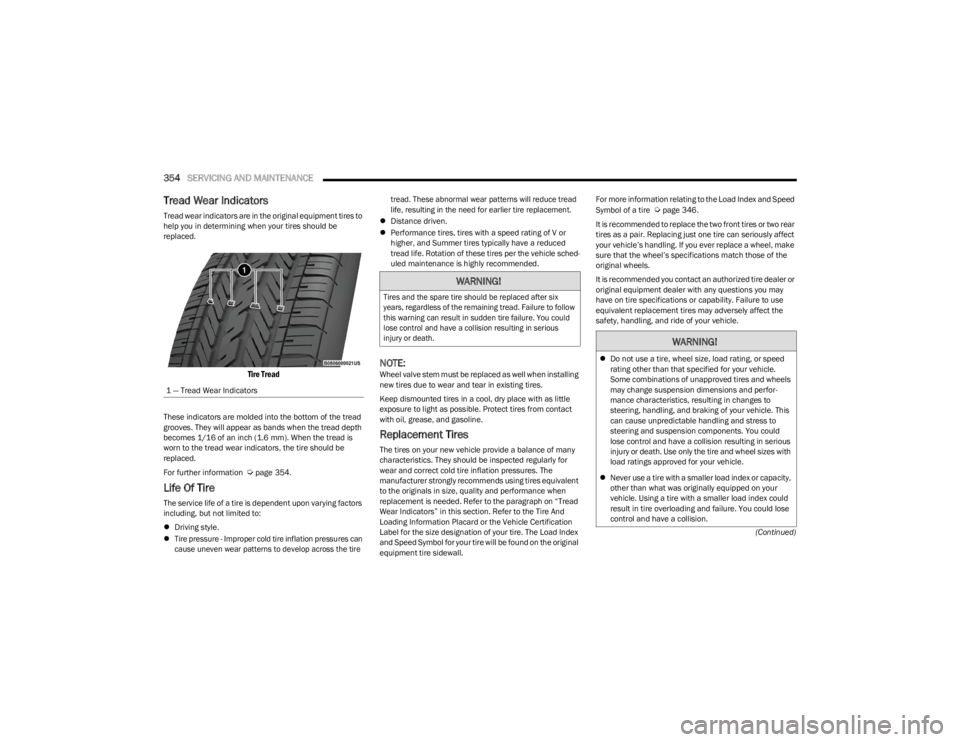

Tread Wear Indicators

Tread wear indicators are in the original equipment tires to

help you in determining when your tires should be

replaced.

Tire Tread

These indicators are molded into the bottom of the tread

grooves. They will appear as bands when the tread depth

becomes 1/16 of an inch (1.6 mm). When the tread is

worn to the tread wear indicators, the tire should be

replaced.

For further information

Úpage 354.

Life Of Tire

The service life of a tire is dependent upon varying factors

including, but not limited to:

Driving style.

Tire pressure - Improper cold tire inflation pressures can

cause uneven wear patterns to develop across the tire tread. These abnormal wear patterns will reduce tread

life, resulting in the need for earlier tire replacement.

Distance driven.

Performance tires, tires with a speed rating of V or

higher, and Summer tires typically have a reduced

tread life. Rotation of these tires per the vehicle sched-

uled maintenance is highly recommended.

NOTE:Wheel valve stem must be replaced as well when installing

new tires due to wear and tear in existing tires.

Keep dismounted tires in a cool, dry place with as little

exposure to light as possible. Protect tires from contact

with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressures. The

manufacturer strongly recommends using tires equivalent

to the originals in size, quality and performance when

replacement is needed. Refer to the paragraph on “Tread

Wear Indicators” in this section. Refer to the Tire And

Loading Information Placard or the Vehicle Certification

Label for the size designation of your tire. The Load Index

and Speed Symbol for your tire will be found on the original

equipment tire sidewall. For more information relating to the Load Index and Speed

Symbol of a tire

Úpage 346.

It is recommended to replace the two front tires or two rear

tires as a pair. Replacing just one tire can seriously affect

your vehicle’s handling. If you ever replace a wheel, make

sure that the wheel’s specifications match those of the

original wheels.

It is recommended you contact an authorized tire dealer or

original equipment dealer with any questions you may

have on tire specifications or capability. Failure to use

equivalent replacement tires may adversely affect the

safety, handling, and ride of your vehicle.

1 — Tread Wear Indicators

WARNING!

Tires and the spare tire should be replaced after six

years, regardless of the remaining tread. Failure to follow

this warning can result in sudden tire failure. You could

lose control and have a collision resulting in serious

injury or death.

