check engine JEEP XJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1457 of 2158

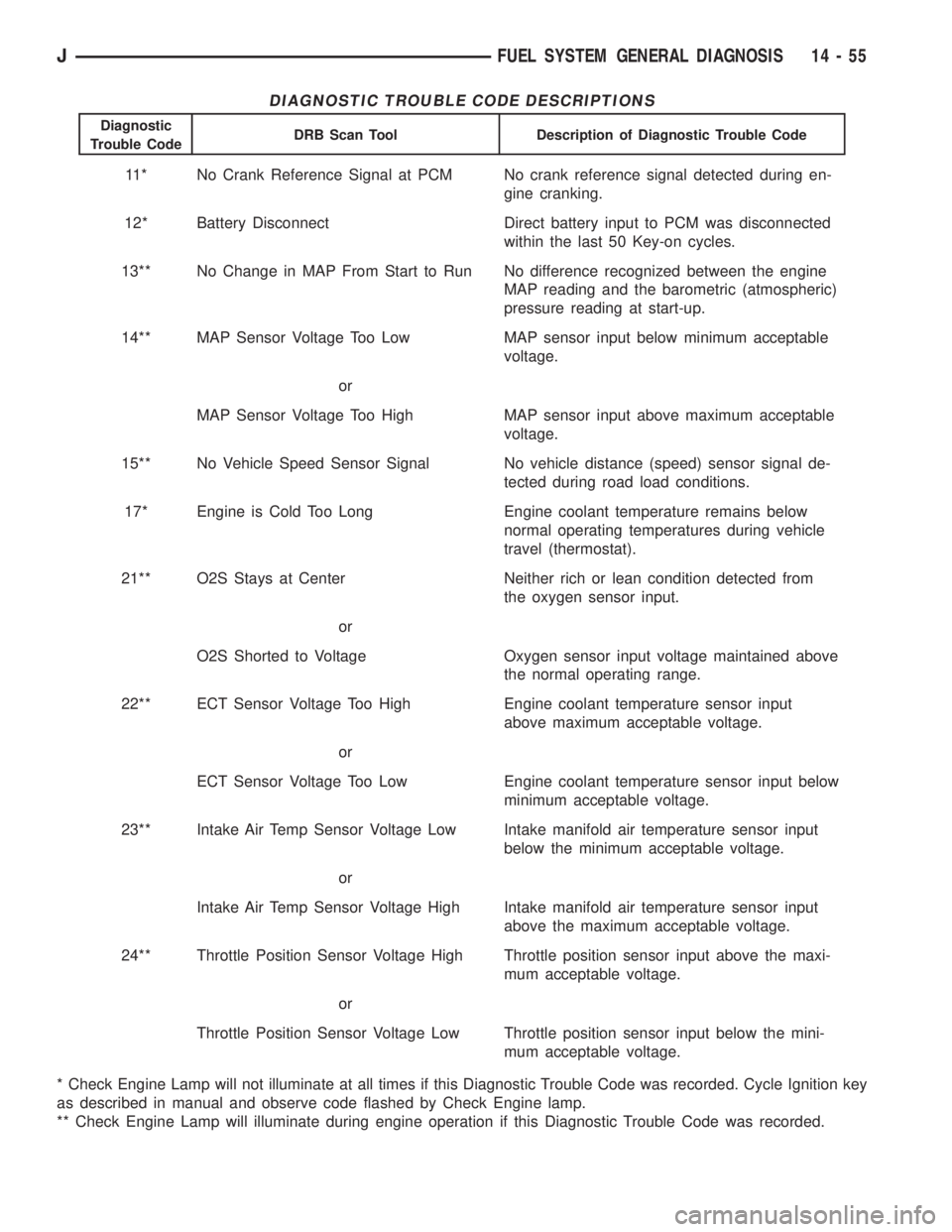

DIAGNOSTIC TROUBLE CODE DESCRIPTIONS

Diagnostic

Trouble CodeDRB Scan Tool Description of Diagnostic Trouble Code

11* No Crank Reference Signal at PCM No crank reference signal detected during en-

gine cranking.

12* Battery Disconnect Direct battery input to PCM was disconnected

within the last 50 Key-on cycles.

13** No Change in MAP From Start to Run No difference recognized between the engine

MAP reading and the barometric (atmospheric)

pressure reading at start-up.

14** MAP Sensor Voltage Too Low MAP sensor input below minimum acceptable

voltage.

or

MAP Sensor Voltage Too High MAP sensor input above maximum acceptable

voltage.

15** No Vehicle Speed Sensor Signal No vehicle distance (speed) sensor signal de-

tected during road load conditions.

17* Engine is Cold Too Long Engine coolant temperature remains below

normal operating temperatures during vehicle

travel (thermostat).

21** O2S Stays at Center Neither rich or lean condition detected from

the oxygen sensor input.

or

O2S Shorted to Voltage Oxygen sensor input voltage maintained above

the normal operating range.

22** ECT Sensor Voltage Too High Engine coolant temperature sensor input

above maximum acceptable voltage.

or

ECT Sensor Voltage Too Low Engine coolant temperature sensor input below

minimum acceptable voltage.

23** Intake Air Temp Sensor Voltage Low Intake manifold air temperature sensor input

below the minimum acceptable voltage.

or

Intake Air Temp Sensor Voltage High Intake manifold air temperature sensor input

above the maximum acceptable voltage.

24** Throttle Position Sensor Voltage High Throttle position sensor input above the maxi-

mum acceptable voltage.

or

Throttle Position Sensor Voltage Low Throttle position sensor input below the mini-

