In case of emergency JEEP WRANGLER UNLIMITED 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: WRANGLER UNLIMITED, Model: JEEP WRANGLER UNLIMITED 2018Pages: 348, PDF Size: 6.5 MB

Page 190 of 348

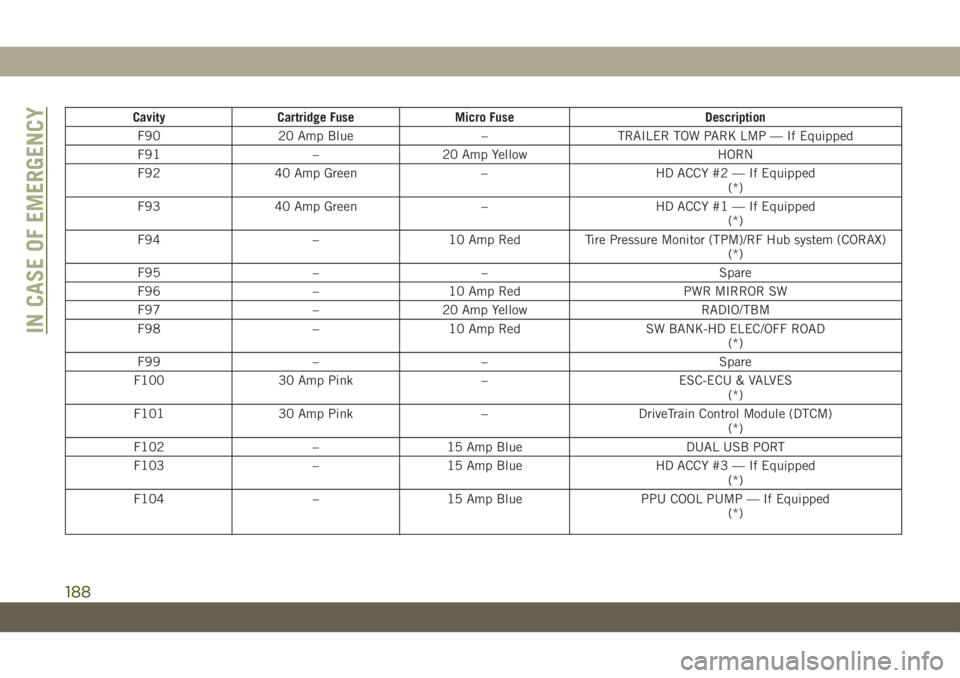

Cavity Cartridge Fuse Micro Fuse Description

F90 20 Amp Blue – TRAILER TOW PARK LMP — If Equipped

F91 – 20 Amp Yellow HORN

F92 40 Amp Green – HD ACCY #2 — If Equipped

(*)

F93 40 Amp Green – HD ACCY #1 — If Equipped

(*)

F94 – 10 Amp Red Tire Pressure Monitor (TPM)/RF Hub system (CORAX)

(*)

F95 – – Spare

F96 – 10 Amp Red PWR MIRROR SW

F97 – 20 Amp Yellow RADIO/TBM

F98 – 10 Amp Red SW BANK-HD ELEC/OFF ROAD

(*)

F99 – – Spare

F100 30 Amp Pink – ESC-ECU & VALVES

(*)

F101 30 Amp Pink – DriveTrain Control Module (DTCM)

(*)

F102 – 15 Amp Blue DUAL USB PORT

F103 – 15 Amp Blue HD ACCY #3 — If Equipped

(*)

F104 – 15 Amp Blue PPU COOL PUMP — If Equipped

(*)

IN CASE OF EMERGENCY

188

Page 192 of 348

WARNING!

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

Jack Location

The jack and lug wrench are located in the

rear cargo area. To remove jack and tools

proceed as follows:

1. Lift the load floor in the cargo area.NOTE:

The load floor can be removed for easier

access by pulling the load floor directly

rearward.

2. Remove the hardware storage cover by

pinching the latch on the left side and

pulling upward.

3. Turn the black plastic wing nut counter-

clockwise to loosen the jack from the

storage bin.

4. Remove tool kit and assemble tools.

Spare Tire Removal

1. To remove the spare tire from the carrier,

remove the tire cover, if equipped.

