charging JEEP XJ 1995 Service And Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 314 of 2158

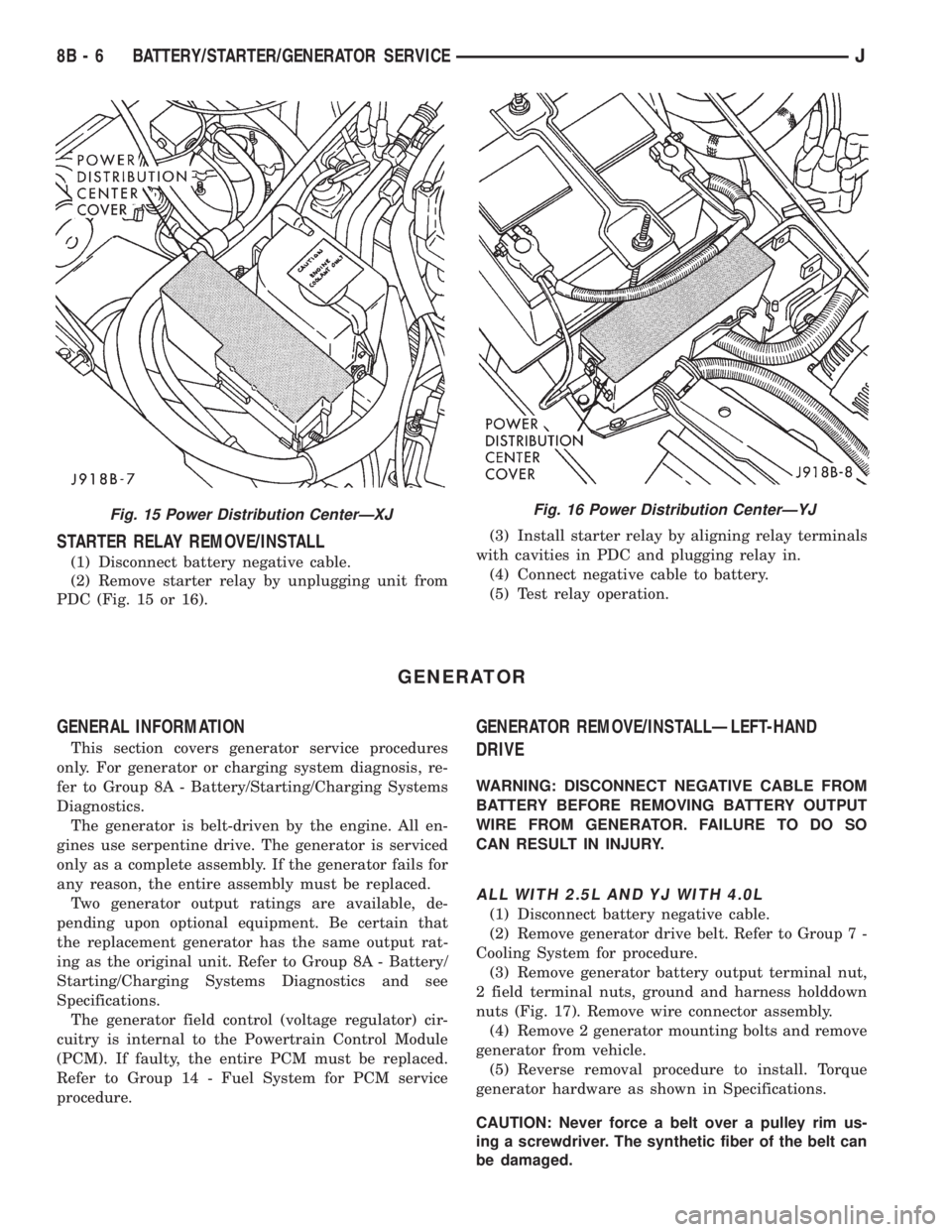

STARTER RELAY REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Remove starter relay by unplugging unit from

PDC (Fig. 15 or 16).(3) Install starter relay by aligning relay terminals

with cavities in PDC and plugging relay in.

(4) Connect negative cable to battery.

(5) Test relay operation.

GENERATOR

GENERAL INFORMATION

This section covers generator service procedures

only. For generator or charging system diagnosis, re-

fer to Group 8A - Battery/Starting/Charging Systems

Diagnostics.

The generator is belt-driven by the engine. All en-

gines use serpentine drive. The generator is serviced

only as a complete assembly. If the generator fails for

any reason, the entire assembly must be replaced.

Two generator output ratings are available, de-

pending upon optional equipment. Be certain that

the replacement generator has the same output rat-

ing as the original unit. Refer to Group 8A - Battery/

Starting/Charging Systems Diagnostics and see

Specifications.

The generator field control (voltage regulator) cir-

cuitry is internal to the Powertrain Control Module

(PCM). If faulty, the entire PCM must be replaced.

Refer to Group 14 - Fuel System for PCM service

procedure.

GENERATOR REMOVE/INSTALLÐLEFT-HAND

DRIVE

WARNING: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

ALL WITH 2.5L AND YJ WITH 4.0L

(1) Disconnect battery negative cable.

