service interval JEEP WRANGLER 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WRANGLER, Model: JEEP WRANGLER 2023Pages: 396, PDF Size: 25.15 MB

Page 269 of 396

SAFETY267

SUPPLEMENTAL RESTRAINT SYSTEMS

(SRS)

Some of the safety features described in this section may

be standard equipment on some models, or may be

optional equipment on others. If you are not sure, ask an

authorized dealer.

The air bag system must be ready to protect you in a

collision. The Occupant Restraint Controller (ORC)

monitors the internal circuits and interconnecting wiring

associated with the electrical Air Bag System

Components. Your vehicle may be equipped with the

following Air Bag System Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

Air Bag Warning Light

The Occupant Restraint Controller (ORC)

monitors the readiness of the electronic parts

of the air bag system whenever the ignition

switch is in the START or ON/RUN position. If

the ignition switch is in the OFF position or in the ACC

position, the air bag system is not on and the air bags will

not inflate.

The ORC contains a backup power supply system that may

deploy the air bag system even if the battery loses power

or it becomes disconnected prior to deployment.

The ORC turns on the Air Bag Warning Light in the

instrument panel for approximately four to eight seconds

for a self-check when the ignition switch is first in the ON/

RUN position. After the self-check, the Air Bag Warning

Light will turn off. If the ORC detects a malfunction in any

part of the system, it turns on the Air Bag Warning Light,

either momentarily or continuously. A single chime will

sound to alert you if the light comes on again after initial

startup.

The ORC also includes diagnostics that will illuminate the

instrument panel Air Bag Warning Light if a malfunction is

detected that could affect the air bag system. The

diagnostics also record the nature of the malfunction. While the air bag system is designed to be maintenance

free, if any of the following occurs, have an authorized

dealer service the air bag system immediately.

The Air Bag Warning Light does not come on during the

four to eight seconds when the ignition switch is first in

the ON/RUN position.

The Air Bag Warning Light remains on after the four to

eight-second interval.

The Air Bag Warning Light comes on intermittently or

remains on while driving.

NOTE:If the speedometer, tachometer, or any engine related

gauges are not working, the Occupant Restraint Controller

(ORC) may also be disabled. In this condition the air bags

may not be ready to inflate for your protection. Have an

authorized dealer service the air bag system immediately.

Redundant Air Bag Warning Light

If a fault with the Air Bag Warning Light is

detected, which could affect the Supplemental

Restraint System (SRS), the Redundant Air Bag

Warning Light will illuminate on the instrument

panel. The Redundant Air Bag Warning Light will stay on

Failure to replace the seat belt assembly could

increase the risk of injury in collisions.

Do not use the Automatic Locking Mode to restrain

occupants who are wearing the seat belt or children

who are using booster seats. The locked mode is only

used to install rear-facing or forward-facing child

restraints that have a harness for restraining the

child.

WARNING!

WARNING!

Ignoring the Air Bag Warning Light in your instrument

panel could mean you won’t have the air bag system to

protect you in a collision. If the light does not come on

as a bulb check when the ignition is first turned on,

stays on after you start the vehicle, or if it comes on as

you drive, have an authorized dealer service the air bag

system immediately.

6

23_JL_OM_EN_USC_t.book Page 267

Page 308 of 396

306

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures will influence when the “Change

Oil” or “Oil Change Required” message is displayed. Have

your vehicle serviced as soon as possible, within the next

500 miles (805 km).On vehicles equipped with instrument cluster display, “Oil

Change Required” will be displayed and a single chime will

sound, indicating that an oil change is necessary.

On non-instrument cluster display equipped vehicles,

“Change Oil” will flash in the instrument cluster odometer

and a single chime will sound, indicating that an oil

change is necessary.

An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

an authorized dealer, the message can be reset by

referring to the steps described under Instrument Cluster

Display for further information

Úpage 108.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km), 12 months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers.

Once A Month Or Before A Long Trip:

Check the engine oil level.

