charging JEEP XJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 303 of 2158

²accessories being left on with the engine not run-

ning

²a faulty or improperly adjusted switch that allows

a lamp to stay on (see Ignition-Off Draw, in this

group).

INSPECTION

(1) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter so-

lenoid and relay. They should be clean and tight. Re-

pair as required.

(2) Inspect all fuses in the fuseblock module and

Power Distribution Center (PDC) for tightness in re-

ceptacles. They should be properly installed and

tight. Repair or replace as required.

(3) Inspect the electrolyte level in the battery. If

cell caps are removable, add water if required. If cell

caps are not removable, replace battery if electrolyte

level is low.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts, if required. Refer to Group

8B - Battery/Starter/Generator Service for torque

specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in Group 7 - Cooling Sys-

tem.

(6) Inspect connections at generator field, battery

output, and ground terminals. Also check ground con-

nection at engine. They should all be clean and tight.

Repair as required.

OUTPUT WIRE RESISTANCE TEST

This test will show the amount of voltage drop

across the generator output wire, from the generator

battery terminal to the battery positive post.

PREPARATION

(1) Before starting test make sure vehicle has a

fully-charged battery. See Battery in this group for

more information.

(2) Turn ignition switch to OFF.

(3) Disconnect negative cable from battery.

(4) Disconnect generator output wire from genera-

tor battery output terminal.

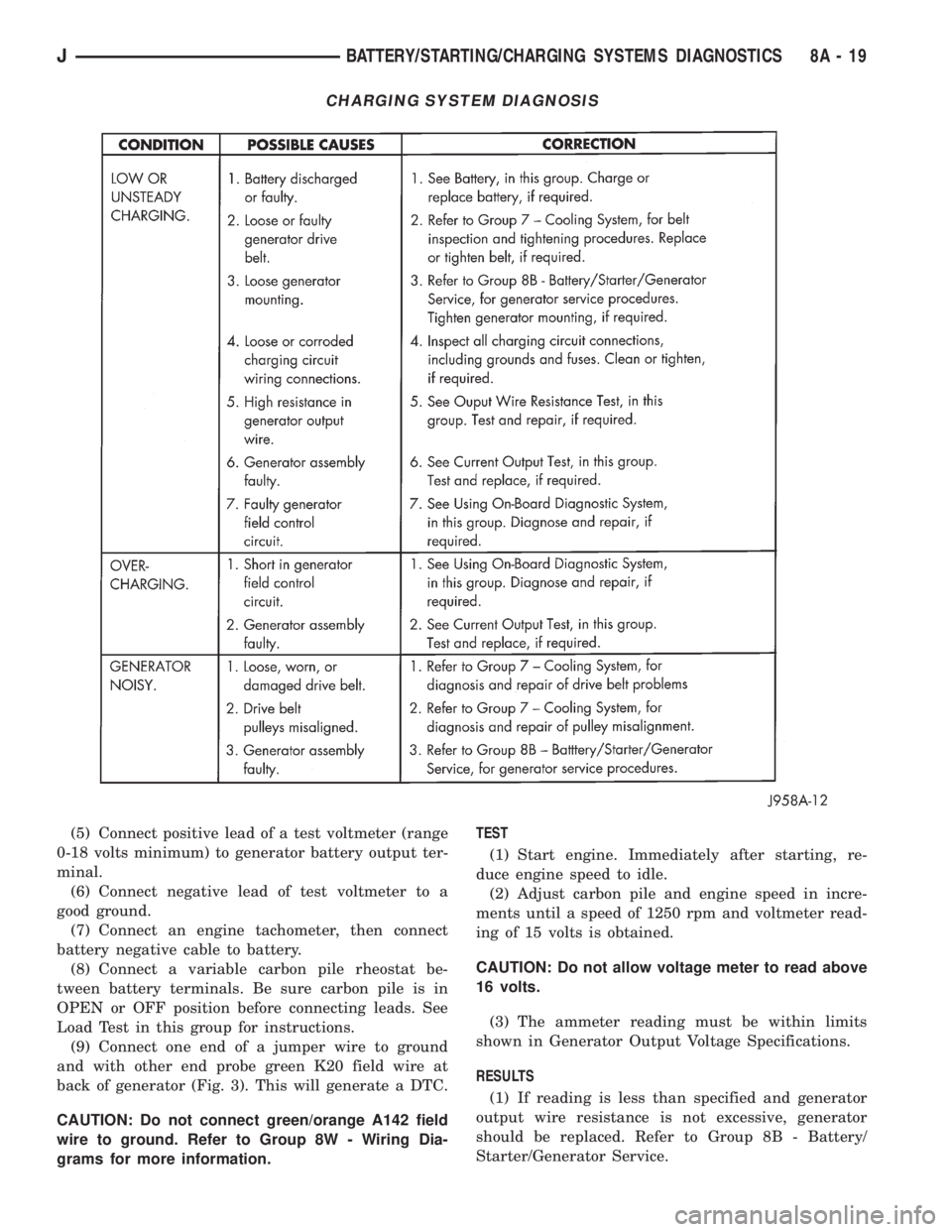

(5) Connect a 0-150 ampere scale DC ammeter

(Fig. 2). Install in series between generator battery

output terminal and disconnected generator output

wire. Connect positive lead to generator battery out-

put terminal and negative lead to disconnected gen-

erator output wire.

(6) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to disconnected generator out-

put wire. Connect negative lead of test voltmeter to

battery positive cable at positive post.

(7) Connect one end of a jumper wire to ground

and with other end probe green K20 field wire at

back of generator (Fig. 2). This will generate a DTC.CAUTION: Do not connect green/orange A142 field

wire to ground. Refer to Group 8W - Wiring Dia-

grams for more information.

(8) Connect an engine tachometer, then connect

battery negative cable to battery.

(9) Connect a variable carbon pile rheostat be-

tween battery terminals. Be sure carbon pile is in

OPEN or OFF position before connecting leads. See

Load Test in this group for instructions.

TEST

(1) Start engine. Immediately after starting, re-

duce engine speed to idle.

(2) Adjust engine speed and carbon pile to main-

tain 20 amperes flowing in circuit. Observe voltmeter

reading. Voltmeter reading should not exceed 0.5

volts.