(2) Remove generator drive belt. Refer to Group 7 -

Cooling System for procedure.

(3) Remove generator battery output terminal nut,

2 field terminal nuts, ground and harness holddown

nuts (Fig. 17). Remove wire connector assembly.

(4) Remove 2 generator mounting bolts and remove

generator from vehicle.

(5) Reverse removal procedure to install. Torque

generator hardware as shown in Specifications.

CAUTION: Never force a belt over a pulley rim us-

ing a screwdriver. The synthetic fiber of the belt can

be damaged.

Fig. 15 Power Distribution CenterÐXJFig. 16 Power Distribution CenterÐYJ

8B - 6 BATTERY/STARTER/GENERATOR SERVICEJ

Page 359 of 2158

TACHOMETER

The tachometer gives an indication of engine speed

in Revolutions-Per-Minute (RPM). With the engine

running, the tachometer receives an engine speed

pulse signal from the Powertrain Control Module

(PCM). An electronic integrated circuit contained

within the tachometer reads and analyzes the pulse

signal. It then adjusts the ground path resistance of

one electromagnet in the gauge to control needle

movement. Frequency values for the pulse signal are

shown in a chart in Specifications.

TRIP ODOMETER

The trip odometer is driven by the same electronic

integrated circuit as the speedometer/odometer. How-

ever, by depressing the trip odometer reset knob on

the face of the speedometer, the trip odometer can be

reset to zero. The trip odometer is serviced only as a

part of the speedometer/odometer gauge assembly.

VOLTMETER

The voltmeter is connected in parallel with the bat-

tery. With the ignition switch ON, the voltmeter in-

dicates battery or generator output voltage,

whichever is greater.

INDICATOR LAMPS

Indicator lamps are located in two areas within the

cluster. Each of these areas is served by a separate

printed circuit and cluster connector. Those lamps in

the gauge area of the cluster share the gauge area

printed circuit and cluster connector A. Those lamps

in the tell-tale area of the cluster use the tell-tale

printed circuit and cluster (tell-tale) connector B.

Up to ten indicator lamps can be found in the tell-

tale area of the cluster. These lamps are arranged in

five stacked rows with two lamps in each row, located

to the driver's side of the main cluster.

ANTI-LOCK BRAKE SYSTEM LAMP

The Anti-Lock Brake System (ABS) lamp is

switched to ground by the ABS module. The module

lights the lamp when the ignition switch is turned to

the START position as a bulb test. The lamp will

stay on for 3 to 5 seconds after vehicle start-up to in-

dicate a system self-test is in process. If the lamp re-

mains on after start-up, or comes on and stays on

while driving, it may indicate that the ABS module

has detected a system malfunction or that the system

has become inoperative. Refer to Group 5 - Brakes

for more information.

BRAKE WARNING LAMP

The brake warning lamp warns the driver that the

parking brake is applied or that the pressures in the

two halves of the split brake hydraulic system are

unequal. With the ignition switch turned ON, batteryvoltage is supplied to one side of the indicator bulb. A

ground path for the bulb is provided by 3 switches.

The bulb will light when:

²the brake warning switch is closed (indicating un-

equal brake system hydraulic pressures possibly due

to brake fluid leakage)

²the ignition switch is in the START position (bulb

test)

²the parking brake switch is closed (parking brake

is applied).

Refer to Group 5 - Brakes for more information.

COOLANT TEMPERATURE WARNING LAMP

The coolant temperature warning lamp lights

whenever engine coolant temperature is too high.

Battery voltage is supplied to one side of the indica-

tor bulb when the ignition switch is turned ON. The

normally open coolant temperature switch is con-

nected to the other side of the bulb. When coolant

temperature is too high, the switch closes. This pro-

vides a ground path for the indicator bulb, which

causes it to light. The lamp is also grounded and

should light with the ignition switch in the START

position as a bulb test.

FOUR-WHEEL DRIVE INDICATOR LAMPS

PART TIME

On vehicles with Command-Trac 4WD, the Part

Time lamp lights when the transfer case is engaged

in the 4H or 4L position. On vehicles with Selec-Trac

4WD, the Part Time lamp lights when the transfer

case is engaged in the4X4PARTTIME or 4 LO po-

sition. Voltage is supplied to one side of the indicator

bulb. A switch in the transfer case is connected to the

other side of the indicator bulb. When the switch is

closed, a path to ground is provided and the indicator

bulb lights.

FULL TIME

The Full Time lamp is only operational on vehicles

equipped with Selec-Trac 4WD. The Full Time lamp

lights when the transfer case is engaged in the4X4

Full Time position. Voltage is supplied to one side of

the indicator bulb. A switch in the transfer case is

connected to the other side of the indicator bulb.

When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

GENERATOR WARNING LAMP

The generator warning lamp lights with the igni-

tion switch turned to ON, but should go out when-

ever the engine is running. If the lamp comes on and

stays on while the engine is running, it indicates

that a charging system malfunction exists. One side

of the bulb is connected to ignition-switched battery

feed. The other side of the bulb is switched to ground

by the Powertrain Control Module (PCM).

