gas type JEEP XJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1662 of 2158

(c) Vehicle is used for trailer towing or heavy

load hauling.

FLUID/FILTER REPLACEMENT PROCEDURE

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Clean oil pan and pan magnet. Then clean re-

maining gasket material from gasket surface of

transmission case.

(4) Remove fluid filter screws and remove filter.

(5) Position new filter on valve body and install fil-

ter screws. Tighten screws to 4 Nzm (35 in. lbs.)

torque.

(6) Adjust rear band at this time if required.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 150 in. lbs. (17

Nzm) torque.

(8) Adjust front band at this time if required.

(9) Lower vehicle and refill transmission with Mo-

par ATF Plus, type 7176 fluid.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The most effective way to avoid overfilling after a

fluid change or overhaul is as follows:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of Mopar ATF

Plus to transmission:

(a) If only fluid and filter were changed, add3

pints (1-1/2 quarts)of ATF Plus to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of ATF Plus to transmission.

(3) Apply parking brakes.

(4) Start and run engine at normal curb idle speed.

(5) Apply service brakes, shift transmission

through all gear ranges then back to Neutral, and

leave engine running at curb idle speed.

(6) Remove funnel, insert dipstick and check fluid

level. Add only enough fluid to bring level toMIN

dot mark on dipstick.

(7) Drive vehicle until transmission fluid is at nor-

mal operating temperature. Then recheck fluid level

as described in next step.

(8) Leave engine running at curb idle speed, shift

into Neutral, and check fluid level again. This time,

add just enough fluid to bring level up toMAX ar-

row mark but do not overfill.

(9) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

SHIFT LINKAGE ADJUSTMENT (YJ)

(1) Check linkage adjustment by starting engine in

Park and Neutral.(2) Adjustment is OK if engine starts only in park

and Neutral. Adjustment is incorrect if engine starts

in one but not both positions.

(3) If engine starts in any position other than Park

or Neutral, or if engine will not start at all, park/

neutral position switch may be faulty.

(4) Shift transmission into Park.

(5) Raise vehicle.

(6) Check condition of shift rods, bellcrank,

bellcrank brackets and linkage bushings/grommets

(Fig. 2). Tighten, repair, replace worn, damaged

parts. Do not attempt adjustment if linkage compo-

nents are worn or damaged.

(7) Loosen shift rod trunnion lock bolt or nut. Be

sure upper shift rod slides freely in trunnion (Fig. 2).

Also be sure shift rods and bellcrank rotate freely

and do not bind at any point.

(8) Verify that manual lever is in Park detent (Fig.

2). Move lever all the way rearward to be sure it is in

Park.

(9) Check for positive engagement of park lock by

attempting to rotate propeller shaft. Shaft will not

turn when park pawl is engaged.

(10) Adjust shift rod trunnion to a obtain free pin

fit in bellcrank arm and tighten trunnion lock bolt or

nut. Prevent shift rod from turning while tightening

bolt or nut. Gearshift linkage lash must be elimi-

nated to obtain proper adjustment. Eliminate lash by

pulling downward on shift rod and pressing upward

on bellcrank.

(11) Confirm proper adjustment by starting engine

in Park and Neutral. Engine should start in these

positions only.If engine starts in any position

other than Park or Neutral, adjustment is in-

correct or neutral switch is faulty.

(12) Lower vehicle and verify that steering lock op-

erates correctly.

SHIFT CABLE ADJUSTMENT (XJ)

(1) Shift transmission into Park.

(2) Raise vehicle.

(3) Release cable adjuster clamp to unlock cable

(Figs. 3 and 4). Clamp is at transmission end of ca-

ble.

(4) Unsnap cable from transmission cable bracket.

(5) Move transmission shift lever fully rearward to

Park detent. Lever is on manual valve shaft at driver

side of case.

(6) Verify positive engagement of park lock by at-

tempting to rotate propeller shaft. Shaft will not ro-

tate when park lock is engaged.

(7) Snap cable into cable bracket.

