torque JEEP WRANGLER UNLIMITED 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: WRANGLER UNLIMITED, Model: JEEP WRANGLER UNLIMITED 2019Pages: 348, PDF Size: 6.5 MB

Page 170 of 348

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

WARNING!

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

• Damage to the fuel system or emission

control system could result from using

an improper fuel filler cap. A poorly

fitting cap could let impurities into the

fuel system. Also, a poorly fitting after-

market cap can cause the “Malfunction

Indicator Light (MIL)” to illuminate, due

to fuel vapors escaping from the system.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.NOTE:

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.

• Tighten the fuel filler cap about 1/4 turn

until you hear one click. This is an indica-

tion that the cap is properly tightened.

• If the fuel filler cap is not tightened prop-

erly, the MIL will come on. Be sure the cap

is tightened every time the vehicle is

refueled.

Adblue (UREA) — If Equipped

The vehicle is equipped with an UREA injec-

tion system and Selective Catalytic Reduc-

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same, they

ensure fuel-efficiency, handling, torque and

power. For messages and system warnings,

refer to the "Warning Lights And Messages" in

the "Getting To Know Your Instrument Panel"

section. AdBlue (UREA) is a very stable prod-

uct with a long shelf life. Stored at tempera-

tures LOWER than 90 °F (32 °C), it has a

shelf life of at least one year. For more infor-

mation on the AdBlue liquid type, see the

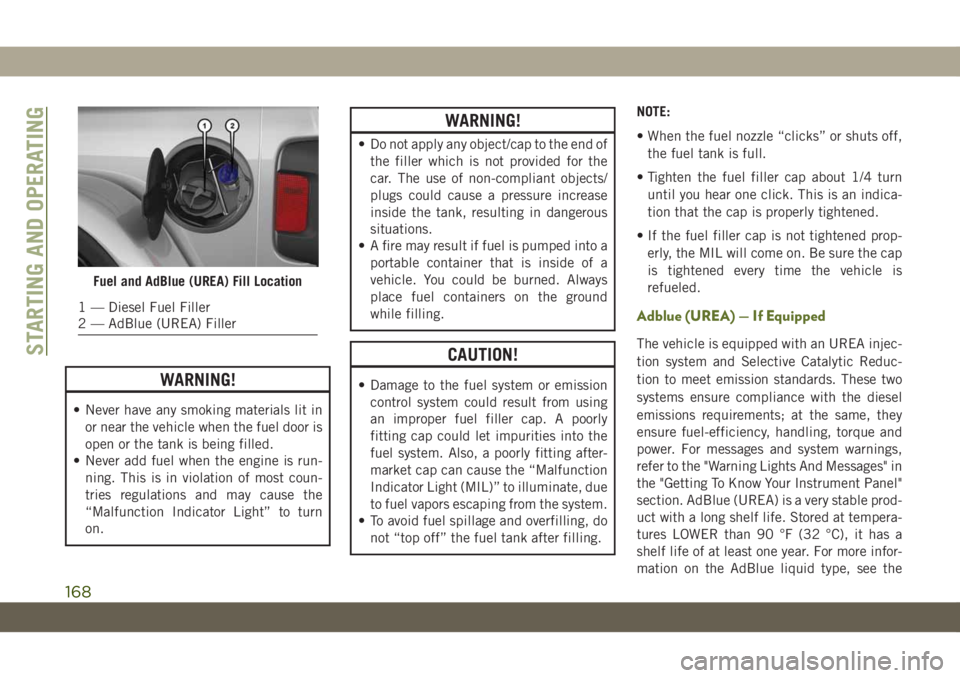

Fuel and AdBlue (UREA) Fill Location

1 — Diesel Fuel Filler

2 — AdBlue (UREA) Filler

STARTING AND OPERATING

168

Page 192 of 348

WARNING!

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

Jack Location

The jack and lug wrench are located in the

rear cargo area. To remove jack and tools

proceed as follows:

1. Lift the load floor in the cargo area.NOTE:

The load floor can be removed for easier

access by pulling the load floor directly

rearward.

2. Remove the hardware storage cover by

pinching the latch on the left side and

pulling upward.

3. Turn the black plastic wing nut counter-

clockwise to loosen the jack from the

storage bin.

4. Remove tool kit and assemble tools.

Spare Tire Removal

1. To remove the spare tire from the carrier,

remove the tire cover, if equipped.