JINSTRUMENT PANEL AND GAUGESÐXJ 8E - 3

Page 429 of 2158

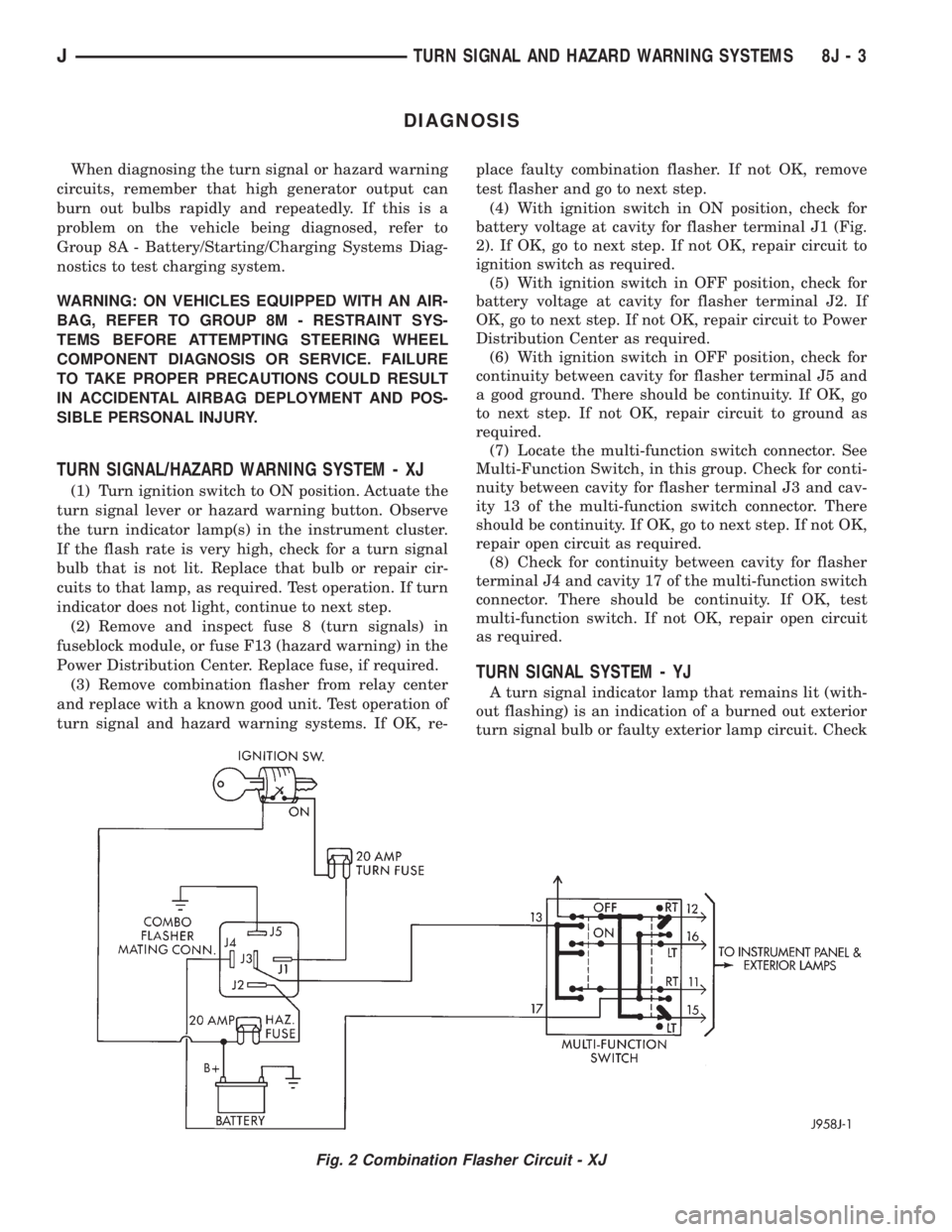

DIAGNOSIS

When diagnosing the turn signal or hazard warning

circuits, remember that high generator output can

burn out bulbs rapidly and repeatedly. If this is a

problem on the vehicle being diagnosed, refer to

Group 8A - Battery/Starting/Charging Systems Diag-

nostics to test charging system.

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

TURN SIGNAL/HAZARD WARNING SYSTEM - XJ

(1) Turn ignition switch to ON position. Actuate the

turn signal lever or hazard warning button. Observe

the turn indicator lamp(s) in the instrument cluster.

If the flash rate is very high, check for a turn signal

bulb that is not lit. Replace that bulb or repair cir-

cuits to that lamp, as required. Test operation. If turn

indicator does not light, continue to next step.

(2) Remove and inspect fuse 8 (turn signals) in

fuseblock module, or fuse F13 (hazard warning) in the

Power Distribution Center. Replace fuse, if required.

(3) Remove combination flasher from relay center

and replace with a known good unit. Test operation of

turn signal and hazard warning systems. If OK, re-place faulty combination flasher. If not OK, remove

test flasher and go to next step.

(4) With ignition switch in ON position, check for

battery voltage at cavity for flasher terminal J1 (Fig.

2). If OK, go to next step. If not OK, repair circuit to

ignition switch as required.