NOTE:

The spare wheel is mounted on the out-

side of the tailgate, protected by a plastic

cover with fasteners. Under traffic regula-

tions, the cover must not be removed or

insecurely fixed during use of the vehicle

on the public highway. Reference should

be made to local laws and regulations. Ifthe spare wheel is used, before continuing

your journey check that the damaged

wheel is securely mounted and the cover

is correctly fixed in place. Also take care

not to obstruct the rear camera.

2. Remove the Rear Camera Cover by turning

the lock bolt to the left with the #T40 Torx

head driver and ratchet from the supplied

tool kit.

3. Remove the lug nuts with the lug wrench

turning them counterclockwise. If

equipped, remove the locking lug nut with

the lock key (located in the glove box)

turning it counterclockwise.

Stowing The Replaced Spare Tire

1. Mount the spare tire onto the carrier.

Torque down lug nuts and locking lug nut.

2. Return the lock bolt to the lock position

on the camera cover by turning the lock to

the right using the provided #T40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

IN CASE OF EMERGENCY

190

Page 194 of 348

WARNING!

• If working on or near a roadway, be

extremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated.

1. Remove the spare tire, jack and tools from

the stored location.

2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left one turn

while the wheel is still on the ground.

3. Assemble the jack and jacking tools. Con-

nect the jack handle driver to the exten-

sion, then to the lug wrench.

4. Operate the jack from the front or the rear

of the vehicle. Place the jack under the

axle tube, as shown.Do not raise the ve-

hicle until you are sure the jack is fully

engaged.

Warning Label

Front Jack Engagement Location

IN CASE OF EMERGENCY

192

Page 196 of 348

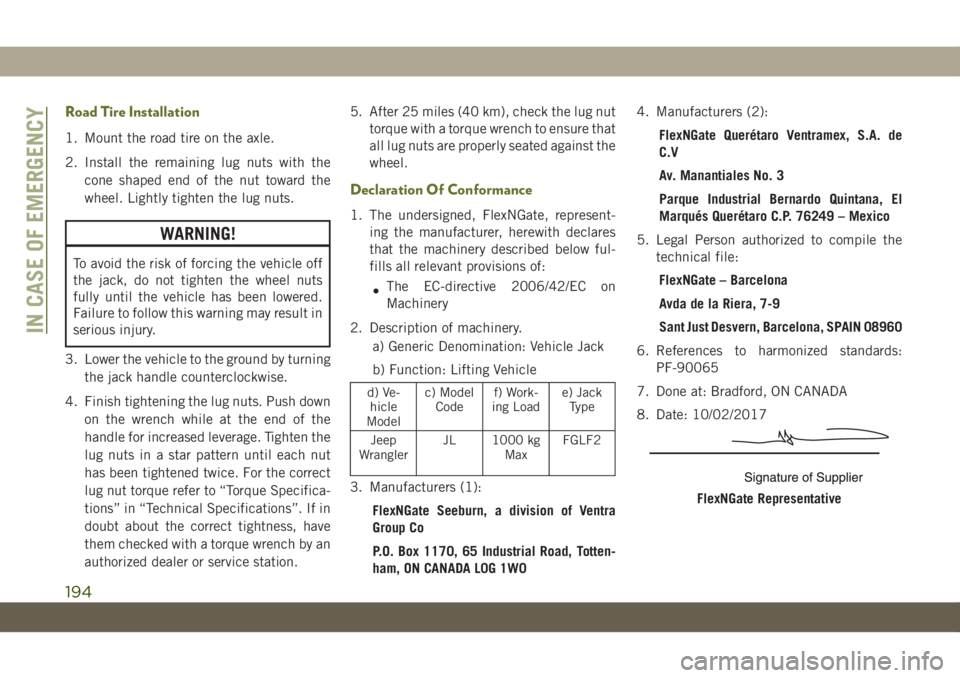

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut

has been tightened twice. For the correct

lug nut torque refer to “Torque Specifica-

tions” in “Technical Specifications”. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.5. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Declaration Of Conformance

1. The undersigned, FlexNGate, represent-

ing the manufacturer, herewith declares

that the machinery described below ful-

fills all relevant provisions of:

•The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

WranglerJL 1000 kg

MaxFGLF2

3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road, Totten-

ham, ON CANADA L0G 1W04. Manufacturers (2):