mum acceptable voltage.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key

as described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 55

Page 1458 of 2158

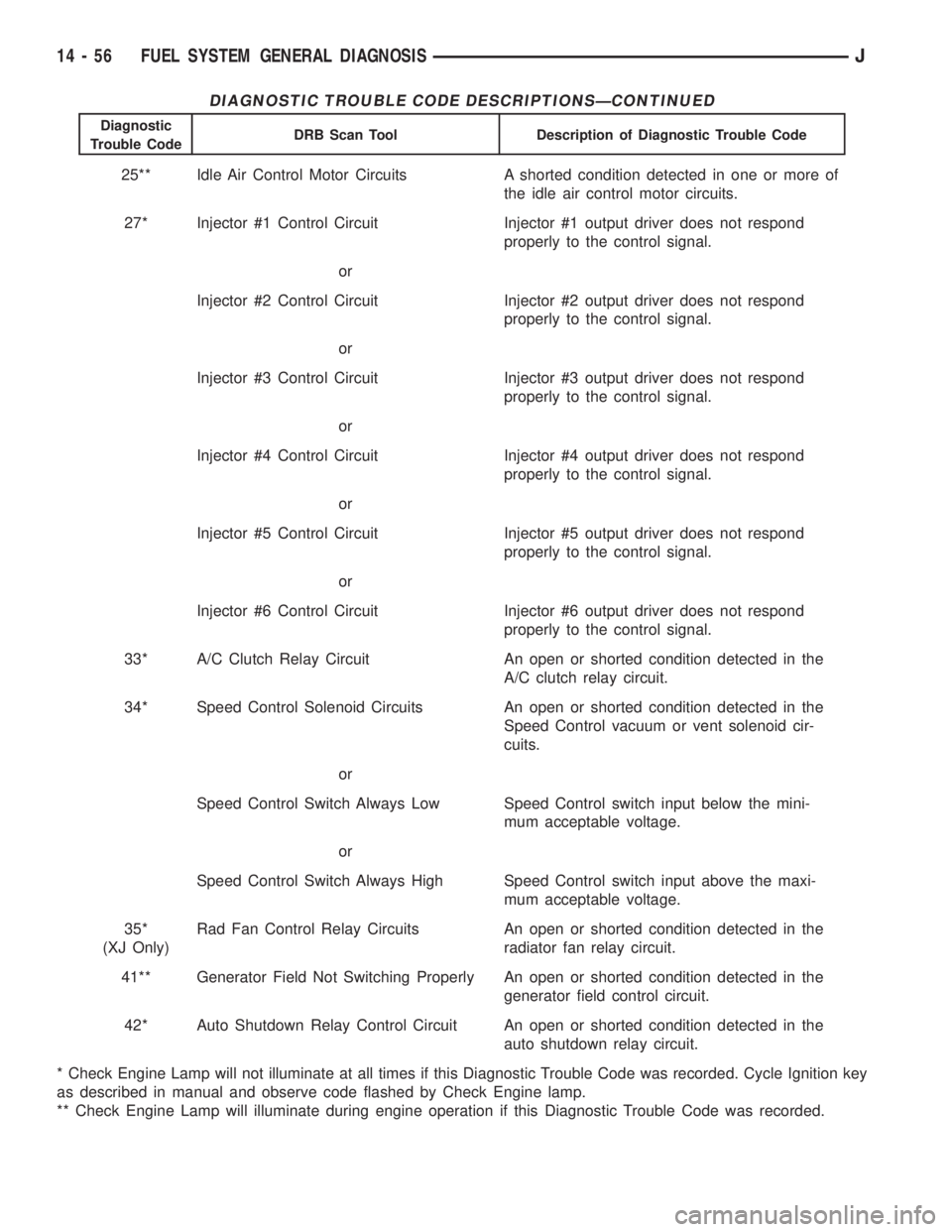

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble CodeDRB Scan Tool Description of Diagnostic Trouble Code

25** Idle Air Control Motor Circuits A shorted condition detected in one or more of

the idle air control motor circuits.

27* Injector #1 Control Circuit Injector #1 output driver does not respond

properly to the control signal.

or

Injector #2 Control Circuit Injector #2 output driver does not respond

properly to the control signal.

or

Injector #3 Control Circuit Injector #3 output driver does not respond

properly to the control signal.

or

Injector #4 Control Circuit Injector #4 output driver does not respond

properly to the control signal.

or

Injector #5 Control Circuit Injector #5 output driver does not respond

properly to the control signal.

or

Injector #6 Control Circuit Injector #6 output driver does not respond

properly to the control signal.

33* A/C Clutch Relay Circuit An open or shorted condition detected in the

A/C clutch relay circuit.

34* Speed Control Solenoid Circuits An open or shorted condition detected in the

Speed Control vacuum or vent solenoid cir-

cuits.

or

Speed Control Switch Always Low Speed Control switch input below the mini-

mum acceptable voltage.

or

Speed Control Switch Always High Speed Control switch input above the maxi-

mum acceptable voltage.

35*

(XJ Only)Rad Fan Control Relay Circuits An open or shorted condition detected in the

radiator fan relay circuit.

41** Generator Field Not Switching Properly An open or shorted condition detected in the

generator field control circuit.

42* Auto Shutdown Relay Control Circuit An open or shorted condition detected in the

auto shutdown relay circuit.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key

