JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1971 of 2158

14). Be careful not to bend the hinge when driving

the hinge pin, support may be required under the

hinge.

(8) Adjust/align latch striker and latch as neces-

sary.(9) Install the door restraint (check) retaining pin

with a punch.

FRONT DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES

REMOVAL

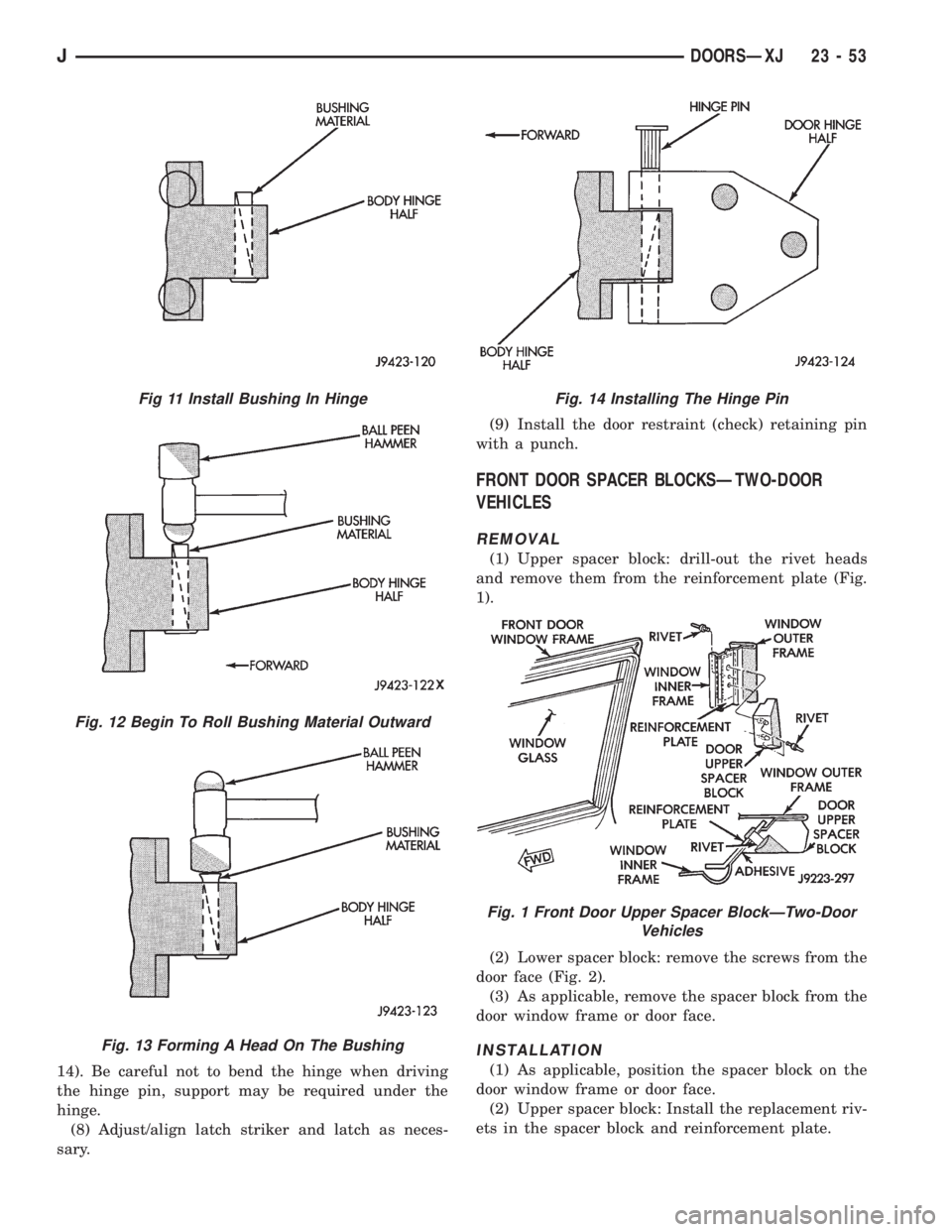

(1) Upper spacer block: drill-out the rivet heads

and remove them from the reinforcement plate (Fig.

1).

(2) Lower spacer block: remove the screws from the

door face (Fig. 2).

(3) As applicable, remove the spacer block from the

door window frame or door face.

INSTALLATION

(1) As applicable, position the spacer block on the

door window frame or door face.

(2) Upper spacer block: Install the replacement riv-

ets in the spacer block and reinforcement plate.

Fig 11 Install Bushing In Hinge

Fig. 12 Begin To Roll Bushing Material Outward

Fig. 13 Forming A Head On The Bushing

Fig. 14 Installing The Hinge Pin

Fig. 1 Front Door Upper Spacer BlockÐTwo-Door

Vehicles

JDOORSÐXJ 23 - 53

Page 1972 of 2158

(3) Lower spacer block: install the screws in the

door face. Tighten the screws to 1 Nzm (11 in-lbs)

torque.