Check the windshield washer fluid level.

Check the tire inflation pressures and look for unusual

wear or damage, rotate at the first sign of irregular

wear.

Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering, and fill as needed.

Check the function of all interior and exterior lights.

23_JL_OM_EN_USC_t.book Page 306

Page 311 of 396

SERVICING AND MAINTENANCE309

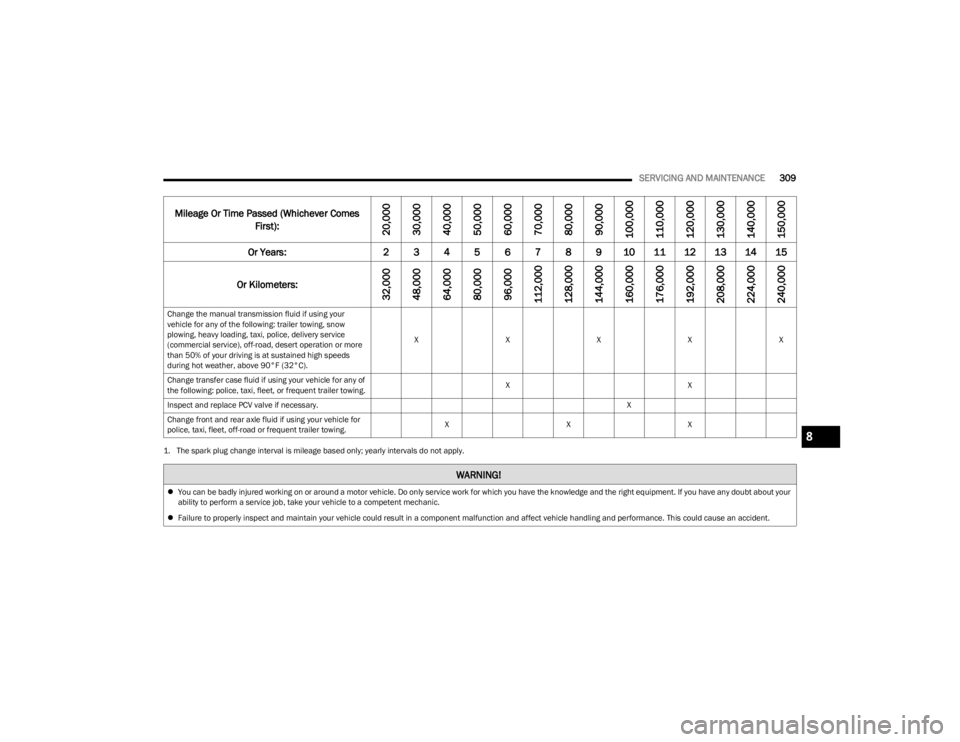

Change the manual transmission fluid if using your

vehicle for any of the following: trailer towing, snow

plowing, heavy loading, taxi, police, delivery service

(commercial service), off-road, desert operation or more

than 50% of your driving is at sustained high speeds

during hot weather, above 90°F (32°C). X

XXXX

Change transfer case fluid if using your vehicle for any of

the following: police, taxi, fleet, or frequent trailer towing. X

X

Inspect and replace PCV valve if necessary. X

Change front and rear axle fluid if using your vehicle for

police, taxi, fleet, off-road or frequent trailer towing. X

XX

1. The spark plug change interval is mileage based only; yearly intervals do not apply.

Mileage Or Time Passed (Whichever Comes

First):

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your

ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause an accident.

8

23_JL_OM_EN_USC_t.book Page 309

Page 312 of 396

310SERVICING AND MAINTENANCE

SCHEDULED SERVICING — DIESEL ENGINE

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next 500 miles

(805 km).

An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

an authorized dealer, to reset the message

Úpage 108.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km) or 12 months,

whichever comes first.

Engine Oil Filter Replacement

Residual oil in the housing may spill from the housing

when the new filter is installed if the residual oil is not

either removed from the housing or enough time has not

elapsed to allow the oil to drain back into the engine.