RESULTS

If a higher voltage drop is indicated, inspect, clean

and tighten all connections. This includes any con-

nection between generator battery output terminal

and battery positive post. A voltage drop test may be

performed at each connection to locate the connection

with excessive resistance. If resistance tests satisfac-

torily, reduce engine speed, turn OFF carbon pile and

turn OFF ignition switch.

(1) Disconnect negative cable from battery.

(2) Remove test ammeter, voltmeter, carbon pile,

and tachometer.

(3) Remove jumper wire.

(4) Connect generator output wire to generator

battery output terminal. Tighten nut to 8.561.5 Nzm

(75615 in. lbs.).

(5) Connect negative cable to battery.

(6) Use DRB scan tool to erase DTC.

CURRENT OUTPUT TEST

The generator current output test determines

whether generator can deliver its rated current out-

put.

PREPARATION

(1) Before starting test make sure vehicle has a

fully-charged battery. See Battery in this group for

more information.

(2) Disconnect negative cable from battery.

(3) Disconnect generator output wire at the gener-

ator battery output terminal.

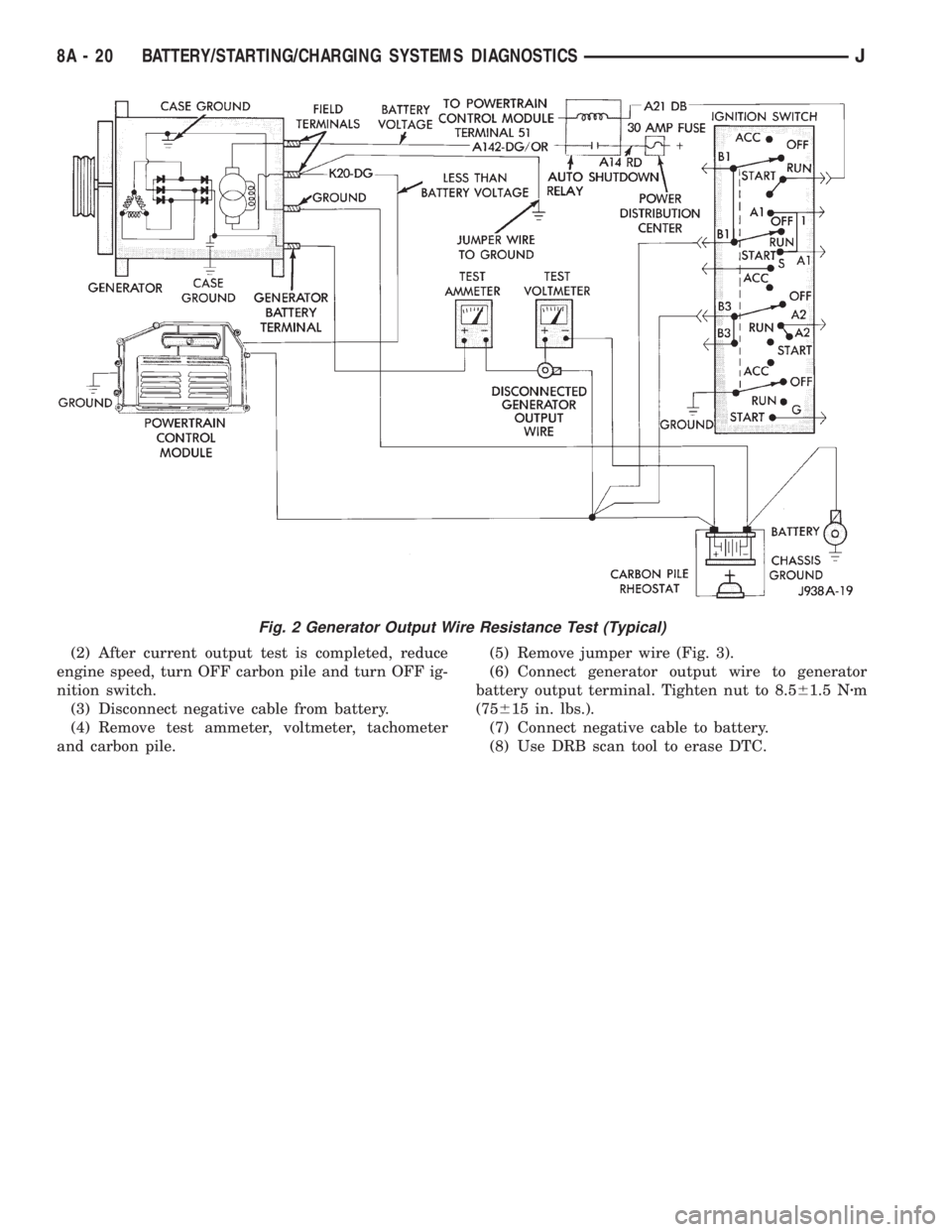

(4) Connect a 0-150 ampere scale DC ammeter

(Fig. 3). Install in series between generator battery

output terminal and disconnected generator output

wire. Connect positive lead to generator battery out-

put terminal and negative lead to disconnected gen-

erator output wire.

8A - 18 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 304 of 2158

(5) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to generator battery output ter-

minal.

(6) Connect negative lead of test voltmeter to a

good ground.

(7) Connect an engine tachometer, then connect

battery negative cable to battery.

(8) Connect a variable carbon pile rheostat be-

tween battery terminals. Be sure carbon pile is in

OPEN or OFF position before connecting leads. See

Load Test in this group for instructions.

(9) Connect one end of a jumper wire to ground

and with other end probe green K20 field wire at

back of generator (Fig. 3). This will generate a DTC.

CAUTION: Do not connect green/orange A142 field

wire to ground. Refer to Group 8W - Wiring Dia-

grams for more information.TEST

(1) Start engine. Immediately after starting, re-

duce engine speed to idle.

(2) Adjust carbon pile and engine speed in incre-

ments until a speed of 1250 rpm and voltmeter read-

ing of 15 volts is obtained.

CAUTION: Do not allow voltage meter to read above

16 volts.

(3) The ammeter reading must be within limits

shown in Generator Output Voltage Specifications.

RESULTS

(1) If reading is less than specified and generator

output wire resistance is not excessive, generator

should be replaced. Refer to Group 8B - Battery/

Starter/Generator Service.