FlexNGate Querétaro Ventramex, S.A. de

C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico

5. Legal Person authorized to compile the

technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN 08960

6. References to harmonized standards:

PF-90065

7. Done at: Bradford, ON CANADA

8. Date: 10/02/2017FlexNGate Representative

IN CASE OF EMERGENCY

194

Page 198 of 348

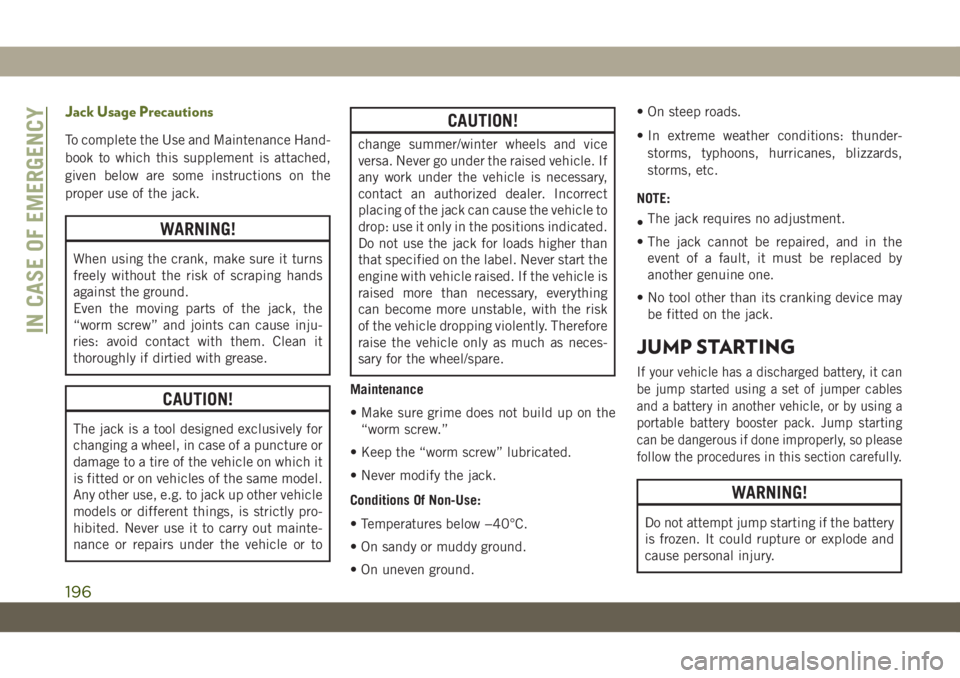

Jack Usage Precautions

To complete the Use and Maintenance Hand-

book to which this supplement is attached,

given below are some instructions on the

proper use of the jack.

WARNING!

When using the crank, make sure it turns

freely without the risk of scraping hands

against the ground.

Even the moving parts of the jack, the

“worm screw” and joints can cause inju-

ries: avoid contact with them. Clean it

thoroughly if dirtied with grease.

CAUTION!

The jack is a tool designed exclusively for

changing a wheel, in case of a puncture or

damage to a tire of the vehicle on which it

is fitted or on vehicles of the same model.

Any other use, e.g. to jack up other vehicle

models or different things, is strictly pro-

hibited. Never use it to carry out mainte-

nance or repairs under the vehicle or to

CAUTION!

change summer/winter wheels and vice

versa. Never go under the raised vehicle. If

any work under the vehicle is necessary,

contact an authorized dealer. Incorrect

placing of the jack can cause the vehicle to

drop: use it only in the positions indicated.

Do not use the jack for loads higher than

that specified on the label. Never start the

engine with vehicle raised. If the vehicle is

raised more than necessary, everything

can become more unstable, with the risk

of the vehicle dropping violently. Therefore

raise the vehicle only as much as neces-

sary for the wheel/spare.

Maintenance

• Make sure grime does not build up on the

“worm screw.”

• Keep the “worm screw” lubricated.

• Never modify the jack.

Conditions Of Non-Use:

• Temperatures below −40°C.

• On sandy or muddy ground.

• On uneven ground.• On steep roads.

• In extreme weather conditions: thunder-

storms, typhoons, hurricanes, blizzards,

storms, etc.

NOTE:

•The jack requires no adjustment.

• The jack cannot be repaired, and in the

event of a fault, it must be replaced by

another genuine one.

