ECO mode JEEP WRANGLER 2023 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WRANGLER, Model: JEEP WRANGLER 2023Pages: 396, PDF Size: 25.15 MB

Page 262 of 396

260SAFETY

The system will be activated when the system detects an

increase in tire pressure while filling the tire. The ignition

must be in the ON/RUN mode with the transmission in

PARK for vehicles equipped with an automatic

transmission. For vehicles equipped with a manual

transmission, the parking brake must be applied.

NOTE:It is not required to have the engine running to enter Tire

Fill Alert mode.

The hazard lamps will come on to confirm the vehicle is in

Tire Fill Alert mode. If the hazard lamps do not come on

while inflating the tire, the Tire Pressure Monitoring

System sensor may be in an inoperative position,

preventing the TPMS sensor signal from being received. In

this case, the vehicle may need to be moved slightly

forward or backward.

When Tire Fill Alert mode is entered, the tire pressure

display screen will be displayed in the instrument cluster.

Operation:

The horn will chirp once to let the user know when to

stop filling the tire, when it reaches recommended

pressure.

The horn will chirp three times if the tire is overfilled

and will continue to chirp every five seconds if the user

continues to inflate the tire.

The horn will chirp once again when enough air is let

out to reach proper inflation level.

The horn will also chirp three times if the tire is then

underinflated and will continue to chirp every five

seconds if the user continues to deflate the tire.

NOTE:The Tire Fill Alert feature is set to “Disabled” every time the

ignition is turned to “OFF”. To re-enable the Tire Fill Alert

feature at the next ignition “RUN” state, the customer

must re-enable the feature through use of the customer

settings in the radio.

SELECTABLE TIRE FILL ALERT (STFA) —

IF EQUIPPED

The STFA system is an optional feature that is included as

part of the normal Tire Fill Alert system. The system is

designed to allow you to select a pressure to inflate or

deflate the vehicle's front and rear axle tires to, and to

provide feedback while inflating or deflating the vehicle's

tires.

NOTE:To use the STFA feature, the Tire Fill Alert feature must be

enabled through use of the customer settings in the radio.

In the Selectable Tire Fill Alert application, which is located

in the apps menu of the Uconnect system, you will be able

to select a pressure setting for both the front and rear axle

tire pressures by scrolling through a pressure range from

XX to 15 psi in 1 psi increments for each axle setting.

XX = the vehicle's cold placard pressure values for the

front and rear axles as shown on the vehicle placard

pressure label.

You may also store pressure values chosen for each axle

in the Uconnect system application as preset pressure

values. Up to two sets of preset pressure values can be

stored in the Uconnect system for the front and rear axle. Once you select the tire pressures for the front and rear

axles that you want to inflate or deflate to, you can begin

inflating or deflating one tire at a time.

NOTE:The STFA system will only support inflating or deflating one

tire at a time.

The system will be activated when the TPMS receiver

module detects a change in tire pressure. The ignition

must be in the ON/RUN mode, with the transmission in

PARK in vehicles with an automatic transmission, and in

NEUTRAL with the parking brake engaged in vehicles with

a manual transmission. The hazard lamps will come on to

confirm the vehicle is in Tire Fill Alert mode.

When Tire Fill Alert mode is entered, the tire pressure

screen will be displayed in the instrument cluster. If the

hazard lamps do not come on while inflating or deflating

the tire, the Tire Pressure Monitoring System sensor may

be in an inoperative position, preventing the TPMS sensor

signal from being received. In this case, the vehicle may

need to be moved slightly forward or backward.

Horn chirps will indicate STFA status as tires are inflated/

deflated. The horn will chirp under the following STFA

states:

1. The horn will chirp once when the selected pressure

is reached to let you know when to stop inflating or

deflating the tire.

2. The horn will chirp three times if the tire is overin -

flated or over-deflated.

3. The horn will chirp once again when enough air is added or removed to reach proper selected pressure

level.

23_JL_OM_EN_USC_t.book Page 260

Page 269 of 396

SAFETY267

SUPPLEMENTAL RESTRAINT SYSTEMS

(SRS)

Some of the safety features described in this section may

be standard equipment on some models, or may be

optional equipment on others. If you are not sure, ask an

authorized dealer.

The air bag system must be ready to protect you in a

collision. The Occupant Restraint Controller (ORC)

monitors the internal circuits and interconnecting wiring

associated with the electrical Air Bag System

Components. Your vehicle may be equipped with the

following Air Bag System Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

Air Bag Warning Light

The Occupant Restraint Controller (ORC)

monitors the readiness of the electronic parts

of the air bag system whenever the ignition

switch is in the START or ON/RUN position. If

the ignition switch is in the OFF position or in the ACC

position, the air bag system is not on and the air bags will

not inflate.

The ORC contains a backup power supply system that may

deploy the air bag system even if the battery loses power

or it becomes disconnected prior to deployment.