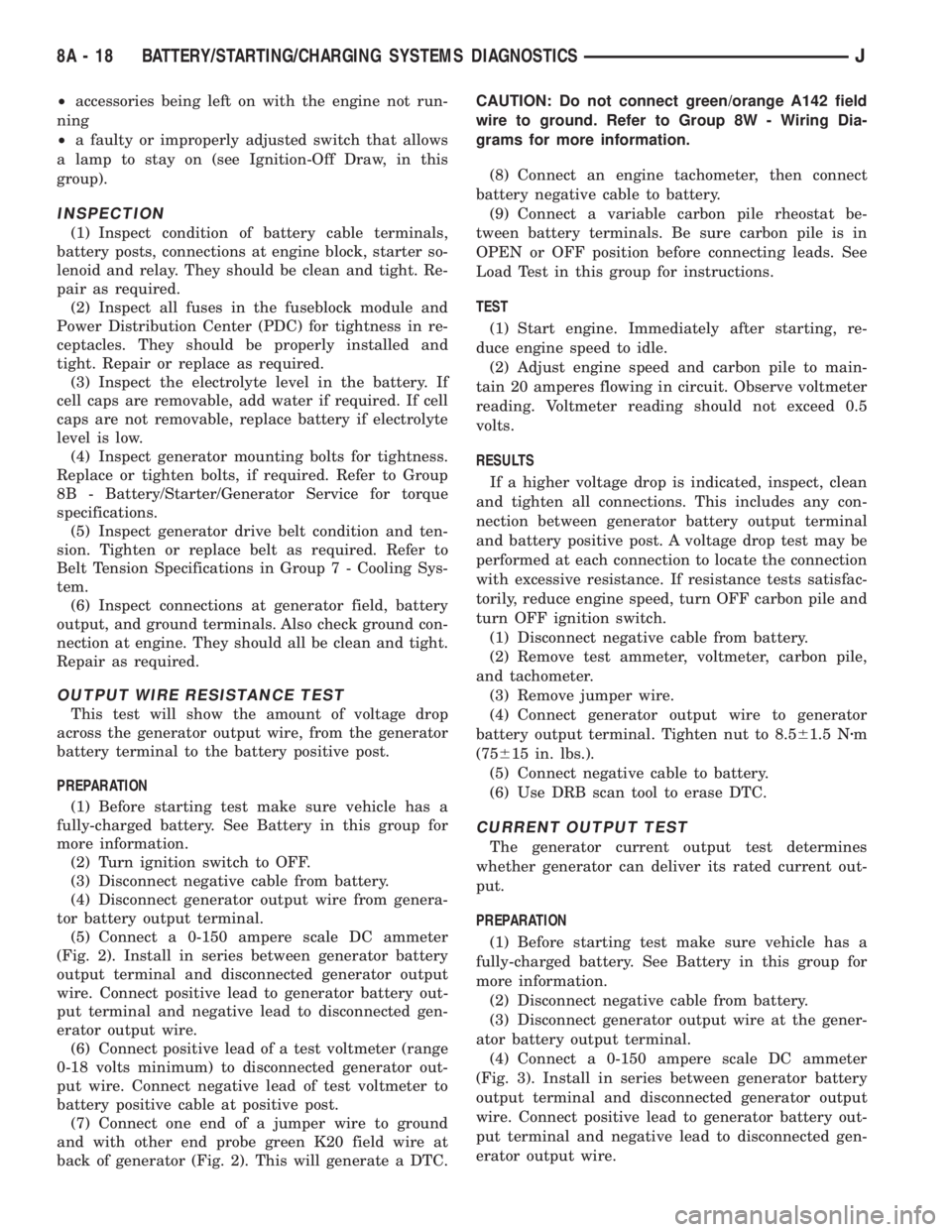

CHARGING SYSTEM DIAGNOSIS

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 19

Page 305 of 2158

(2) After current output test is completed, reduce

engine speed, turn OFF carbon pile and turn OFF ig-

nition switch.

(3) Disconnect negative cable from battery.

(4) Remove test ammeter, voltmeter, tachometer

and carbon pile.(5) Remove jumper wire (Fig. 3).

(6) Connect generator output wire to generator

battery output terminal. Tighten nut to 8.561.5 Nzm

(75615 in. lbs.).

(7) Connect negative cable to battery.

(8) Use DRB scan tool to erase DTC.

Fig. 2 Generator Output Wire Resistance Test (Typical)

8A - 20 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 306 of 2158

Fig. 3 Generator Current Output Test (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 21

Page 307 of 2158

USING ON-BOARD DIAGNOSTIC SYSTEM

GENERAL INFORMATION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 50 engine starts, if the

problem does not occur again.