(8) Lock shift cable by pressing cable adjuster

clamp down until it snaps into place.

(9) Check engine starting. Engine should start only

in Park and Neutral.

(10) Lower vehicle.

21 - 100 30RH/32RH IN-VEHICLE SERVICEJ

Page 1667 of 2158

(7) Align valve body and seat it on case. Be sure

manual lever shaft and accumulator spring are prop-

erly seated.

(8) Hold valve body in position and install one or

two attaching bolts to hold valve body in place.

(9) Install remaining valve body bolts. Tighten all

bolts evenly in a diagonal pattern to 12 Nzm (105 in-

lbs) torque.

(10) Install new oil filter and tighten filter screws

to4Nzm (35 in. lbs.) torque.

(11) Connect converter solenoid wire to case con-

nector.

(12) Install manual and throttle levers on throttle

lever shaft. Tighten lever clamp screws and check for

free operation. Shaft and levers must operate freely

without any bind.

(13) Install oil pan and new gasket. Tighten pan

bolts to 17 Nzm (13 ft. lbs.) torque.

(14) Install seal on neutral switch, install switch in

case, and connect switch wires.

(15) Lower vehicle.

(16) Fill transmission with Mopar ATF Plus, Type

7176 fluid.

(17) Adjust gearshift linkage and throttle valve

(kickdown) cable if necessary.

GOVERNOR AND PARK GEAR SERVICE

GOVERNOR/PARK GEAR REMOVAL

(1) Raise vehicle.

(2) Mark both propeller shaft yokes for assembly

reference and disconnect propeller shafts at transfer

case.

(3) Disconnect speed sensor wires and remove

speedometer adapter and sensor.

(4) Position support stand under transmission con-

verter housing.

(5) Remove rear crossmember.

(6) Disconnect parking brake cable at equalizer

and disconnect exhaust components as necessary.

(7) Support transfer case with jack.

(8) Remove bolts attaching transfer case to trans-

mission adapter housing and remove transfer case.

(9) Remove bolts attaching adapter, or extension

housing to transmission and remove adapter/housing.

(10) Loosen but do not remove bolts that attach

governor body to park gear.

(11) Rotate transmission output shaft until gover-

nor weight assembly is accessible. Then remove

E-clip at this end of governor shaft.