• No tool other than its cranking device may

be fitted on the jack.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so please

follow the procedures in this section carefully.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

IN CASE OF EMERGENCY

196

Page 200 of 348

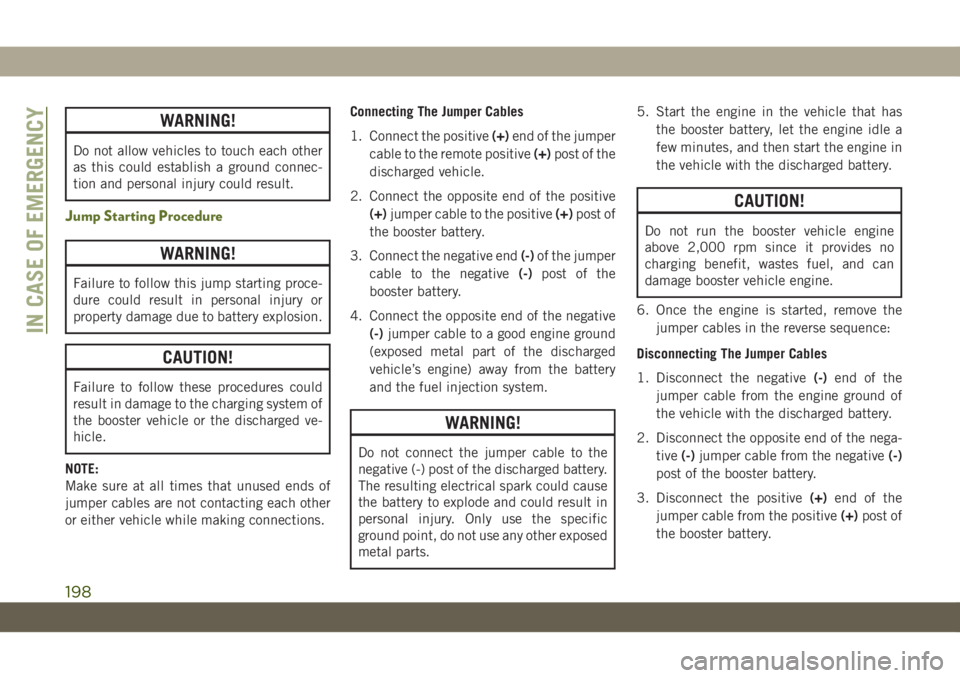

WARNING!

Do not allow vehicles to touch each other

as this could establish a ground connec-

tion and personal injury could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump starting proce-

dure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged ve-

hicle.

NOTE:

Make sure at all times that unused ends of

jumper cables are not contacting each other

or either vehicle while making connections.Connecting The Jumper Cables

1. Connect the positive(+)end of the jumper

cable to the remote positive(+)post of the

discharged vehicle.

2. Connect the opposite end of the positive

(+)jumper cable to the positive(+)post of

the booster battery.

3. Connect the negative end(-)of the jumper

cable to the negative(-)post of the

booster battery.

4. Connect the opposite end of the negative

(-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts.5. Start the engine in the vehicle that has

the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery.

CAUTION!

Do not run the booster vehicle engine

above 2,000 rpm since it provides no

charging benefit, wastes fuel, and can

damage booster vehicle engine.

6. Once the engine is started, remove the

jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative(-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the nega-

tive(-)jumper cable from the negative(-)

post of the booster battery.

3. Disconnect the positive(+)end of the

jumper cable from the positive(+)post of

the booster battery.

IN CASE OF EMERGENCY

198

Page 202 of 348

MANUAL PARK RELEASE

WARNING!

Always secure your vehicle by fully apply-

ing the parking brake before activating the

Manual Park Release. In addition, you

should be seated in the driver’s seat with

your foot firmly on the brake pedal when

activating the Manual Park Release. Acti-

vating the Manual Park Release will allow

your vehicle to roll away if it is not secured

by the parking brake, or by proper connec-

tion to a tow vehicle. Activating the

Manual Park Release on an unsecured

vehicle could lead to serious injury or

death for those in or around the vehicle.

In order to push or tow the vehicle in cases

where the transmission will not shift out of

PARK (such as a dead battery), a Manual

Park Release is available.