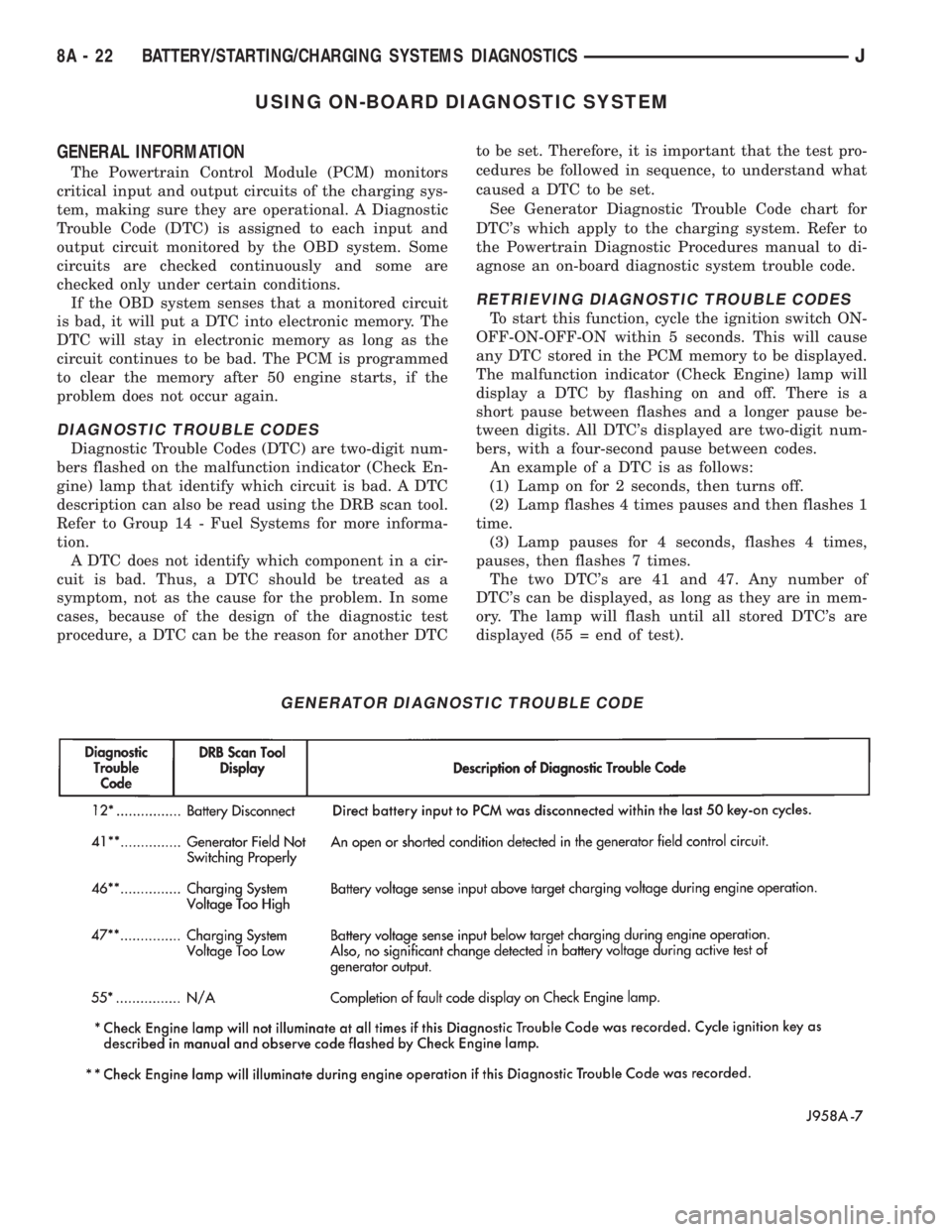

DIAGNOSTIC TROUBLE CODES

Diagnostic Trouble Codes (DTC) are two-digit num-

bers flashed on the malfunction indicator (Check En-

gine) lamp that identify which circuit is bad. A DTC

description can also be read using the DRB scan tool.

Refer to Group 14 - Fuel Systems for more informa-

tion.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTCto be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.

See Generator Diagnostic Trouble Code chart for

DTC's which apply to the charging system. Refer to

the Powertrain Diagnostic Procedures manual to di-

agnose an on-board diagnostic system trouble code.

RETRIEVING DIAGNOSTIC TROUBLE CODES

To start this function, cycle the ignition switch ON-

OFF-ON-OFF-ON within 5 seconds. This will cause

any DTC stored in the PCM memory to be displayed.

The malfunction indicator (Check Engine) lamp will

display a DTC by flashing on and off. There is a

short pause between flashes and a longer pause be-

tween digits. All DTC's displayed are two-digit num-

bers, with a four-second pause between codes.

An example of a DTC is as follows:

(1) Lamp on for 2 seconds, then turns off.

(2) Lamp flashes 4 times pauses and then flashes 1

time.

(3) Lamp pauses for 4 seconds, flashes 4 times,

pauses, then flashes 7 times.

The two DTC's are 41 and 47. Any number of

DTC's can be displayed, as long as they are in mem-

ory. The lamp will flash until all stored DTC's are

displayed (55 = end of test).