When servicing the oil filter on this engine, open the filter

cap approximately six turns until the cap o-ring is visible

and stop. Wait five minutes with the cap in this position to

allow dirty engine oil to drain back into the engine. After

five minutes, the cap and filter assembly can be removed

and discarded. When installing the new oil filter cartridge

assembly, ensure the cap is tightened to the specified

torque to prevent low oil pressure conditions. Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire pressures and look for unusual wear or

damage

Check the fluid levels of the coolant reservoir, brake

master cylinder, and fill as needed

Check function of all interior and exterior lights

23_JL_OM_EN_USC_t.book Page 310

Page 315 of 396

SERVICING AND MAINTENANCE313

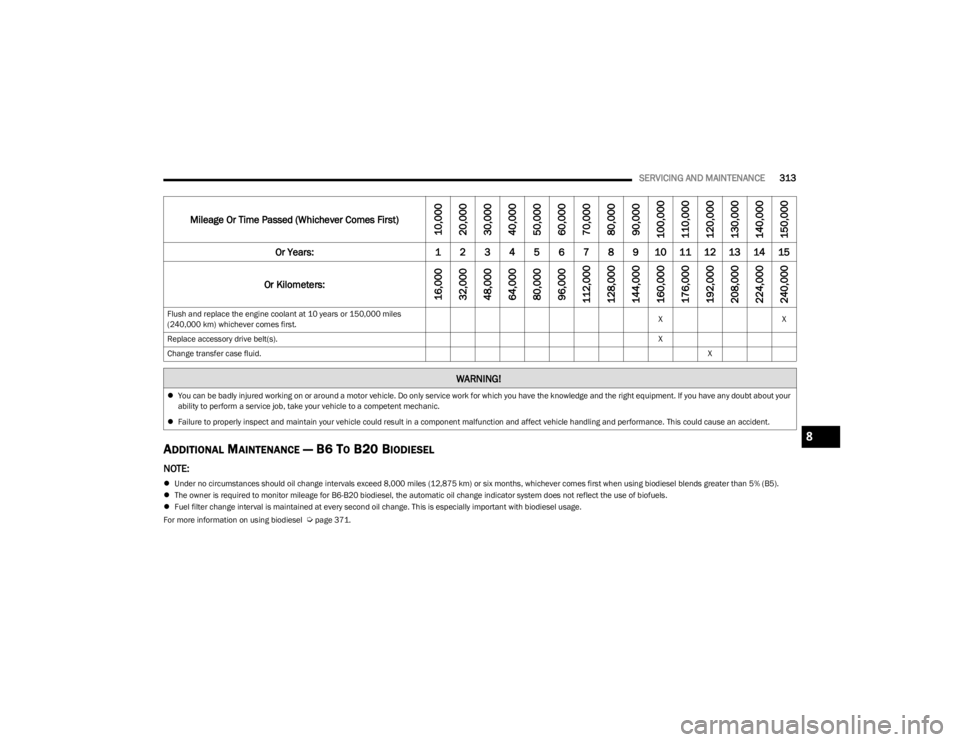

ADDITIONAL MAINTENANCE — B6 TO B20 BIODIESEL

NOTE:

Under no circumstances should oil change intervals exceed 8,000 miles (12,875 km) or six months, whichever comes first when using biodiesel blends greater than 5% (B5).

The owner is required to monitor mileage for B6-B20 biodiesel, the automatic oil change indicator system does not reflect the use of biofuels.

Fuel filter change interval is maintained at every second oil change. This is especially important with biodiesel usage.

For more information on using biodiesel

Úpage 371.

Flush and replace the engine coolant at 10 years or 150,000 miles

(240,000 km) whichever comes first.

X

X

Replace accessory drive belt(s). X

Change transfer case fluid. X

Mileage Or Time Passed (Whichever Comes First)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your

ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause an accident.