DOOR EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ

REPLACEMENT

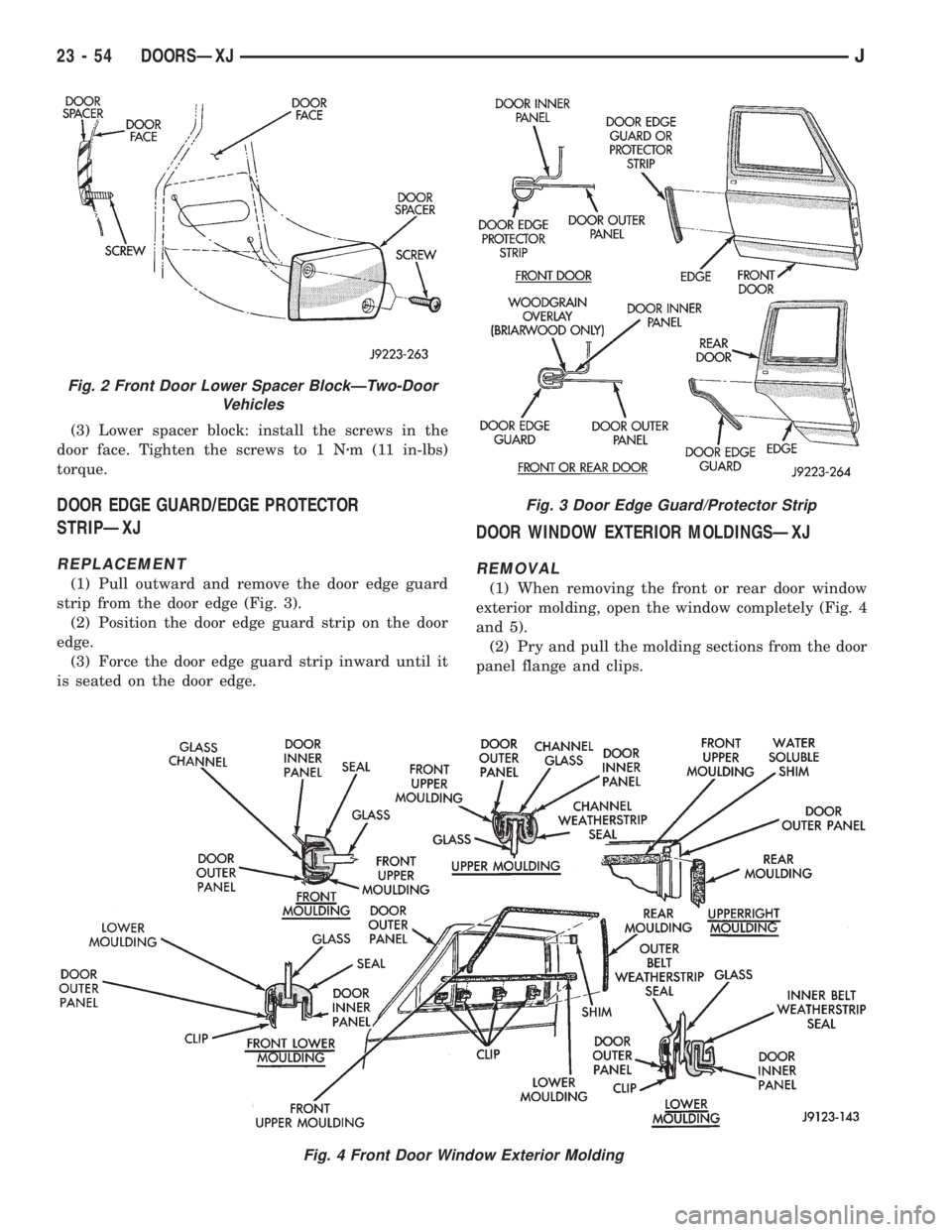

(1) Pull outward and remove the door edge guard

strip from the door edge (Fig. 3).

(2) Position the door edge guard strip on the door

edge.

(3) Force the door edge guard strip inward until it

is seated on the door edge.

DOOR WINDOW EXTERIOR MOLDINGSÐXJ

REMOVAL

(1) When removing the front or rear door window

exterior molding, open the window completely (Fig. 4

and 5).

(2) Pry and pull the molding sections from the door

panel flange and clips.

Fig. 3 Door Edge Guard/Protector Strip

Fig. 4 Front Door Window Exterior Molding

Fig. 2 Front Door Lower Spacer BlockÐTwo-Door

Vehicles

23 - 54 DOORSÐXJJ

Page 1973 of 2158

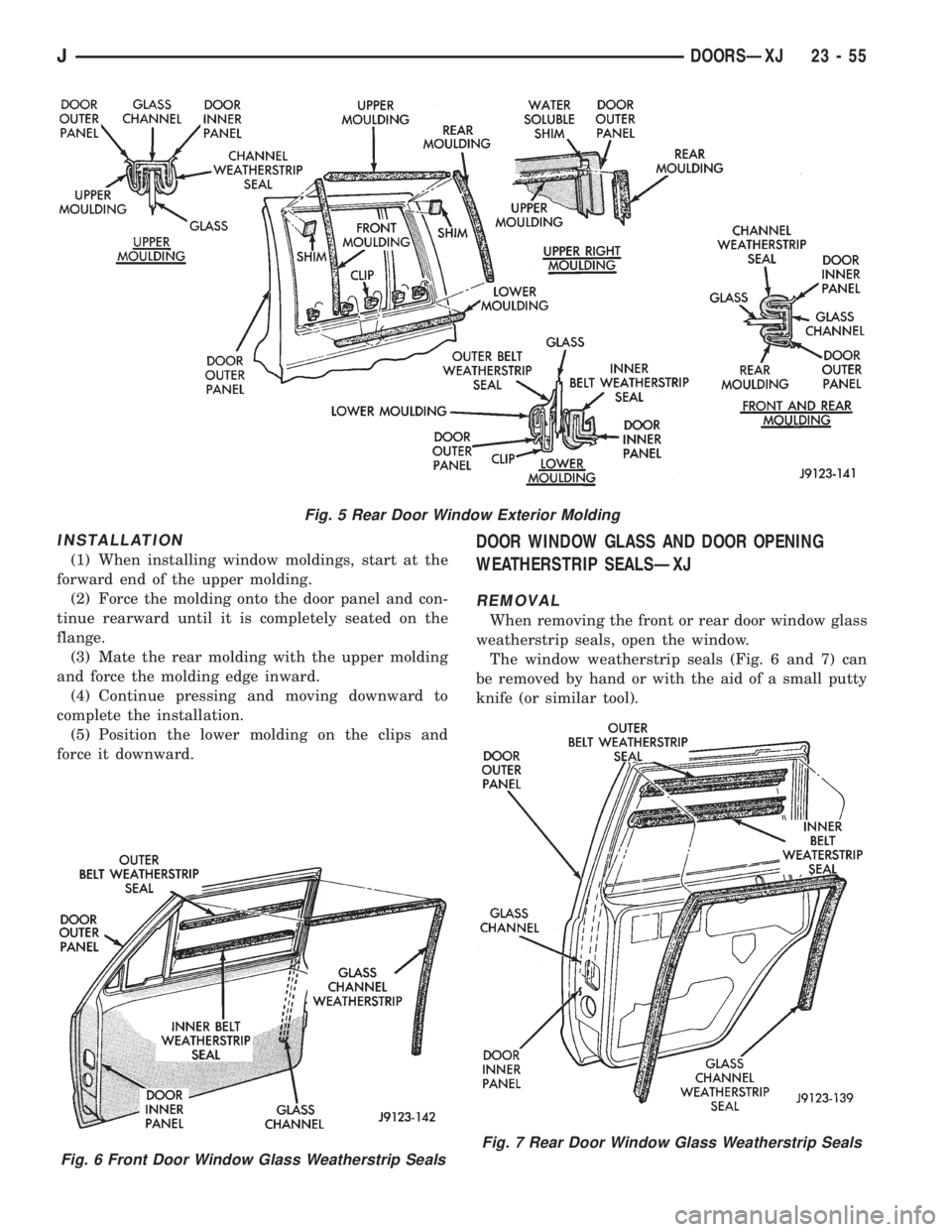

INSTALLATION

(1) When installing window moldings, start at the

forward end of the upper molding.