GENERATOR DIAGNOSTIC TROUBLE CODE

8A - 22 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 308 of 2158

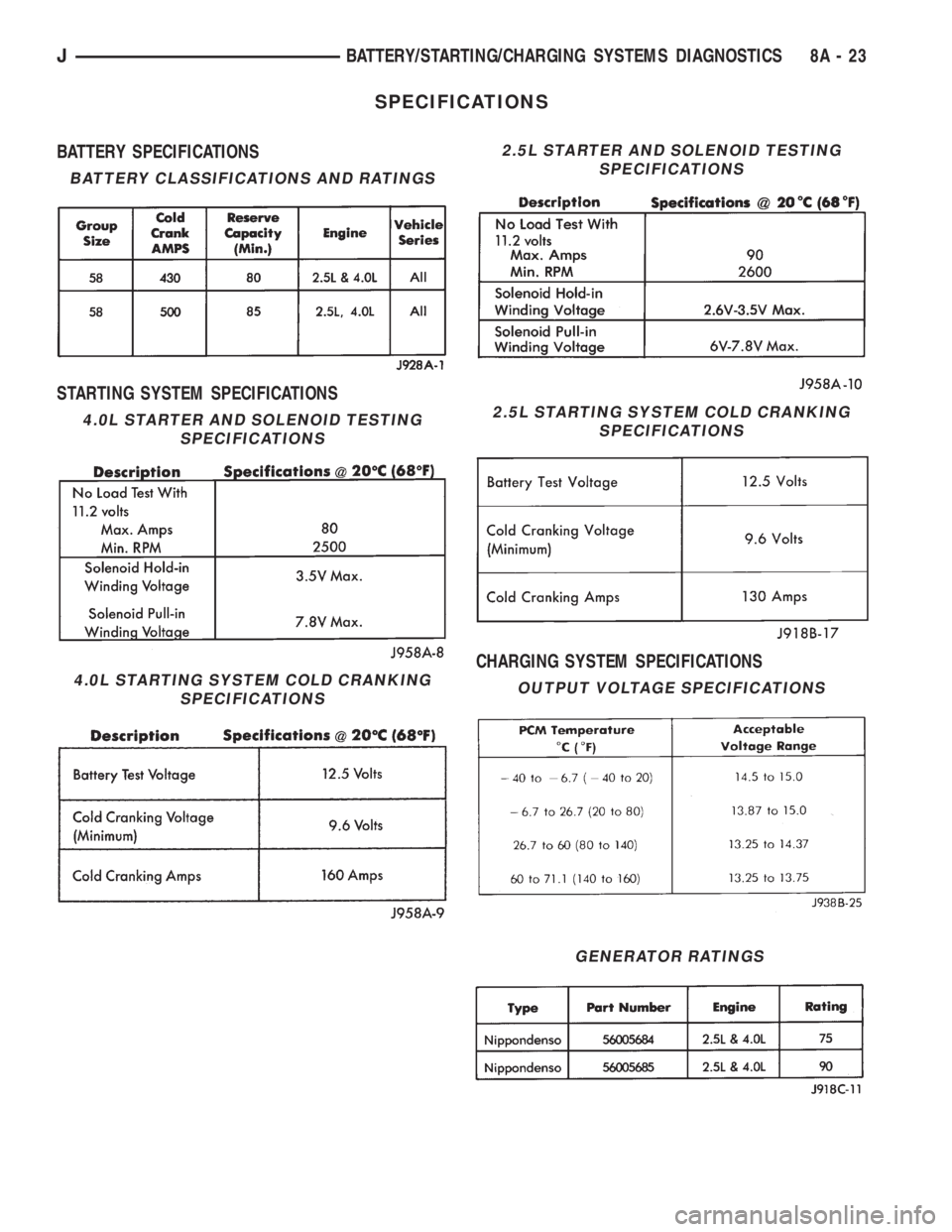

SPECIFICATIONS

BATTERY SPECIFICATIONS

STARTING SYSTEM SPECIFICATIONS

CHARGING SYSTEM SPECIFICATIONS

2.5L STARTER AND SOLENOID TESTING

SPECIFICATIONS

GENERATOR RATINGS

BATTERY CLASSIFICATIONS AND RATINGS

4.0L STARTER AND SOLENOID TESTING

SPECIFICATIONS

4.0L STARTING SYSTEM COLD CRANKING

SPECIFICATIONS

2.5L STARTING SYSTEM COLD CRANKING

SPECIFICATIONS

OUTPUT VOLTAGE SPECIFICATIONS

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 23

Page 309 of 2158

BATTERY/STARTER/GENERATOR SERVICE

CONTENTS

page page

BATTERY............................... 1

GENERATOR............................ 6SPECIFICATIONS......................... 8

STARTER AND STARTER RELAY............. 4

GENERAL INFORMATION

Group 8B covers battery, starter and generator ser-

vice procedures. For diagnosis of these components

and their related systems, refer to Group 8A - Bat-tery/Starting/Charging Systems Diagnostics. Refer to

Group 8W - Wiring Diagrams for complete circuit de-

scriptions and diagrams.

BATTERY

GENERAL INFORMATION

This section covers battery service procedures only.

For battery maintenance procedures, refer to Group 0

- Lubrication and Maintenance. While battery charg-

ing can be considered a service or maintenance pro-

cedure, this information is located in Group 8A -

Battery/Starting/Charging Systems Diagnostics. This

was done because the battery must be fully charged

before any diagnosis is performed.

It is important that the battery, starting, and

charging systems be thoroughly tested and inspected

any time a battery needs to be charged or replaced.

The cause of abnormal discharge, over-charging, or

premature failure of the battery must be diagnosed

and corrected before a battery is replaced or returned

to service. Refer to Group 8A - Battery/Starting/

Charging Systems Diagnostics.

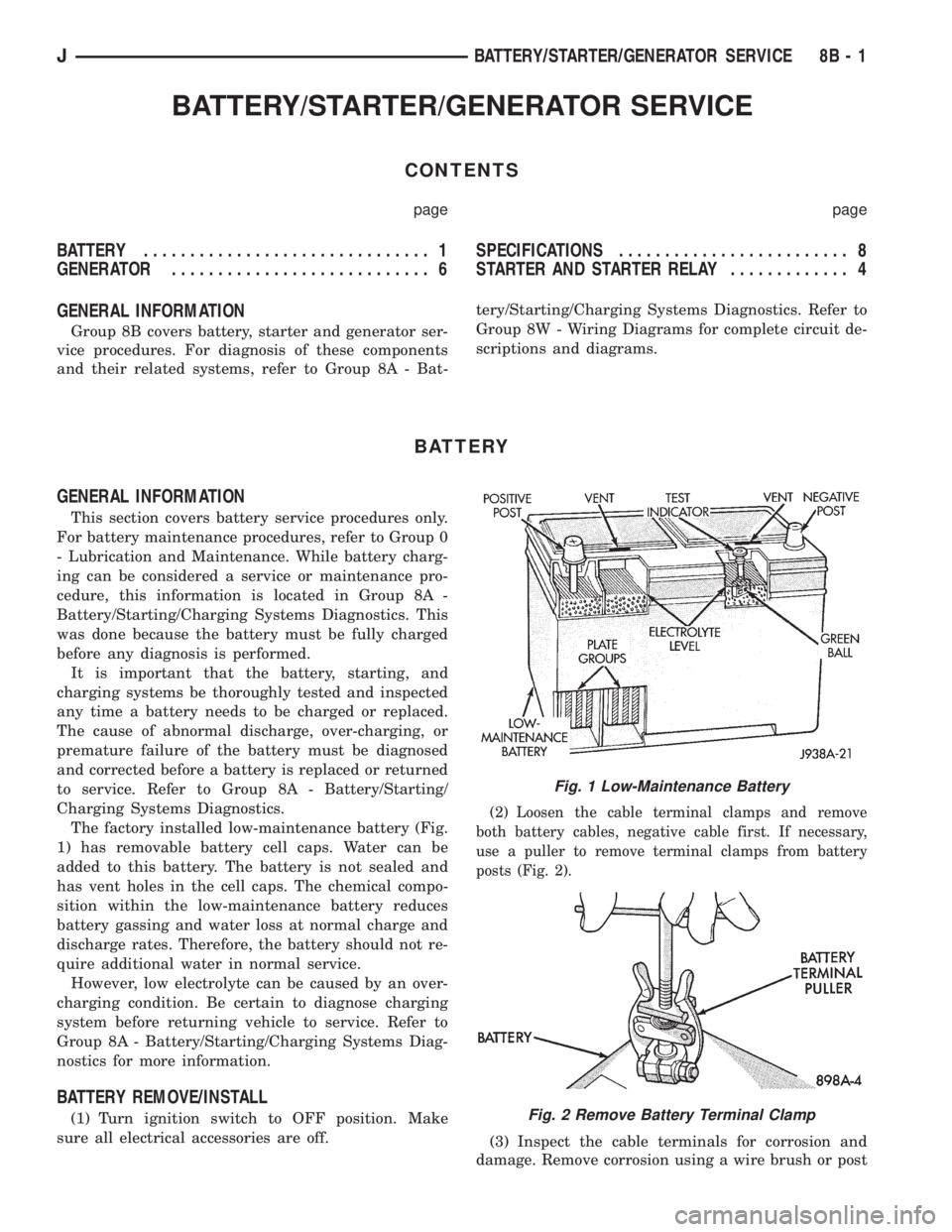

The factory installed low-maintenance battery (Fig.