8

23_JL_OM_EN_USC_t.book Page 313

Page 321 of 396

SERVICING AND MAINTENANCE319

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used for

replacement. The quality of replacement filters varies

considerably. We recommend using a Mopar® Engine Oil

Filter. If a Mopar® Engine Oil Filter is unavailable only use

filters that meet or exceed SAE/USCAR-36 Filter

Performance Requirements.

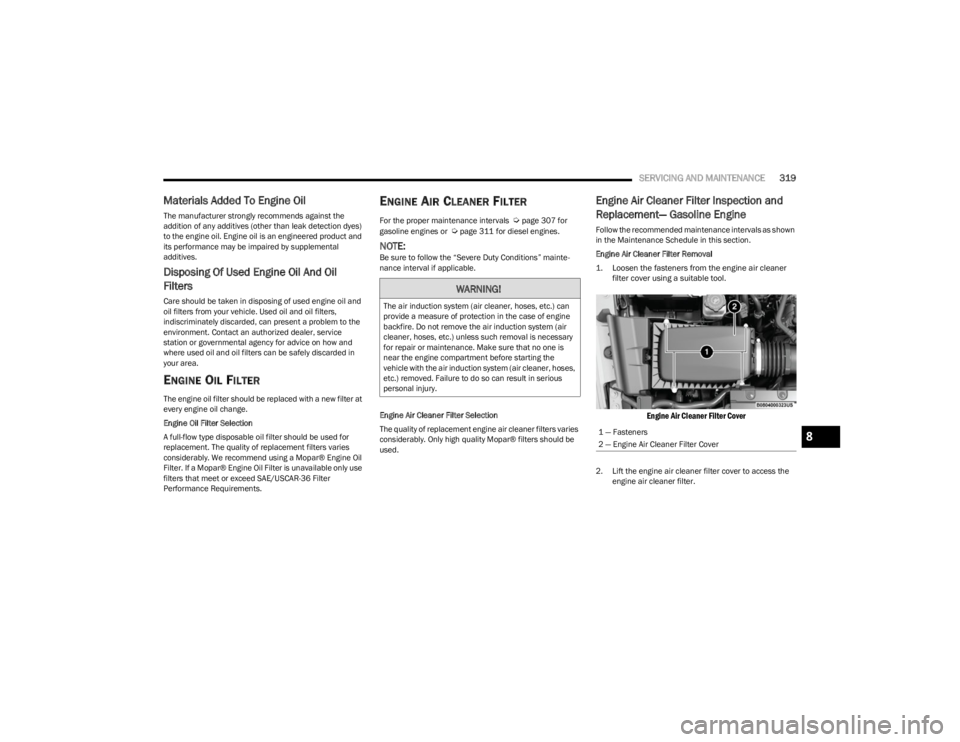

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 307 for

gasoline engines or Úpage 311 for diesel engines.

NOTE:Be sure to follow the “Severe Duty Conditions” mainte -

nance interval if applicable.

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner filters varies

considerably. Only high quality Mopar® filters should be

used.

Engine Air Cleaner Filter Inspection and

Replacement— Gasoline Engine

Follow the recommended maintenance intervals as shown

in the Maintenance Schedule in this section.

Engine Air Cleaner Filter Removal

1. Loosen the fasteners from the engine air cleaner filter cover using a suitable tool.

Engine Air Cleaner Filter Cover

2. Lift the engine air cleaner filter cover to access the engine air cleaner filter.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc.) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in serious

personal injury.