(5) With ignition switch in OFF position, check for

battery voltage at cavity for flasher terminal J2. If

OK, go to next step. If not OK, repair circuit to Power

Distribution Center as required.

(6) With ignition switch in OFF position, check for

continuity between cavity for flasher terminal J5 and

a good ground. There should be continuity. If OK, go

to next step. If not OK, repair circuit to ground as

required.

(7) Locate the multi-function switch connector. See

Multi-Function Switch, in this group. Check for conti-

nuity between cavity for flasher terminal J3 and cav-

ity 13 of the multi-function switch connector. There

should be continuity. If OK, go to next step. If not OK,

repair open circuit as required.

(8) Check for continuity between cavity for flasher

terminal J4 and cavity 17 of the multi-function switch

connector. There should be continuity. If OK, test

multi-function switch. If not OK, repair open circuit

as required.

TURN SIGNAL SYSTEM - YJ

A turn signal indicator lamp that remains lit (with-

out flashing) is an indication of a burned out exterior

turn signal bulb or faulty exterior lamp circuit. Check

Fig. 2 Combination Flasher Circuit - XJ

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 3

Page 461 of 2158

LAMPS

CONTENTS

page page

BULB APPLICATIONÐXJ VEHICLES......... 18

GENERAL INFORMATION.................. 1INTERIOR LAMPS....................... 16

SERVICE PROCEDURES................... 6

GENERAL INFORMATION

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

DIAGNOSTIC PROCEDURESÐXJ

When a vehicle experiences problems with the

headlamp system, verify the condition of the batteryconnections, charging system, headlamp bulbs, wire

connectors, relay, high beam dimmer switch and

headlamp switch. Refer to Group 8W, Wiring Dia-

grams for component locations and circuit informa-

tion.

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to

Group 8W, Wiring Diagrams.

JLAMPS 8L - 1

Page 479 of 2158

LAMPS

CONTENTS

page page

BULB APPLICATIONÐYJ VEHICLES......... 32

GENERAL INFORMATION................. 19INTERIOR LAMPS....................... 31

SERVICE PROCEDURES.................. 22

GENERAL INFORMATION

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

DIAGNOSTIC PROCEDURESÐYJ

When a vehicle experiences problems with the

headlamp system, verify the condition of the batteryconnections, charging system, headlamp bulbs, wire

connectors, relay, high beam dimmer switch and

headlamp switch. Refer to Group 8W, Wiring Dia-

grams for component locations and circuit informa-

tion.

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to

Group 8W, Wiring Diagrams.

