JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 2011 of 2158

(2) Ensure that all the retainer clips, screws and

Velcro strips are disengaged before removing the

headliner.

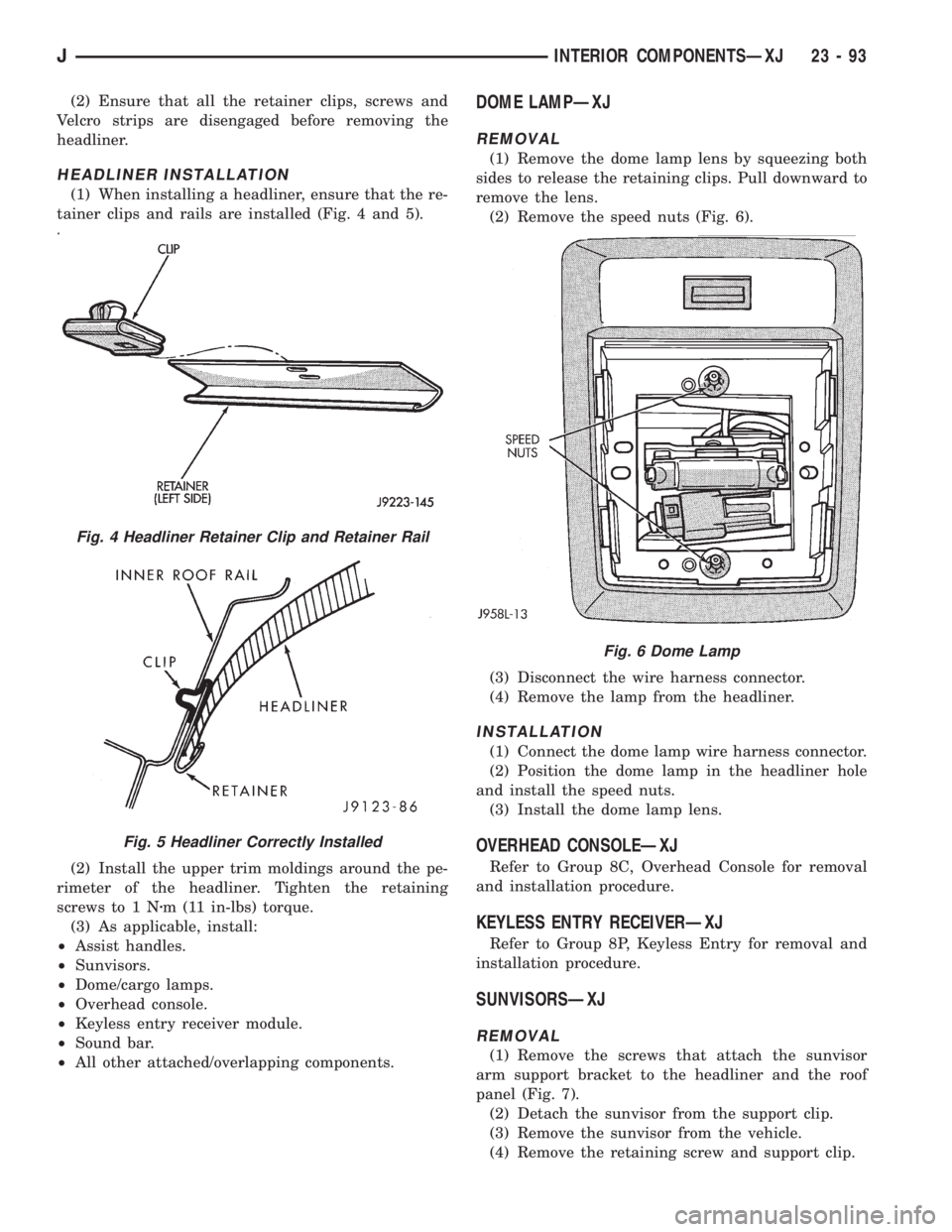

HEADLINER INSTALLATION

(1) When installing a headliner, ensure that the re-

tainer clips and rails are installed (Fig. 4 and 5).

(2) Install the upper trim moldings around the pe-

rimeter of the headliner. Tighten the retaining

screws to 1 Nzm (11 in-lbs) torque.

(3) As applicable, install:

²Assist handles.

²Sunvisors.

²Dome/cargo lamps.

²Overhead console.

²Keyless entry receiver module.

²Sound bar.

²All other attached/overlapping components.