The ORC turns on the Air Bag Warning Light in the

instrument panel for approximately four to eight seconds

for a self-check when the ignition switch is first in the ON/

RUN position. After the self-check, the Air Bag Warning

Light will turn off. If the ORC detects a malfunction in any

part of the system, it turns on the Air Bag Warning Light,

either momentarily or continuously. A single chime will

sound to alert you if the light comes on again after initial

startup.

The ORC also includes diagnostics that will illuminate the

instrument panel Air Bag Warning Light if a malfunction is

detected that could affect the air bag system. The

diagnostics also record the nature of the malfunction. While the air bag system is designed to be maintenance

free, if any of the following occurs, have an authorized

dealer service the air bag system immediately.

The Air Bag Warning Light does not come on during the

four to eight seconds when the ignition switch is first in

the ON/RUN position.

The Air Bag Warning Light remains on after the four to

eight-second interval.

The Air Bag Warning Light comes on intermittently or

remains on while driving.

NOTE:If the speedometer, tachometer, or any engine related

gauges are not working, the Occupant Restraint Controller

(ORC) may also be disabled. In this condition the air bags

may not be ready to inflate for your protection. Have an

authorized dealer service the air bag system immediately.

Redundant Air Bag Warning Light

If a fault with the Air Bag Warning Light is

detected, which could affect the Supplemental

Restraint System (SRS), the Redundant Air Bag

Warning Light will illuminate on the instrument

panel. The Redundant Air Bag Warning Light will stay on

Failure to replace the seat belt assembly could

increase the risk of injury in collisions.

Do not use the Automatic Locking Mode to restrain

occupants who are wearing the seat belt or children

who are using booster seats. The locked mode is only

used to install rear-facing or forward-facing child

restraints that have a harness for restraining the

child.

WARNING!

WARNING!

Ignoring the Air Bag Warning Light in your instrument

panel could mean you won’t have the air bag system to

protect you in a collision. If the light does not come on

as a bulb check when the ignition is first turned on,

stays on after you start the vehicle, or if it comes on as

you drive, have an authorized dealer service the air bag

system immediately.

6

23_JL_OM_EN_USC_t.book Page 267

Page 276 of 396

274SAFETY

The following requirements must be strictly followed:

Do not modify the front passenger seat assembly or

components in any way.

Do not use prior or future model year seat covers or

cushions not designated by FCA US LLC for the specific

model being repaired. Always use the correct seat

cover and cushion specified for the vehicle.

Do not replace the seat cover or cushion with an after -

market seat cover or cushion.

Do not add a secondary seat cover or mat.

At no time should any Supplemental Restraint System

(SRS) component or SRS related component or

fastener be modified or replaced with any part except

those which are approved by FCA US LLC.Knee Impact Bolsters

The knee impact bolsters help protect the knees of the

driver and front passenger, and position the front

occupants for improved interaction with the front air bags.

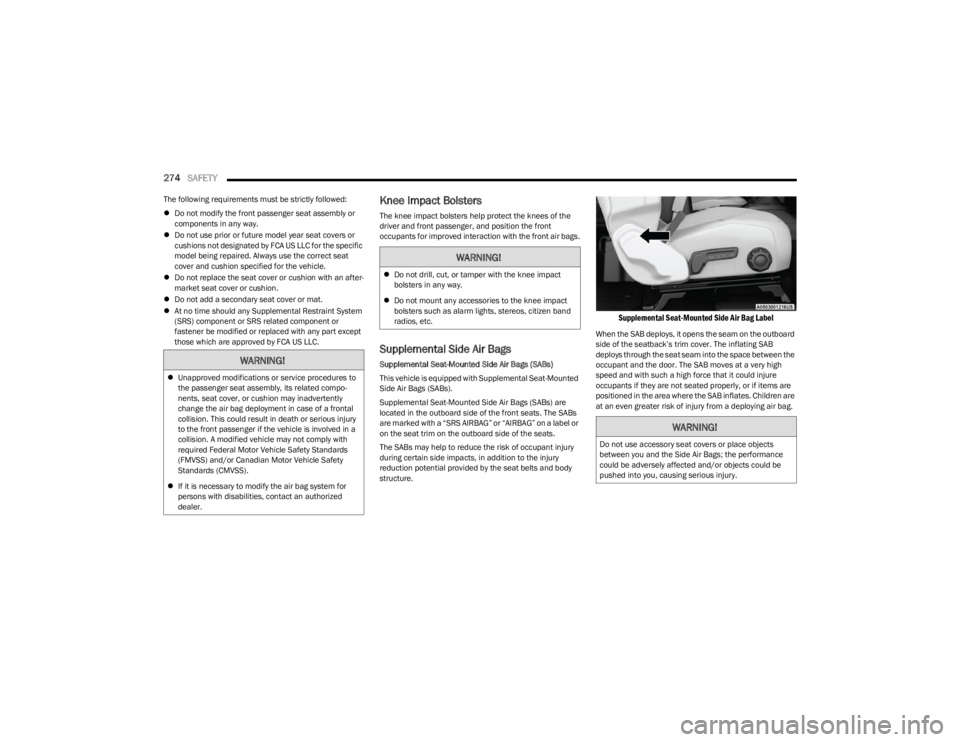

Supplemental Side Air Bags

Supplemental Seat-Mounted Side Air Bags (SABs)

This vehicle is equipped with Supplemental Seat-Mounted

Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags (SABs) are

located in the outboard side of the front seats. The SABs

are marked with a “SRS AIRBAG” or “AIRBAG” on a label or

on the seat trim on the outboard side of the seats.