JLAMPSÐYJ VEHICLES 8L - 19

Page 543 of 2158

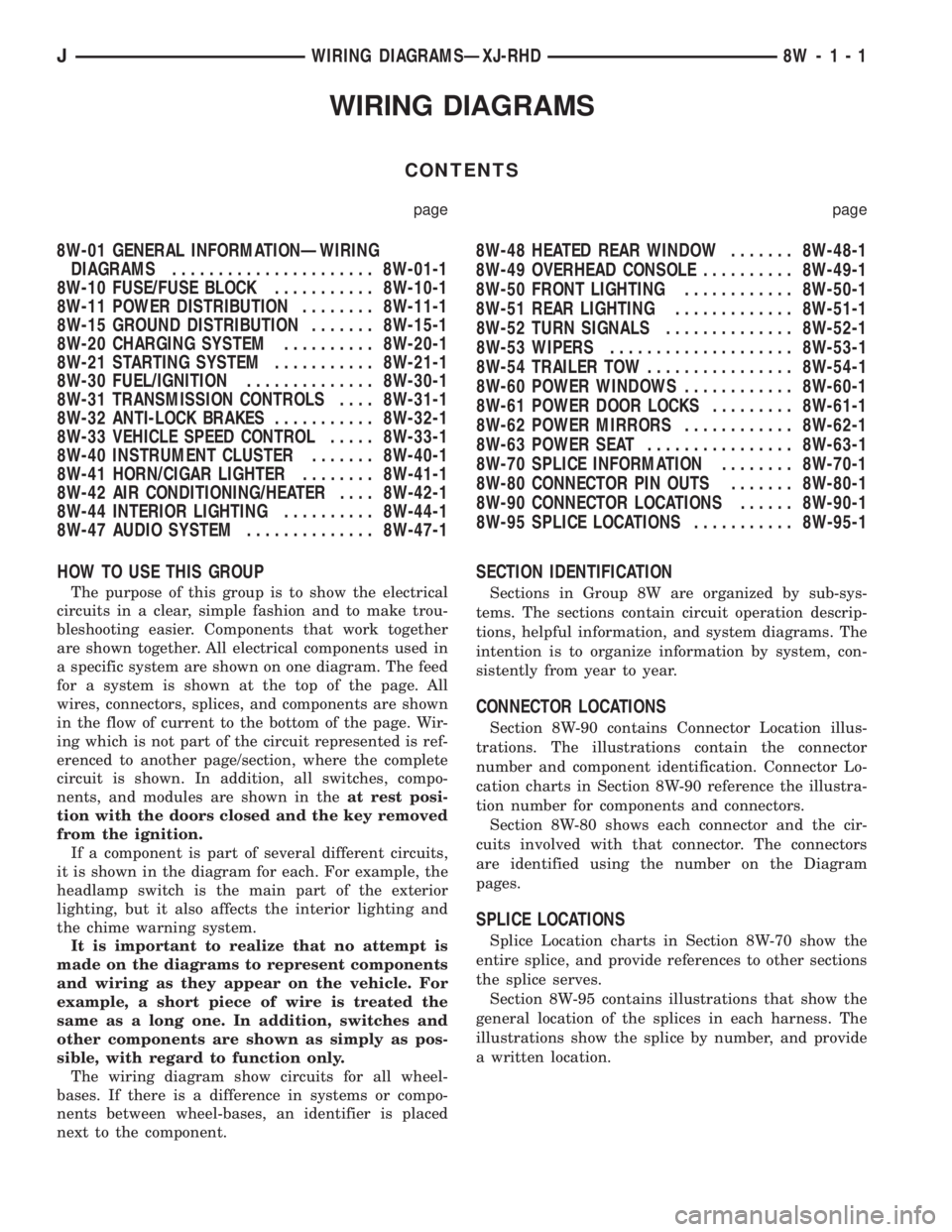

WIRING DIAGRAMS

CONTENTS

page page

8W-01 GENERAL INFORMATIONÐWIRING

DIAGRAMS.................... 8W-01-1

8W-10 FUSE/FUSE BLOCK........... 8W-10-1

8W-11 POWER DISTRIBUTION........ 8W-11-1

8W-15 GROUND DISTRIBUTION....... 8W-15-1

8W-20 CHARGING SYSTEM.......... 8W-20-1

8W-21 STARTING SYSTEM........... 8W-21-1

8W-30 FUEL/IGNITION.............. 8W-30-1

8W-31 TRANSMISSION CONTROLS.... 8W-31-1

8W-32 ANTI-LOCK BRAKES.......... 8W-32-1

8W-33 VEHICLE SPEED CONTROL..... 8W-33-1

8W-40 INSTRUMENT CLUSTER....... 8W-40-1

8W-41 HORN/CIGAR LIGHTER......... 8W-41-1

8W-42 AIR CONDITIONING/HEATER.... 8W-42-1

8W-44 INTERIOR LIGHTING.......... 8W-44-1

8W-47 AUDIO SYSTEM.............. 8W-47-18W-48 HEATED REAR WINDOW....... 8W-48-1

8W-49 OVERHEAD CONSOLE......... 8W-49-1

8W-50 FRONT LIGHTING............. 8W-50-1

8W-51 REAR LIGHTING............. 8W-51-1

8W-52 TURN SIGNALS.............. 8W-52-1

8W-53 WIPERS..................... 8W-53-1

8W-54 TRAILER TOW................ 8W-54-1

8W-60 POWER WINDOWS.......... 8W-60-1

8W-61 POWER DOOR LOCKS......... 8W-61-1

8W-62 POWER MIRRORS............ 8W-62-1

8W-63 POWER SEAT................ 8W-63-1

8W-70 SPLICE INFORMATION........ 8W-70-1

8W-80 CONNECTOR PIN OUTS....... 8W-80-1

8W-90 CONNECTOR LOCATIONS...... 8W-90-1

8W-95 SPLICE LOCATIONS........... 8W-95-1

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.

It is important to realize that no attempt is

made on the diagrams to represent components

and wiring as they appear on the vehicle. For

example, a short piece of wire is treated the

same as a long one. In addition, switches and

other components are shown as simply as pos-

sible, with regard to function only.

The wiring diagram show circuits for all wheel-

bases. If there is a difference in systems or compo-

nents between wheel-bases, an identifier is placed

next to the component.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR LOCATIONS

Section 8W-90 contains Connector Location illus-

trations. The illustrations contain the connector

number and component identification. Connector Lo-

cation charts in Section 8W-90 reference the illustra-

tion number for components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the number on the Diagram

pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

JWIRING DIAGRAMSÐXJ VEHICLES 8W - 1 - 1

Page 581 of 2158

CHARGING SYSTEM

CHARGING SYSTEM

The charging system is an integral part of the bat-

tery and starting systems. Because all these systems

work in conjunction, diagnose and test them together.

Circuit A11 connects to the generator output termi-

nal and splices to fuse 1 and fuse 8 in the Power Dis-

tribution Center (PDC). Circuit A0 connects the

battery to the PDC.

Circuit Z0 provides ground for the generator. Cir-

cuit Z0 attaches to the right rear of the engine.

When the ignition switch is in either the START or

RUN positions, it connects circuit A1 from fuse 6 in

the PDC to circuit A21. Circuit A21 splices to supply

current to the coil side of the automatic shut down

(ASD) relay. The powertrain control module (PCM)

provides ground for the relay on circuit K51. Circuit

K51 connects to cavity 51 of the PCM.

When the PCM grounds the ASD relay, contacts in-

side the relay close and connect circuit A18 from fuse

14 in the PDC to circuit A142. Circuit A142 splices to

the generator field terminal.

The PCM has an internal voltage regulator that

controls generator output. The PCM controls the gen-

erator field on circuit K20. Circuit K20 connects to

PCM cavity 20.