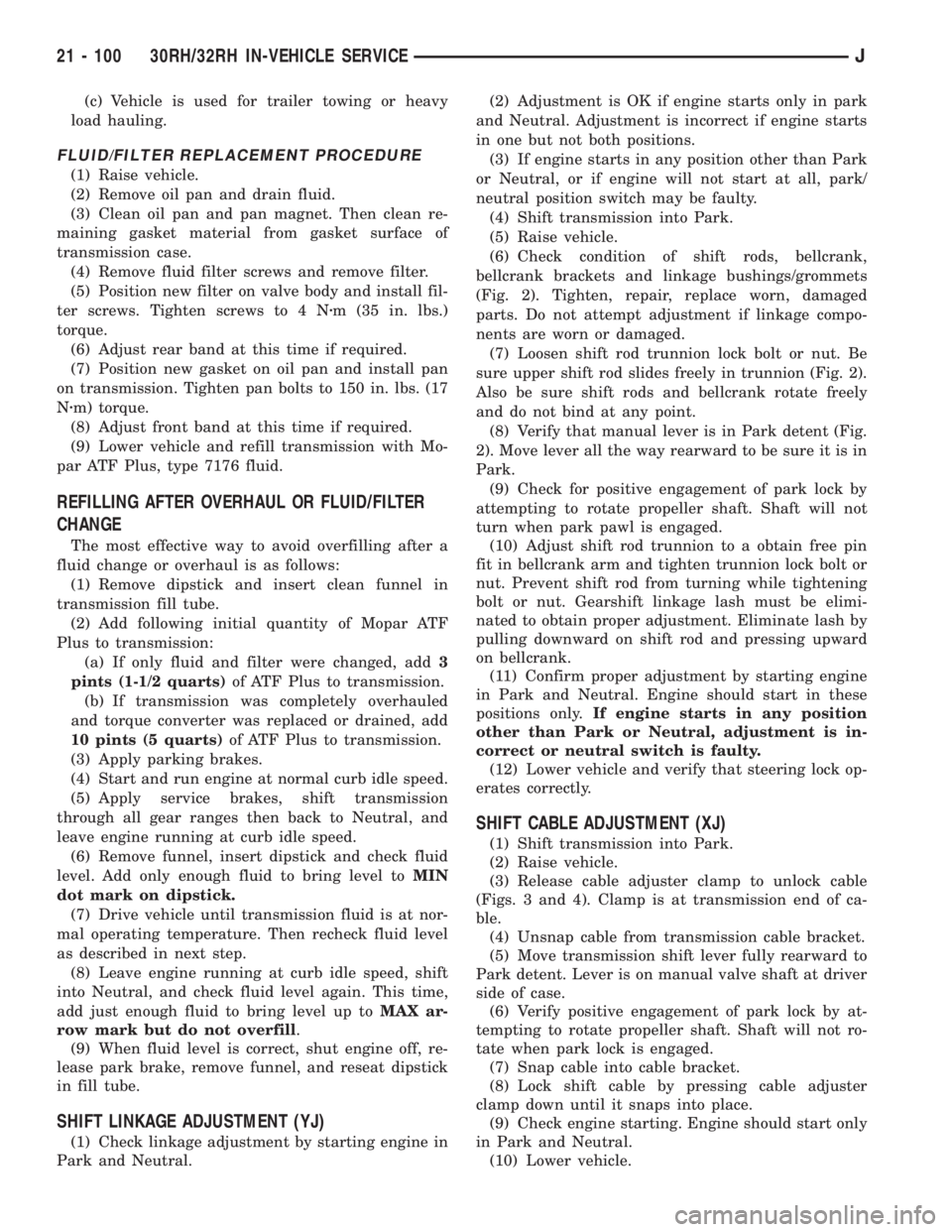

(12) Remove governor valve and shaft from gover-

nor body (Fig. 13).

(13) Remove snap rings and washers that retain

governor body and park gear assembly on output

shaft (Fig. 14).

(14) Remove governor body-park gear assembly

from output shaft (Fig. 15).

GOVERNOR BODY/PARK GEAR DISASSEMBLY

(1) Remove bolts attaching governor body to park

gear; then separate body from gear.