(2) Force the molding onto the door panel and con-

tinue rearward until it is completely seated on the

flange.

(3) Mate the rear molding with the upper molding

and force the molding edge inward.

(4) Continue pressing and moving downward to

complete the installation.

(5) Position the lower molding on the clips and

force it downward.

DOOR WINDOW GLASS AND DOOR OPENING

WEATHERSTRIP SEALSÐXJ

REMOVAL

When removing the front or rear door window glass

weatherstrip seals, open the window.

The window weatherstrip seals (Fig. 6 and 7) can

be removed by hand or with the aid of a small putty

knife (or similar tool).

Fig. 6 Front Door Window Glass Weatherstrip Seals

Fig. 5 Rear Door Window Exterior Molding

Fig. 7 Rear Door Window Glass Weatherstrip Seals

JDOORSÐXJ 23 - 55

Page 1974 of 2158

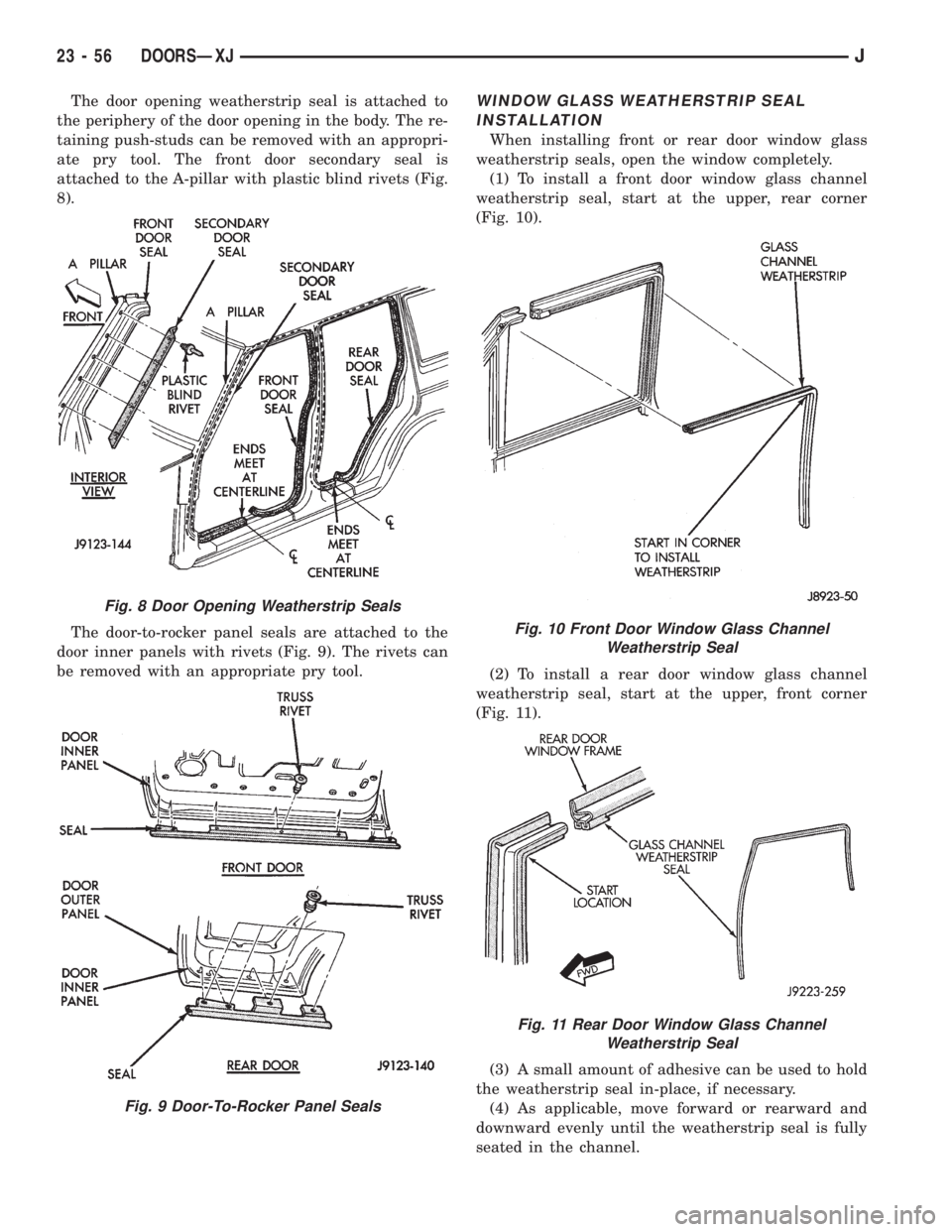

The door opening weatherstrip seal is attached to

the periphery of the door opening in the body. The re-

taining push-studs can be removed with an appropri-

ate pry tool. The front door secondary seal is

attached to the A-pillar with plastic blind rivets (Fig.

8).

The door-to-rocker panel seals are attached to the

door inner panels with rivets (Fig. 9). The rivets can

be removed with an appropriate pry tool.WINDOW GLASS WEATHERSTRIP SEAL

INSTALLATION

When installing front or rear door window glass

weatherstrip seals, open the window completely.

(1) To install a front door window glass channel

weatherstrip seal, start at the upper, rear corner

(Fig. 10).