When the engine operates and there is current in

the generator field, the generator produces a B+ volt-

age. The generator supplies B+ voltage to the battery

through the A11 and A0 circuits.

HELPFUL INFORMATION

²If the vehicle is equipped with a 2.5L engine, cir-

cuit Z0 also connects to the battery.

²Circuit A14 from fuse 2 in the PDC supplies volt-

age to the fuse block for fuse 14.

²The ignition switch also connects circuit A1 with

circuits A41, A38, and A48.

²Circuit A21 also splices to power fuse 17 in the

fuse block.

²Circuit A21 also powers the coil side of the fuel

pump relay.

²The ASD relay supplies battery voltage for the fuel

injectors, ignition coil, and the heated oxygen sensor.

The fuel pump relay powers the fuel pump module.

²Circuit K51 also provides ground for the coil side

of the fuel pump relay.

DIAGRAM INDEX

Component Page

Battery (2.5L)...........................8W-20-2

Battery (4.0L)...........................8W-20-3

PDC Fuse 1 (2.5L).......................8W-20-2

PDC Fuse 1 (4.0L).......................8W-20-3

PDC Fuse 9 (2.5L).......................8W-20-2

PDC Fuse 9 (4.0L).......................8W-20-3

Generator (2.5L).........................8W-20-2

Generator (4.0L).........................8W-20-3

Powertrain Control Module (2.5L)..............8W-20-2

Powertrain Control Module (4.0L)..............8W-20-3

J8W-20 CHARGING SYSTEMÐXJ VEHICLES 8W - 20 - 1

Page 625 of 2158

INSTRUMENT CLUSTER

INDEX

page page

ABS Warning Lamp........................ 2

Brake Warning Lamp....................... 2

Charging System Indicator Lamp............... 3

Cluster Ground............................ 3

Diagram Index............................. 3

Engine Coolant Temperature Gauge............ 1

Engine Coolant Temperature Warning Lamp...... 1

Fuel Gauge.............................. 1

High-Beam Indicator Lamp................... 2

Instrument Cluster......................... 1Low Fuel Warning Lamp..................... 1

Low Washer Fluid Warning Lamp.............. 2

Malfunction Indicator Lamp (MIL)............... 2

Manual Transmission Up-Shift Lamp............ 2

Oil Pressure Gauge........................ 2

Oil Pressure Warning Lamp.................. 2

Seat Belt Indicator Warning Lamp.............. 2

Speedometer............................. 2

Tachometer.............................. 2

Turn Signal Indicator Lamps.................. 2

INSTRUMENT CLUSTER

The instrument cluster contains the gauges and

warning lamps. All gauges have magnetic move-

ments.

When the ignition switch is in the START or RUN

position, circuit A21 feeds circuit F87 through fuse 17

in the fuse block. Circuit A1 from fuse 6 in the Power

Distribution Center (PDC) supplies voltage to circuit

A21. Circuit A1 is HOT at all times.

Circuit F87 connects to the cluster connector to

power the gauges and to the telltale connector to

power the warning lamps.

Circuit E2 from fuse 19 in the fuse block feeds the

illumination lamps. Circuit E2 originates at the head-

lamp switch and continues through fuse 19. The

headlamp switch powers circuit E2 when the parking

lamps or headlamp are ON.

Circuit Z2 provides ground for the indicator lamps

and illumination lamps.

ENGINE COOLANT TEMPERATURE GAUGE

Circuit G20 connects the engine coolant tempera-

ture gauge to the engine coolant temperature sensor.

The sensor is a variable resistor and case grounded to

the engine. Circuit F87 connects to the instrument

cluster left connector and supplies voltage for the

gauge.

The gauge uses two coils. Current passing through

the coils creates a magnetic field. Position of the

gauge needle is controlled by the amount of current

passing through the coils to ground at the sensor.

ENGINE COOLANT TEMPERATURE WARNING

LAMP

Circuit G20 connects the engine coolant tempera-

ture warning lamp to the engine coolant temperature

switch. When the switch closes, battery voltage from

circuit F87 flows through the lamp to ground through

the switch on circuit G20. The engine coolant tem-

perature switch is case grounded to the engine. Cir-cuit F87 connects to the instrument cluster connector

and supplies voltage for the lamp.

Circuit G20 also connects to the warning lamp to

ground when the ignition switch is in the START

position. When the ignition switch is in the START

position, the lamp illuminates for a bulb test.

FUEL GAUGE

The fuel level sensor is a variable resistor. Circuit

G4 connects the fuel level sensor to the fuel gauge in

the instrument cluster. Circuit F87 from fuse 17 in

the fuse block supplies voltage to the fuel gauge. The

fuel level sensor draws voltage from circuit F87

through the fuel gauge on circuit G4. Circuit G4

connects to circuit 57 in the fuel pump module har-

ness. Circuit 57 connects to the fuel level sensor.

Circuit 99 in the fuel pump module harness con-

nects to circuit Z1. Circuit Z1 provides the ground

path for the fuel level sensor. The grounding point for

circuit Z1 is the left side of the cowl panel.