NOTE:

The spare wheel is mounted on the out-

side of the tailgate, protected by a plastic

cover with fasteners. Under traffic regula-

tions, the cover must not be removed or

insecurely fixed during use of the vehicle

on the public highway. Reference should

be made to local laws and regulations. Ifthe spare wheel is used, before continuing

your journey check that the damaged

wheel is securely mounted and the cover

is correctly fixed in place. Also take care

not to obstruct the rear camera.

2. Remove the Rear Camera Cover by turning

the lock bolt to the left with the #T40 Torx

head driver and ratchet from the supplied

tool kit.

3. Remove the lug nuts with the lug wrench

turning them counterclockwise. If

equipped, remove the locking lug nut with

the lock key (located in the glove box)

turning it counterclockwise.

Stowing The Replaced Spare Tire

1. Mount the spare tire onto the carrier.

Torque down lug nuts and locking lug nut.

2. Return the lock bolt to the lock position

on the camera cover by turning the lock to

the right using the provided #T40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

IN CASE OF EMERGENCY

190

Page 195 of 348

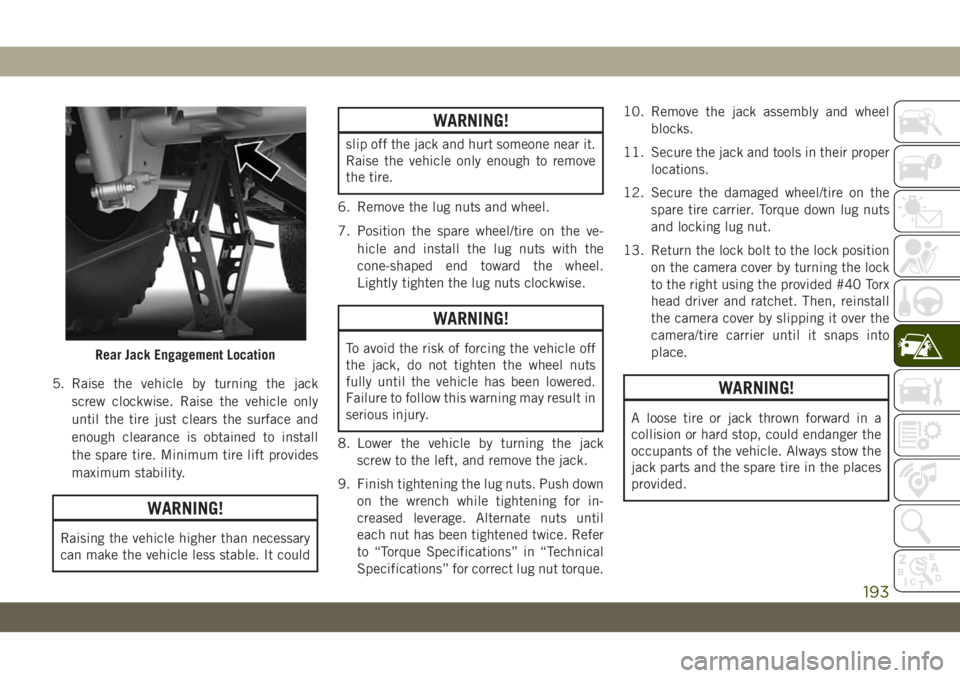

5. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.

9. Finish tightening the lug nuts. Push down

on the wrench while tightening for in-

creased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.10. Remove the jack assembly and wheel

blocks.

11. Secure the jack and tools in their proper

locations.

12. Secure the damaged wheel/tire on the

spare tire carrier. Torque down lug nuts

and locking lug nut.

13. Return the lock bolt to the lock position

on the camera cover by turning the lock

to the right using the provided #40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

Rear Jack Engagement Location

193

Page 196 of 348

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut

has been tightened twice. For the correct

lug nut torque refer to “Torque Specifica-

tions” in “Technical Specifications”. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.5. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Declaration Of Conformance

1. The undersigned, FlexNGate, represent-

ing the manufacturer, herewith declares

that the machinery described below ful-

fills all relevant provisions of:

•The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

WranglerJL 1000 kg

MaxFGLF2

3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road, Totten-

ham, ON CANADA L0G 1W04. Manufacturers (2):