Fig. 13 Governor Valve And Shaft Removal

Fig. 14 Governor Body/Park Gear Retaining Snap

Rings And Thrust Washer Position

Fig. 15 Governor Body And Park Gear Removal/

Installation

J30RH/32RH IN-VEHICLE SERVICE 21 - 105

Page 1687 of 2158

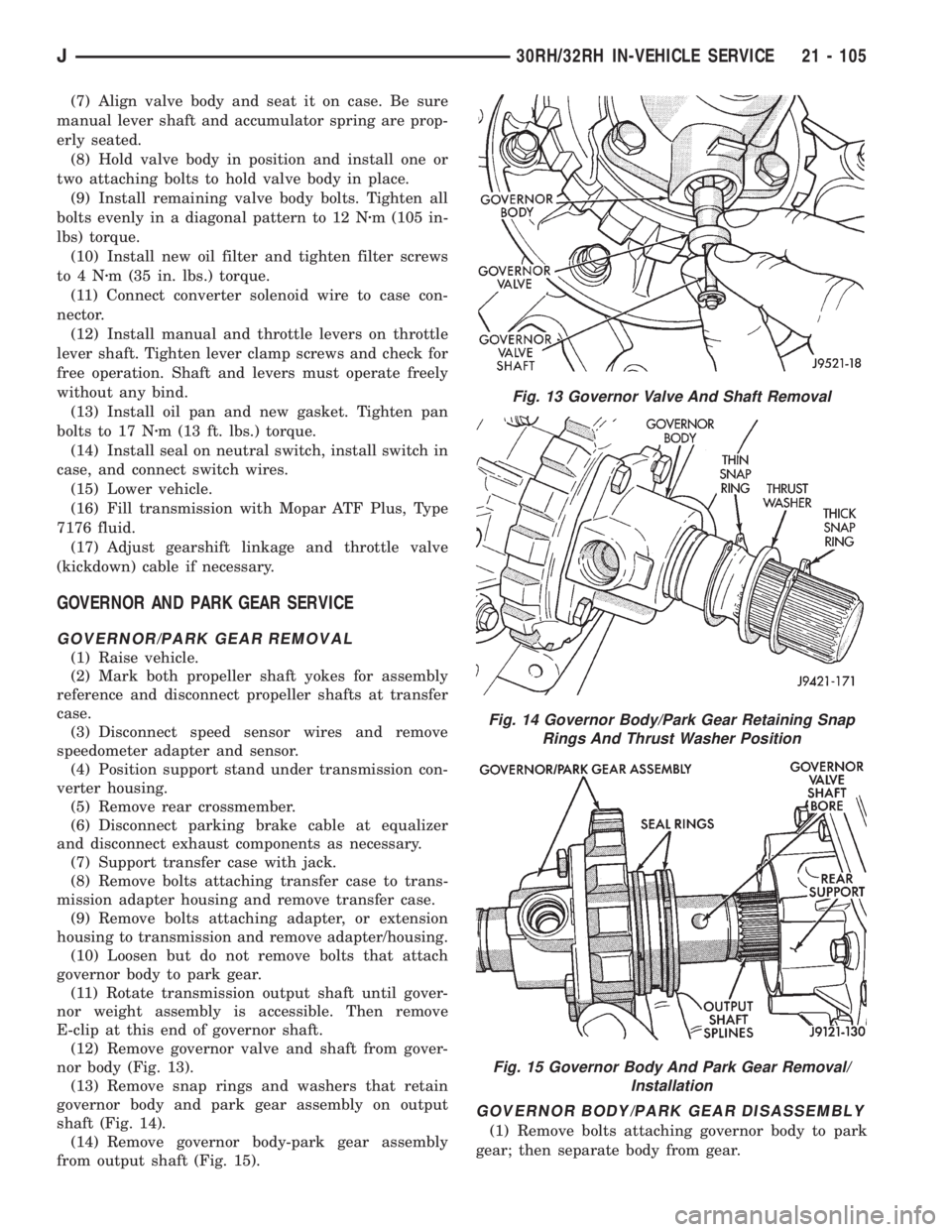

(47) Remove rear servo spring retainer snap ring.

Then remove compressor tools and remove rear servo

spring and piston.

OVERHAUL SERVICE INFORMATION

Inspect the transmission bushings during overhaul.

Bushing condition is important as severely worn, or

scored bushings contribute to low pressures, clutch

slip and accelerated wear of other components.How-

ever, do not replace bushings as a matter of

course. Replace bushings only when they are

actually worn, or scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B or

C-3887-J. The bushing tools are manufactured by

Miller Tool Co. and is available through the dealer

tool program.

Pre-sized service bushings are available for replace-

ment purposes. Only the sun gear bushings are not

serviced. Replace the gear as an assembly if the

bushings are worn, or scored.

Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts. These inserts are available from most automo-

tive jobbers. Stainless steel inserts are preferred.

The use of crocus cloth is permissible where neces-

sary. When used on valves, use care to avoid round-

ing off sharp edges. Sharp edges are vital as they

prevent foreign matter from getting between the

valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or E-

clips that are bent or distorted. Replace these parts

as well.Lubricate transmission parts with Mopar ATF

Plus, Type 7176 transmission fluid during overhaul

and assembly.

Use petroleum jelly to hold parts like thrust wash-

ers in place during assembly. Use Mopar Door Ease,

Ru-Glyde, or similar products to lubricate piston

seals and O-rings to ease installation. Petroleum jelly

can also be used to prelubricate parts during reas-

sembly if desired.