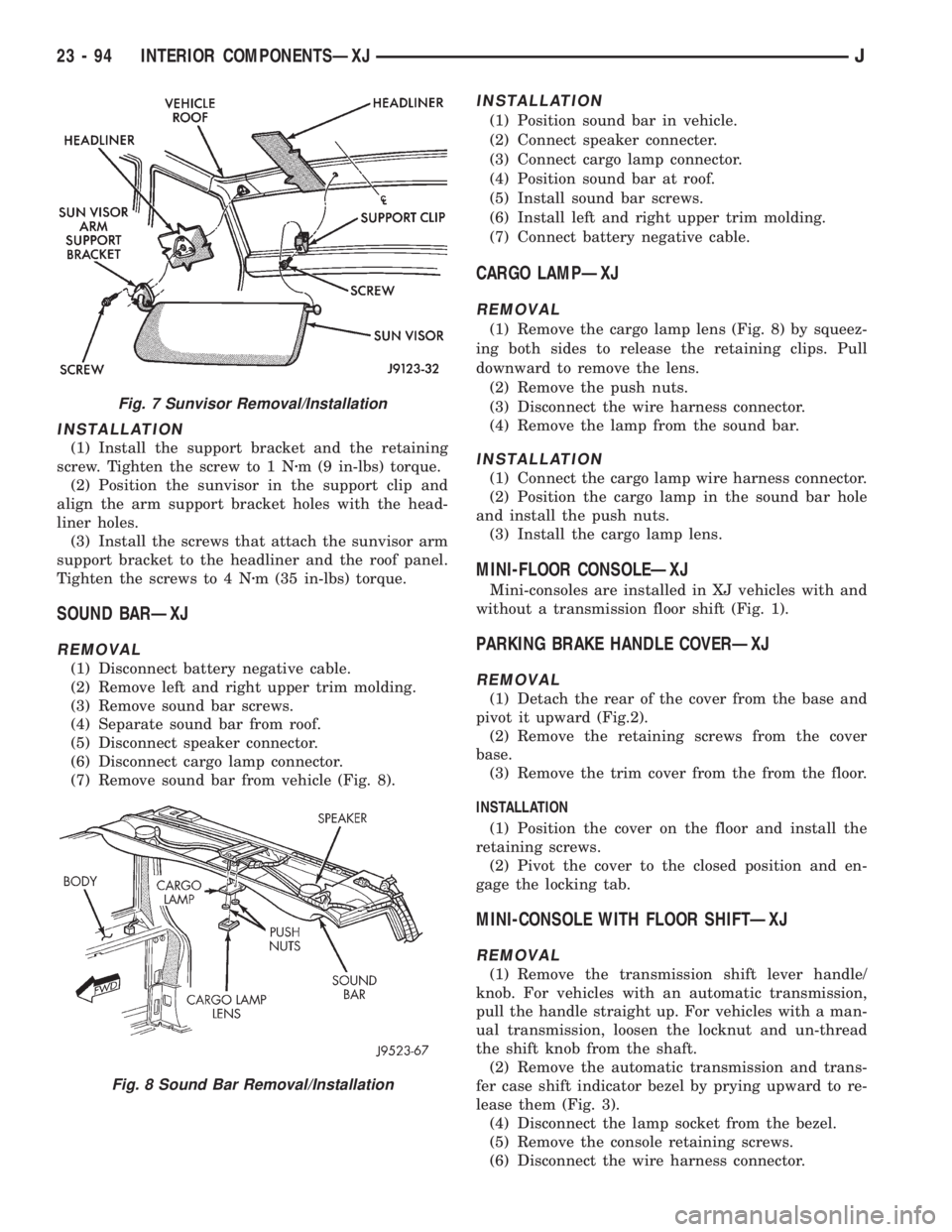

DOME LAMPÐXJ

REMOVAL

(1) Remove the dome lamp lens by squeezing both

sides to release the retaining clips. Pull downward to

remove the lens.

(2) Remove the speed nuts (Fig. 6).

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the headliner.

INSTALLATION

(1) Connect the dome lamp wire harness connector.

(2) Position the dome lamp in the headliner hole

and install the speed nuts.

(3) Install the dome lamp lens.

OVERHEAD CONSOLEÐXJ

Refer to Group 8C, Overhead Console for removal

and installation procedure.

KEYLESS ENTRY RECEIVERÐXJ

Refer to Group 8P, Keyless Entry for removal and

installation procedure.

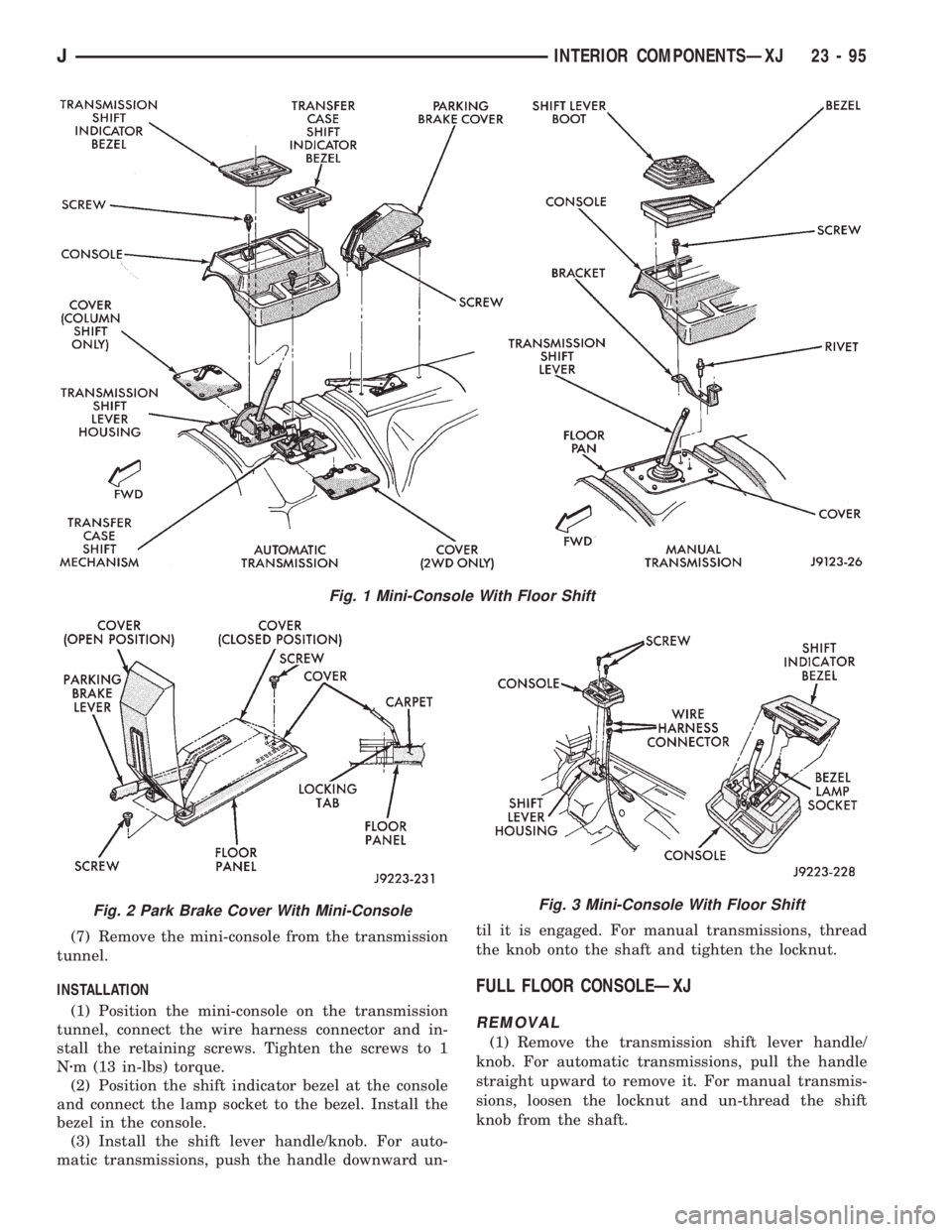

SUNVISORSÐXJ

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support bracket to the headliner and the roof

panel (Fig. 7).

(2) Detach the sunvisor from the support clip.

(3) Remove the sunvisor from the vehicle.

(4) Remove the retaining screw and support clip.