1) has removable battery cell caps. Water can be

added to this battery. The battery is not sealed and

has vent holes in the cell caps. The chemical compo-

sition within the low-maintenance battery reduces

battery gassing and water loss at normal charge and

discharge rates. Therefore, the battery should not re-

quire additional water in normal service.

However, low electrolyte can be caused by an over-

charging condition. Be certain to diagnose charging

system before returning vehicle to service. Refer to

Group 8A - Battery/Starting/Charging Systems Diag-

nostics for more information.

BATTERY REMOVE/INSTALL

(1) Turn ignition switch to OFF position. Make

sure all electrical accessories are off.

(2) Loosen the cable terminal clamps and remove

both battery cables, negative cable first. If necessary,

use a puller to remove terminal clamps from battery

posts (Fig. 2).

(3) Inspect the cable terminals for corrosion and

damage. Remove corrosion using a wire brush or post

Fig. 1 Low-Maintenance Battery

Fig. 2 Remove Battery Terminal Clamp

JBATTERY/STARTER/GENERATOR SERVICE 8B - 1

Page 311 of 2158

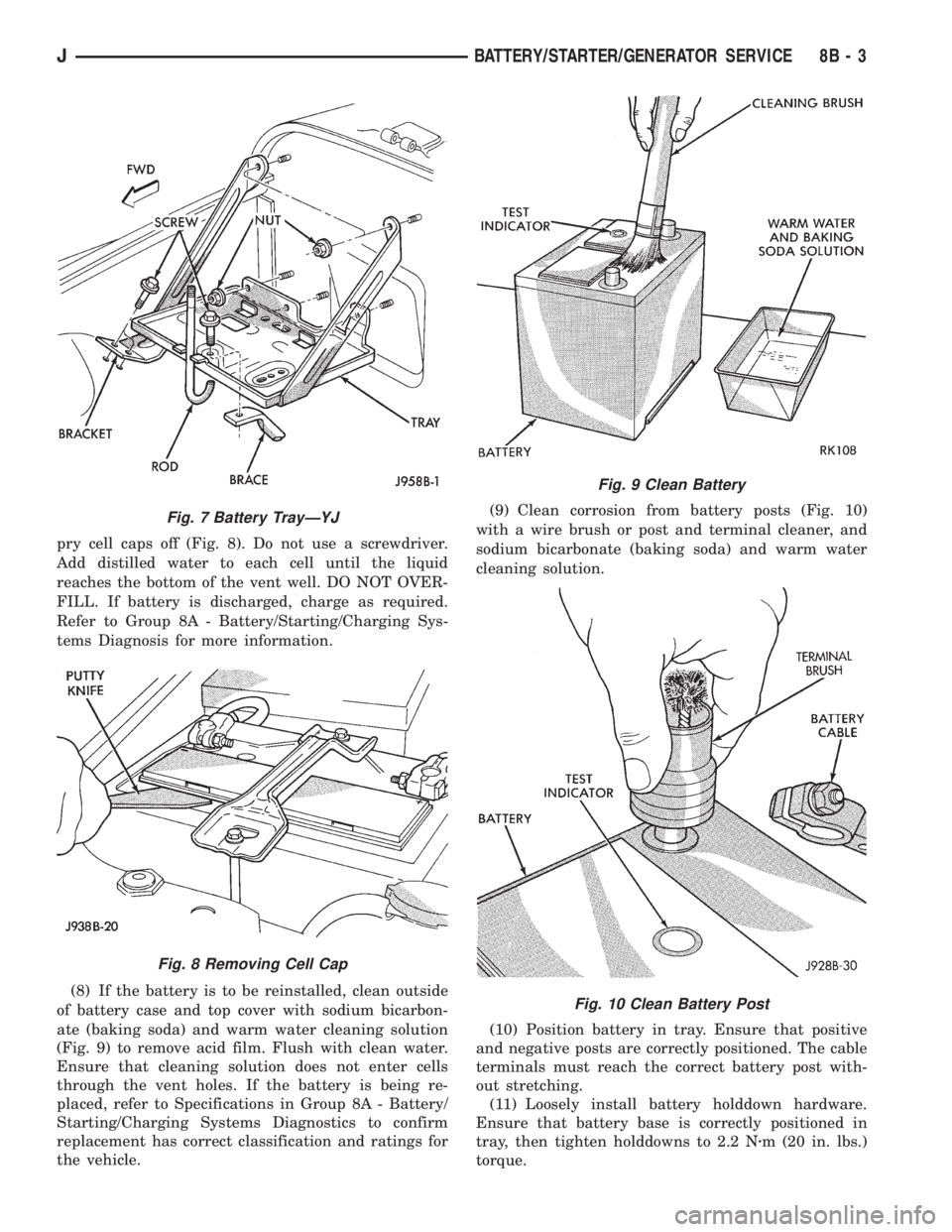

pry cell caps off (Fig. 8). Do not use a screwdriver.

Add distilled water to each cell until the liquid

reaches the bottom of the vent well. DO NOT OVER-

FILL. If battery is discharged, charge as required.

Refer to Group 8A - Battery/Starting/Charging Sys-

tems Diagnosis for more information.

(8) If the battery is to be reinstalled, clean outside

of battery case and top cover with sodium bicarbon-

ate (baking soda) and warm water cleaning solution

(Fig. 9) to remove acid film. Flush with clean water.

Ensure that cleaning solution does not enter cells

through the vent holes. If the battery is being re-

placed, refer to Specifications in Group 8A - Battery/

Starting/Charging Systems Diagnostics to confirm

replacement has correct classification and ratings for

the vehicle.(9) Clean corrosion from battery posts (Fig. 10)

with a wire brush or post and terminal cleaner, and

sodium bicarbonate (baking soda) and warm water

cleaning solution.

(10) Position battery in tray. Ensure that positive

and negative posts are correctly positioned. The cable

terminals must reach the correct battery post with-

out stretching.

(11) Loosely install battery holddown hardware.