Follow these steps to use the Manual Park

Release:

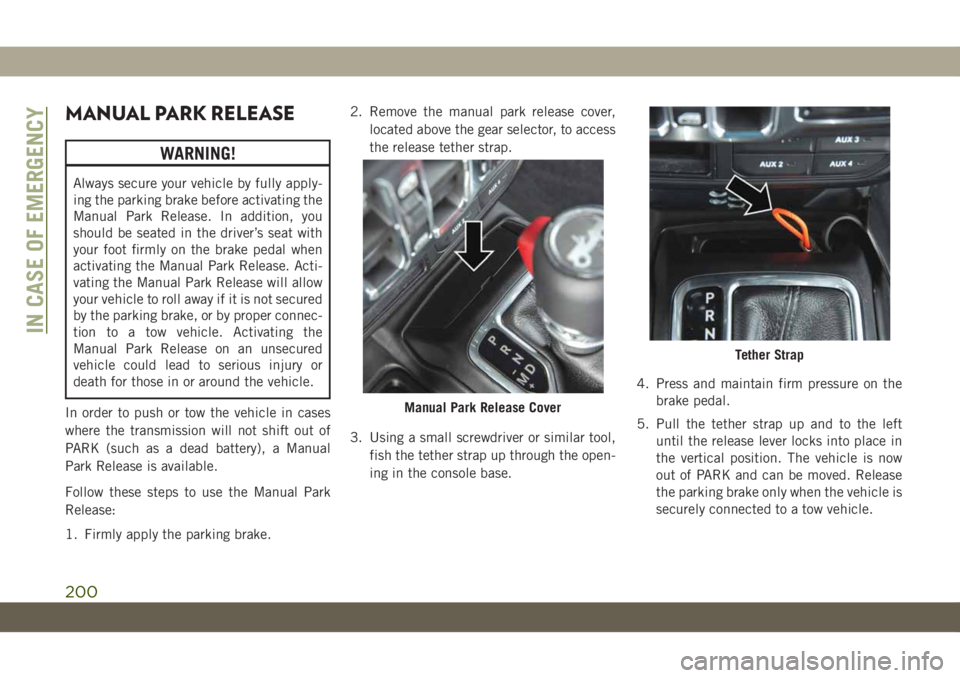

1. Firmly apply the parking brake.2. Remove the manual park release cover,

located above the gear selector, to access

the release tether strap.

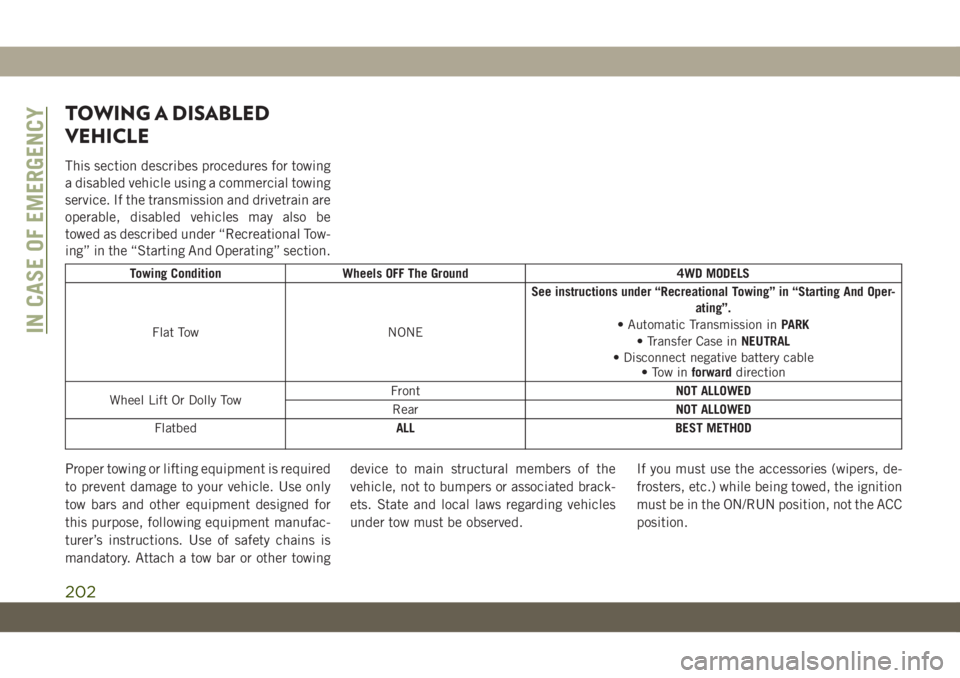

3. Using a small screwdriver or similar tool,

fish the tether strap up through the open-

ing in the console base.4. Press and maintain firm pressure on the

brake pedal.

5. Pull the tether strap up and to the left

until the release lever locks into place in

the vertical position. The vehicle is now

out of PARK and can be moved. Release

the parking brake only when the vehicle is

securely connected to a tow vehicle.