as described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

14 - 56 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1459 of 2158

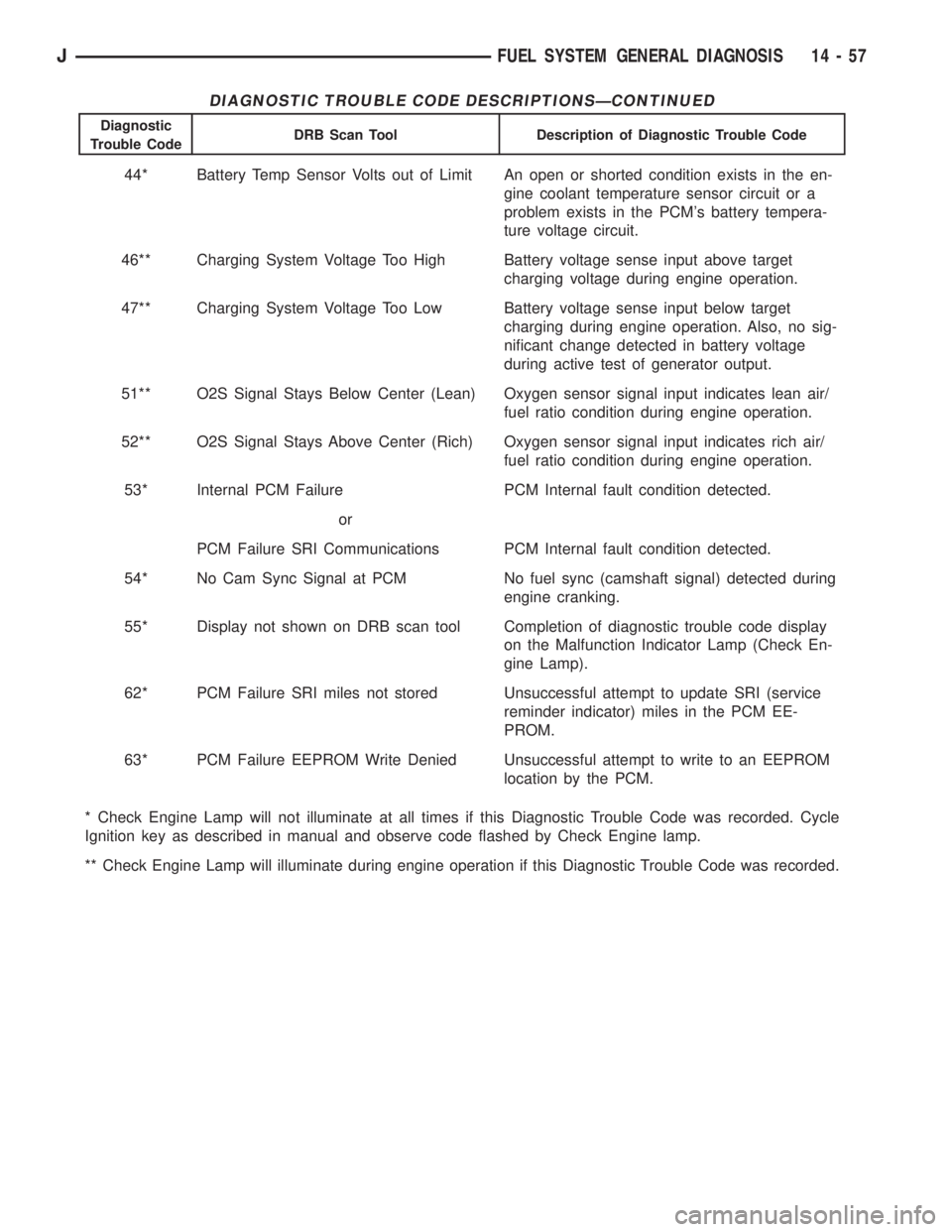

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble CodeDRB Scan Tool Description of Diagnostic Trouble Code

44* Battery Temp Sensor Volts out of Limit An open or shorted condition exists in the en-

gine coolant temperature sensor circuit or a

problem exists in the PCM's battery tempera-

ture voltage circuit.

46** Charging System Voltage Too High Battery voltage sense input above target

charging voltage during engine operation.

47** Charging System Voltage Too Low Battery voltage sense input below target

charging during engine operation. Also, no sig-

nificant change detected in battery voltage

during active test of generator output.

51** O2S Signal Stays Below Center (Lean) Oxygen sensor signal input indicates lean air/

fuel ratio condition during engine operation.

52** O2S Signal Stays Above Center (Rich) Oxygen sensor signal input indicates rich air/

fuel ratio condition during engine operation.

53* Internal PCM Failure PCM Internal fault condition detected.

or

PCM Failure SRI Communications PCM Internal fault condition detected.

54* No Cam Sync Signal at PCM No fuel sync (camshaft signal) detected during

engine cranking.

55* Display not shown on DRB scan tool Completion of diagnostic trouble code display

on the Malfunction Indicator Lamp (Check En-

gine Lamp).

62* PCM Failure SRI miles not stored Unsuccessful attempt to update SRI (service

reminder indicator) miles in the PCM EE-

PROM.

63* PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM

location by the PCM.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle

Ignition key as described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 57

Page 1462 of 2158

CAMSHAFT POSITION SENSOR

For removal/installation procedures, refer to Group

8D, Ignition System. See Camshaft Position Sensor.

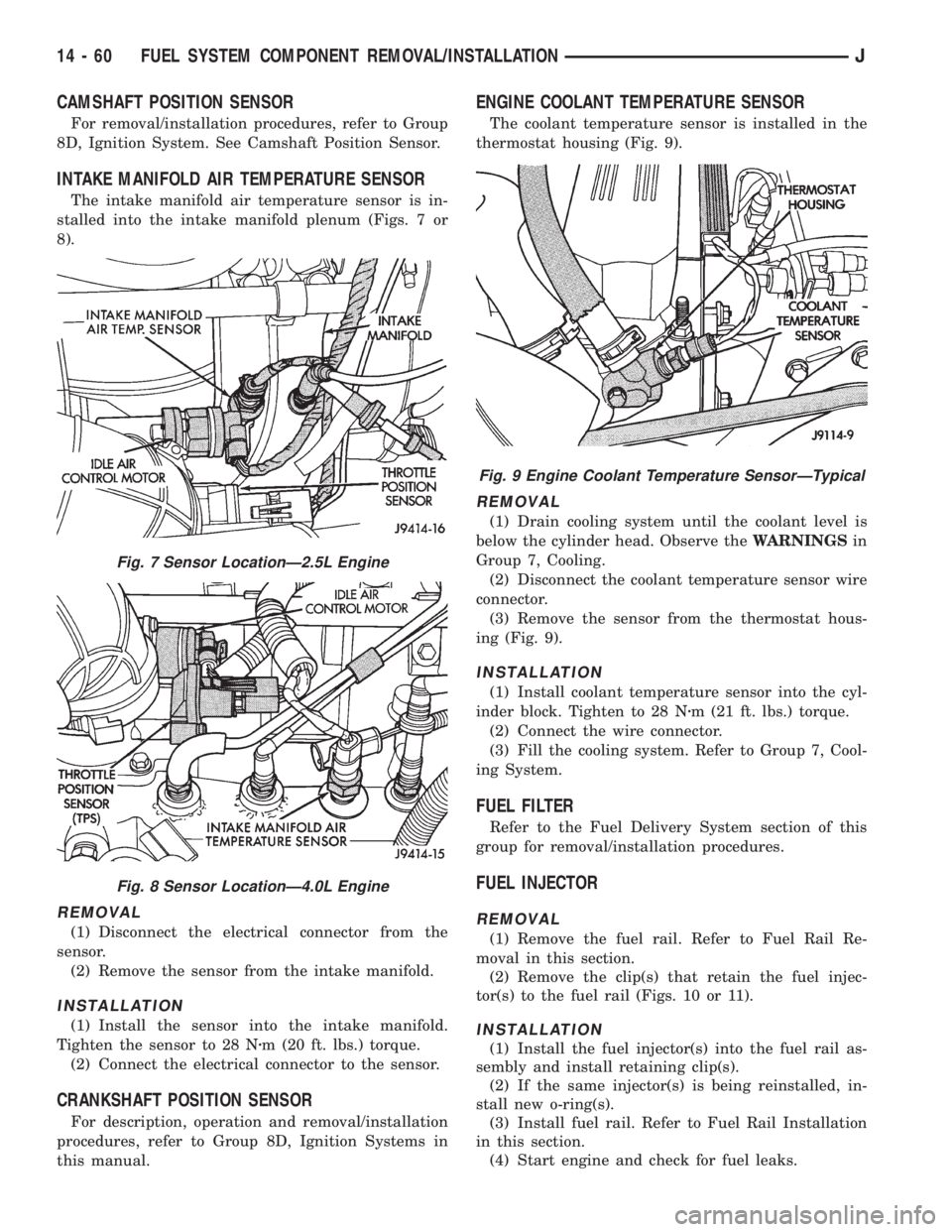

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

The intake manifold air temperature sensor is in-

stalled into the intake manifold plenum (Figs. 7 or

8).

REMOVAL

(1) Disconnect the electrical connector from the

sensor.

(2) Remove the sensor from the intake manifold.