(2) To install a rear door window glass channel

weatherstrip seal, start at the upper, front corner

(Fig. 11).

(3) A small amount of adhesive can be used to hold

the weatherstrip seal in-place, if necessary.

(4) As applicable, move forward or rearward and

downward evenly until the weatherstrip seal is fully

seated in the channel.

Fig. 8 Door Opening Weatherstrip Seals

Fig. 9 Door-To-Rocker Panel Seals

Fig. 10 Front Door Window Glass Channel

Weatherstrip Seal

Fig. 11 Rear Door Window Glass Channel

Weatherstrip Seal

23 - 56 DOORSÐXJJ

Page 1975 of 2158

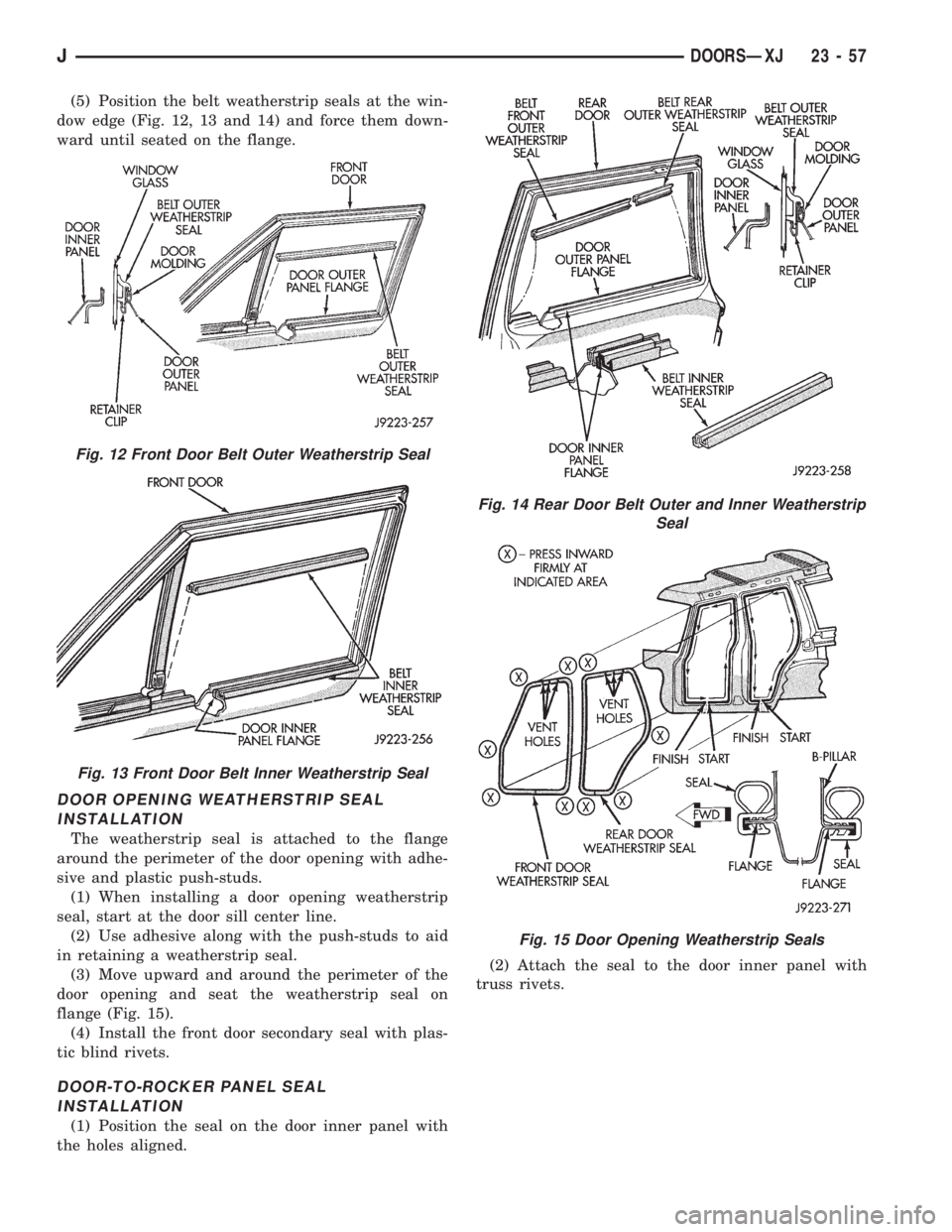

(5) Position the belt weatherstrip seals at the win-

dow edge (Fig. 12, 13 and 14) and force them down-

ward until seated on the flange.

DOOR OPENING WEATHERSTRIP SEAL

INSTALLATION

The weatherstrip seal is attached to the flange

around the perimeter of the door opening with adhe-

sive and plastic push-studs.

(1) When installing a door opening weatherstrip

seal, start at the door sill center line.

(2) Use adhesive along with the push-studs to aid

in retaining a weatherstrip seal.

(3) Move upward and around the perimeter of the

door opening and seat the weatherstrip seal on

flange (Fig. 15).

(4) Install the front door secondary seal with plas-

tic blind rivets.

DOOR-TO-ROCKER PANEL SEAL

INSTALLATION

(1) Position the seal on the door inner panel with

the holes aligned.(2) Attach the seal to the door inner panel with

truss rivets.