TRANSMISSION CASE CLEANING AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Use compressed air to dry the case and clear the

fluid passages. Be sure all solvent is removed from

the case as well.

Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint

will readily adhere to case surfaces and trans-

mission components and will circulate through-

out the transmission after assembly. A sufficient

quantity of lint can block fluid passages and in-

terfere with valve body operation.

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Remount the case in a repair stand after cleaning

and inspection.

OVERRUNNING CLUTCHÐLOW-REVERSE

DRUMÐREAR SUPPORT OVERHAUL

DISASSEMBLING OVERRUNNING CLUTCH/

LOW-REVERSE DRUM

If the clutch assembly came out with the low-re-

verse drum, thread two clutch cam bolts into the

cam. Then lift the cam out of the drum with the bolts

(Fig. 30). Rotate the cam back and forth to ease re-

moval if necessary. Remove the clutch roller and

spring assembly from the race afterward.

CLEANING AND INSPECTION

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum and rear support in solvent. Dry

them with compressed air after cleaning.

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring as-

sembly if any rollers or springs are worn or damaged,

or if the roller cage is distorted, or damaged. Replace

the cam if worn, cracked or damaged.

Fig. 29 Compressing Rear Servo Spring

J30RH/32RH TRANSMISSION OVERHAUL 21 - 125

Page 1712 of 2158

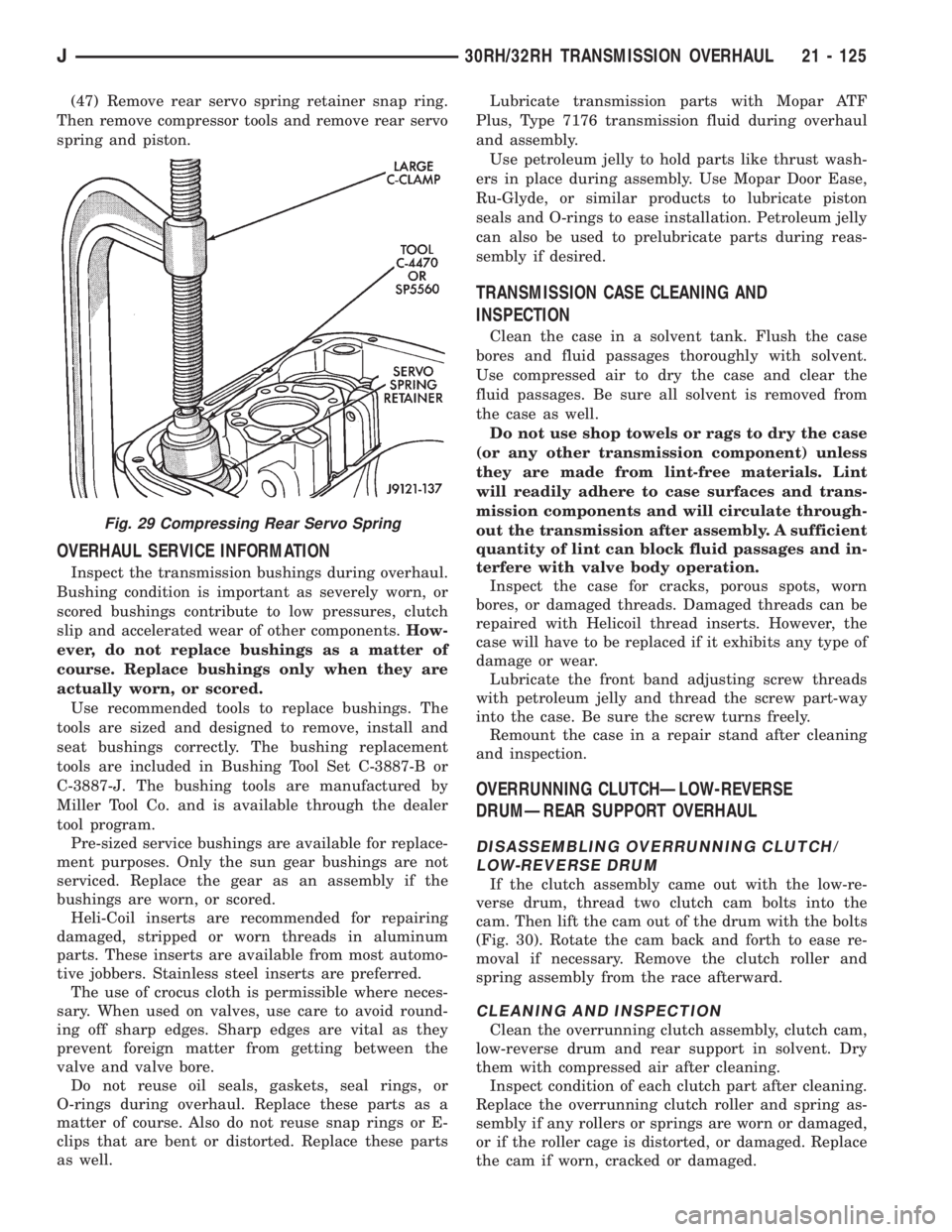

(24) Remove 1-2 shift control valve and spring

from valve body (Fig. 118).

(25) Remove 2-3 shift valve and spring from valve

body (Fig. 118).