INSTALLATION

(1) Install the sensor into the intake manifold.

Tighten the sensor to 28 Nzm (20 ft. lbs.) torque.

(2) Connect the electrical connector to the sensor.

CRANKSHAFT POSITION SENSOR

For description, operation and removal/installation

procedures, refer to Group 8D, Ignition Systems in

this manual.

ENGINE COOLANT TEMPERATURE SENSOR

The coolant temperature sensor is installed in the

thermostat housing (Fig. 9).

REMOVAL

(1) Drain cooling system until the coolant level is

below the cylinder head. Observe theWARNINGSin

Group 7, Cooling.

(2) Disconnect the coolant temperature sensor wire

connector.

(3) Remove the sensor from the thermostat hous-

ing (Fig. 9).

INSTALLATION

(1) Install coolant temperature sensor into the cyl-

inder block. Tighten to 28 Nzm (21 ft. lbs.) torque.

(2) Connect the wire connector.

(3) Fill the cooling system. Refer to Group 7, Cool-

ing System.

FUEL FILTER

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

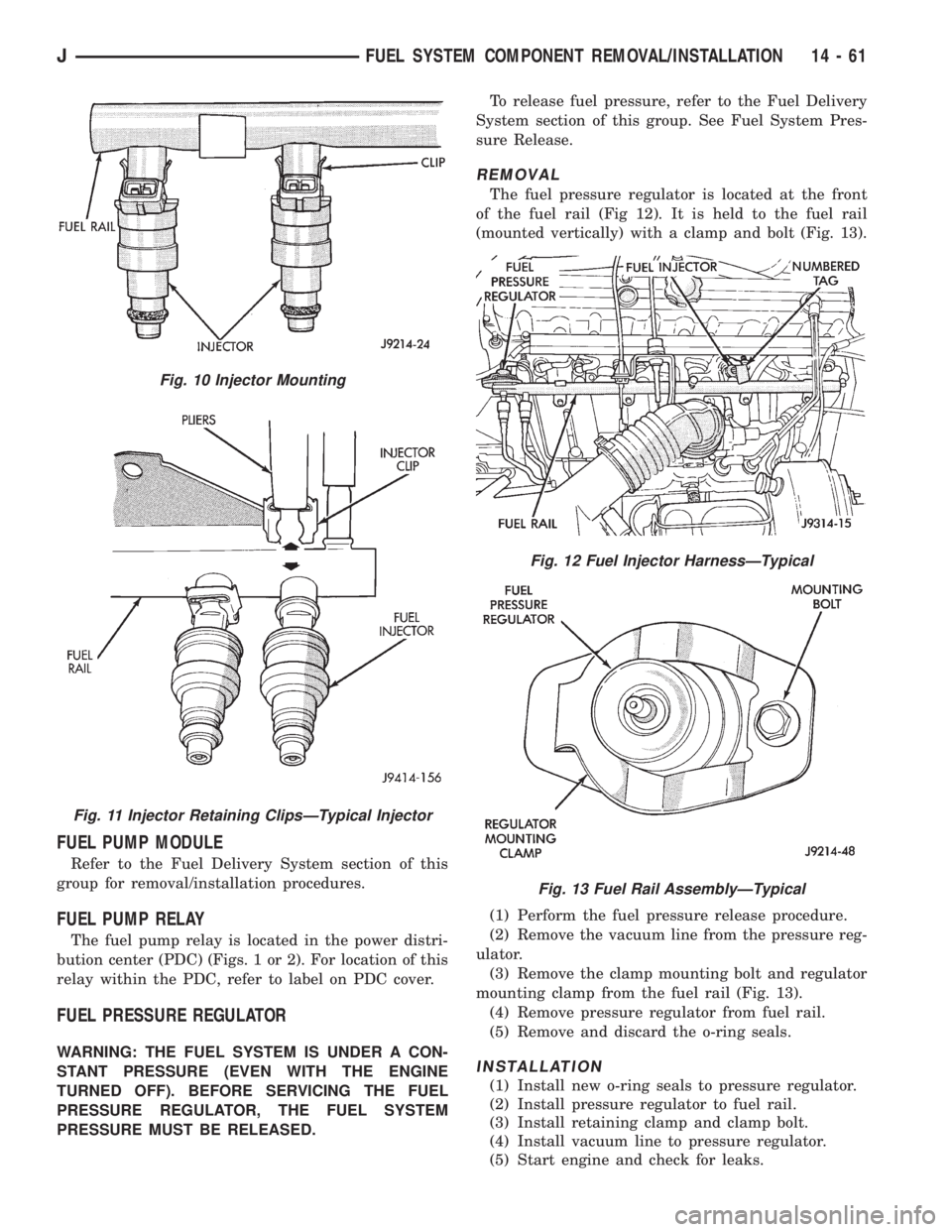

FUEL INJECTOR

REMOVAL

(1) Remove the fuel rail. Refer to Fuel Rail Re-

moval in this section.

(2) Remove the clip(s) that retain the fuel injec-

tor(s) to the fuel rail (Figs. 10 or 11).

INSTALLATION

(1) Install the fuel injector(s) into the fuel rail as-

sembly and install retaining clip(s).

(2) If the same injector(s) is being reinstalled, in-

stall new o-ring(s).

(3) Install fuel rail. Refer to Fuel Rail Installation

in this section.

(4) Start engine and check for fuel leaks.

Fig. 7 Sensor LocationÐ2.5L Engine

Fig. 8 Sensor LocationÐ4.0L Engine

Fig. 9 Engine Coolant Temperature SensorÐTypical

14 - 60 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1463 of 2158

FUEL PUMP MODULE

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

FUEL PUMP RELAY

The fuel pump relay is located in the power distri-

bution center (PDC) (Figs. 1 or 2). For location of this

relay within the PDC, refer to label on PDC cover.