Fig. 12 Front Door Belt Outer Weatherstrip Seal

Fig. 13 Front Door Belt Inner Weatherstrip Seal

Fig. 14 Rear Door Belt Outer and Inner Weatherstrip

Seal

Fig. 15 Door Opening Weatherstrip Seals

JDOORSÐXJ 23 - 57

Page 1976 of 2158

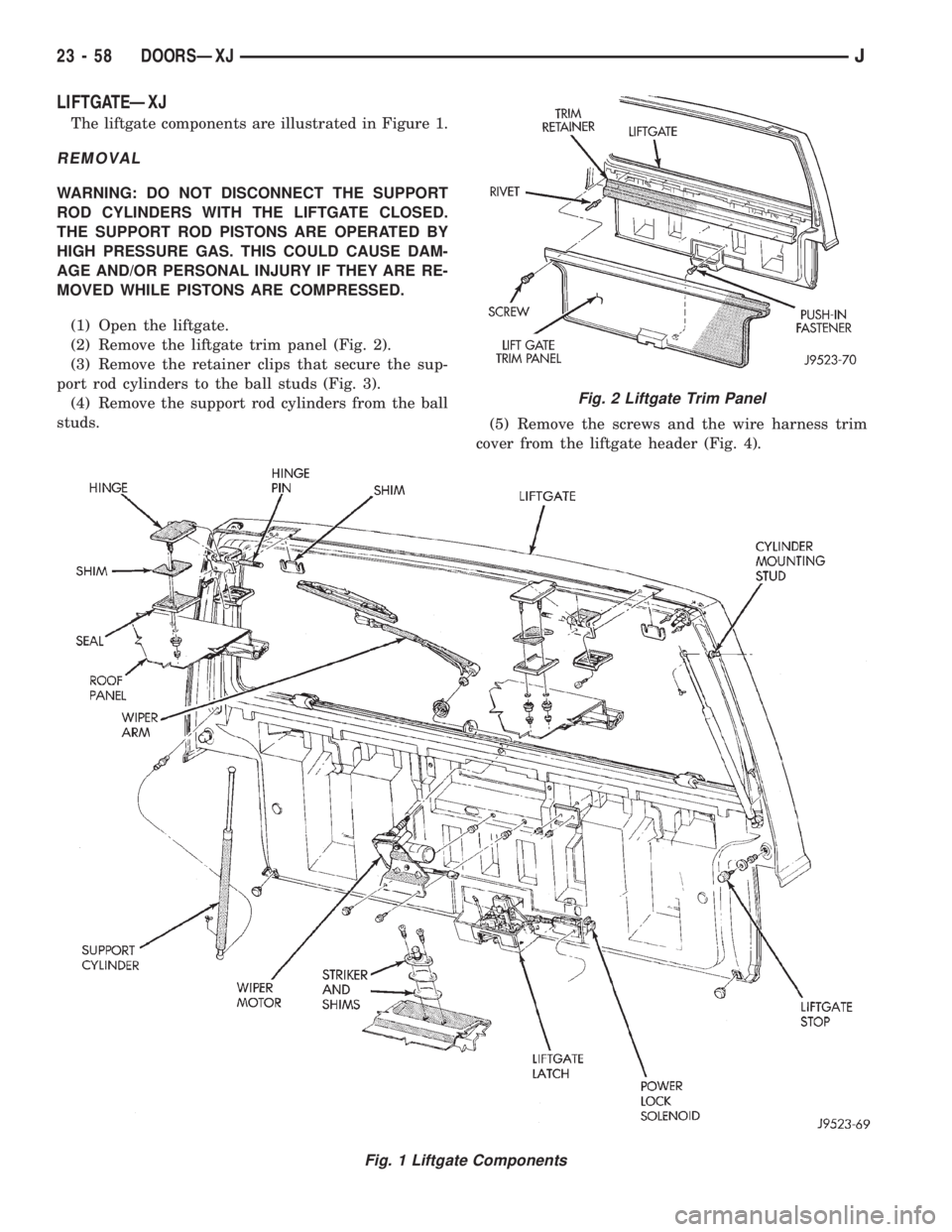

LIFTGATEÐXJ

The liftgate components are illustrated in Figure 1.

REMOVAL

WARNING: DO NOT DISCONNECT THE SUPPORT

ROD CYLINDERS WITH THE LIFTGATE CLOSED.

THE SUPPORT ROD PISTONS ARE OPERATED BY

HIGH PRESSURE GAS. THIS COULD CAUSE DAM-

AGE AND/OR PERSONAL INJURY IF THEY ARE RE-

MOVED WHILE PISTONS ARE COMPRESSED.

(1) Open the liftgate.

(2) Remove the liftgate trim panel (Fig. 2).