The SABs may help to reduce the risk of occupant injury

during certain side impacts, in addition to the injury

reduction potential provided by the seat belts and body

structure.

Supplemental Seat-Mounted Side Air Bag Label

When the SAB deploys, it opens the seam on the outboard

side of the seatback’s trim cover. The inflating SAB

deploys through the seat seam into the space between the

occupant and the door. The SAB moves at a very high

speed and with such a high force that it could injure

occupants if they are not seated properly, or if items are

positioned in the area where the SAB inflates. Children are

at an even greater risk of injury from a deploying air bag.

WARNING!

Unapproved modifications or service procedures to

the passenger seat assembly, its related compo -

nents, seat cover, or cushion may inadvertently

change the air bag deployment in case of a frontal

collision. This could result in death or serious injury

to the front passenger if the vehicle is involved in a

collision. A modified vehicle may not comply with

required Federal Motor Vehicle Safety Standards

(FMVSS) and/or Canadian Motor Vehicle Safety

Standards (CMVSS).

If it is necessary to modify the air bag system for

persons with disabilities, contact an authorized

dealer.

WARNING!

Do not drill, cut, or tamper with the knee impact

bolsters in any way.

Do not mount any accessories to the knee impact

bolsters such as alarm lights, stereos, citizen band

radios, etc.

WARNING!

Do not use accessory seat covers or place objects

between you and the Side Air Bags; the performance

could be adversely affected and/or objects could be

pushed into you, causing serious injury.

23_JL_OM_EN_USC_t.book Page 274

Page 286 of 396

284SAFETY

Always follow the directions of the child restraint

manufacturer when installing your child restraint. Not all

child restraint systems will be installed as described here.

To Install A LATCH-Compatible Child

Restraint

If the selected seating position has a Switchable

Automatic Locking Retractor (ALR) seat belt, stow the seat

belt, following the instructions below. See

Úpage 284 to

check what type of seat belt each seating position has.

1. Loosen the adjusters on the lower straps and on the tether strap of the child seat so that you can more

easily attach the hooks or connectors to the vehicle

anchorages.

2. Place the child seat between the lower anchorages for that seating position. If the second row seat can

be reclined, you may recline the seat and/or raise the

head restraint (if adjustable) to get a better fit. If the

rear seat can be moved forward and rearward in the

vehicle, you may wish to move it to its rear-most

position to make room for the child seat. You may

also move the front seat forward to allow more room

for the child seat.

3. Attach the lower hooks or connectors of the child restraint to the lower anchorages in the selected

seating position.

4. If the child restraint has a tether strap, connect it to the top tether anchorage. See

Úpage 287 for

directions to attach a tether anchor.

5. Tighten all of the straps as you push the child restraint rearward and downward into the seat.

Remove slack in the straps according to the child

restraint manufacturer’s instructions. 6. Test that the child restraint is installed tightly by

pulling back and forth on the child seat at the belt

path. It should not move more than 1 inch (25.4 mm) in any direction.

How To Stow An Unused Switchable-ALR

(ALR) Seat Belt:

When using the LATCH attaching system to install a child

restraint, stow all ALR seat belts that are not being used

by other occupants or being used to secure child

restraints. An unused belt could injure a child if they play

with it and accidentally lock the seat belt retractor. Before

installing a child restraint using the LATCH system, buckle

the seat belt behind the child restraint and out of the

child’s reach. If the buckled seat belt interferes with the

child restraint installation, instead of buckling it behind

the child restraint, route the seat belt through the child

restraint belt path and then buckle it. Do not lock the seat

belt. Remind all children in the vehicle that the seat belts

are not toys and that they should not play with them.

Installing Child Restraints Using The

Vehicle Seat Belt

Child restraint systems are designed to be secured in

vehicle seats by lap belts or the lap belt portion of a lap/

shoulder belt.

The seat belts in the passenger seating positions are

equipped with a Switchable Automatic Locking Retractor

(ALR) that is designed to keep the lap portion of the seat

belt tight around the child restraint so that it is not

necessary to use a locking clip. The ALR retractor can be

“switched” into a locked mode by pulling all of the webbing

out of the retractor and then letting the webbing retract

back into the retractor. If it is locked, the ALR will make a

clicking noise while the webbing is pulled back into the

retractor.

Refer to the “Automatic Locking Mode” description in

“Switchable Automatic Locking Retractors (ALR)”

Úpage 265 for additional information on ALR.