(26) Remove 1-2 shift valve and spring from valve

body (Fig. 118).

(27) Remove regulator valve end plate (Fig. 118).

(28) Remove regulator valve line pressure plug,

pressure plug sleeve, throttle pressure plug and

spring (Fig. 118).

VALVE BODY CLEANING AND INSPECTION

The only serviceable valve body components are:

²park lock rod and E-clip

²switch valve and spring

²pressure adjusting screw bracket

²throttle valve lever

²manual lever

²manual lever shaft seal, washer, E-clip and detent

ball

²fluid filter

²converter clutch solenoid

The remaining valve body components are serviced

only as part of a complete valve body assembly.

Clean the valve body components in a parts clean-

ing solution only. Do not use gasoline, kerosene, orany type of caustic solution. Dry the parts with com-

pressed air. Make sure all passages are clean and

free from obstructions.

Do not use rags or shop towels to wipe off

valve body components. Lint from these materi-

als will adhere to the valve body components.

Lint will interfere with valve operation and

may clog filters and fluid passages.

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with cro-

cus cloth. The cloth should be in sheet form and be

positioned on a surface plate, sheet of plate glass, or

equally flat surface. However, if distortion is severe

or any surfaces are heavily scored, the valve body

will have to be replaced.

Fig. 117 Control Valves And Governor Plugs

21 - 150 30RH/32RH TRANSMISSION OVERHAULJ

Page 1731 of 2158

The rear planetary ring gear is splined to the out-

put shaft. The front planetary carrier and rear car-

rier ring gear are meshed and rotate as a unit with

the output shaft.