WARNING!

Do not use a tire, wheel size, load rating, or speed

rating other than that specified for your vehicle.

Some combinations of unapproved tires and wheels

may change suspension dimensions and perfor -

mance characteristics, resulting in changes to

steering, handling, and braking of your vehicle. This

can cause unpredictable handling and stress to

steering and suspension components. You could

lose control and have a collision resulting in serious

injury or death. Use only the tire and wheel sizes with

load ratings approved for your vehicle.

Never use a tire with a smaller load index or capacity,

other than what was originally equipped on your

vehicle. Using a tire with a smaller load index could

result in tire overloading and failure. You could lose

control and have a collision.

23_JL_OM_EN_USC_t.book Page 354

Page 363 of 396

SERVICING AND MAINTENANCE361

8

BODY AND UNDERBODY MAINTENANCE

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights that are lighter and less susceptible to stone

breakage than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution followed

by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

PRESERVING THE BODYWORK

Washing

Wash your vehicle regularly. Always wash your vehicle

in the shade using Mopar® Car Wash, or a mild car

wash soap and rinse the panels completely with water.

If insects, tar, or other similar deposits have accumu -

lated on your vehicle, use Mopar® Super Kleen Bug

and Tar Remover to remove.

Use a high quality cleaner wax, such as Mopar®

Cleaner Wax to remove road film, stains and to protect

your paint finish. Use precautions to not scratch the

paint.

Avoid using abrasive compounds and power buffing

that may diminish the gloss or thin out the paint finish.

Special Care

If you drive on salted or dusty roads or if you drive near

the ocean, hose off the undercarriage at least once a

month.

It is important that the drain holes in the lower edges of

the doors, rocker panels, and trunk be kept clear and

open.

If you detect any stone chips or scratches in the paint,

touch them up immediately. The cost of such repairs is

considered the responsibility of the owner.

If your vehicle is damaged due to a collision or similar

cause that destroys the paint and protective coating,

have your vehicle repaired as soon as possible. The

cost of such repairs is considered the responsibility of

the owner.

If you carry special cargo such as chemicals, fertilizers,

de-icer salt, etc., be sure that such materials are well

packaged and sealed.

If a lot of driving is done on gravel roads, consider mud

or stone shields behind each wheel.

Use Mopar® Touch Up Paint on scratches as soon as

possible. An authorized dealer has touch up paint to

match the color of your vehicle.

Appearance Care For Fabric Top Models

To maintain the appearance of your vehicle's interior trim

and top, follow these precautions:

Do not run a fabric top through an automatic car wash.

Window scratches and wax build-up may result.

Avoid leaving your vehicle unattended with the top

down, as exposure to sun or rain may damage interior

trim.

Do not use harsh cleaners or bleaching agents on top

material, as damage may result.

Do not allow any vinyl cleaner to run down and dry on

the paint, leaving a streak.

After cleaning your vehicle's fabric top, always make

sure it is completely dry before lowering.

Be especially careful when washing the windows by

following the directions for “Care of Fabric Top

Windows.”

Washing – Use Mopar® Car Wash or equivalent, or mild

soap suds, lukewarm water, and a brush with soft bristles.

If extra cleaning is required, use Mopar® Convertible Cloth

Top Cleaner or equivalent, or a mild foaming cleaner on

the entire top, but support the top from underneath.

Rinsing – Be sure to remove all traces of cleaner by rinsing

the top thoroughly with clean water. Remember to allow

the top to dry before lowering it.CAUTION!

Do not use abrasive or strong cleaning materials

such as steel wool or scouring powder that will

scratch metal and painted surfaces.

Use of power washers exceeding 1,200 psi

(8,274 kPa) can result in damage or removal of paint

and decals.

23_JL_OM_EN_USC_t.book Page 361

Page 364 of 396

362SERVICING AND MAINTENANCE

(Continued)

Care Of Fabric Top Windows

Your vehicle's fabric top has pliable plastic windows which

can be scratched unless special care is taken by following

these directions:

Never use a dry cloth to remove dust. Instead, use a

microfiber towel or soft cotton cloth moistened with

cold or warm, clean water, and wipe across the

window, not up and down. Mopar® Jeep® Soft Glass

Window Cleaner or equivalent will safely clean all

plastic windows without scratching. It removes fine

scratches to improve visibility and provides UV protec -

tion to help prevent yellowing.

When washing, never use hot water or anything

stronger than a mild soap. Never use solvents such as

alcohol or harsh cleaning agents.

Always rinse thoroughly with cold water, then wipe with

a soft and slightly moist, clean cloth.