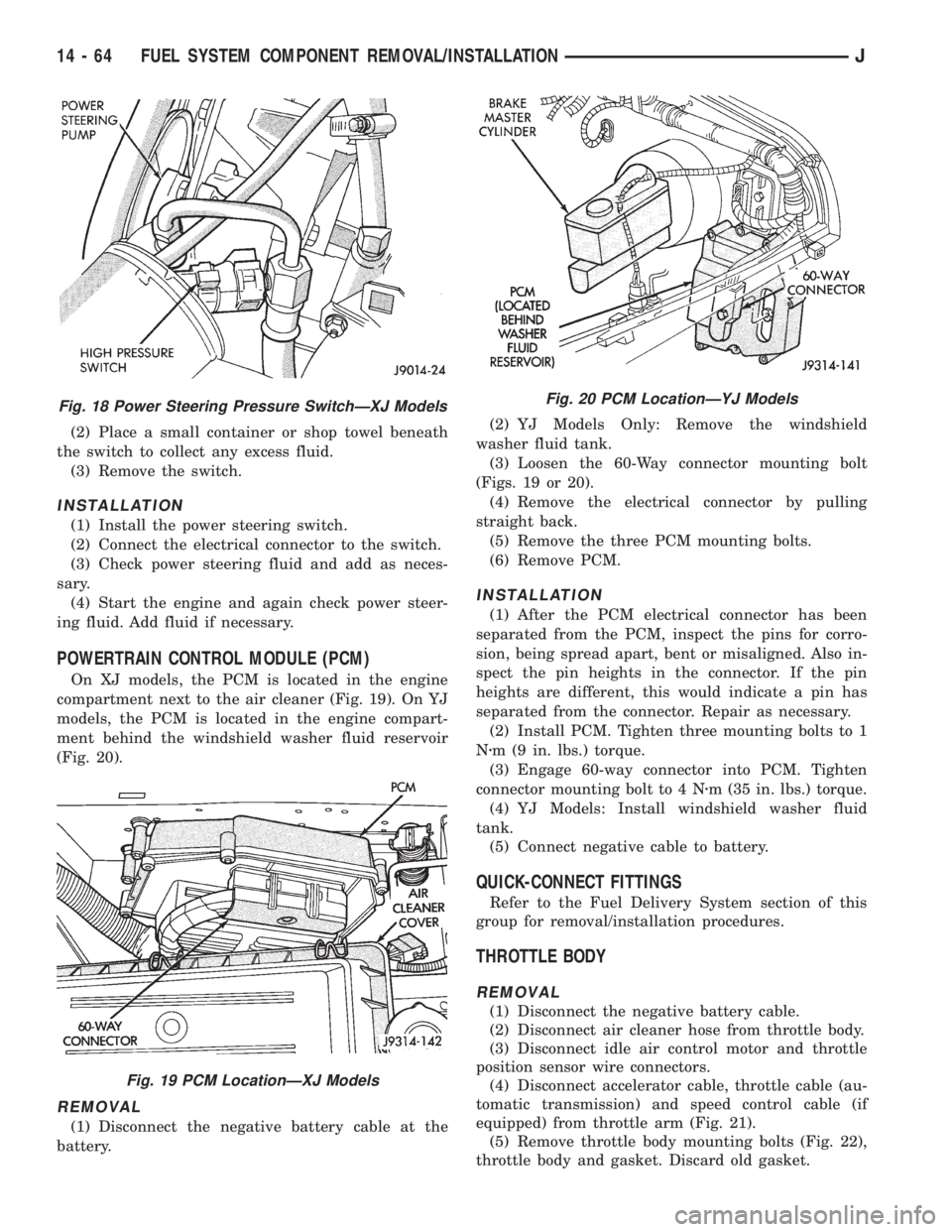

FUEL PRESSURE REGULATOR

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE

TURNED OFF). BEFORE SERVICING THE FUEL

PRESSURE REGULATOR, THE FUEL SYSTEM

PRESSURE MUST BE RELEASED.To release fuel pressure, refer to the Fuel Delivery

System section of this group. See Fuel System Pres-

sure Release.

REMOVAL

The fuel pressure regulator is located at the front

of the fuel rail (Fig 12). It is held to the fuel rail

(mounted vertically) with a clamp and bolt (Fig. 13).

(1) Perform the fuel pressure release procedure.

(2) Remove the vacuum line from the pressure reg-

ulator.

(3) Remove the clamp mounting bolt and regulator

mounting clamp from the fuel rail (Fig. 13).

(4) Remove pressure regulator from fuel rail.

(5) Remove and discard the o-ring seals.

INSTALLATION

(1) Install new o-ring seals to pressure regulator.

(2) Install pressure regulator to fuel rail.

(3) Install retaining clamp and clamp bolt.

(4) Install vacuum line to pressure regulator.

(5) Start engine and check for leaks.

Fig. 10 Injector Mounting

Fig. 11 Injector Retaining ClipsÐTypical Injector

Fig. 12 Fuel Injector HarnessÐTypical

Fig. 13 Fuel Rail AssemblyÐTypical

JFUEL SYSTEM COMPONENT REMOVAL/INSTALLATION 14 - 61

Page 1464 of 2158

FUEL RAIL ASSEMBLY

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39 PSI).

THIS PRESSURE MUST BE RELEASED BEFORE

SERVICING THE FUEL RAIL.

(1) Remove fuel tank filler tube cap.

(2) Disconnect the negative battery cable from bat-

tery.

(3) Perform the Fuel System Pressure Release Pro-

cedure as described in the Fuel Delivery System sec-

tion of this Group.

(4) Remove and numerically attach a tag (if fuel

injector is not already tagged), the injector harness

connectors. Do this at each injector (Fig. 12).

(5) Disconnect vacuum line from fuel pressure reg-

ulator (Fig. 12).

(6) Disconnect fuel supply line from fuel rail and

the fuel return line from fuel pressure regulator (Fig.

12). Refer to Fuel Tubes/Lines/Hoses and Clamps, or

Quick-Connect Fittings. These can both be found in

the Fuel Delivery section of this group.

(7) Remove fuel rail mounting bolts.

On models with automatic transmissions, it may be

necessary to remove automatic transmission throttle

line pressure cable and bracket. This will aid in fuel

rail assembly removal.

(8) Remove fuel rail by gently rocking until all the

fuel injectors are out of the intake manifold.

INSTALLATION

(1) Position tips of all fuel injectors into the corre-

sponding injector bore in the intake manifold. Seat

injectors into manifold.

(2) Tighten fuel rail mounting bolts to 27 Nzm (20

ft. lbs.) torque.

(3) Connect injector harness connectors to appro-

priate (tagged) injector.

(4) Connect both fuel lines to fuel rail. Refer to the

Fuel Delivery section of this group for procedures.

(5) Connect vacuum supply line to fuel pressure

regulator.

(6) Install protective cap to pressure test port fit-

ting.

(7) Install fuel tank cap.

(8) Connect negative battery cable to battery.

(9) Start engine and check for fuel leaks.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF)

OF APPROXIMATELY 100 KPA (14.5 PSI). BEFORE

SERVICING THE FUEL PUMP, FUEL RAIL, FUELLINES, FUEL FILTER OR FUEL INJECTOR, THE

FUEL SYSTEM PRESSURE MUST BE RELEASED.

Refer to the Fuel Delivery System section of this

group. See Fuel Pressure Release procedure.

FUEL TANKS

Refer to the Fuel Tank section of this group for re-

moval/installation procedures.

FUEL TANK PRESSURE RELIEF/ROLLOVER VALVE

Refer to the Fuel Tank section of this group for re-

moval/installation procedures.