Fig. 4 Headliner Retainer Clip and Retainer Rail

Fig. 5 Headliner Correctly Installed

Fig. 6 Dome Lamp

JINTERIOR COMPONENTSÐXJ 23 - 93

Page 2012 of 2158

INSTALLATION

(1) Install the support bracket and the retaining

screw. Tighten the screw to 1 Nzm (9 in-lbs) torque.

(2) Position the sunvisor in the support clip and

align the arm support bracket holes with the head-

liner holes.

(3) Install the screws that attach the sunvisor arm

support bracket to the headliner and the roof panel.

Tighten the screws to 4 Nzm (35 in-lbs) torque.

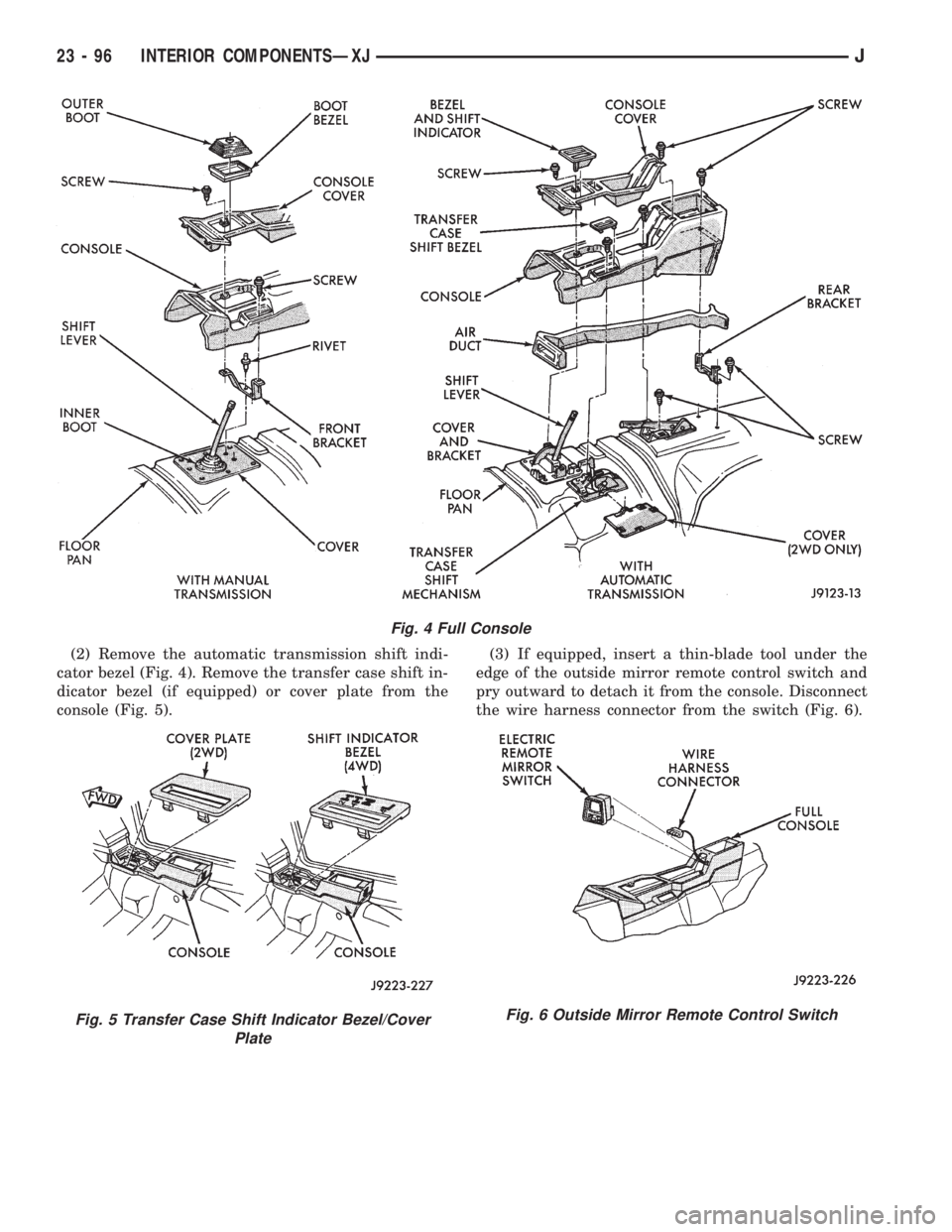

SOUND BARÐXJ

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove left and right upper trim molding.

(3) Remove sound bar screws.

(4) Separate sound bar from roof.

(5) Disconnect speaker connector.

(6) Disconnect cargo lamp connector.

(7) Remove sound bar from vehicle (Fig. 8).

INSTALLATION

(1) Position sound bar in vehicle.

(2) Connect speaker connecter.

(3) Connect cargo lamp connector.

(4) Position sound bar at roof.

(5) Install sound bar screws.

(6) Install left and right upper trim molding.

(7) Connect battery negative cable.

CARGO LAMPÐXJ

REMOVAL

(1) Remove the cargo lamp lens (Fig. 8) by squeez-

ing both sides to release the retaining clips. Pull

downward to remove the lens.

(2) Remove the push nuts.

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the sound bar.

INSTALLATION

(1) Connect the cargo lamp wire harness connector.

(2) Position the cargo lamp in the sound bar hole

and install the push nuts.

(3) Install the cargo lamp lens.

MINI-FLOOR CONSOLEÐXJ

Mini-consoles are installed in XJ vehicles with and

without a transmission floor shift (Fig. 1).

PARKING BRAKE HANDLE COVERÐXJ

REMOVAL

(1) Detach the rear of the cover from the base and

pivot it upward (Fig.2).

(2) Remove the retaining screws from the cover

base.

(3) Remove the trim cover from the from the floor.

INSTALLATION

(1) Position the cover on the floor and install the

retaining screws.

(2) Pivot the cover to the closed position and en-

gage the locking tab.

MINI-CONSOLE WITH FLOOR SHIFTÐXJ

REMOVAL

(1) Remove the transmission shift lever handle/

knob. For vehicles with an automatic transmission,

pull the handle straight up. For vehicles with a man-

ual transmission, loosen the locknut and un-thread

the shift knob from the shaft.

(2) Remove the automatic transmission and trans-

fer case shift indicator bezel by prying upward to re-

lease them (Fig. 3).

(4) Disconnect the lamp socket from the bezel.

(5) Remove the console retaining screws.