When removing frost, snow or ice, never use a scraper

or de-icing chemicals. Use warm water only if you must

clean the window quickly.

Debris (sand, mud/dirt, dust, or salt) from off-road

driving will have an impact on plastic retainer opera -

tion. Even normal on-road driving and vehicle washing

will eventually impact window plastic retainer opera -

tion. To maintain ease of use of the window plastic

retainers, each window plastic retainer should be

cleaned and lubricated regularly. Clean them with a

mild soap solution and a small brush. Cleaning prod -

ucts are available through an authorized dealer.

Never paste stickers, gummed labels or any tape to the

windows. Adhesives are hard to remove and may

damage the windows.

INTERIORS

CARPET SAFETY INFORMATION

Always use carpet designed to fit your vehicle. Only use

carpet that does not interfere with the operation of the

pedal assemblies. Only operate the vehicle when the

carpet is securely attached by the grommets so it cannot

slip out of position and interfere with the pedal assemblies

or impair safe operation of your vehicle in other ways.

CAUTION!

Failure to follow these cautions may cause interior

water damage, stains, or mildew of the top material:

Do not run a fabric top through an automatic car

wash. Window scratches and wax build-up may

result.

It is recommended that the top be free of water prior

to opening it. Operating the top, opening a door or

lowering a window while the top is wet may allow

water to drip into the vehicle’s interior.

Use care when washing the vehicle, water pressure

directed at the weather strip seals may cause water

to leak into the vehicle’s interior.

Careless handling and storage of the removable roof

panels may damage the seals, causing water to leak

into the vehicle’s interior.

The front panel(s) must be positioned properly to

ensure sealing. Improper installation can cause

water to leak into the vehicle’s interior.

CAUTION!

Avoid washing with rollers and/or brushes in washing

stations. Wash the vehicle only by hand using neutral

pH detergents; dry it with a wet chamois leather.

Abrasive products and/or polishes should not be

used for cleaning the car.

Bird droppings must be washed off immediately and

thoroughly as the acid they contain is particularly

aggressive.

Avoid (if at all possible) parking the vehicle under

trees; remove vegetable resins immediately as, when

dried, it may only be possible to remove them with

abrasive products and/or polishes, which is highly

inadvisable as they could alter the typical opaque -

ness of the paint.

Do not use pure windshield washer fluid for cleaning

the front windshield and rear window; dilute it to a

minimum of 50% water. Only use pure windshield

washer fluid when strictly necessary due to outside

temperature conditions.

CAUTION!

23_JL_OM_EN_USC_t.book Page 362

Page 369 of 396

SERVICING AND MAINTENANCE367

SEATS AND FABRIC PARTS

Use Mopar® Total Clean to clean fabric upholstery and

carpeting.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

Sun damage can also weaken the fabric.

If the belts need cleaning, use a mild soap solution or

lukewarm water. Do not remove the belts from the vehicle

to wash them. Dry with a soft cloth.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

PLASTIC AND COATED PARTS

Use Mopar® Total Clean to clean vinyl upholstery.

Cleaning Plastic Instrument Cluster

Lenses

The lenses in front of the instruments in this vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

Clean with a wet soft cloth. A mild soap solution may be

used, but do not use high alcohol content or abrasive

cleaners. If soap is used, wipe clean with a clean damp

cloth. Dry with a soft cloth.

LEATHER SURFACES

Mopar® Total Clean is specifically recommended for

leather upholstery.

Your leather upholstery can be best preserved by regular

cleaning with a damp soft cloth. Small particles of dirt can

act as an abrasive and damage the leather upholstery and

should be removed promptly with a damp cloth. Stubborn

soils can be removed easily with a soft cloth and Mopar®

Total Clean. Care should be taken to avoid soaking your leather upholstery with any liquid. Please do not use

polishes, oils, cleaning fluids, solvents, detergents, or

ammonia-based cleaners to clean your leather upholstery.

NOTE:If equipped with light colored leather, it tends to show any

foreign material, dirt, and fabric dye transfer more so than

darker colors. The leather is designed for easy cleaning,

and FCA recommends Mopar® total care leather cleaner

applied on a cloth to clean the leather seats as needed.

GLASS SURFACES

All glass surfaces should be cleaned on a regular basis

with Mopar® Glass Cleaner, or any commercial

household-type glass cleaner. Never use an abrasive type

cleaner. Use caution when cleaning the inside rear

window equipped with electric defrosters or windows

equipped with radio antennas. Do not use scrapers or

other sharp instruments that may scratch the elements.

When cleaning the rearview mirror, spray cleaner on the

towel or cloth that you are using. Do not spray cleaner

directly on the mirror.