As current flows through the coils in the fuel gauge,

it creates a magnetic field. One of the coils in the

gauge receives fixed current. The other coil is con-

nected to the level sensor. The magnetic field controls

the position of the fuel gauge pointer.

The fuel level sensor contains a variable resistor. As

the position of the float arm on the fuel level sensor

changes, the resistor changes the current flow

through second coil in the fuel gauge. A change in

current flow alters the magnetic field in the fuel

gauge, which changes the pointer position.

LOW FUEL WARNING LAMP

Circuit G4 connects the fuel level sensor to the fuel

gauge. The low fuel level module at the rear of the

gauge monitors resistance in circuit G4. The low fuel

level module powers an light emitting diode (LED)

when the resistance in circuit G4 reaches a calibrated

level. The LED illuminates the Low Fuel indicator.

Refer to Group 8E for additional information.

J8W-40 INSTRUMENT CLUSTERÐXJ VEHICLES 8W - 40 - 1

Page 627 of 2158

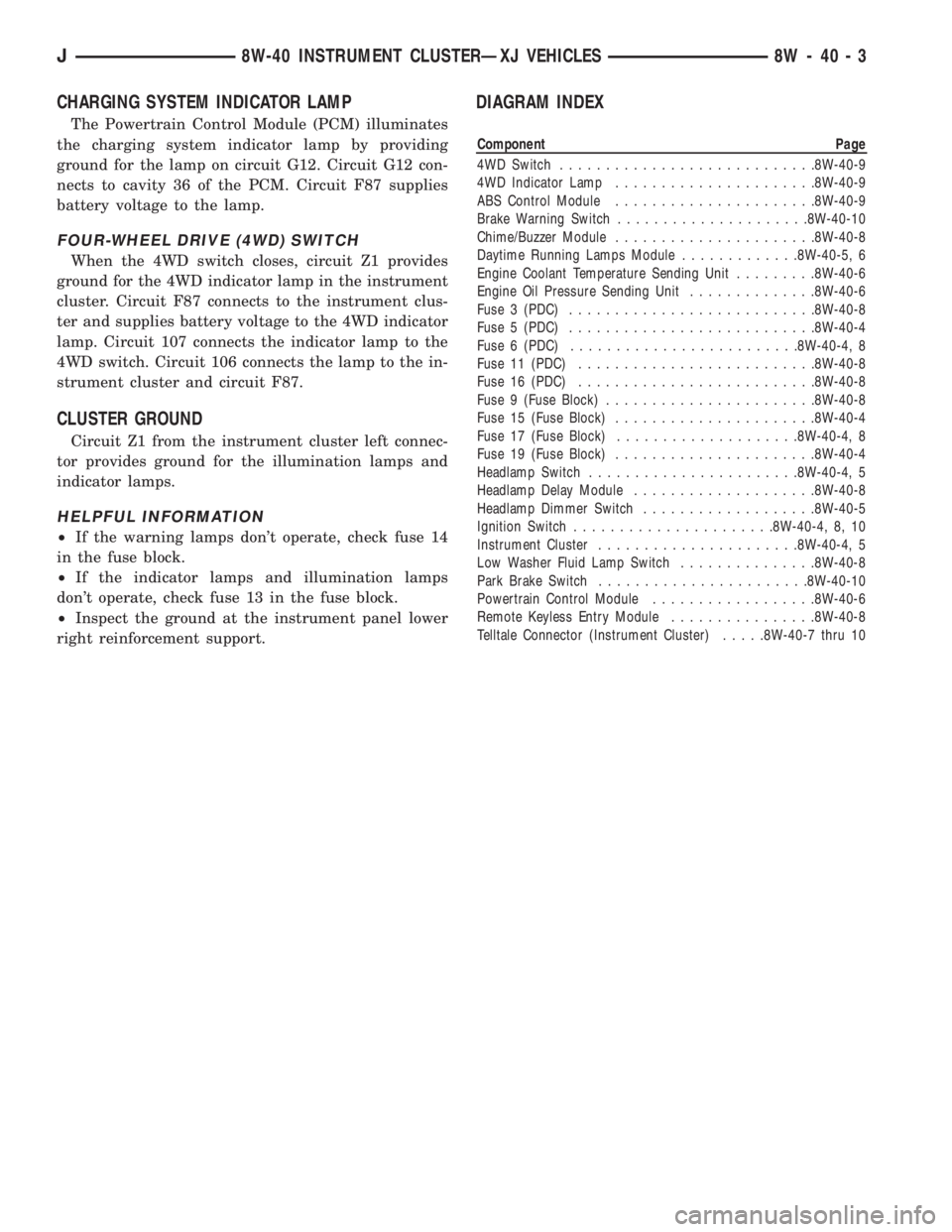

CHARGING SYSTEM INDICATOR LAMP

The Powertrain Control Module (PCM) illuminates

the charging system indicator lamp by providing

ground for the lamp on circuit G12. Circuit G12 con-

nects to cavity 36 of the PCM. Circuit F87 supplies

battery voltage to the lamp.