(6) Disconnect the wire harness connector.

Fig. 7 Sunvisor Removal/Installation

Fig. 8 Sound Bar Removal/Installation

23 - 94 INTERIOR COMPONENTSÐXJJ

Page 2013 of 2158

(7) Remove the mini-console from the transmission

tunnel.

INSTALLATION

(1) Position the mini-console on the transmission

tunnel, connect the wire harness connector and in-

stall the retaining screws. Tighten the screws to 1

Nzm (13 in-lbs) torque.

(2) Position the shift indicator bezel at the console

and connect the lamp socket to the bezel. Install the

bezel in the console.

(3) Install the shift lever handle/knob. For auto-

matic transmissions, push the handle downward un-til it is engaged. For manual transmissions, thread

the knob onto the shaft and tighten the locknut.

FULL FLOOR CONSOLEÐXJ

REMOVAL

(1) Remove the transmission shift lever handle/

knob. For automatic transmissions, pull the handle

straight upward to remove it. For manual transmis-

sions, loosen the locknut and un-thread the shift

knob from the shaft.

Fig. 1 Mini-Console With Floor Shift

Fig. 2 Park Brake Cover With Mini-ConsoleFig. 3 Mini-Console With Floor Shift

JINTERIOR COMPONENTSÐXJ 23 - 95

Page 2014 of 2158

(2) Remove the automatic transmission shift indi-

cator bezel (Fig. 4). Remove the transfer case shift in-

dicator bezel (if equipped) or cover plate from the

console (Fig. 5).(3) If equipped, insert a thin-blade tool under the

edge of the outside mirror remote control switch and

pry outward to detach it from the console. Disconnect

the wire harness connector from the switch (Fig. 6).

Fig. 4 Full Console

Fig. 5 Transfer Case Shift Indicator Bezel/Cover

PlateFig. 6 Outside Mirror Remote Control Switch

23 - 96 INTERIOR COMPONENTSÐXJJ

Page 2015 of 2158

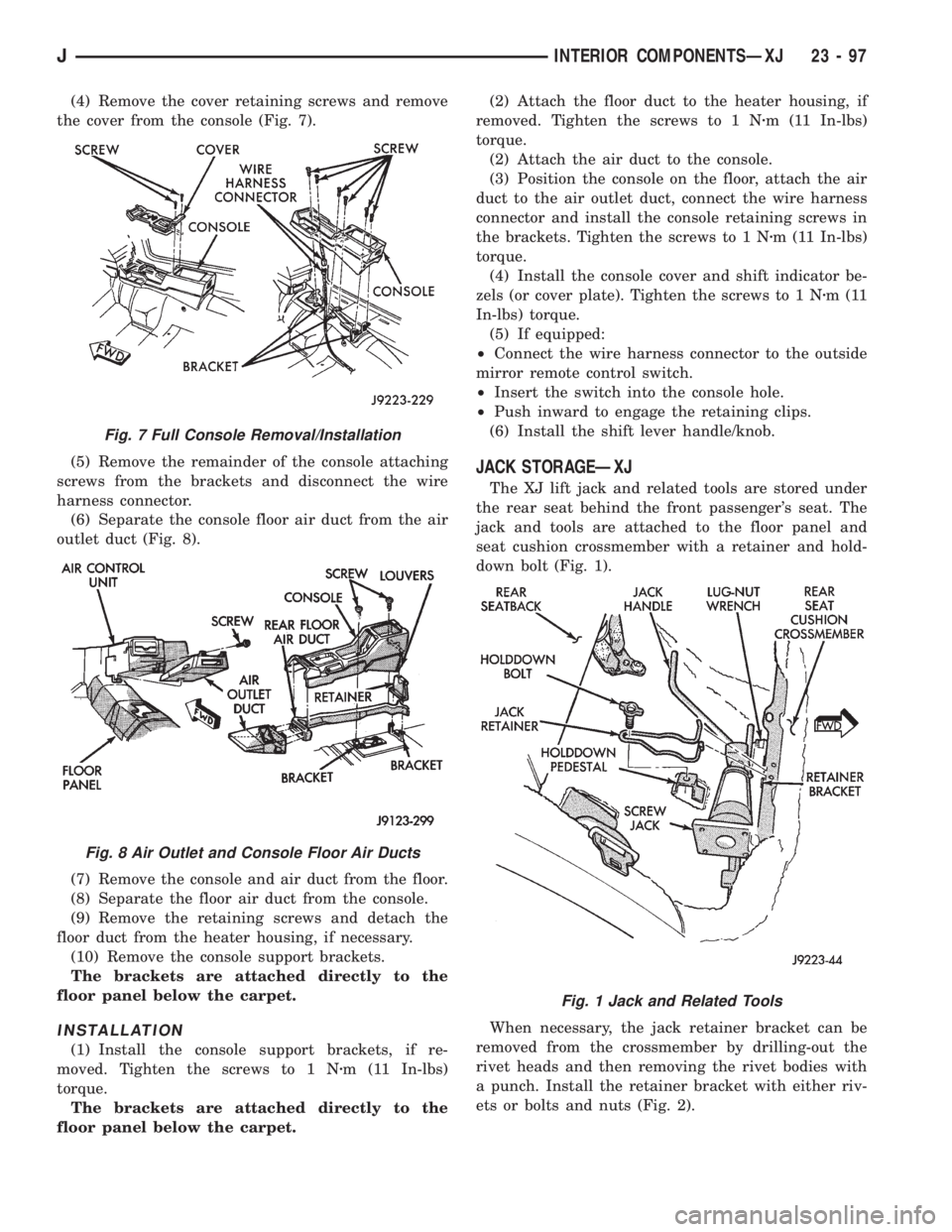

(4) Remove the cover retaining screws and remove

the cover from the console (Fig. 7).

(5) Remove the remainder of the console attaching

screws from the brackets and disconnect the wire

harness connector.

(6) Separate the console floor air duct from the air

outlet duct (Fig. 8).

(7) Remove the console and air duct from the floor.

(8) Separate the floor air duct from the console.

(9) Remove the retaining screws and detach the

floor duct from the heater housing, if necessary.

(10) Remove the console support brackets.

The brackets are attached directly to the

floor panel below the carpet.

INSTALLATION

(1) Install the console support brackets, if re-

moved. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

The brackets are attached directly to the

floor panel below the carpet.(2) Attach the floor duct to the heater housing, if

removed. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

(2) Attach the air duct to the console.