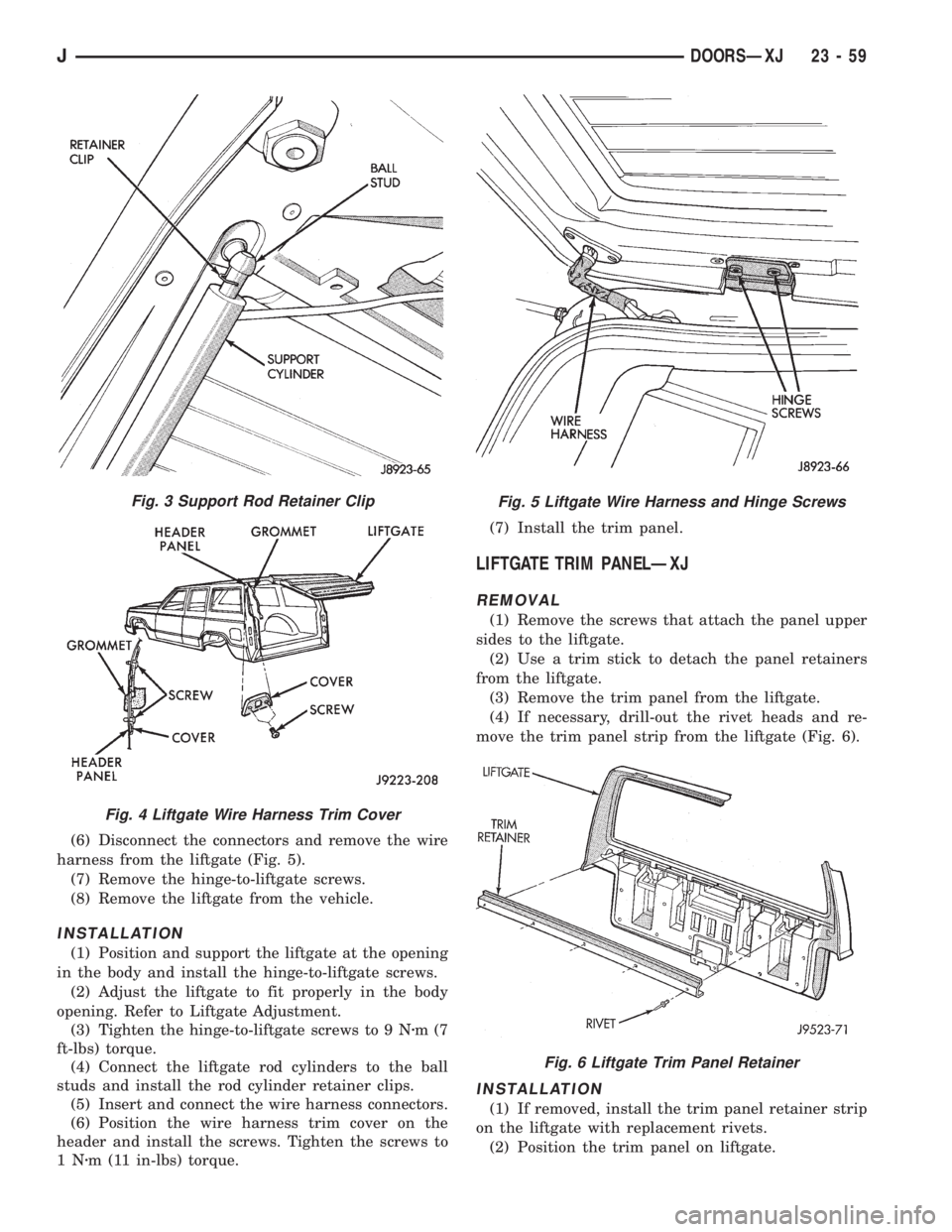

(3) Remove the retainer clips that secure the sup-

port rod cylinders to the ball studs (Fig. 3).

(4) Remove the support rod cylinders from the ball

studs.

(5) Remove the screws and the wire harness trim

cover from the liftgate header (Fig. 4).

Fig. 1 Liftgate Components

Fig. 2 Liftgate Trim Panel

23 - 58 DOORSÐXJJ

Page 1977 of 2158

(6) Disconnect the connectors and remove the wire

harness from the liftgate (Fig. 5).

(7) Remove the hinge-to-liftgate screws.

(8) Remove the liftgate from the vehicle.

INSTALLATION

(1) Position and support the liftgate at the opening

in the body and install the hinge-to-liftgate screws.

(2) Adjust the liftgate to fit properly in the body

opening. Refer to Liftgate Adjustment.

(3) Tighten the hinge-to-liftgate screws to 9 Nzm(7

ft-lbs) torque.

(4) Connect the liftgate rod cylinders to the ball

studs and install the rod cylinder retainer clips.

(5) Insert and connect the wire harness connectors.

(6) Position the wire harness trim cover on the

header and install the screws. Tighten the screws to

1Nzm (11 in-lbs) torque.(7) Install the trim panel.

LIFTGATE TRIM PANELÐXJ

REMOVAL

(1) Remove the screws that attach the panel upper

sides to the liftgate.

(2) Use a trim stick to detach the panel retainers

from the liftgate.

(3) Remove the trim panel from the liftgate.

(4) If necessary, drill-out the rivet heads and re-

move the trim panel strip from the liftgate (Fig. 6).

INSTALLATION

(1) If removed, install the trim panel retainer strip

on the liftgate with replacement rivets.

(2) Position the trim panel on liftgate.

Fig. 3 Support Rod Retainer Clip

Fig. 4 Liftgate Wire Harness Trim Cover

Fig. 5 Liftgate Wire Harness and Hinge Screws

Fig. 6 Liftgate Trim Panel Retainer

JDOORSÐXJ 23 - 59

Page 1978 of 2158

(3) Align the trim panel retainers with the holes in

the liftgate inner panel and force the trim panel in-

ward.

(4) Install the screws to attach the panel upper

sides to the liftgate.