FUEL TUBES/LINES/HOSES AND CLAMPS

Refer to the Fuel Delivery System section of this

group for removal/installation procedures. Also refer

to Quick-Connect Fittings in the Fuel Delivery sec-

tion of this group.

IDLE AIR CONTROL (IAC) MOTOR

The IAC motor is mounted to the throttle body ad-

jacent to the throttle position sensor (Fig. 14).

REMOVAL

(1) Disconnect the electrical connector from the

IAC motor.

(2) Remove IAC motor torx head mounting bolts.

(3) Remove IAC motor.

INSTALLATION

(1) Install IAC motor into throttle body and

tighten retaining bolts.

(2) Connect electrical connector to IAC motor.

IGNITION COIL

Refer to Group 8D, Ignition Systems for removal/

installation procedures.

Fig. 14 Idle Air Control MotorÐRemoval/

InstallationÐTypical

14 - 62 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1466 of 2158

(2) Place a small container or shop towel beneath

the switch to collect any excess fluid.

(3) Remove the switch.

INSTALLATION

(1) Install the power steering switch.

(2) Connect the electrical connector to the switch.

(3) Check power steering fluid and add as neces-

sary.

(4) Start the engine and again check power steer-

ing fluid. Add fluid if necessary.

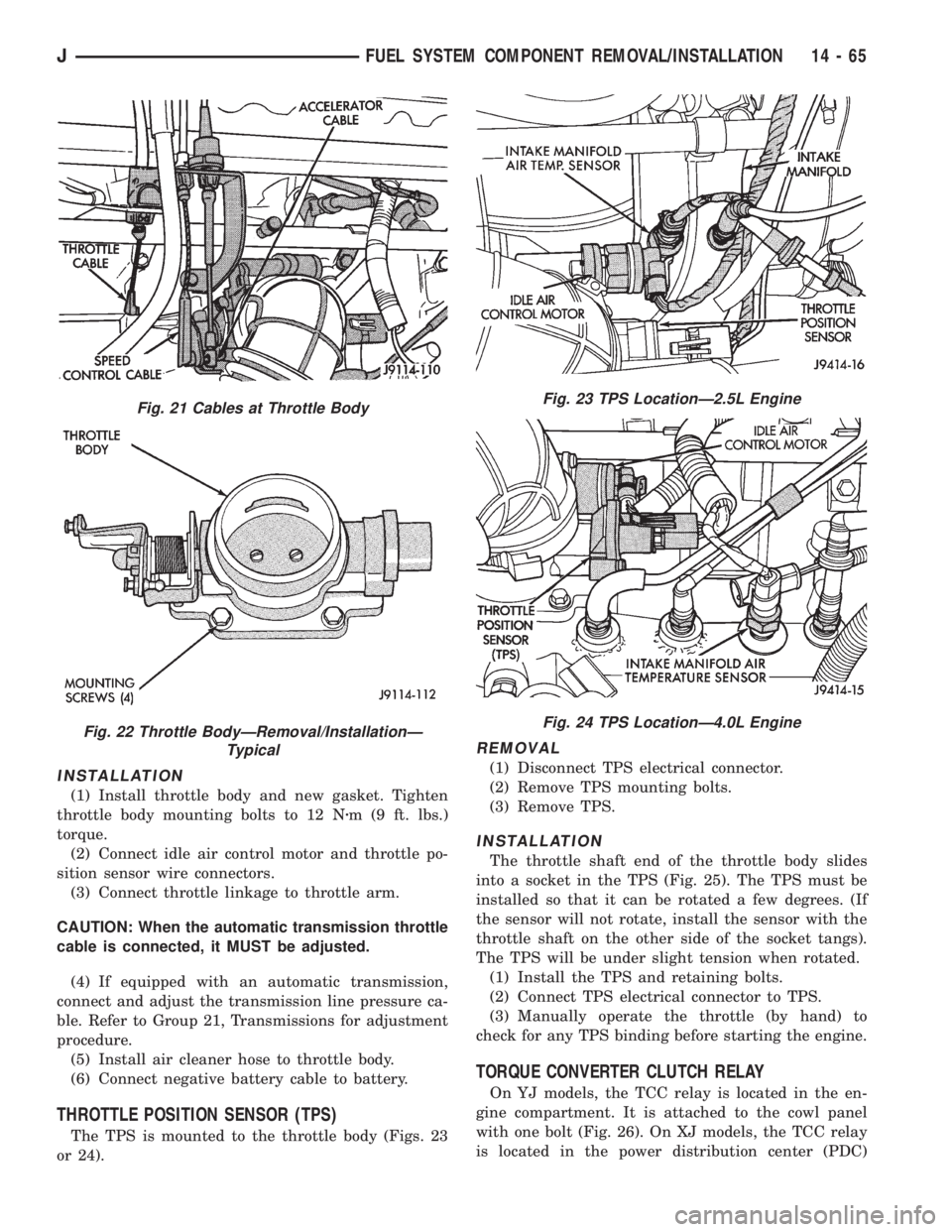

POWERTRAIN CONTROL MODULE (PCM)

On XJ models, the PCM is located in the engine

compartment next to the air cleaner (Fig. 19). On YJ

models, the PCM is located in the engine compart-

ment behind the windshield washer fluid reservoir

(Fig. 20).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.(2) YJ Models Only: Remove the windshield

washer fluid tank.

(3) Loosen the 60-Way connector mounting bolt

(Figs. 19 or 20).

(4) Remove the electrical connector by pulling

straight back.

(5) Remove the three PCM mounting bolts.

(6) Remove PCM.

INSTALLATION

(1) After the PCM electrical connector has been

separated from the PCM, inspect the pins for corro-

sion, being spread apart, bent or misaligned. Also in-

spect the pin heights in the connector. If the pin

heights are different, this would indicate a pin has

separated from the connector. Repair as necessary.

(2) Install PCM. Tighten three mounting bolts to 1

Nzm (9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting bolt to 4 Nzm (35 in. lbs.) torque.

(4) YJ Models: Install windshield washer fluid

tank.

(5) Connect negative cable to battery.

QUICK-CONNECT FITTINGS

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

THROTTLE BODY

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect air cleaner hose from throttle body.

(3) Disconnect idle air control motor and throttle

position sensor wire connectors.

(4) Disconnect accelerator cable, throttle cable (au-

tomatic transmission) and speed control cable (if

equipped) from throttle arm (Fig. 21).

(5) Remove throttle body mounting bolts (Fig. 22),

throttle body and gasket. Discard old gasket.

Fig. 18 Power Steering Pressure SwitchÐXJ Models

Fig. 19 PCM LocationÐXJ Models

Fig. 20 PCM LocationÐYJ Models

14 - 64 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1467 of 2158

INSTALLATION

(1) Install throttle body and new gasket. Tighten

throttle body mounting bolts to 12 Nzm (9 ft. lbs.)

torque.