(3) Position the console on the floor, attach the air

duct to the air outlet duct, connect the wire harness

connector and install the console retaining screws in

the brackets. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

(4) Install the console cover and shift indicator be-

zels (or cover plate). Tighten the screws to 1 Nzm(11

In-lbs) torque.

(5) If equipped:

²Connect the wire harness connector to the outside

mirror remote control switch.

²Insert the switch into the console hole.

²Push inward to engage the retaining clips.

(6) Install the shift lever handle/knob.

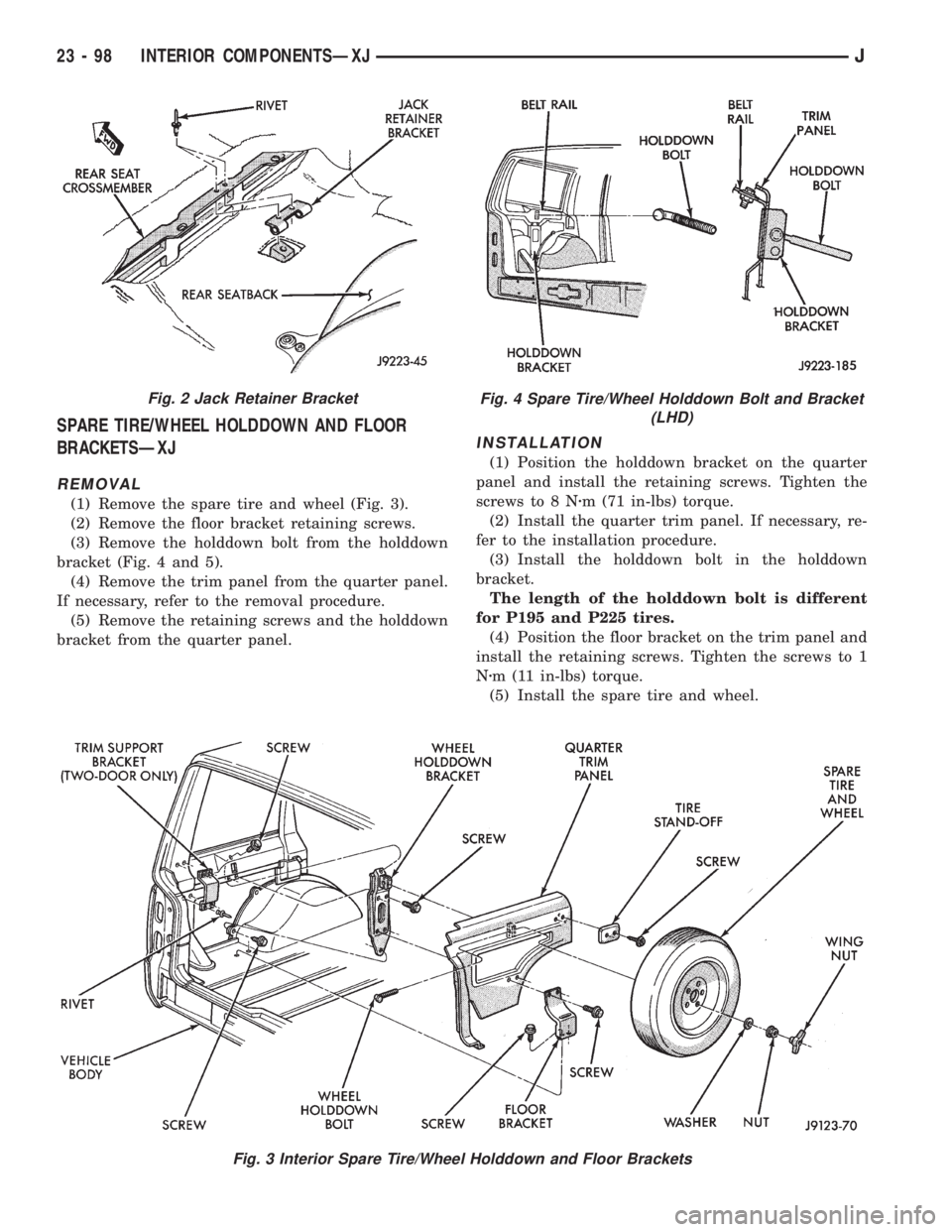

JACK STORAGEÐXJ

The XJ lift jack and related tools are stored under

the rear seat behind the front passenger's seat. The

jack and tools are attached to the floor panel and

seat cushion crossmember with a retainer and hold-

down bolt (Fig. 1).

When necessary, the jack retainer bracket can be

removed from the crossmember by drilling-out the

rivet heads and then removing the rivet bodies with

a punch. Install the retainer bracket with either riv-

ets or bolts and nuts (Fig. 2).

Fig. 7 Full Console Removal/Installation

Fig. 8 Air Outlet and Console Floor Air Ducts

Fig. 1 Jack and Related Tools

JINTERIOR COMPONENTSÐXJ 23 - 97

Page 2016 of 2158

SPARE TIRE/WHEEL HOLDDOWN AND FLOOR

BRACKETSÐXJ

REMOVAL

(1) Remove the spare tire and wheel (Fig. 3).

(2) Remove the floor bracket retaining screws.

(3) Remove the holddown bolt from the holddown

bracket (Fig. 4 and 5).

(4) Remove the trim panel from the quarter panel.

If necessary, refer to the removal procedure.

(5) Remove the retaining screws and the holddown

bracket from the quarter panel.

INSTALLATION

(1) Position the holddown bracket on the quarter

panel and install the retaining screws. Tighten the

screws to 8 Nzm (71 in-lbs) torque.

(2) Install the quarter trim panel. If necessary, re-

fer to the installation procedure.

(3) Install the holddown bolt in the holddown

bracket.

The length of the holddown bolt is different

for P195 and P225 tires.

(4) Position the floor bracket on the trim panel and

install the retaining screws. Tighten the screws to 1

Nzm (11 in-lbs) torque.

(5) Install the spare tire and wheel.