FlexNGate Querétaro Ventramex, S.A. de

C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico

5. Legal Person authorized to compile the

technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN 08960

6. References to harmonized standards:

PF-90065

7. Done at: Bradford, ON CANADA

8. Date: 10/02/2017FlexNGate Representative

IN CASE OF EMERGENCY

194

Page 247 of 348

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION

NUMBER.................246

WHEEL AND TIRE TORQUE

SPECIFICATIONS...........246

Torque Specifications............246

DIMENSIONS...............247

WHEELS..................250

WEIGHTS.................250FUEL REQUIREMENTS — GASOLINE

ENGINE...................252

2.0L Engine.................252

3.6L Engine.................252

Materials Added To Fuel.........253

Fuel Icon Identification Compliant To

EN16942...................253

FUEL REQUIREMENTS — DIESEL

ENGINE..................255

Fuel Icon Identification Compliant To

EN16942...................256

FLUID CAPACITIES..........257

FLUIDS AND LUBRICANTS.....259

Engine....................259

Chassis....................261

FUEL CONSUMPTION AND CO2EMISSIONS................262

MOPAR ACCESSORIES.......262

Authentic Accessories And Jeep

Performance Parts By Mopar.......262

TECHNICAL SPECIFICATIONS

245

Page 248 of 348

VEHICLE IDENTIFICATION

NUMBER

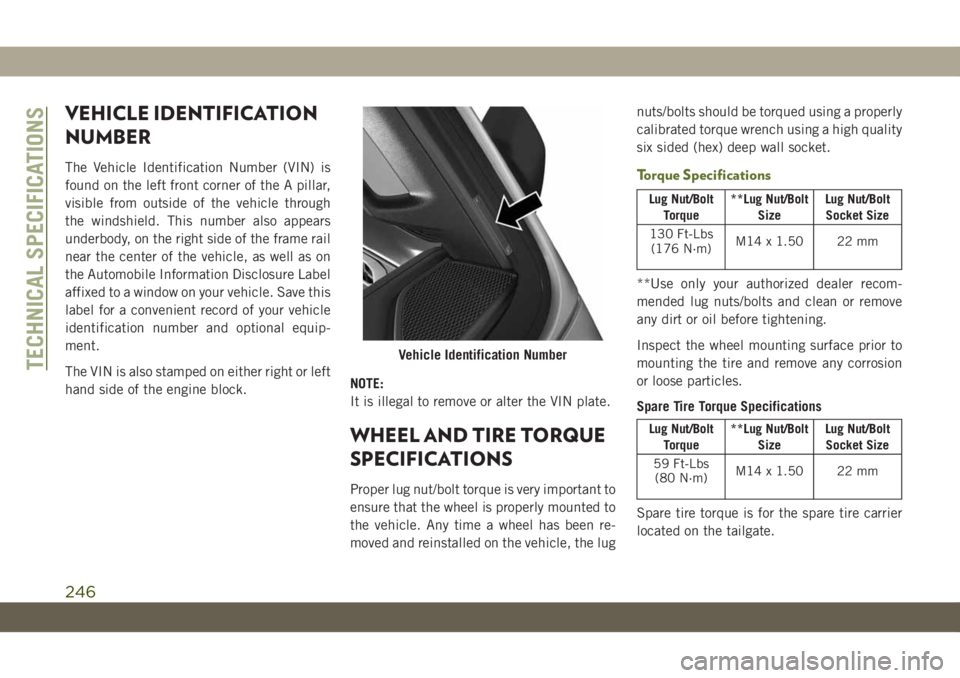

The Vehicle Identification Number (VIN) is

found on the left front corner of the A pillar,

visible from outside of the vehicle through

the windshield. This number also appears

underbody, on the right side of the frame rail

near the center of the vehicle, as well as on

the Automobile Information Disclosure Label

affixed to a window on your vehicle. Save this

label for a convenient record of your vehicle

identification number and optional equip-

ment.

The VIN is also stamped on either right or left

hand side of the engine block.NOTE:

It is illegal to remove or alter the VIN plate.

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lugnuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

130 Ft-Lbs

(176 N·m)M14 x 1.50 22 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Spare Tire Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

59 Ft-Lbs

(80 N·m)M14 x 1.50 22 mm

Spare tire torque is for the spare tire carrier

located on the tailgate.