Please see the table below and the following sections for

more information.

WARNING!

Improper installation of a child restraint to the LATCH

anchorages can lead to failure of the restraint. The

child could be badly injured or killed. Follow the child

restraint manufacturer’s directions exactly when

installing an infant or child restraint.

Child restraint anchorages are designed to withstand

only those loads imposed by correctly-fitted child

restraints. Under no circumstances are they to be

used for adult seat belts, harnesses, or for attaching

other items or equipment to the vehicle.

WARNING!

Improper installation or failure to properly secure a

child restraint can lead to failure of the restraint. The

child could be badly injured or killed.

Follow the child restraint manufacturer’s directions

exactly when installing an infant or child restraint.

23_JL_OM_EN_USC_t.book Page 284

Page 287 of 396

SAFETY285

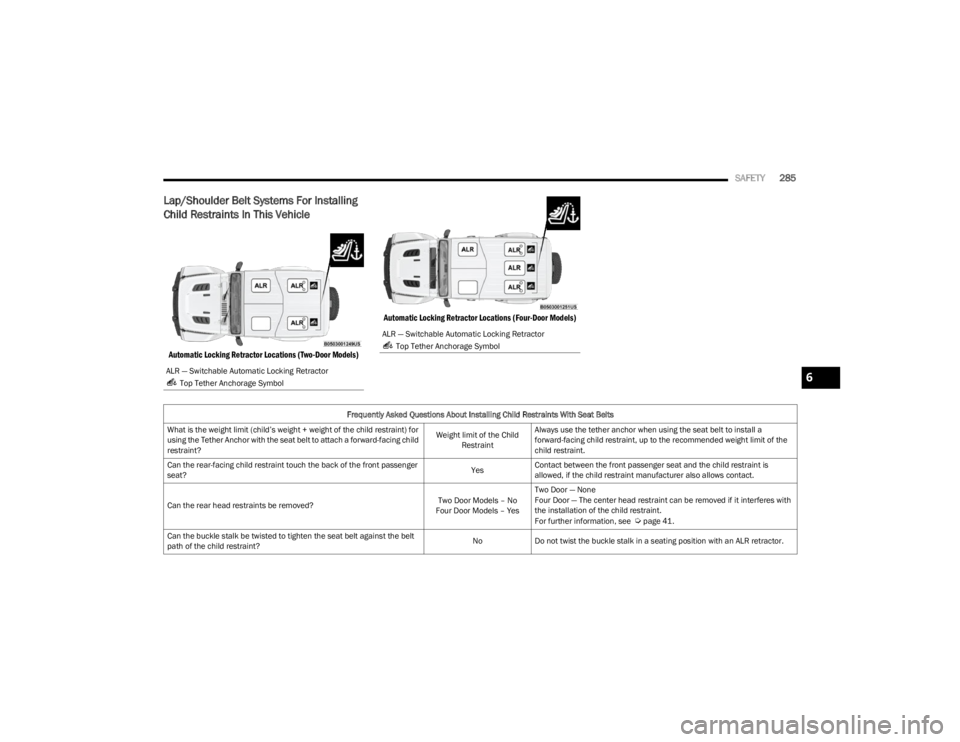

Lap/Shoulder Belt Systems For Installing

Child Restraints In This Vehicle

Automatic Locking Retractor Locations (Two-Door Models) Automatic Locking Retractor Locations (Four-Door Models)

ALR — Switchable Automatic Locking Retractor

Top Tether Anchorage Symbol

ALR — Switchable Automatic Locking Retractor Top Tether Anchorage Symbol

Frequently Asked Questions About Installing Child Restraints With Seat Belts

What is the weight limit (child’s weight + weight of the child restraint) for

using the Tether Anchor with the seat belt to attach a forward-facing child

restraint? Weight limit of the Child

Restraint Always use the tether anchor when using the seat belt to install a

forward-facing child restraint, up to the recommended weight limit of the

child restraint.

Can the rear-facing child restraint touch the back of the front passenger

seat? YesContact between the front passenger seat and the child restraint is

allowed, if the child restraint manufacturer also allows contact.

Can the rear head restraints be removed? Two Door Models – No

Four Door Models – Yes Two Door — None

Four Door — The center head restraint can be removed if it interferes with

the installation of the child restraint.

For further information, see

Úpage 41.

Can the buckle stalk be twisted to tighten the seat belt against the belt

path of the child restraint? No

Do not twist the buckle stalk in a seating position with an ALR retractor.