Manual Park Release Cover

Tether Strap

IN CASE OF EMERGENCY

200

Page 204 of 348

TOWING A DISABLED

VEHICLE

This section describes procedures for towing

a disabled vehicle using a commercial towing

service. If the transmission and drivetrain are

operable, disabled vehicles may also be

towed as described under “Recreational Tow-

ing” in the “Starting And Operating” section.

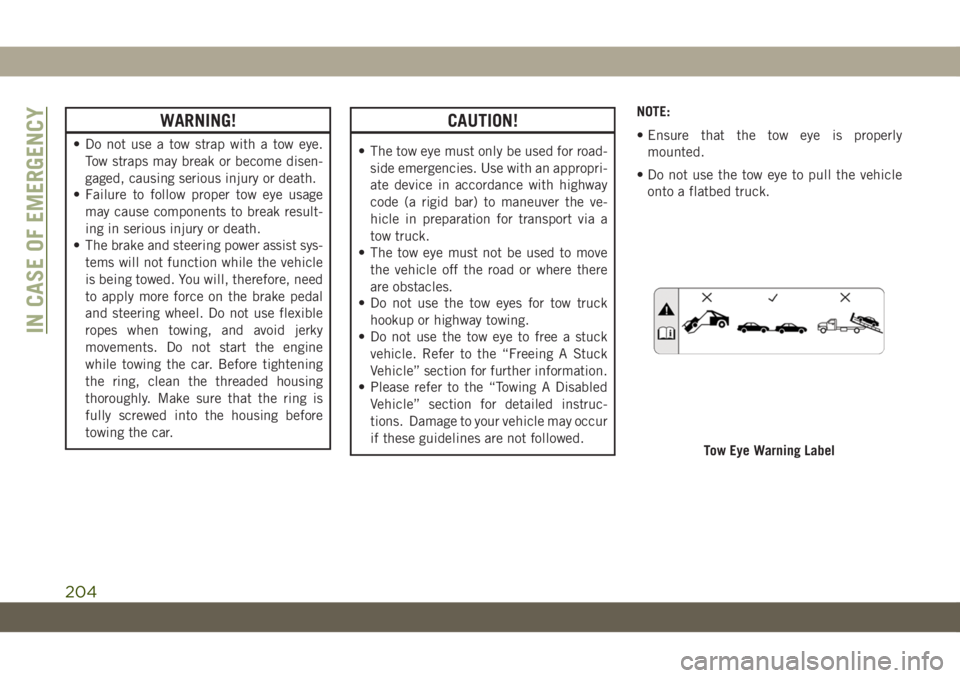

Towing Condition Wheels OFF The Ground 4WD MODELS

Flat Tow NONESee instructions under “Recreational Towing” in “Starting And Oper-

ating”.

• Automatic Transmission inPARK

• Transfer Case inNEUTRAL

• Disconnect negative battery cable

• Tow inforwarddirection

Wheel Lift Or Dolly TowFrontNOT ALLOWED

RearNOT ALLOWED

FlatbedALL BEST METHOD

Proper towing or lifting equipment is required

to prevent damage to your vehicle. Use only

tow bars and other equipment designed for

this purpose, following equipment manufac-

turer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towingdevice to main structural members of the

vehicle, not to bumpers or associated brack-

ets. State and local laws regarding vehicles

under tow must be observed.If you must use the accessories (wipers, de-

frosters, etc.) while being towed, the ignition

must be in the ON/RUN position, not the ACC

position.

IN CASE OF EMERGENCY

202

Page 206 of 348

WARNING!

• Do not use a tow strap with a tow eye.

Tow straps may break or become disen-

gaged, causing serious injury or death.

• Failure to follow proper tow eye usage

may cause components to break result-

ing in serious injury or death.

• The brake and steering power assist sys-

tems will not function while the vehicle

is being towed. You will, therefore, need

to apply more force on the brake pedal

and steering wheel. Do not use flexible

ropes when towing, and avoid jerky

movements. Do not start the engine

while towing the car. Before tightening

the ring, clean the threaded housing

thoroughly. Make sure that the ring is

fully screwed into the housing before

towing the car.

CAUTION!

• The tow eye must only be used for road-

side emergencies. Use with an appropri-

ate device in accordance with highway

code (a rigid bar) to maneuver the ve-

hicle in preparation for transport via a

tow truck.

• The tow eye must not be used to move

the vehicle off the road or where there

are obstacles.