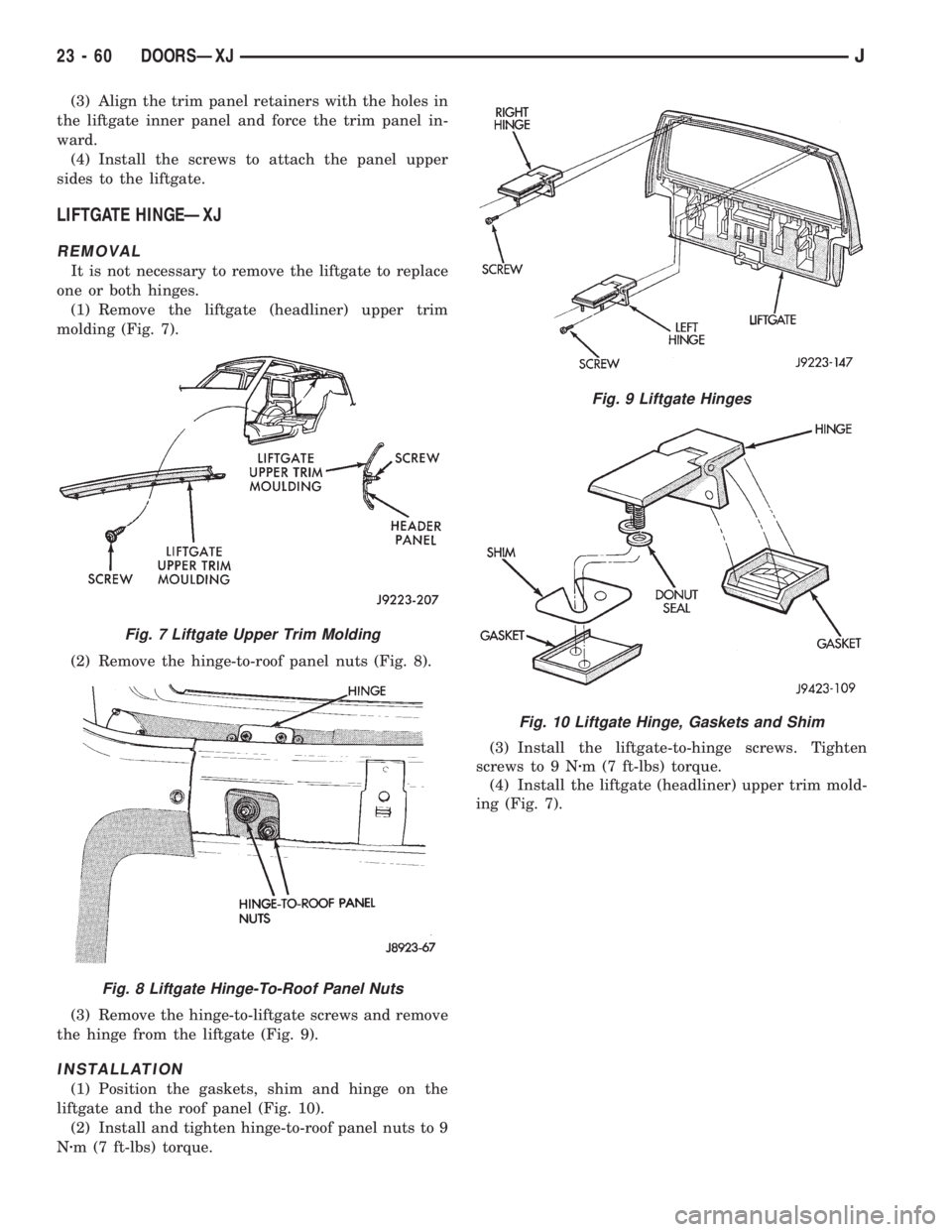

LIFTGATE HINGEÐXJ

REMOVAL

It is not necessary to remove the liftgate to replace

one or both hinges.

(1) Remove the liftgate (headliner) upper trim

molding (Fig. 7).

(2) Remove the hinge-to-roof panel nuts (Fig. 8).

(3) Remove the hinge-to-liftgate screws and remove

the hinge from the liftgate (Fig. 9).

INSTALLATION

(1) Position the gaskets, shim and hinge on the

liftgate and the roof panel (Fig. 10).

(2) Install and tighten hinge-to-roof panel nuts to 9

Nzm (7 ft-lbs) torque.(3) Install the liftgate-to-hinge screws. Tighten

screws to 9 Nzm (7 ft-lbs) torque.

(4) Install the liftgate (headliner) upper trim mold-

ing (Fig. 7).

Fig. 7 Liftgate Upper Trim Molding

Fig. 8 Liftgate Hinge-To-Roof Panel Nuts

Fig. 9 Liftgate Hinges

Fig. 10 Liftgate Hinge, Gaskets and Shim

23 - 60 DOORSÐXJJ

Page 1979 of 2158

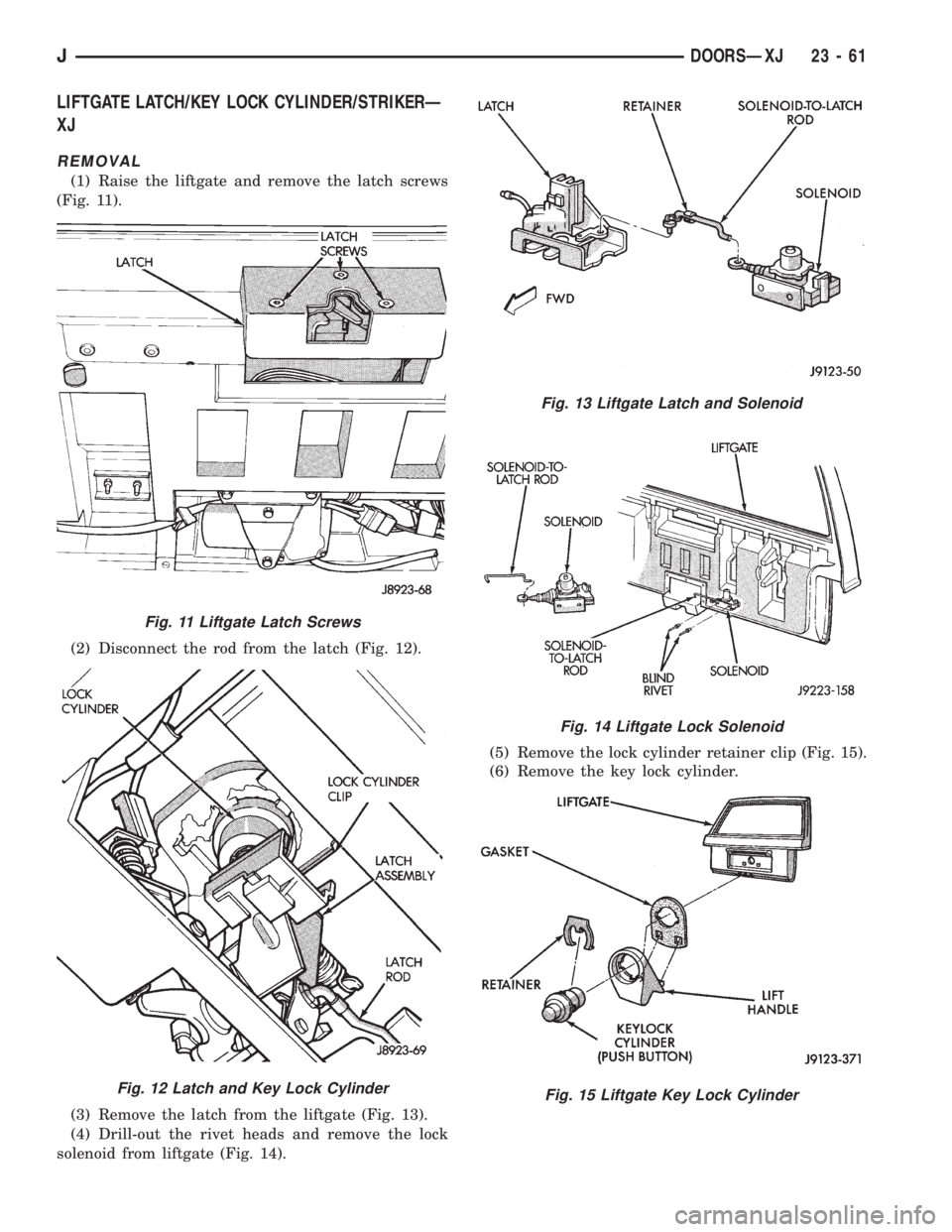

LIFTGATE LATCH/KEY LOCK CYLINDER/STRIKERÐ

XJ

REMOVAL

(1) Raise the liftgate and remove the latch screws

(Fig. 11).

(2) Disconnect the rod from the latch (Fig. 12).