1 — Fasteners

2 — Engine Air Cleaner Filter Cover8

23_JL_OM_EN_USC_t.book Page 319

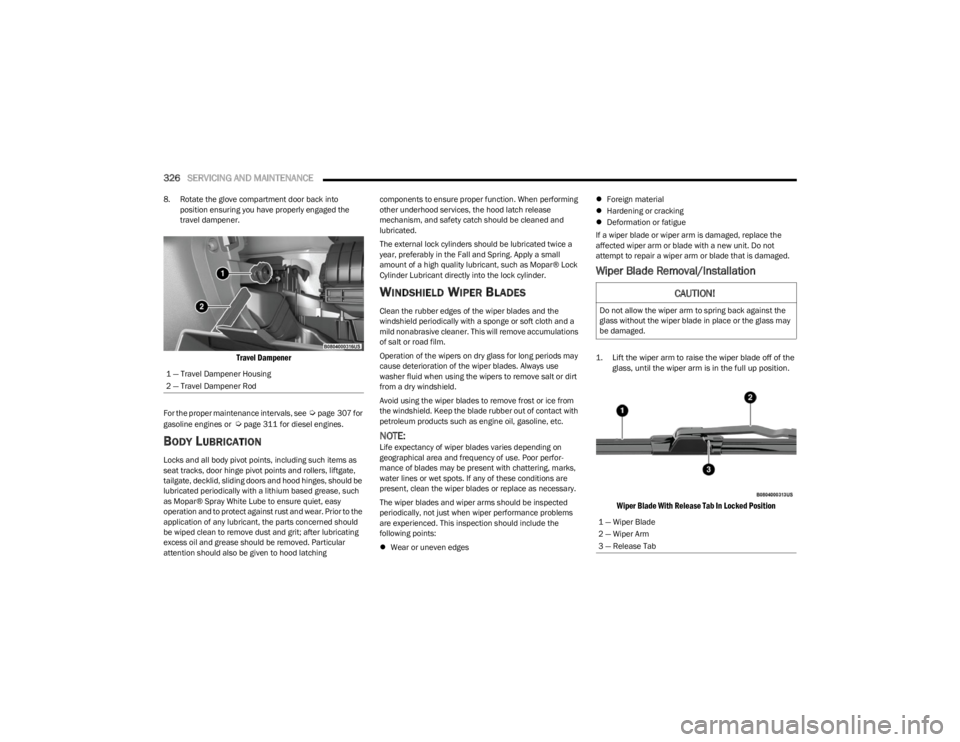

Page 328 of 396

326SERVICING AND MAINTENANCE

8. Rotate the glove compartment door back into

position ensuring you have properly engaged the

travel dampener.

Travel Dampener

For the proper maintenance intervals, see Úpage 307 for

gasoline engines or Úpage 311 for diesel engines.

BODY LUBRICATION

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically with a lithium based grease, such

as Mopar® Spray White Lube to ensure quiet, easy

operation and to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned should

be wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching components to ensure proper function. When performing

other underhood services, the hood latch release

mechanism, and safety catch should be cleaned and

lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as Mopar® Lock

Cylinder Lubricant directly into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending on

geographical area and frequency of use. Poor perfor

-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

The wiper blades and wiper arms should be inspected

periodically, not just when wiper performance problems

are experienced. This inspection should include the

following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged, replace the

affected wiper arm or blade with a new unit. Do not

attempt to repair a wiper arm or blade that is damaged.

Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off of the glass, until the wiper arm is in the full up position.

Wiper Blade With Release Tab In Locked Position

1 — Travel Dampener Housing

2 — Travel Dampener Rod

CAUTION!

Do not allow the wiper arm to spring back against the

glass without the wiper blade in place or the glass may

be damaged.