6

23_JL_OM_EN_USC_t.book Page 285

Page 288 of 396

286SAFETY

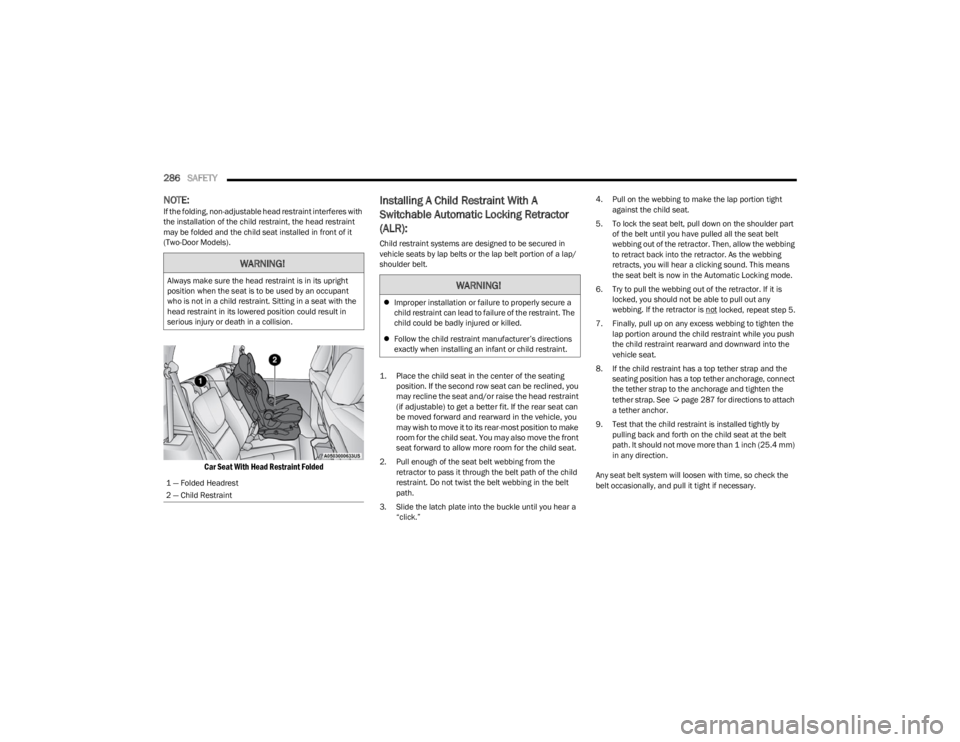

NOTE:If the folding, non-adjustable head restraint interferes with

the installation of the child restraint, the head restraint

may be folded and the child seat installed in front of it

(Two-Door Models).

Car Seat With Head Restraint Folded

Installing A Child Restraint With A

Switchable Automatic Locking Retractor

(ALR):

Child restraint systems are designed to be secured in

vehicle seats by lap belts or the lap belt portion of a lap/

shoulder belt.

1. Place the child seat in the center of the seating

position. If the second row seat can be reclined, you

may recline the seat and/or raise the head restraint

(if adjustable) to get a better fit. If the rear seat can

be moved forward and rearward in the vehicle, you

may wish to move it to its rear-most position to make

room for the child seat. You may also move the front

seat forward to allow more room for the child seat.

2. Pull enough of the seat belt webbing from the retractor to pass it through the belt path of the child

restraint. Do not twist the belt webbing in the belt

path.

3. Slide the latch plate into the buckle until you hear a “click.” 4. Pull on the webbing to make the lap portion tight

against the child seat.

5. To lock the seat belt, pull down on the shoulder part of the belt until you have pulled all the seat belt

webbing out of the retractor. Then, allow the webbing

to retract back into the retractor. As the webbing

retracts, you will hear a clicking sound. This means

the seat belt is now in the Automatic Locking mode.

6. Try to pull the webbing out of the retractor. If it is locked, you should not be able to pull out any

webbing. If the retractor is not

locked, repeat step 5.

7. Finally, pull up on any excess webbing to tighten the lap portion around the child restraint while you push

the child restraint rearward and downward into the

vehicle seat.

8. If the child restraint has a top tether strap and the seating position has a top tether anchorage, connect

the tether strap to the anchorage and tighten the

tether strap. See

Úpage 287 for directions to attach

a tether anchor.

9. Test that the child restraint is installed tightly by pulling back and forth on the child seat at the belt

path. It should not move more than 1 inch (25.4 mm) in any direction.

Any seat belt system will loosen with time, so check the

belt occasionally, and pull it tight if necessary.

WARNING!

Always make sure the head restraint is in its upright

position when the seat is to be used by an occupant

who is not in a child restraint. Sitting in a seat with the

head restraint in its lowered position could result in

serious injury or death in a collision.

1 — Folded Headrest

2 — Child RestraintWARNING!

Improper installation or failure to properly secure a

child restraint can lead to failure of the restraint. The

child could be badly injured or killed.

Follow the child restraint manufacturer’s directions

exactly when installing an infant or child restraint.

23_JL_OM_EN_USC_t.book Page 286

Page 291 of 396

SAFETY289

(Continued)

Air Bag Warning Light

The Air Bag Warning Light will turn on for four to

eight seconds as a bulb check when the

ignition switch is first placed in the ON/RUN

position. If the light is either not on during

starting, stays on, or turns on while driving, have the

system inspected at an authorized dealer as soon as

possible. This light will illuminate with a single chime when

a fault with the Air Bag Warning Light has been detected,

it will stay on until the fault is removed. If the light comes

on intermittently or remains on while driving, have an

authorized dealer service the vehicle immediately. See

Úpage 261 for further information.