(2) Connect idle air control motor and throttle po-

sition sensor wire connectors.

(3) Connect throttle linkage to throttle arm.

CAUTION: When the automatic transmission throttle

cable is connected, it MUST be adjusted.

(4) If equipped with an automatic transmission,

connect and adjust the transmission line pressure ca-

ble. Refer to Group 21, Transmissions for adjustment

procedure.

(5) Install air cleaner hose to throttle body.

(6) Connect negative battery cable to battery.

THROTTLE POSITION SENSOR (TPS)

The TPS is mounted to the throttle body (Figs. 23

or 24).

REMOVAL

(1) Disconnect TPS electrical connector.

(2) Remove TPS mounting bolts.

(3) Remove TPS.

INSTALLATION

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 25). The TPS must be

installed so that it can be rotated a few degrees. (If

the sensor will not rotate, install the sensor with the

throttle shaft on the other side of the socket tangs).

The TPS will be under slight tension when rotated.

(1) Install the TPS and retaining bolts.

(2) Connect TPS electrical connector to TPS.

(3) Manually operate the throttle (by hand) to

check for any TPS binding before starting the engine.

TORQUE CONVERTER CLUTCH RELAY

On YJ models, the TCC relay is located in the en-

gine compartment. It is attached to the cowl panel

with one bolt (Fig. 26). On XJ models, the TCC relay

is located in the power distribution center (PDC)

Fig. 21 Cables at Throttle Body

Fig. 22 Throttle BodyÐRemoval/InstallationÐ

Typical

Fig. 23 TPS LocationÐ2.5L Engine

Fig. 24 TPS LocationÐ4.0L Engine

JFUEL SYSTEM COMPONENT REMOVAL/INSTALLATION 14 - 65

Page 1472 of 2158

SERVICE DIAGNOSIS

INDEX

page page

Runout.................................. 4

Unbalance............................... 3Universal Joint Angle Measurement............. 4

Vibration................................. 3

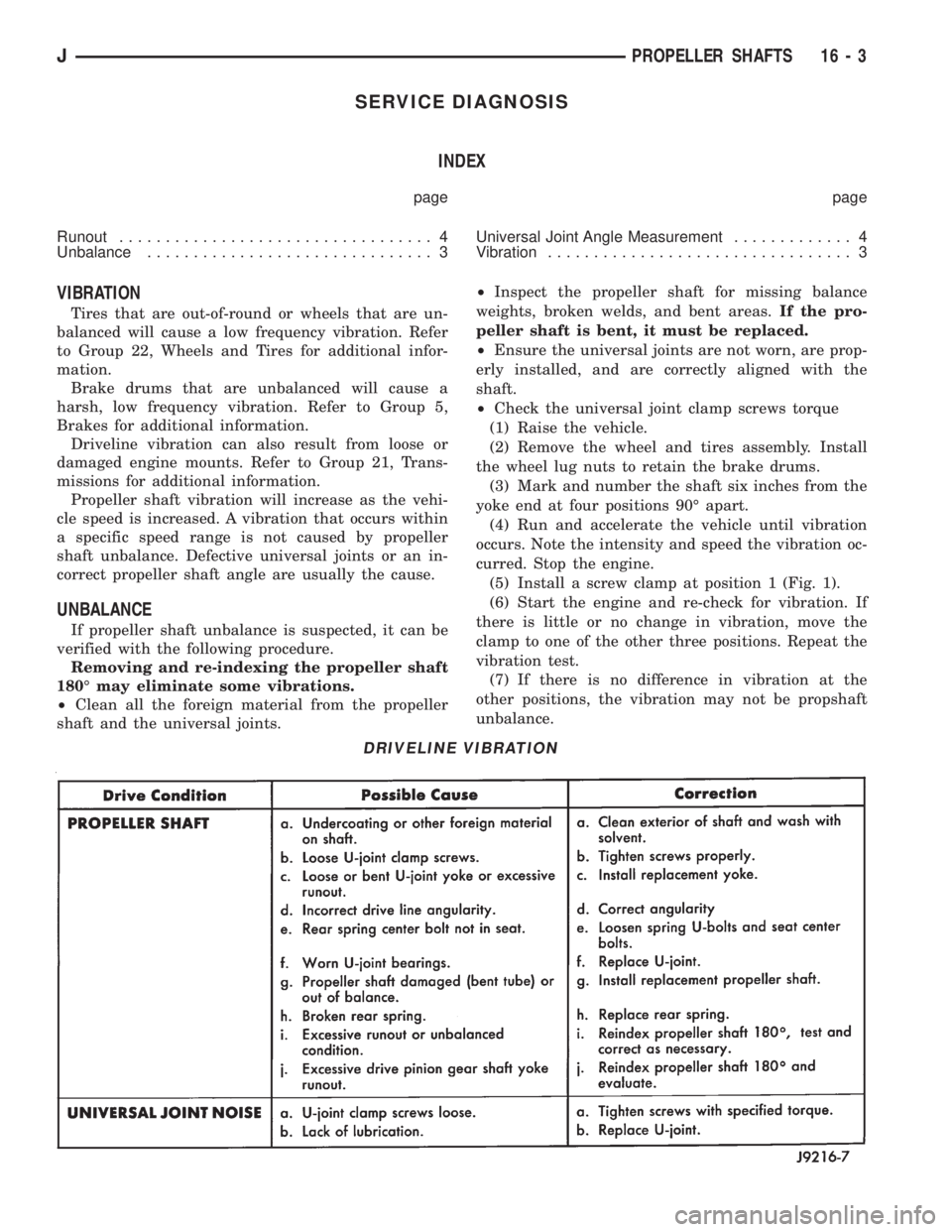

VIBRATION

Tires that are out-of-round or wheels that are un-

balanced will cause a low frequency vibration. Refer

to Group 22, Wheels and Tires for additional infor-

mation.

Brake drums that are unbalanced will cause a

harsh, low frequency vibration. Refer to Group 5,

Brakes for additional information.

Driveline vibration can also result from loose or

damaged engine mounts. Refer to Group 21, Trans-

missions for additional information.

Propeller shaft vibration will increase as the vehi-

cle speed is increased. A vibration that occurs within

a specific speed range is not caused by propeller

shaft unbalance. Defective universal joints or an in-

correct propeller shaft angle are usually the cause.

UNBALANCE

If propeller shaft unbalance is suspected, it can be

verified with the following procedure.

Removing and re-indexing the propeller shaft

180É may eliminate some vibrations.

²Clean all the foreign material from the propeller

shaft and the universal joints.²Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

²Ensure the universal joints are not worn, are prop-

erly installed, and are correctly aligned with the

shaft.