1 — Wiper Blade

2 — Wiper Arm

3 — Release Tab

23_JL_OM_EN_USC_t.book Page 326

Page 333 of 396

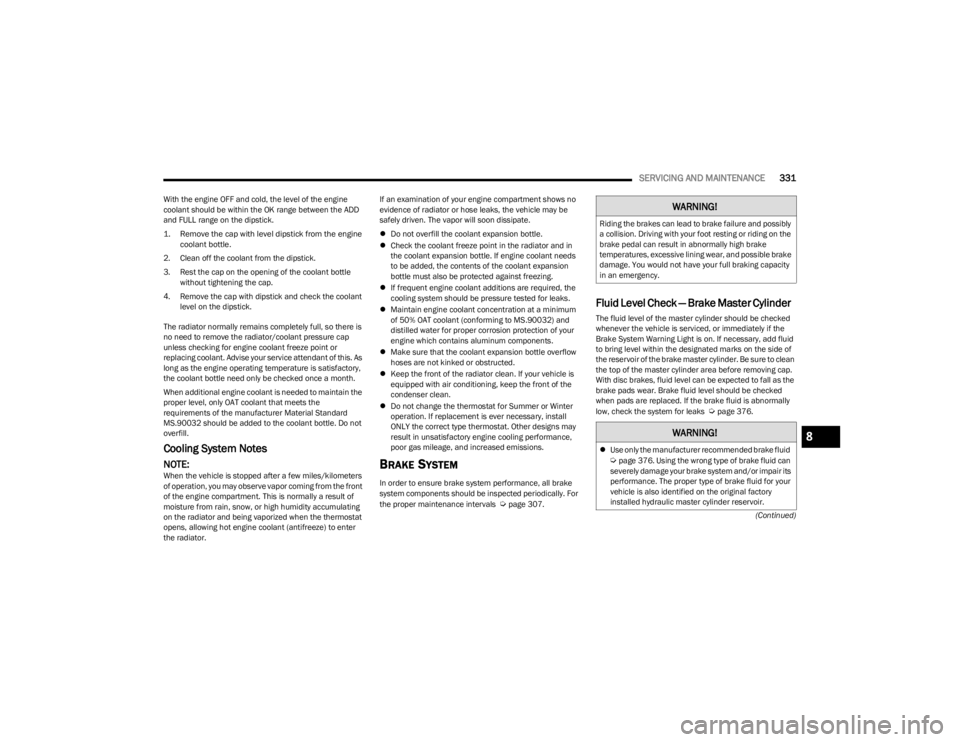

SERVICING AND MAINTENANCE331

(Continued)

With the engine OFF and cold, the level of the engine

coolant should be within the OK range between the ADD

and FULL range on the dipstick.

1. Remove the cap with level dipstick from the engine

coolant bottle.

2. Clean off the coolant from the dipstick.

3. Rest the cap on the opening of the coolant bottle without tightening the cap.

4. Remove the cap with dipstick and check the coolant level on the dipstick.

The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant freeze point or

replacing coolant. Advise your service attendant of this. As

long as the engine operating temperature is satisfactory,

the coolant bottle need only be checked once a month.

When additional engine coolant is needed to maintain the

proper level, only OAT coolant that meets the

requirements of the manufacturer Material Standard

MS.90032 should be added to the coolant bottle. Do not

overfill.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilometers

of operation, you may observe vapor coming from the front

of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumulating

on the radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to enter

the radiator. If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant needs

to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

If frequent engine coolant additions are required, the

cooling system should be pressure tested for leaks.

Maintain engine coolant concentration at a minimum

of 50% OAT coolant (conforming to MS.90032) and

distilled water for proper corrosion protection of your

engine which contains aluminum components.

Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine cooling performance,

poor gas mileage, and increased emissions.BRAKE SYSTEM

In order to ensure brake system performance, all brake

system components should be inspected periodically. For

the proper maintenance intervals

Úpage 307.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be checked

whenever the vehicle is serviced, or immediately if the

Brake System Warning Light is on. If necessary, add fluid

to bring level within the designated marks on the side of

the reservoir of the brake master cylinder. Be sure to clean

the top of the master cylinder area before removing cap.

With disc brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. If the brake fluid is abnormally

low, check the system for leaks

Úpage 376.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on the

brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

Use only the manufacturer recommended brake fluid Úpage 376. Using the wrong type of brake fluid can

severely damage your brake system and/or impair its

performance. The proper type of brake fluid for your

vehicle is also identified on the original factory

installed hydraulic master cylinder reservoir.