Fig. 3 Interior Spare Tire/Wheel Holddown and Floor Brackets

Fig. 2 Jack Retainer BracketFig. 4 Spare Tire/Wheel Holddown Bolt and Bracket

(LHD)

23 - 98 INTERIOR COMPONENTSÐXJJ

Page 2017 of 2158

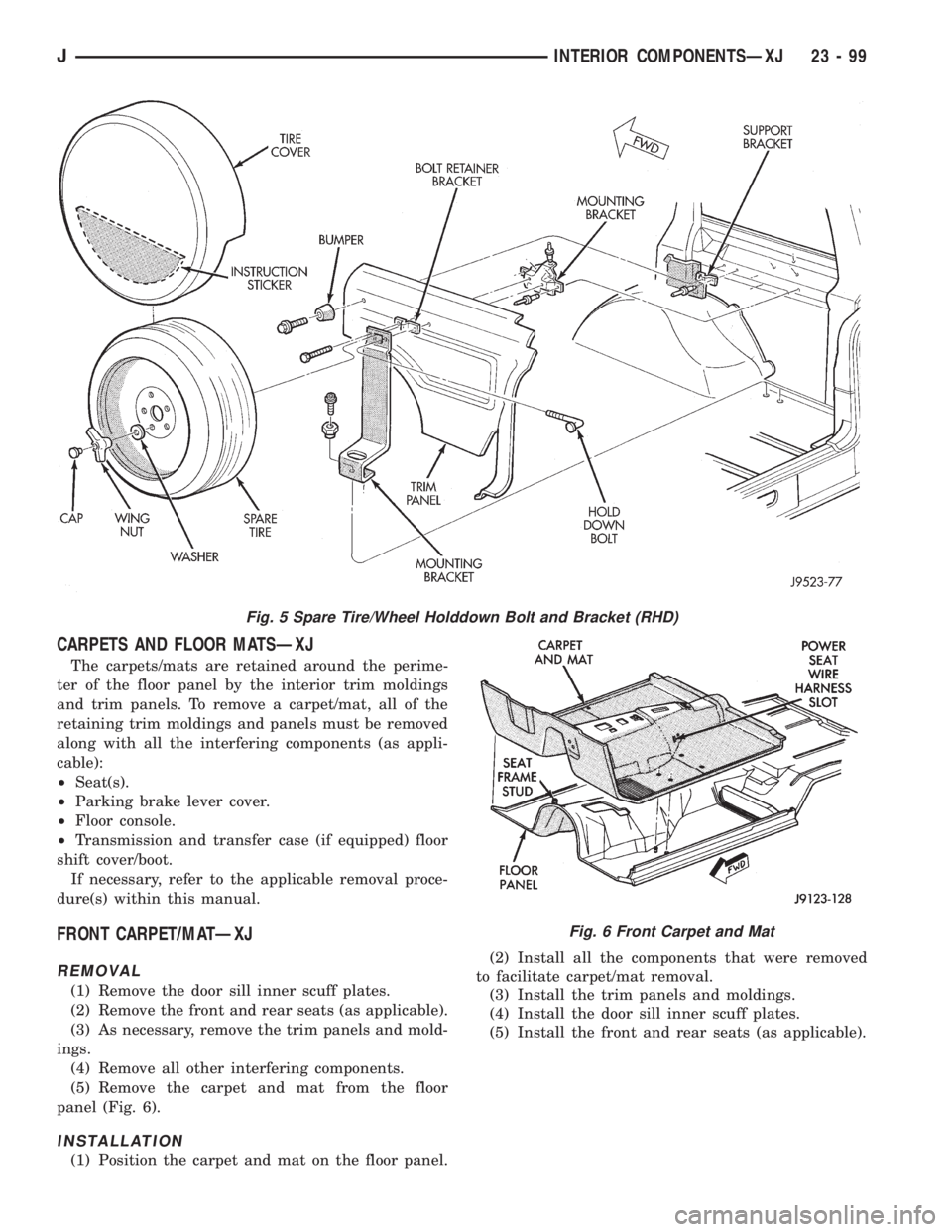

CARPETS AND FLOOR MATSÐXJ

The carpets/mats are retained around the perime-

ter of the floor panel by the interior trim moldings

and trim panels. To remove a carpet/mat, all of the

retaining trim moldings and panels must be removed

along with all the interfering components (as appli-

cable):

²Seat(s).

²Parking brake lever cover.

²Floor console.

²Transmission and transfer case (if equipped) floor

shift cover/boot.

If necessary, refer to the applicable removal proce-

dure(s) within this manual.

FRONT CARPET/MATÐXJ

REMOVAL

(1) Remove the door sill inner scuff plates.

(2) Remove the front and rear seats (as applicable).

(3) As necessary, remove the trim panels and mold-

ings.

(4) Remove all other interfering components.

(5) Remove the carpet and mat from the floor

panel (Fig. 6).

INSTALLATION

(1) Position the carpet and mat on the floor panel.(2) Install all the components that were removed

to facilitate carpet/mat removal.

(3) Install the trim panels and moldings.

(4) Install the door sill inner scuff plates.

(5) Install the front and rear seats (as applicable).

Fig. 5 Spare Tire/Wheel Holddown Bolt and Bracket (RHD)