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield. See an

authorized dealer for service if your defroster is

inoperable.

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle. Only use

a floor mat that does not interfere with the operation of the

pedal assemblies. Only use a floor mat that is securely

attached using the floor mat fasteners so it cannot slip out

of position and interfere with the pedal assemblies or

impair safe operation of your vehicle in other ways.

WARNING!

An improperly attached, damaged, folded, or stacked

floor mat, or damaged floor mat fasteners may cause

your floor mat to interfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle control. To

prevent SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT install

your floor mat upside down or turn your floor

mat over. Lightly pull to confirm mat is

secured using the floor mat fasteners on a regular basis.

ALWAYS REMOVE THE EXISTING FLOOR

MAT FROM THE VEHICLE before installing

any other floor mat. NEVER install or stack an

additional floor mat on top of an existing floor

mat.

ONLY install floor mats designed to fit your vehicle.

NEVER install a floor mat that cannot be properly

attached and secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA approved floor

mat for the specific make, model, and year of your

vehicle.

ONLY use the driver’s side floor mat on the driver’s

side floor area. To check for interference, with the

vehicle properly parked with the engine off, fully

depress the accelerator, the brake, and the clutch

pedal (if present) to check for interference. If your

floor mat interferes with the operation of any pedal, or

is not secure to the floor, remove the floor mat from

the vehicle and place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on the

passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the floor mat (e.g.,

towels, keys, etc.). These objects could change the

position of the floor mat and may cause interference

with the accelerator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

6

23_JL_OM_EN_USC_t.book Page 289

Page 304 of 396

302IN CASE OF EMERGENCY

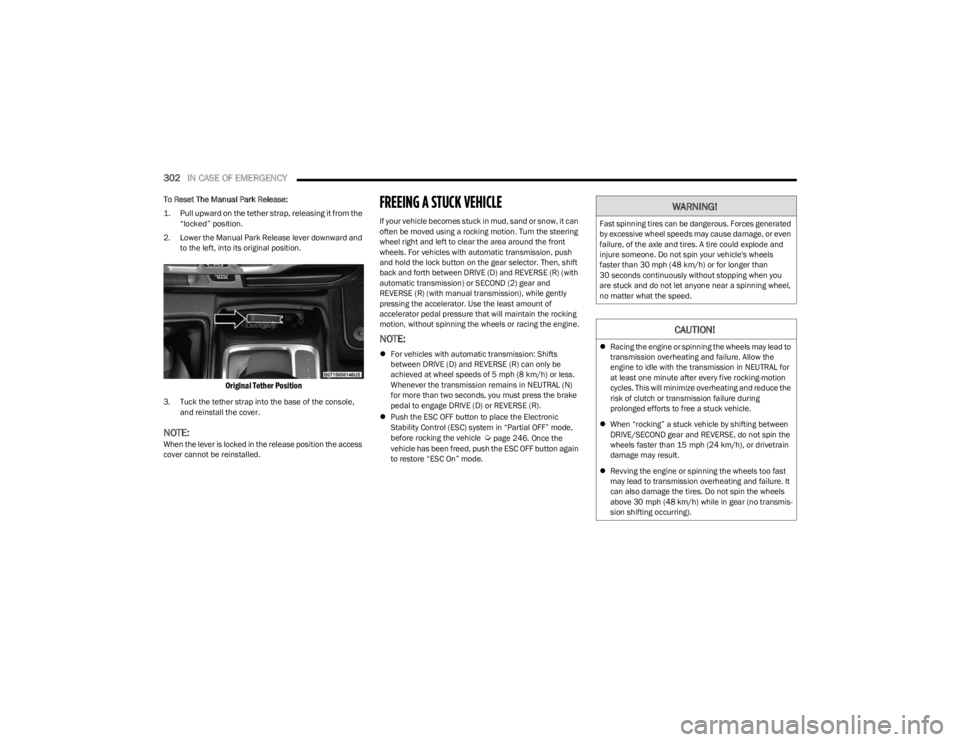

To Reset The Manual Park Release:

1. Pull upward on the tether strap, releasing it from the

“locked” position.

2. Lower the Manual Park Release lever downward and to the left, into its original position.

Original Tether Position

3. Tuck the tether strap into the base of the console, and reinstall the cover.

NOTE:When the lever is locked in the release position the access

cover cannot be reinstalled.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it can

often be moved using a rocking motion. Turn the steering

wheel right and left to clear the area around the front

wheels. For vehicles with automatic transmission, push

and hold the lock button on the gear selector. Then, shift

back and forth between DRIVE (D) and REVERSE (R) (with

automatic transmission) or SECOND (2) gear and

REVERSE (R) (with manual transmission), while gently

pressing the accelerator. Use the least amount of

accelerator pedal pressure that will maintain the rocking

motion, without spinning the wheels or racing the engine.