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in closed

areas they may cause respiratory harm.

WARNING!

A frayed or torn seat belt could rip apart in a collision

and leave you with no protection. Inspect the seat belt

system periodically, checking for cuts, frays, or loose

parts. Damaged parts must be replaced immediately.

Do not disassemble or modify the seat belt system. If

your vehicle is involved in a collision, or if you have

questions regarding seat belt or retractor conditions,

take your vehicle to an authorized FCA dealer or

authorized FCA Certified Collision Care Program facility

for inspection.

CAUTION!

Direct contact of air fresheners, insect repellents,

suntan lotions, or hand sanitizers to the plastic,

painted, or decorated surfaces of the interior may

cause permanent damage. Wipe away immediately.

Damage caused by these type of products may not

be covered by your New Vehicle Limited Warranty.

CAUTION!

Do not use alcohol and alcohol-based and/or ketone

based cleaning products to clean leather upholstery, as

damage to the upholstery may result.

8

23_JL_OM_EN_USC_t.book Page 367

Page 370 of 396

368

TECHNICAL SPECIFICATIONS

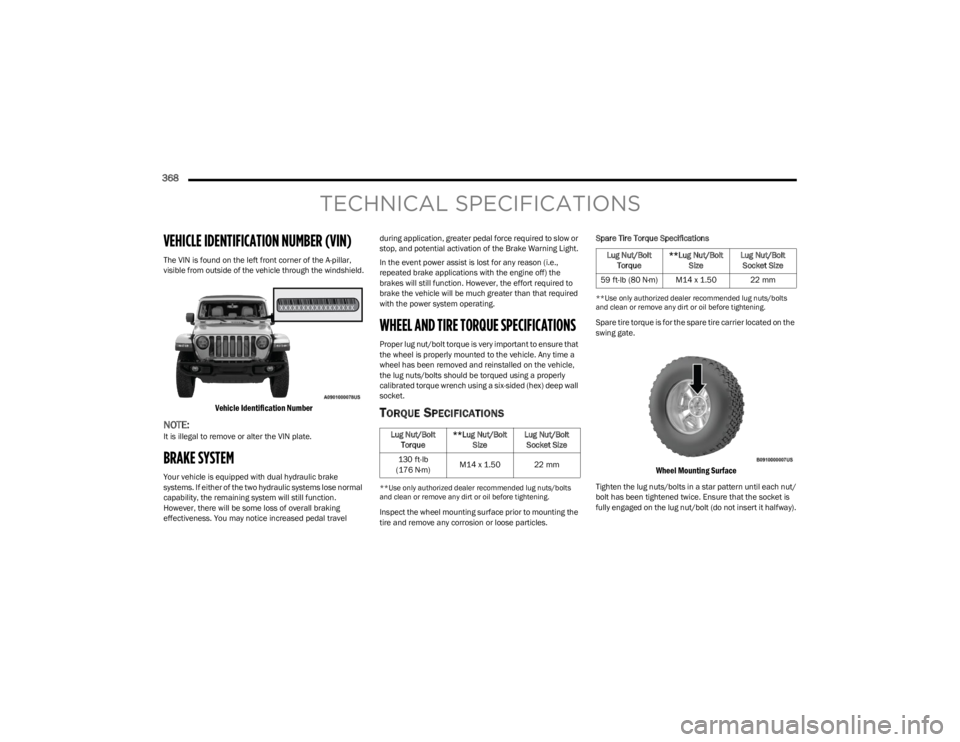

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the A-pillar,

visible from outside of the vehicle through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN plate.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose normal

capability, the remaining system will still function.

However, there will be some loss of overall braking

effectiveness. You may notice increased pedal travel during application, greater pedal force required to slow or

stop, and potential activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repeated brake applications with the engine off) the

brakes will still function. However, the effort required to

brake the vehicle will be much greater than that required

with the power system operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle,

the lug nuts/bolts should be torqued using a properly

calibrated torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/bolts

and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.Spare Tire Torque Specifications

**Use only authorized dealer recommended lug nuts/bolts

and clean or remove any dirt or oil before tightening.

Spare tire torque is for the spare tire carrier located on the

swing gate.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until each nut/

bolt has been tightened twice. Ensure that the socket is

fully engaged on the lug nut/bolt (do not insert it halfway).

Lug Nut/Bolt

Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

130 ft-lb

(176 N·m) M14 x 1.50 22 mm

Lug Nut/Bolt

Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

59 ft-lb (80 N·m) M14 x 1.50 22 mm

23_JL_OM_EN_USC_t.book Page 368