Vehicle Identification NumberTECHNICAL SPECIFICATIONS

246

Page 249 of 348

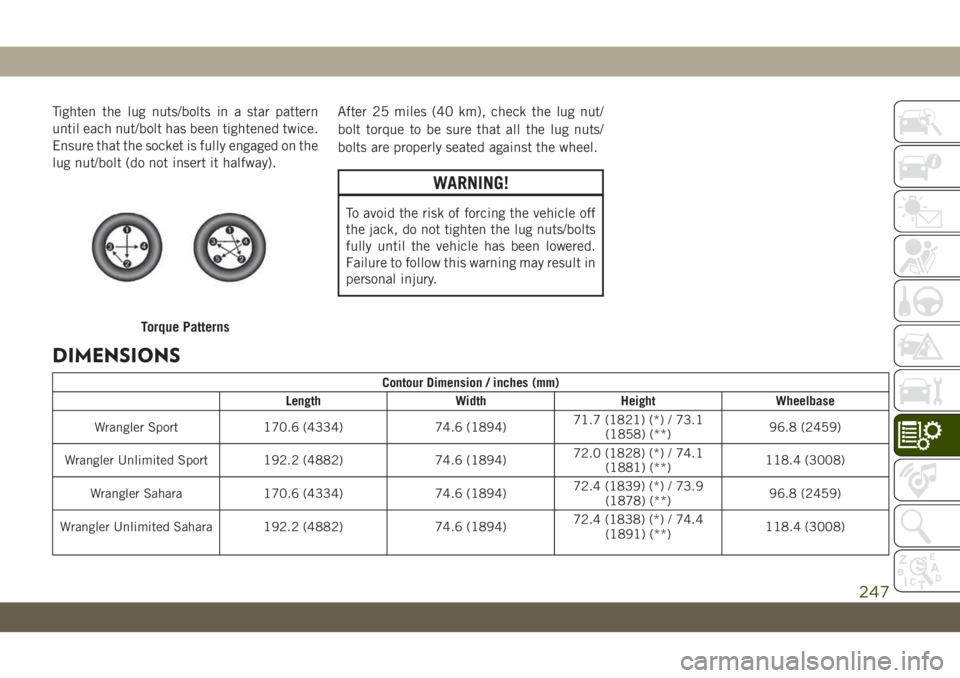

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts/bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

personal injury.

DIMENSIONS

Contour Dimension / inches (mm)

Length Width Height Wheelbase

Wrangler Sport 170.6 (4334) 74.6 (1894)71.7 (1821) (*) / 73.1

(1858) (**)96.8 (2459)

Wrangler Unlimited Sport 192.2 (4882) 74.6 (1894)72.0 (1828) (*) / 74.1

(1881) (**)118.4 (3008)

Wrangler Sahara 170.6 (4334) 74.6 (1894)72.4 (1839) (*) / 73.9

(1878) (**)96.8 (2459)

Wrangler Unlimited Sahara 192.2 (4882) 74.6 (1894)72.4 (1838) (*) / 74.4

(1891) (**)118.4 (3008)

Torque Patterns

247

Page 343 of 348

Starting....................142

Button...................15

Remote...................16

Starting And Operating...........142

Starting Procedures.............142

Steering.....................33

Tilt Column.................33

Wheel, Heated...............34

Wheel, Tilt.................33

Steering Wheel Mounted Sound System

Controls..................288

Stop/Start System..............157

Storage, Vehicle............45, 239

Storing Your Vehicle............239

Stuck, Freeing................201

Sun Roof....................54

Sway Bar Disconnect, Electronic.....156

Sway Control, Trailer.............89

Swing Gate, Rear...............57

System, Remote Starting..........16

Telescoping Steering Column........33

Temperature Control, Automatic (ATC) . .44

Text Messages.............270, 305

Tilt Steering Column.............33

Tips ......................288

Tip Start....................145Tire And Loading Information Placard . .226

Tires...............139, 230, 235

Aging (Life Of Tires)..........233

Air Pressure...............230

Chains...................237

Changing..............189, 226

Compact Spare.............235

General Information.......230, 235

High Speed................231

Inflation Pressure............231

Jacking...............192, 226

Life Of Tires...............233

Load Capacity...........226, 227

Pressure Monitoring System

(TPMS)...................72

Pressure Monitor System (TPMS) . . .94

Radial..................

.232

Replacement...............233

Rotation..................238

Safety...............226, 230

Snow Tires................235

Spare Tire.................190

Spare Tires............235, 236

Spinning.................232

Tread Wear Indicators.........233

Wheel Nut Torque............246

Tire Safety Information...........226To Open Hood.................56

To p

Dual..................47, 54

Freedom..................51

Hard.....................51

Power Sliding...............54

Removable............47, 51, 54

Soft...................47, 54

Towing.................171, 202

Disabled Vehicle.............202

Recreational...............171

Weight...................171

Towing Eyes.................203

Towing Vehicle Behind A Motorhome . .171

Trac-Lok Rear Axle.............155

Traction Control................85

Trailer Sway Control (TSC)..........89

Trailer Towing................171

Trailer And Tongue Weight.......171

Trailer Towing Guide............171

Trailer Weight................171

Transfer Case

Fluid....................261

Four-Wheel-Drive Operation . .150, 153

Transmission.................148

Automatic.............148, 225

Fluid....................261

341