NOTE:

For vehicles with automatic transmission: Shifts

between DRIVE (D) and REVERSE (R) can only be

achieved at wheel speeds of 5 mph (8 km/h) or less.

Whenever the transmission remains in NEUTRAL (N)

for more than two seconds, you must press the brake

pedal to engage DRIVE (D) or REVERSE (R).

Push the ESC OFF button to place the Electronic

Stability Control (ESC) system in “Partial OFF” mode,

before rocking the vehicle

Úpage 246. Once the

vehicle has been freed, push the ESC OFF button again

to restore “ESC On” mode.

WARNING!

Fast spinning tires can be dangerous. Forces generated

by excessive wheel speeds may cause damage, or even

failure, of the axle and tires. A tire could explode and

injure someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer than

30 seconds continuously without stopping when you

are stuck and do not let anyone near a spinning wheel,

no matter what the speed.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the

engine to idle with the transmission in NEUTRAL for

at least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce the

risk of clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

When “rocking” a stuck vehicle by shifting between

DRIVE/SECOND gear and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or drivetrain

damage may result.

Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure. It

can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmis -

sion shifting occurring).

23_JL_OM_EN_USC_t.book Page 302

Page 305 of 396

IN CASE OF EMERGENCY303

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

If the transmission and drivetrain are operable, disabled 4x4 vehicles may also be towed as described

Úpage 176.

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equipment

manufacturer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to

main structural members of the vehicle, not to fascia/

bumpers or associated brackets. State and local laws

regarding vehicles under tow must be observed.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

position, not the ACC position.

If the vehicle's battery is discharged, instructions on

shifting the automatic transmission out of PARK (P) in

order to move the vehicle

Úpage 301.

FOUR–WHEEL DRIVE MODELS

FCA US LLC recommends towing with all wheels OFF the

ground. Acceptable methods are to tow the vehicle on a

flatbed or with one end of the vehicle raised and the

opposite end on a towing dolly.

If flatbed equipment is not available and the transfer case

is operable, the vehicle may be towed (in the forward

direction, with ALL wheels on the ground), IF the transfer

case is in NEUTRAL (N) and the transmission is in PARK (P)

(for automatic transmissions) or in gear NOT in NEUTRAL ,

for manual transmissions)

Úpage 176.

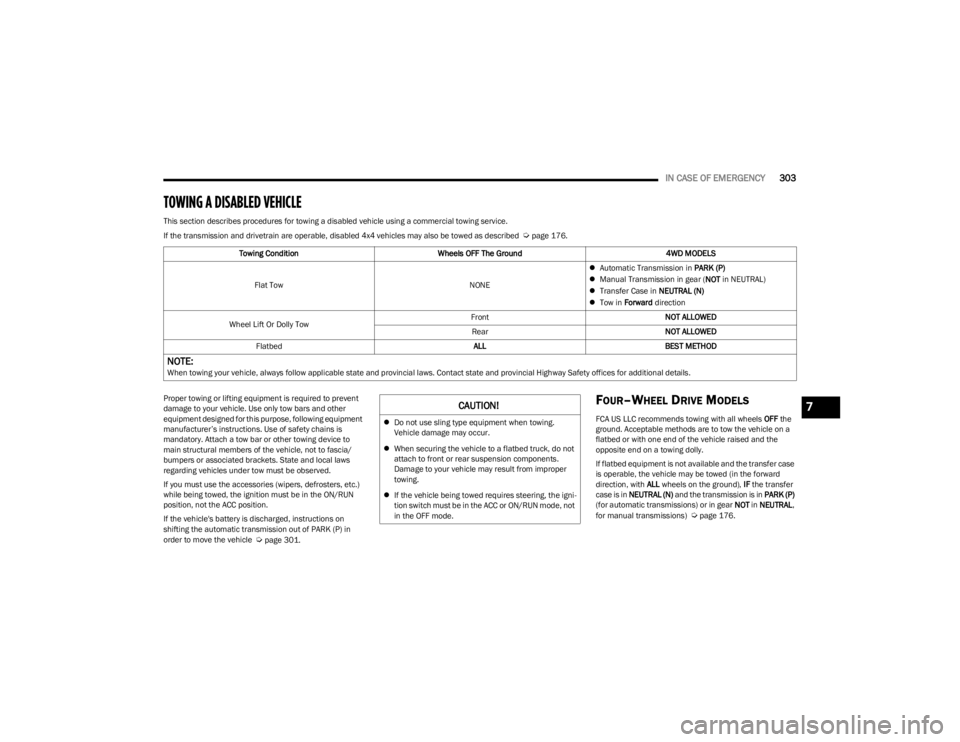

Towing Condition

Wheels OFF The Ground 4WD MODELS

Flat Tow NONE

Automatic Transmission in PARK (P)

Manual Transmission in gear ( NOT in NEUTRAL)

Transfer Case in NEUTRAL (N)

Tow in Forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear NOT ALLOWED

Flatbed ALLBEST METHOD

NOTE:When towing your vehicle, always follow applicable state and provincial laws. Contact state and provincial Highway Safety offices for additional details.