Fig. 6 Front Carpet and Mat

JINTERIOR COMPONENTSÐXJ 23 - 99

Page 2018 of 2158

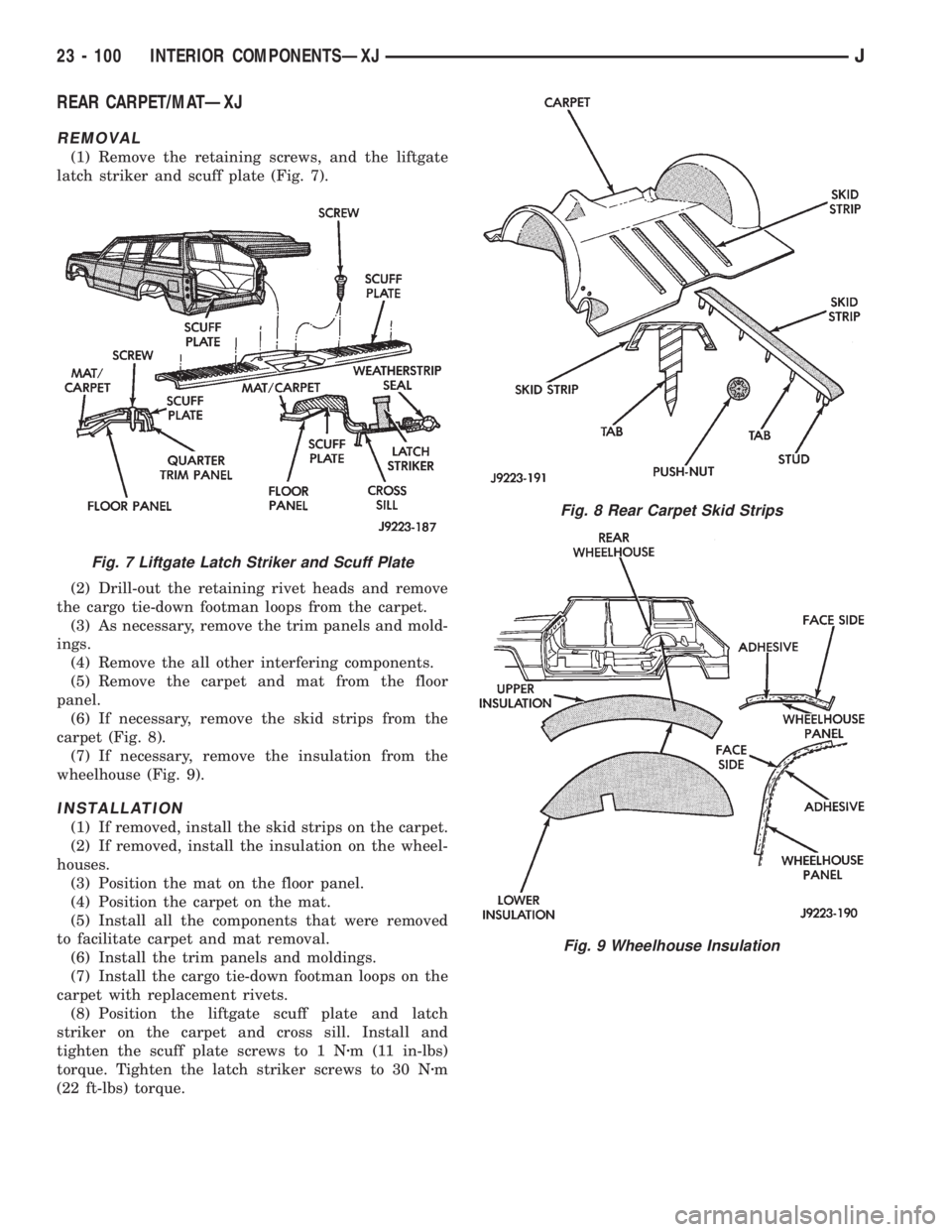

REAR CARPET/MATÐXJ

REMOVAL

(1) Remove the retaining screws, and the liftgate

latch striker and scuff plate (Fig. 7).

(2) Drill-out the retaining rivet heads and remove

the cargo tie-down footman loops from the carpet.

(3) As necessary, remove the trim panels and mold-

ings.

(4) Remove the all other interfering components.

(5) Remove the carpet and mat from the floor

panel.

(6) If necessary, remove the skid strips from the

carpet (Fig. 8).

(7) If necessary, remove the insulation from the

wheelhouse (Fig. 9).

INSTALLATION

(1) If removed, install the skid strips on the carpet.

(2) If removed, install the insulation on the wheel-

houses.

(3) Position the mat on the floor panel.

(4) Position the carpet on the mat.

(5) Install all the components that were removed

to facilitate carpet and mat removal.

(6) Install the trim panels and moldings.

(7) Install the cargo tie-down footman loops on the

carpet with replacement rivets.

(8) Position the liftgate scuff plate and latch

striker on the carpet and cross sill. Install and

tighten the scuff plate screws to 1 Nzm (11 in-lbs)

torque. Tighten the latch striker screws to 30 Nzm

(22 ft-lbs) torque.