8

23_JL_OM_EN_USC_t.book Page 331

Page 334 of 396

332SERVICING AND MAINTENANCE

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the fluid

level.

Fluid Level Check

Lubricant should be approximately 1/8 inch (3 mm) below

the bottom edge of the oil fill hole.

NOTE:Make sure that the vehicle is level and supported by the

axles.

Adding Fluid

Add lubricant only at the fill hole and only to the level

specified above.

Selection Of Lubricant

Use only manufacturer recommended fluid Úpage 376.

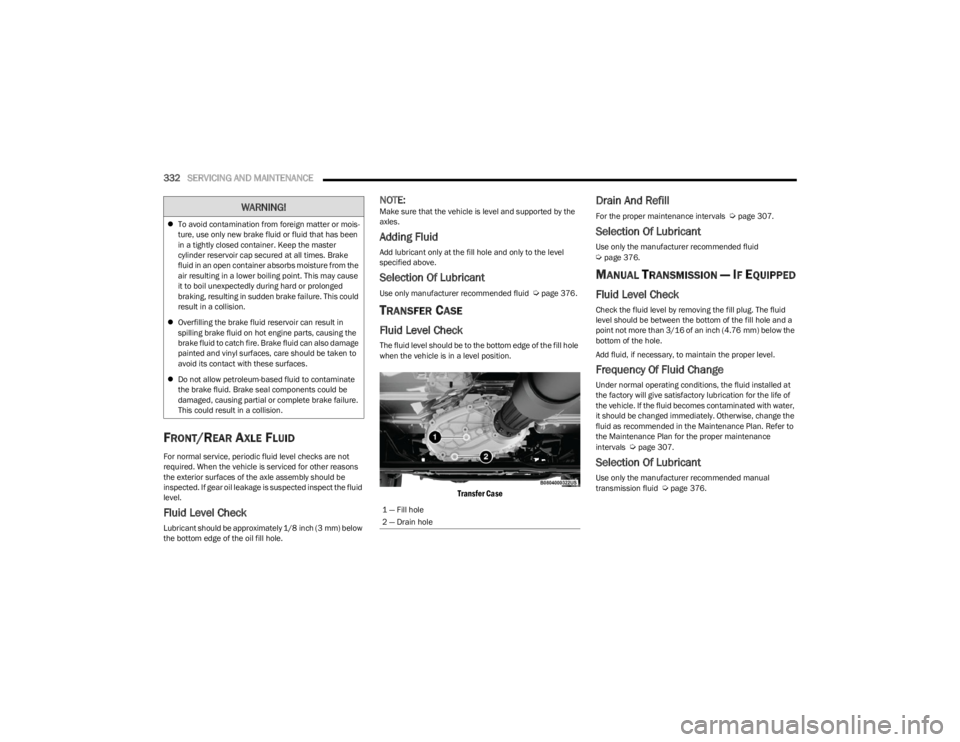

TRANSFER CASE

Fluid Level Check

The fluid level should be to the bottom edge of the fill hole

when the vehicle is in a level position.

Transfer Case

Drain And Refill

For the proper maintenance intervals Úpage 307.

Selection Of Lubricant

Use only the manufacturer recommended fluid Úpage 376.

MANUAL TRANSMISSION — IF EQUIPPED

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more than 3/16 of an inch (4.76 mm) below the

bottom of the hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Under normal operating conditions, the fluid installed at

the factory will give satisfactory lubrication for the life of

the vehicle. If the fluid becomes contaminated with water,

it should be changed immediately. Otherwise, change the

fluid as recommended in the Maintenance Plan. Refer to

the Maintenance Plan for the proper maintenance

intervals

Úpage 307.

Selection Of Lubricant

Use only the manufacturer recommended manual

transmission fluid Úpage 376.

To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in an open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum-based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

WARNING!