Ensure that battery base is correctly positioned in

tray, then tighten holddowns to 2.2 Nzm (20 in. lbs.)

torque.

Fig. 7 Battery TrayÐYJ

Fig. 8 Removing Cell Cap

Fig. 9 Clean Battery

Fig. 10 Clean Battery Post

JBATTERY/STARTER/GENERATOR SERVICE 8B - 3

Page 312 of 2158

CAUTION: Be certain that battery cables are con-

nected to the correct battery terminals. Reverse po-

larity can damage electrical components.

(12) Place oiled felt washer on battery positive ter-

minal post.

(13) Install and tighten battery positive cable ter-

minal clamp. Then install and tighten negative cableterminal clamp. Both cable clamp bolts require

torque of 8.5 Nzm (75 in. lbs.).

(14) Apply a thin coating of petroleum jelly or

chassis grease to cable terminals and battery posts.

STARTER AND STARTER RELAY

GENERAL INFORMATION

This section covers starter and starter relay service

procedures only. For diagnostic procedures, refer to

Group 8A - Battery/Starting/Charging Systems Diag-

nostics. Service procedures for other starting system

components can be found as follows:

²battery - see Battery, in this group

²ignition switch - refer to Group 8D - Ignition Sys-

tems

²park/neutral position switch (automatic transmis-

sion) - refer to Group 21 - Transmission and Transfer

Case

²wiring harness and connectors - refer to Group 8W

- Wiring Diagrams.

STARTER

The starter motor incorporates several features to

create a reliable, efficient, compact and lightweight

unit. A planetary gear system (intermediate trans-

mission) is used between the electric motor and pin-

ion gear. This feature makes it possible to reduce the

dimensions of the starter. At the same time, it allows

higher armature rotational speed and delivers in-

creased torque through the pinion gear to the fly-

wheel or drive plate ring gear.

The use of a permanent magnet field also reduces

starter size and weight. This field consists of six

high-strength permanent magnets. The magnets are

aligned according to their polarity and are perma-

nently fixed in the starter field frame.

The starter motors for all engines are activated by

a solenoid mounted to the overrunning clutch hous-

ing. However, the starter motor/solenoid are serviced

only as a complete assembly. If either component

fails, the entire assembly must be replaced.

This unit is highly sensitive to hammering, shocks

and external pressure.

CAUTION: The starter motor MUST NOT BE

CLAMPED in a vise by the starter field frame. Doing

so may damage the magnets. It may be clamped by

the mounting flange ONLY.CAUTION: Do not connect starter motor incorrectly

when tests are being performed. The permanent

magnets may be damaged and rendered unservice-

able.

STARTER RELAY

The starter relay is an International Standards Or-

ganization (ISO) type relay, and is located in the

Power Distribution Center (PDC). Refer to underside

of PDC cover for relay location.

STARTER REMOVE/INSTALLÐ2.5L

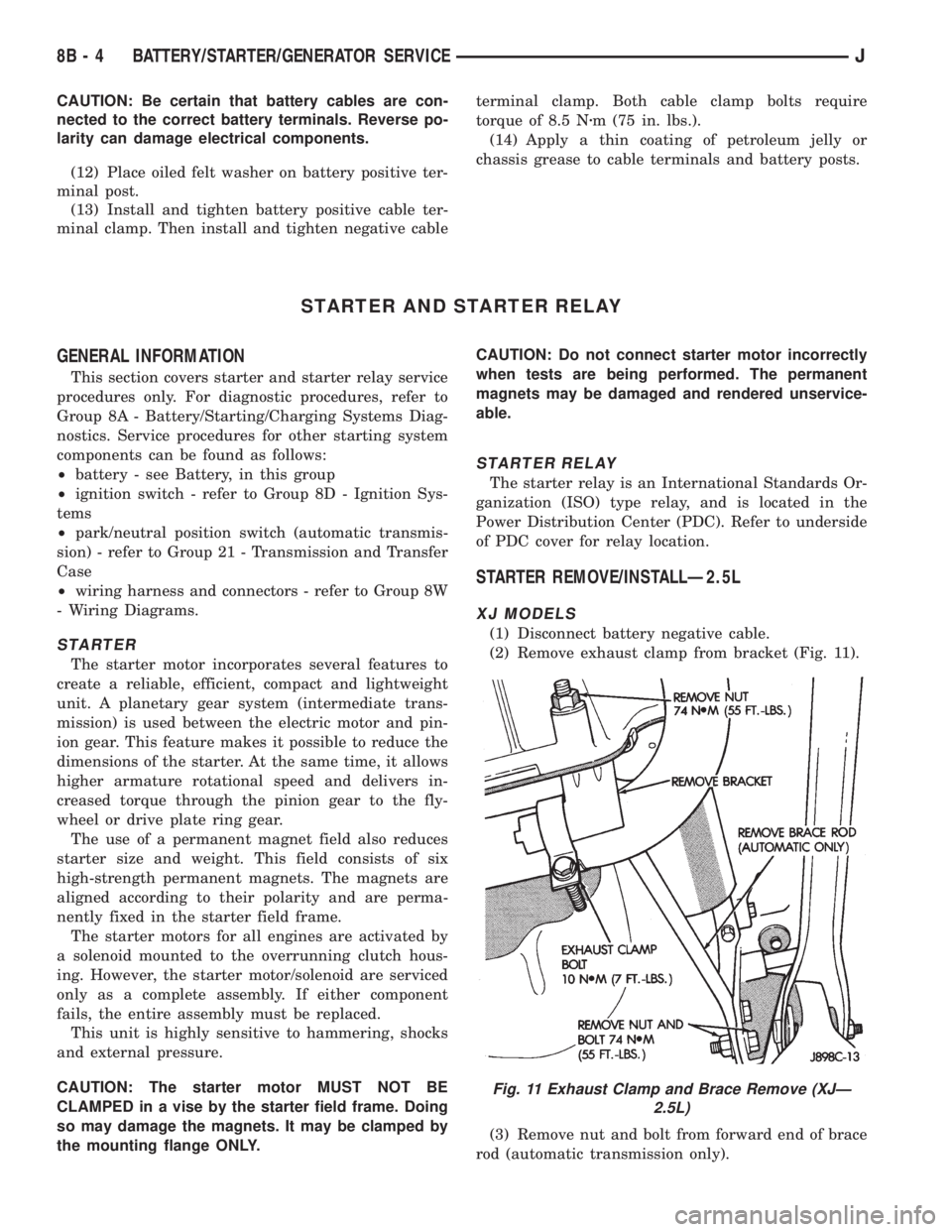

XJ MODELS

(1) Disconnect battery negative cable.