²Check the universal joint clamp screws torque

(1) Raise the vehicle.

(2) Remove the wheel and tires assembly. Install

the wheel lug nuts to retain the brake drums.

(3) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.

(4) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration oc-

curred. Stop the engine.

(5) Install a screw clamp at position 1 (Fig. 1).

(6) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(7) If there is no difference in vibration at the

other positions, the vibration may not be propshaft

unbalance.

DRIVELINE VIBRATION

JPROPELLER SHAFTS 16 - 3

Page 1474 of 2158

²Have at least a 1/2 degree continuous operating

(propeller shaft) angle

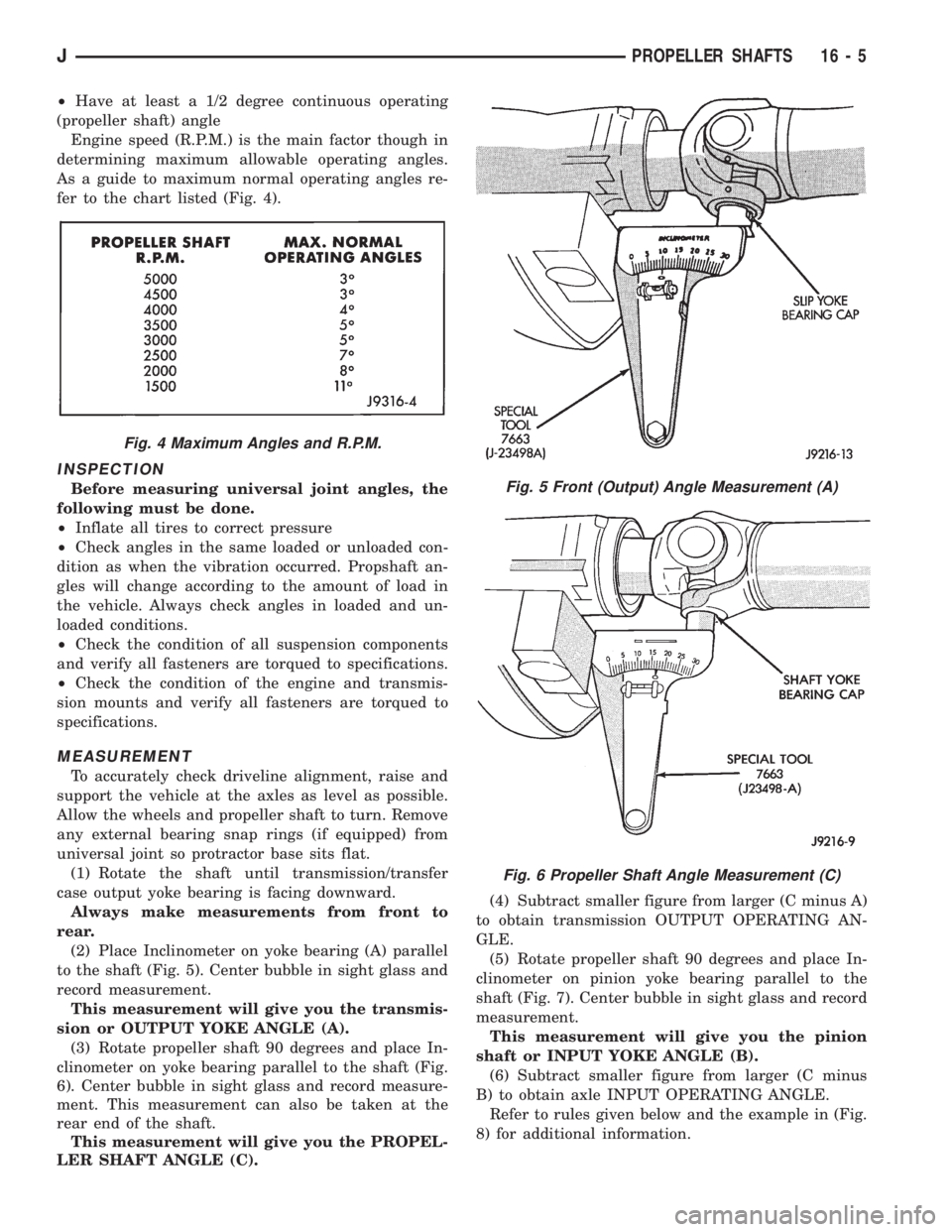

Engine speed (R.P.M.) is the main factor though in

determining maximum allowable operating angles.

As a guide to maximum normal operating angles re-

fer to the chart listed (Fig. 4).

INSPECTION

Before measuring universal joint angles, the

following must be done.

²Inflate all tires to correct pressure

²Check angles in the same loaded or unloaded con-

dition as when the vibration occurred. Propshaft an-

gles will change according to the amount of load in

the vehicle. Always check angles in loaded and un-

loaded conditions.

²Check the condition of all suspension components

and verify all fasteners are torqued to specifications.

²Check the condition of the engine and transmis-

sion mounts and verify all fasteners are torqued to

specifications.

MEASUREMENT

To accurately check driveline alignment, raise and

support the vehicle at the axles as level as possible.

Allow the wheels and propeller shaft to turn. Remove

any external bearing snap rings (if equipped) from

universal joint so protractor base sits flat.

(1) Rotate the shaft until transmission/transfer

case output yoke bearing is facing downward.

Always make measurements from front to

rear.

(2) Place Inclinometer on yoke bearing (A) parallel

to the shaft (Fig. 5). Center bubble in sight glass and

record measurement.

This measurement will give you the transmis-

sion or OUTPUT YOKE ANGLE (A).

(3) Rotate propeller shaft 90 degrees and place In-

clinometer on yoke bearing parallel to the shaft (Fig.

6). Center bubble in sight glass and record measure-

ment. This measurement can also be taken at the

rear end of the shaft.

This measurement will give you the PROPEL-

LER SHAFT ANGLE (C).(4) Subtract smaller figure from larger (C minus A)

to obtain transmission OUTPUT OPERATING AN-

GLE.

(5) Rotate propeller shaft 90 degrees and place In-

clinometer on pinion yoke bearing parallel to the

shaft (Fig. 7). Center bubble in sight glass and record

measurement.

This measurement will give you the pinion

shaft or INPUT YOKE ANGLE (B).

(6) Subtract smaller figure from larger (C minus

B) to obtain axle INPUT OPERATING ANGLE.

Refer to rules given below and the example in (Fig.

8) for additional information.

Fig. 4 Maximum Angles and R.P.M.

Fig. 5 Front (Output) Angle Measurement (A)

Fig. 6 Propeller Shaft Angle Measurement (C)

JPROPELLER SHAFTS 16 - 5