1 — Fill hole

2 — Drain hole

23_JL_OM_EN_USC_t.book Page 332

Page 373 of 396

TECHNICAL SPECIFICATIONS371

FUEL REQUIREMENTS – DIESEL ENGINE

Federal law requires that you must fuel this vehicle with

Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur

maximum) and prohibits the use of Low Sulfur Highway

Diesel fuel (500 ppm Sulfur maximum) to avoid damage to

the emissions control system.

Use good quality diesel fuel from a reputable supplier in

your vehicle. For most year-round service, No. 2 diesel fuel

meeting ASTM (formerly known as the American Society

for Testing and Materials) specification D-975 Grade S15

will provide good performance. If the vehicle is exposed to

extreme cold (below 20°F or -7°C), or is required to

operate at colder-than-normal conditions for prolonged

periods, use climatized No. 2 diesel fuel or dilute the No.

2 diesel fuel with 50% No. 1 diesel fuel. This will provide

better protection from fuel gelling or wax-plugging of the

fuel filters.

Diesel fuel is seldom completely free of water. To prevent

fuel system trouble, drain the accumulated water from the

fuel/water separator using the fuel/water separator drain

provided on the fuel filter housing. If you buy good quality

fuel and follow the cold weather advice above, fuel

conditioners should not be required in your vehicle. If

available in your area, a high cetane “premium” diesel fuel

may offer improved cold-starting and warm-up

performance.

DIESEL FUEL SPECIFICATIONS

This diesel engine has been developed to take advantage

of the high energy content and generally lower cost No. 2

Ultra Low Sulfur diesel fuel or No. 2 Ultra Low Sulfur

climatized diesel fuels.

NOTE:

If you accidentally fill the fuel tank with gasoline on your

diesel vehicle, do not start the engine. Damage to the

engine and fuel system could occur. Please call an

authorized dealer for service.

A maximum blend of 5% biodiesel meeting ASTM spec -

ification D-975 may be used with your diesel engine

without any adjustments to regular service schedules.

Commercially available fuel additives are not neces -

sary for the proper operation of your diesel engine.

No. 1 Ultra Low Sulfur diesel fuel should only be used

where extended arctic conditions (-10°F or -23°C)

exist.

BIODIESEL FUEL REQUIREMENTS

A maximum blend of 5% biodiesel meeting ASTM

specification D975 is recommended for use with your

diesel engine. If frequent operation with Biodiesel blends

that are between 6% and 20% (B6–B20) is desired, the

maintenance schedule is subject to shorter intervals. The oil and filter change along with fuel filter replacement

is subject to shorter intervals when operating your engine

on biodiesel greater than 5%. Do not use biodiesel greater

than 20%.

For regular use of biodiesel blends between 6% and 20%

(B6–B20) it is important that you understand and comply

with these requirements

Úpage 311.

Biodiesel is a fuel produced from renewable resources

typically derived from animal fat, rapeseed oil (Rapeseed

Methyl Ester (RME) base), or soybean oil (Soy Methyl Ester

(SME or SOME) base).

Biodiesel fuel has inherent limitations which require that

you understand and adhere to the following requirements

if you use blends of Biodiesel between 6% and 20%

(B6–B20). There are no unique restrictions for the use of

B5.

WARNING!

Do not use alcohol or gasoline as a fuel blending agent.

They can be unstable under certain conditions and

hazardous or explosive when mixed with diesel fuel.

CAUTION!

If the Water in Fuel Indicator Light remains on, DO NOT

START engine before you drain the water from the fuel

filter(s) to avoid engine damage

Úpage 321.

CAUTION!

Failure to comply with Oil Change requirements for

vehicles operating on biodiesel blends between 6% and

20% (B6–B20) will result in premature engine wear.

Such wear is not covered by the New Vehicle Limited

Warranty.

CAUTION!

Use of blends greater than 20% is not approved. Use of

blends greater than 20% can result in engine damage.

Such damage is not covered by the New Vehicle Limited

Warranty.

9

23_JL_OM_EN_USC_t.book Page 371