(3) Remove the latch from the liftgate (Fig. 13).

(4) Drill-out the rivet heads and remove the lock

solenoid from liftgate (Fig. 14).(5) Remove the lock cylinder retainer clip (Fig. 15).

(6) Remove the key lock cylinder.

Fig. 11 Liftgate Latch Screws

Fig. 12 Latch and Key Lock Cylinder

Fig. 13 Liftgate Latch and Solenoid

Fig. 14 Liftgate Lock Solenoid

Fig. 15 Liftgate Key Lock Cylinder

JDOORSÐXJ 23 - 61

Page 1980 of 2158

(7) Remove the latch striker screws from the scuff

plate and cross sill (Fig. 16)

(8) Remove the striker and shim from the retainer.

INSTALLATION

(1) Install the key lock cylinder. Secure the lock

cylinder with the retainer clip (Fig. 17).

(2) Position the latch in the liftgate.

(3) Connect the latch rod.

(4) Install and tighten the latch screws to 12 Nzm

(110 in-lbs) torque.

(5) Install the striker retainer, shim, striker and

screws in the scuff plate cross sill.

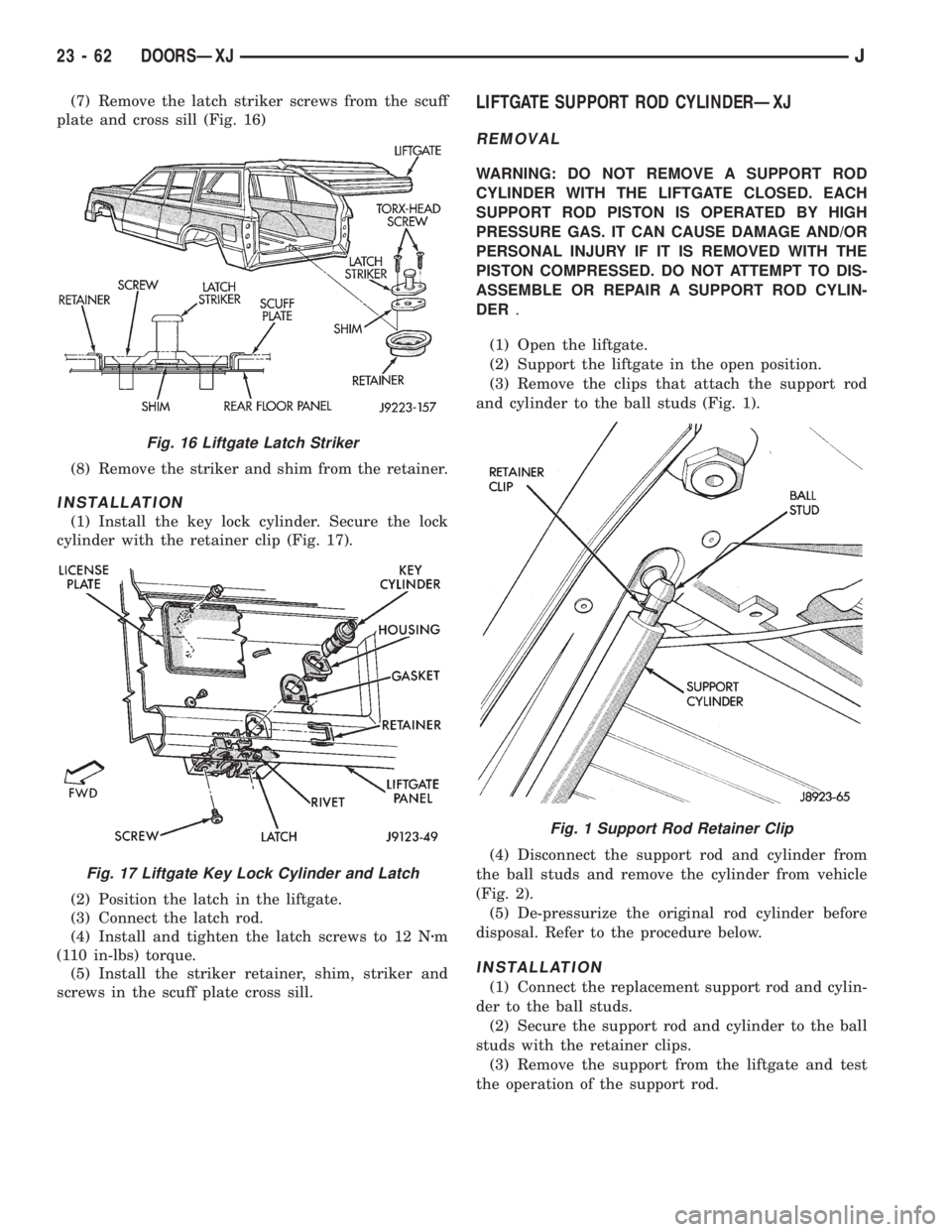

LIFTGATE SUPPORT ROD CYLINDERÐXJ

REMOVAL

WARNING: DO NOT REMOVE A SUPPORT ROD

CYLINDER WITH THE LIFTGATE CLOSED. EACH

SUPPORT ROD PISTON IS OPERATED BY HIGH

PRESSURE GAS. IT CAN CAUSE DAMAGE AND/OR

PERSONAL INJURY IF IT IS REMOVED WITH THE

PISTON COMPRESSED. DO NOT ATTEMPT TO DIS-

ASSEMBLE OR REPAIR A SUPPORT ROD CYLIN-

DER.

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the clips that attach the support rod

and cylinder to the ball studs (Fig. 1).

(4) Disconnect the support rod and cylinder from

the ball studs and remove the cylinder from vehicle

(Fig. 2).

(5) De-pressurize the original rod cylinder before

disposal. Refer to the procedure below.

INSTALLATION

(1) Connect the replacement support rod and cylin-

der to the ball studs.

(2) Secure the support rod and cylinder to the ball

studs with the retainer clips.

(3) Remove the support from the liftgate and test

the operation of the support rod.

Fig. 16 Liftgate Latch Striker

Fig. 17 Liftgate Key Lock Cylinder and Latch

Fig. 1 Support Rod Retainer Clip

23 - 62 DOORSÐXJJ