• Do not use the tow eyes for tow truck

hookup or highway towing.

• Do not use the tow eye to free a stuck

vehicle. Refer to the “Freeing A Stuck

Vehicle” section for further information.

• Please refer to the “Towing A Disabled

Vehicle” section for detailed instruc-

tions. Damage to your vehicle may occur

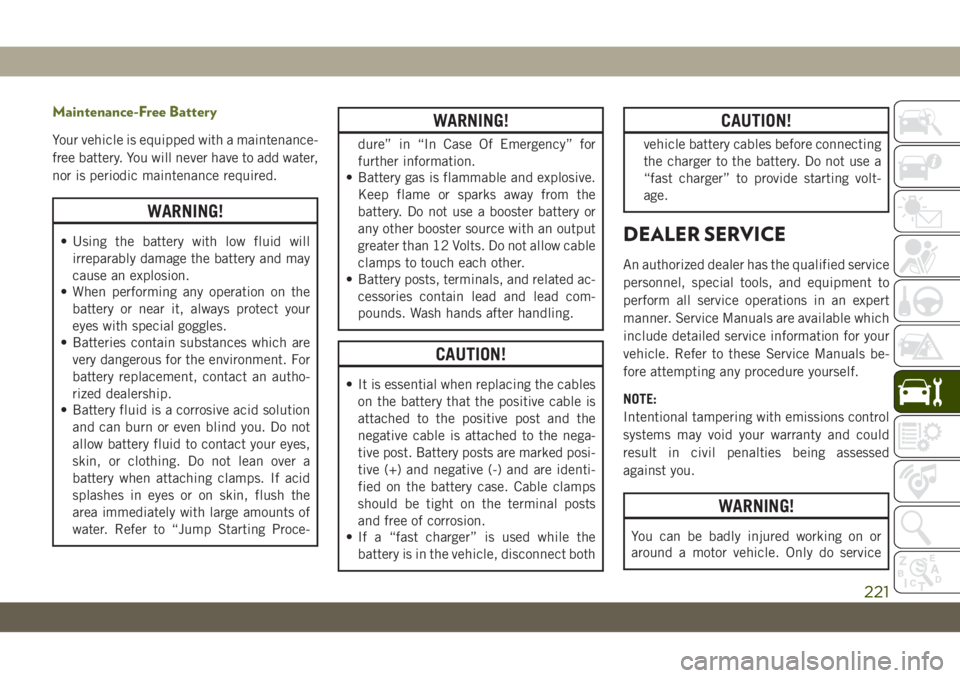

if these guidelines are not followed.NOTE:

• Ensure that the tow eye is properly

mounted.

• Do not use the tow eye to pull the vehicle

onto a flatbed truck.

Tow Eye Warning Label

IN CASE OF EMERGENCY

204

Page 223 of 348

Maintenance-Free Battery

Your vehicle is equipped with a maintenance-

free battery. You will never have to add water,

nor is periodic maintenance required.

WARNING!

• Using the battery with low fluid will

irreparably damage the battery and may

cause an explosion.

• When performing any operation on the

battery or near it, always protect your

eyes with special goggles.

• Batteries contain substances which are

very dangerous for the environment. For

battery replacement, contact an autho-

rized dealership.

• Battery fluid is a corrosive acid solution

and can burn or even blind you. Do not

allow battery fluid to contact your eyes,

skin, or clothing. Do not lean over a

battery when attaching clamps. If acid

splashes in eyes or on skin, flush the

area immediately with large amounts of

water. Refer to “Jump Starting Proce-

WARNING!

dure” in “In Case Of Emergency” for

further information.

• Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or

any other booster source with an output

greater than 12 Volts. Do not allow cable

clamps to touch each other.

• Battery posts, terminals, and related ac-

cessories contain lead and lead com-

pounds. Wash hands after handling.

CAUTION!

• It is essential when replacing the cables

on the battery that the positive cable is

attached to the positive post and the

negative cable is attached to the nega-

tive post. Battery posts are marked posi-

tive (+) and negative (-) and are identi-

fied on the battery case. Cable clamps

should be tight on the terminal posts

and free of corrosion.

• If a “fast charger” is used while the

battery is in the vehicle, disconnect both

CAUTION!

vehicle battery cables before connecting

the charger to the battery. Do not use a

“fast charger” to provide starting volt-

age.

DEALER SERVICE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals be-

fore attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service

221