CAUTION!

Do not use sling type equipment when towing.

Vehicle damage may occur.

When securing the vehicle to a flatbed truck, do not

attach to front or rear suspension components.

Damage to your vehicle may result from improper

towing.

If the vehicle being towed requires steering, the igni -

tion switch must be in the ACC or ON/RUN mode, not

in the OFF mode.

7

23_JL_OM_EN_USC_t.book Page 303

Page 306 of 396

304IN CASE OF EMERGENCY

(Continued)

WITHOUT THE KEY FOB

Special care must be taken when the vehicle is towed with

the ignition in the OFF mode. The only approved method of

towing without the key fob is with a flatbed truck. Proper

towing equipment is necessary to prevent damage to the

vehicle.

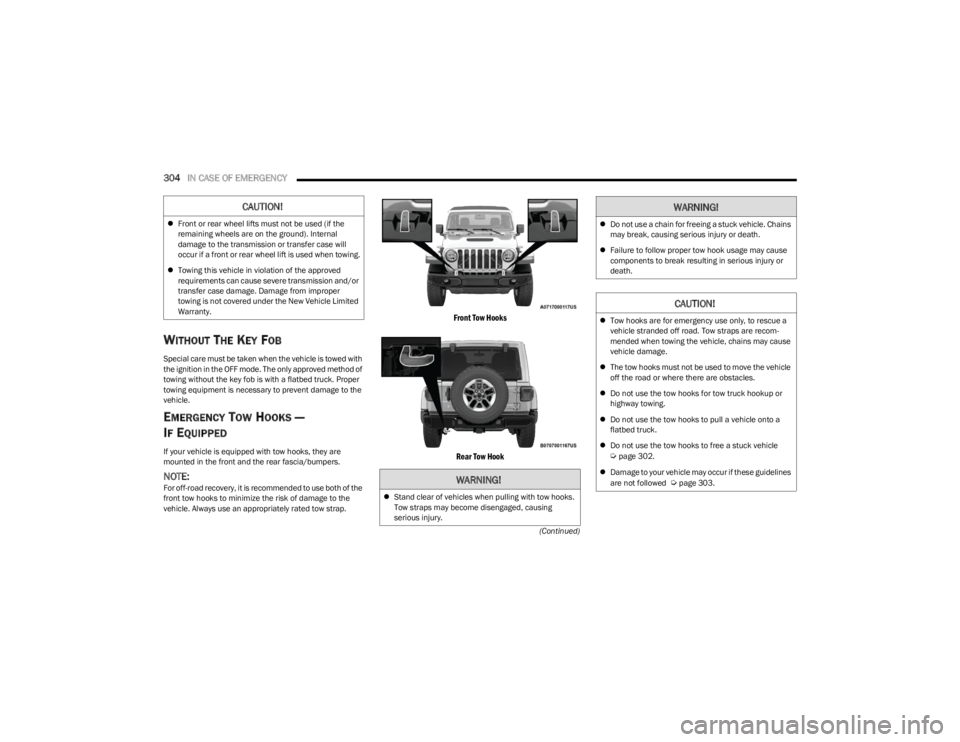

EMERGENCY TOW HOOKS —

I

F EQUIPPED

If your vehicle is equipped with tow hooks, they are

mounted in the front and the rear fascia/bumpers.

NOTE:For off-road recovery, it is recommended to use both of the

front tow hooks to minimize the risk of damage to the

vehicle. Always use an appropriately rated tow strap.

Front Tow Hooks

Rear Tow Hook

CAUTION!

Front or rear wheel lifts must not be used (if the

remaining wheels are on the ground). Internal

damage to the transmission or transfer case will

occur if a front or rear wheel lift is used when towing.

Towing this vehicle in violation of the approved

requirements can cause severe transmission and/or

transfer case damage. Damage from improper

towing is not covered under the New Vehicle Limited

Warranty.

WARNING!

Stand clear of vehicles when pulling with tow hooks.

Tow straps may become disengaged, causing

serious injury.

Do not use a chain for freeing a stuck vehicle. Chains

may break, causing serious injury or death.

Failure to follow proper tow hook usage may cause

components to break resulting in serious injury or

death.

CAUTION!

Tow hooks are for emergency use only, to rescue a

vehicle stranded off road. Tow straps are recom -

mended when towing the vehicle, chains may cause

vehicle damage.

The tow hooks must not be used to move the vehicle

off the road or where there are obstacles.

Do not use the tow hooks for tow truck hookup or

highway towing.

Do not use the tow hooks to pull a vehicle onto a

flatbed truck.

Do not use the tow hooks to free a stuck vehicle

Úpage 302.

Damage to your vehicle may occur if these guidelines

are not followed

Úpage 303.

WARNING!

23_JL_OM_EN_USC_t.book Page 304