FOUR-WHEEL DRIVE (4WD) SWITCH

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

cluster. Circuit F87 connects to the instrument clus-

ter and supplies battery voltage to the 4WD indicator

lamp. Circuit 107 connects the indicator lamp to the

4WD switch. Circuit 106 connects the lamp to the in-

strument cluster and circuit F87.

CLUSTER GROUND

Circuit Z1 from the instrument cluster left connec-

tor provides ground for the illumination lamps and

indicator lamps.

HELPFUL INFORMATION

²If the warning lamps don't operate, check fuse 14

in the fuse block.

²If the indicator lamps and illumination lamps

don't operate, check fuse 13 in the fuse block.

²Inspect the ground at the instrument panel lower

right reinforcement support.

DIAGRAM INDEX

Component Page

4WD Switch............................8W-40-9

4WD Indicator Lamp......................8W-40-9

ABS Control Module......................8W-40-9

Brake Warning Switch.....................8W-40-10

Chime/Buzzer Module......................8W-40-8

Daytime Running Lamps Module.............8W-40-5, 6

Engine Coolant Temperature Sending Unit.........8W-40-6

Engine Oil Pressure Sending Unit..............8W-40-6

Fuse 3 (PDC)...........................8W-40-8

Fuse 5 (PDC)...........................8W-40-4

Fuse 6 (PDC).........................8W-40-4, 8

Fuse 11 (PDC)..........................8W-40-8

Fuse 16 (PDC)..........................8W-40-8

Fuse 9 (Fuse Block).......................8W-40-8

Fuse 15 (Fuse Block)......................8W-40-4

Fuse 17 (Fuse Block)....................8W-40-4, 8

Fuse 19 (Fuse Block)......................8W-40-4

Headlamp Switch.......................8W-40-4, 5

Headlamp Delay Module....................8W-40-8

Headlamp Dimmer Switch...................8W-40-5

Ignition Switch......................8W-40-4, 8, 10

Instrument Cluster......................8W-40-4, 5

Low Washer Fluid Lamp Switch...............8W-40-8

Park Brake Switch.......................8W-40-10

Powertrain Control Module..................8W-40-6

Remote Keyless Entry Module................8W-40-8

Telltale Connector (Instrument Cluster).....8W-40-7 thru 10

J8W-40 INSTRUMENT CLUSTERÐXJ VEHICLES 8W - 40 - 3

Page 819 of 2158

WIRING DIAGRAMS

CONTENTS

page page

8W-01 GENERAL INFORMATIONÐWIRING

DIAGRAMS...................... 8W-01-1

8W-10 FUSE/FUSE BLOCK........... 8W-10-1

8W-11 POWER DISTRIBUTION........ 8W-11-1

8W-15 GROUND DISTRIBUTION....... 8W-15-1

8W-20 CHARGING SYSTEM.......... 8W-20-1

8W-21 STARTING SYSTEM........... 8W-21-1

8W-30 FUEL/IGNITION.............. 8W-30-1

8W-31 TRANSMISSION CONTROLS.... 8W-31-1

8W-32 ANTI-LOCK BRAKES........... 8W-32-1

8W-33 VEHICLE SPEED CONTROL..... 8W-33-1

8W-40 INSTRUMENT CLUSTER....... 8W-40-1

8W-41 HORN/CIGAR LIGHTER........ 8W-41-1

8W-42 AIR CONDITIONING/HEATER.... 8W-42-1

8W-44 INTERIOR LIGHTING.......... 8W-44-1

8W-47 AUDIO SYSTEM.............. 8W-47-18W-48 HEATED REAR WINDOW....... 8W-48-1

8W-49 OVERHEAD CONSOLE.......... 8W-49-1

8W-50 FRONT LIGHTING............ 8W-50-1

8W-51 REAR LIGHTING............. 8W-51-1

8W-52 TURN SIGNALS.............. 8W-52-1

8W-53 WIPERS.................... 8W-53-1

8W-54 TRAILER TOW................ 8W-54-1

8W-60 POWER WINDOWS............ 8W-60-1

8W-61 POWER DOOR LOCKS......... 8W-61-1

8W-62 POWER MIRRORS............ 8W-62-1

8W-63 POWER SEAT................ 8W-63-1

8W-70 SPLICE INFORMATION........ 8W-70-1

8W-80 CONNECTOR PIN OUTS....... 8W-80-1

8W-90 CONNECTOR LOCATIONS...... 8W-90-1

8W-95 SPLICE LOCATIONS........... 8W-95-1

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.

It is important to realize that no attempt is

made on the diagrams to represent components

and wiring as they appear on the vehicle. For

example, a short piece of wire is treated the

same as a long one. In addition, switches and

other components are shown as simply as pos-

sible, with regard to function only.

The wiring diagram show circuits for all wheel-

bases. If there is a difference in systems or compo-

nents between wheel-bases, an identifier is placed

next to the component.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR LOCATIONS

Section 8W-90 contains Connector Location illus-

trations. The illustrations contain the connector

number and component identification. Connector Lo-

cation charts in Section 8W-90 reference the illustra-

tion number for components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the number on the Diagram

pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

JWIRING DIAGRAMSÐXJ-RHD 8W - 1 - 1