Fig. 7 Liftgate Latch Striker and Scuff Plate

Fig. 8 Rear Carpet Skid Strips

Fig. 9 Wheelhouse Insulation

23 - 100 INTERIOR COMPONENTSÐXJJ

Page 2019 of 2158

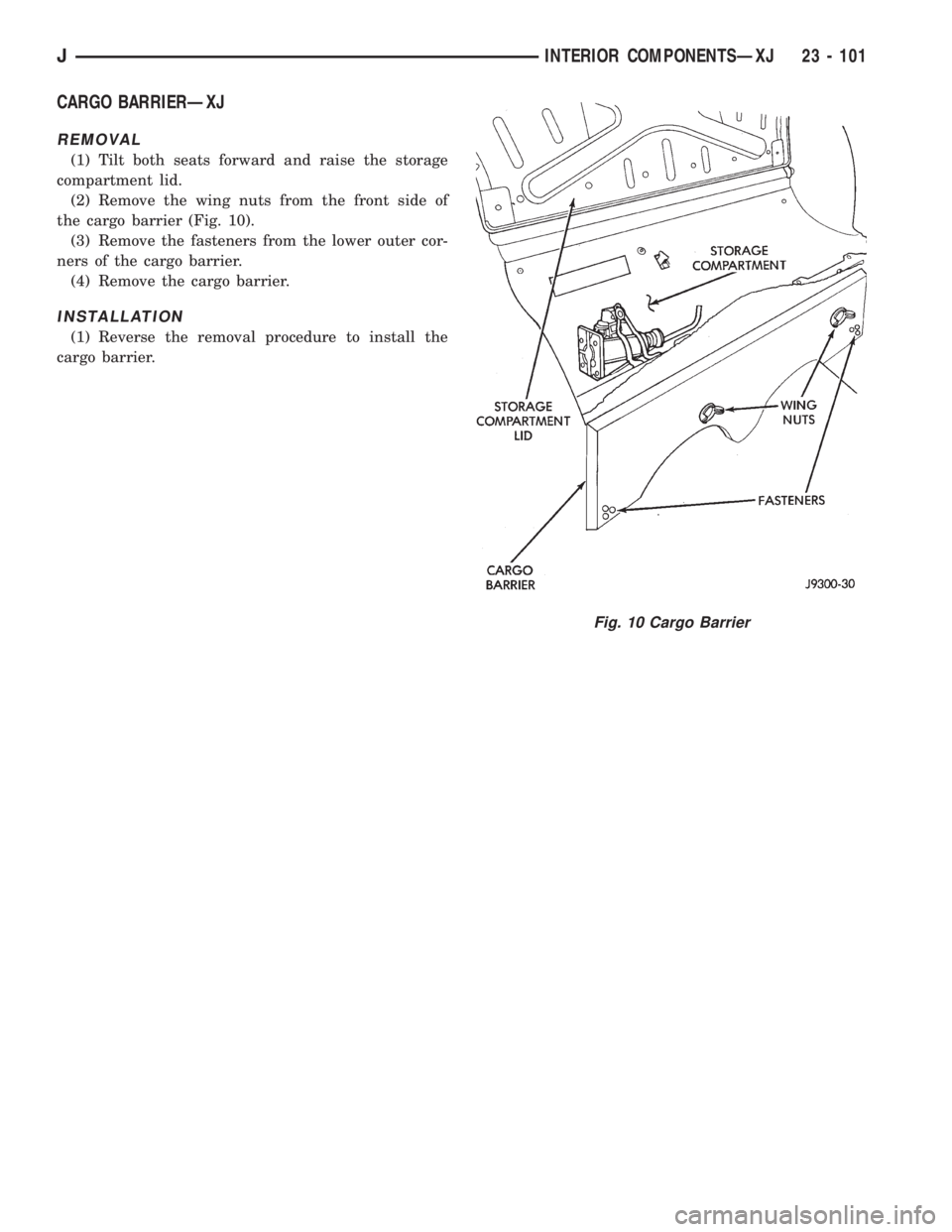

CARGO BARRIERÐXJ

REMOVAL

(1) Tilt both seats forward and raise the storage

compartment lid.

(2) Remove the wing nuts from the front side of

the cargo barrier (Fig. 10).

(3) Remove the fasteners from the lower outer cor-

ners of the cargo barrier.

(4) Remove the cargo barrier.

INSTALLATION

(1) Reverse the removal procedure to install the

cargo barrier.

Fig. 10 Cargo Barrier

JINTERIOR COMPONENTSÐXJ 23 - 101

Page 2020 of 2158

BODY COMPONENTSÐYJ VEHICLES

CONTENTS

page page

DOORS............................... 134

EXTERIOR COMPONENTS................ 104

GENERAL SERVICE INFORMATION......... 102INTERIOR COMPONENTS................ 151

PAINT................................ 158

STATIONARY GLASS.................... 144

GENERAL SERVICE INFORMATION

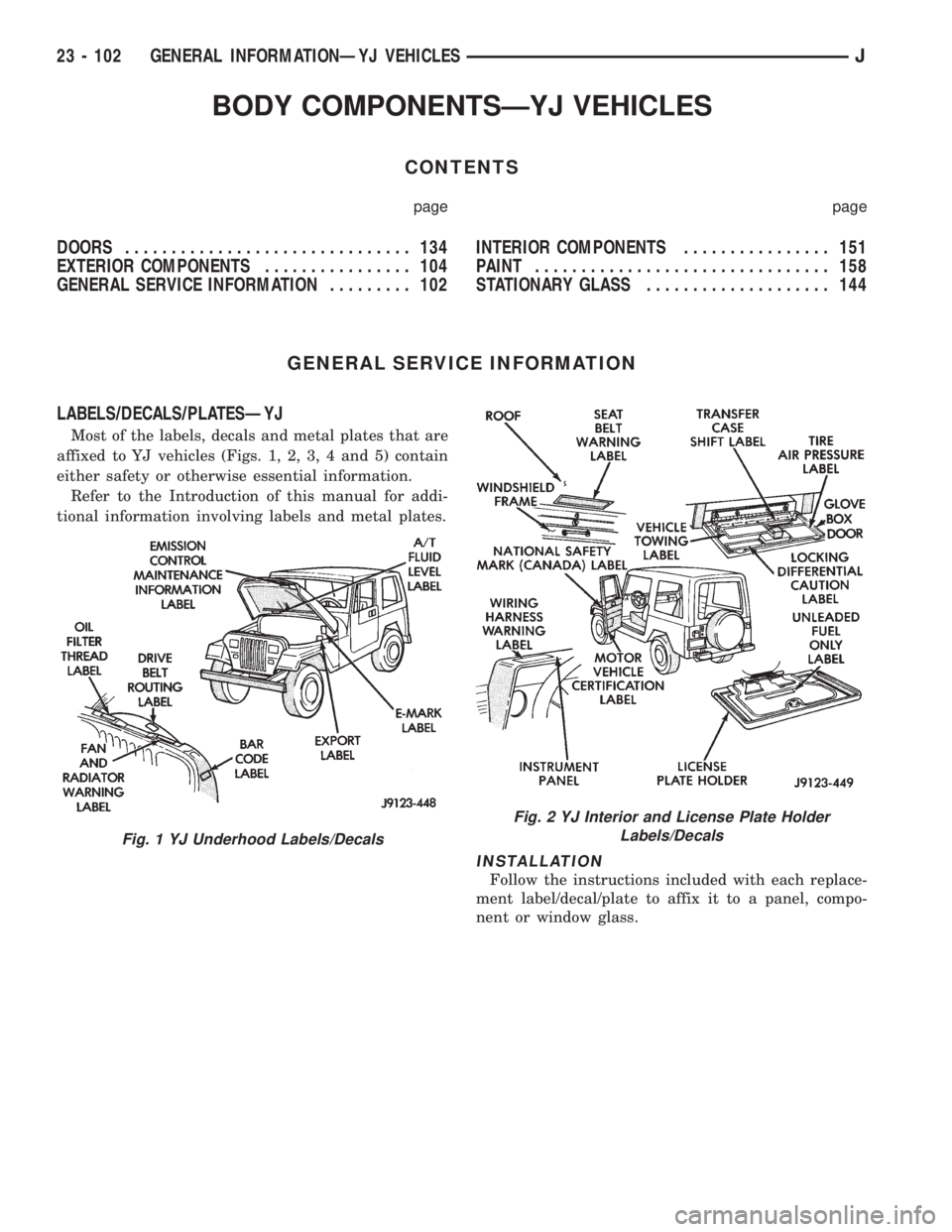

LABELS/DECALS/PLATESÐYJ

Most of the labels, decals and metal plates that are

affixed to YJ vehicles (Figs. 1, 2, 3, 4 and 5) contain

either safety or otherwise essential information.

Refer to the Introduction of this manual for addi-

tional information involving labels and metal plates.

INSTALLATION

Follow the instructions included with each replace-

ment label/decal/plate to affix it to a panel, compo-

nent or window glass.

Fig. 1 YJ Underhood Labels/Decals

Fig. 2 YJ Interior and License Plate Holder

Labels/Decals

23 - 102 GENERAL INFORMATIONÐYJ VEHICLESJ