(2) Remove exhaust clamp from bracket (Fig. 11).

(3) Remove nut and bolt from forward end of brace

rod (automatic transmission only).

Fig. 11 Exhaust Clamp and Brace Remove (XJÐ

2.5L)

8B - 4 BATTERY/STARTER/GENERATOR SERVICEJ

Page 313 of 2158

(4) Remove nut from lower end of brace rod (auto-

matic transmission only).

(5) Remove brace rod and bracket (automatic

transmission only).

(6) Remove nut, bolt and bracket from bell housing

(manual transmission only).

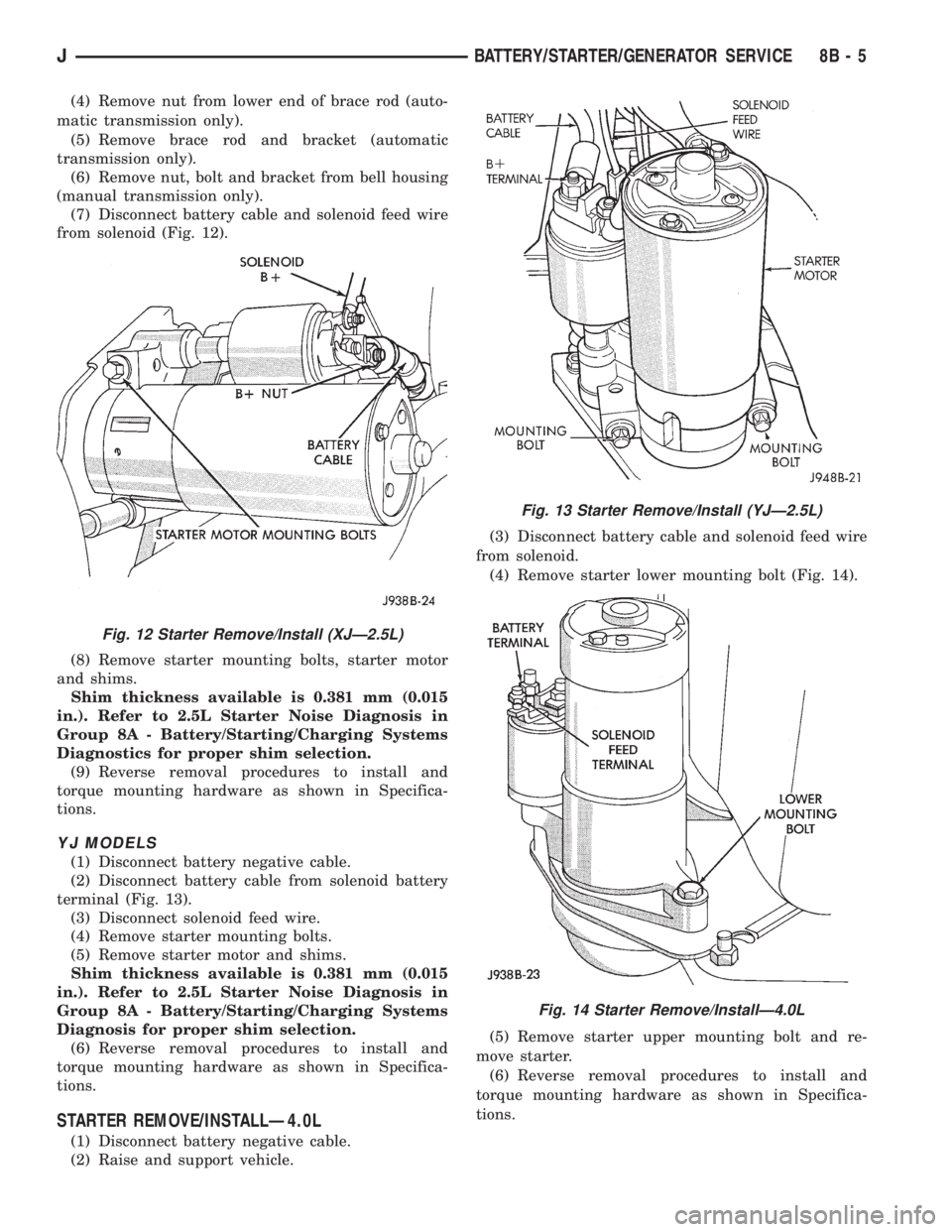

(7) Disconnect battery cable and solenoid feed wire

from solenoid (Fig. 12).

(8) Remove starter mounting bolts, starter motor

and shims.

Shim thickness available is 0.381 mm (0.015

in.). Refer to 2.5L Starter Noise Diagnosis in

Group 8A - Battery/Starting/Charging Systems

Diagnostics for proper shim selection.

(9) Reverse removal procedures to install and

torque mounting hardware as shown in Specifica-

tions.

YJ MODELS

(1) Disconnect battery negative cable.

(2) Disconnect battery cable from solenoid battery

terminal (Fig. 13).

(3) Disconnect solenoid feed wire.

(4) Remove starter mounting bolts.

(5) Remove starter motor and shims.

Shim thickness available is 0.381 mm (0.015

in.). Refer to 2.5L Starter Noise Diagnosis in

Group 8A - Battery/Starting/Charging Systems

Diagnosis for proper shim selection.

(6) Reverse removal procedures to install and

torque mounting hardware as shown in Specifica-

tions.

STARTER REMOVE/INSTALLÐ4.0L

(1) Disconnect battery negative cable.

(2) Raise and support vehicle.(3) Disconnect battery cable and solenoid feed wire

from solenoid.

(4) Remove starter lower mounting bolt (Fig. 14).

(5) Remove starter upper mounting bolt and re-

move starter.

(6) Reverse removal procedures to install and

torque mounting hardware as shown in Specifica-

tions.

Fig. 12 Starter Remove/Install (XJÐ2.5L)

Fig. 13 Starter Remove/Install (YJÐ2.5L)

Fig. 14 Starter Remove/InstallÐ4.0L

JBATTERY/STARTER/GENERATOR SERVICE 8B - 5