GEARTRAIN OPERATION AND APPLICATION

CHARTS

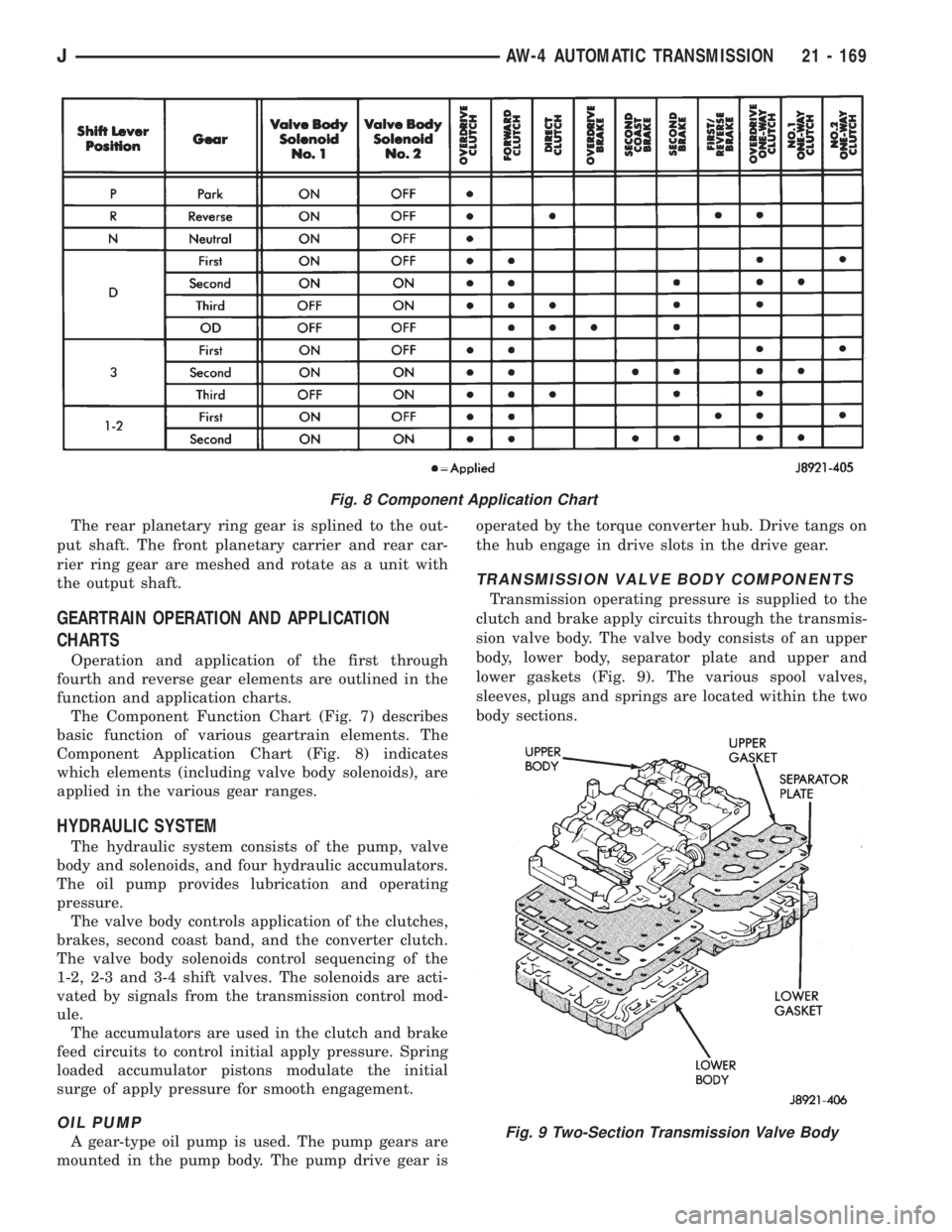

Operation and application of the first through

fourth and reverse gear elements are outlined in the

function and application charts.

The Component Function Chart (Fig. 7) describes

basic function of various geartrain elements. The

Component Application Chart (Fig. 8) indicates

which elements (including valve body solenoids), are

applied in the various gear ranges.

HYDRAULIC SYSTEM

The hydraulic system consists of the pump, valve

body and solenoids, and four hydraulic accumulators.

The oil pump provides lubrication and operating

pressure.

The valve body controls application of the clutches,

brakes, second coast band, and the converter clutch.

The valve body solenoids control sequencing of the

1-2, 2-3 and 3-4 shift valves. The solenoids are acti-

vated by signals from the transmission control mod-

ule.

The accumulators are used in the clutch and brake

feed circuits to control initial apply pressure. Spring

loaded accumulator pistons modulate the initial

surge of apply pressure for smooth engagement.

OIL PUMP

A gear-type oil pump is used. The pump gears are

mounted in the pump body. The pump drive gear isoperated by the torque converter hub. Drive tangs on

the hub engage in drive slots in the drive gear.

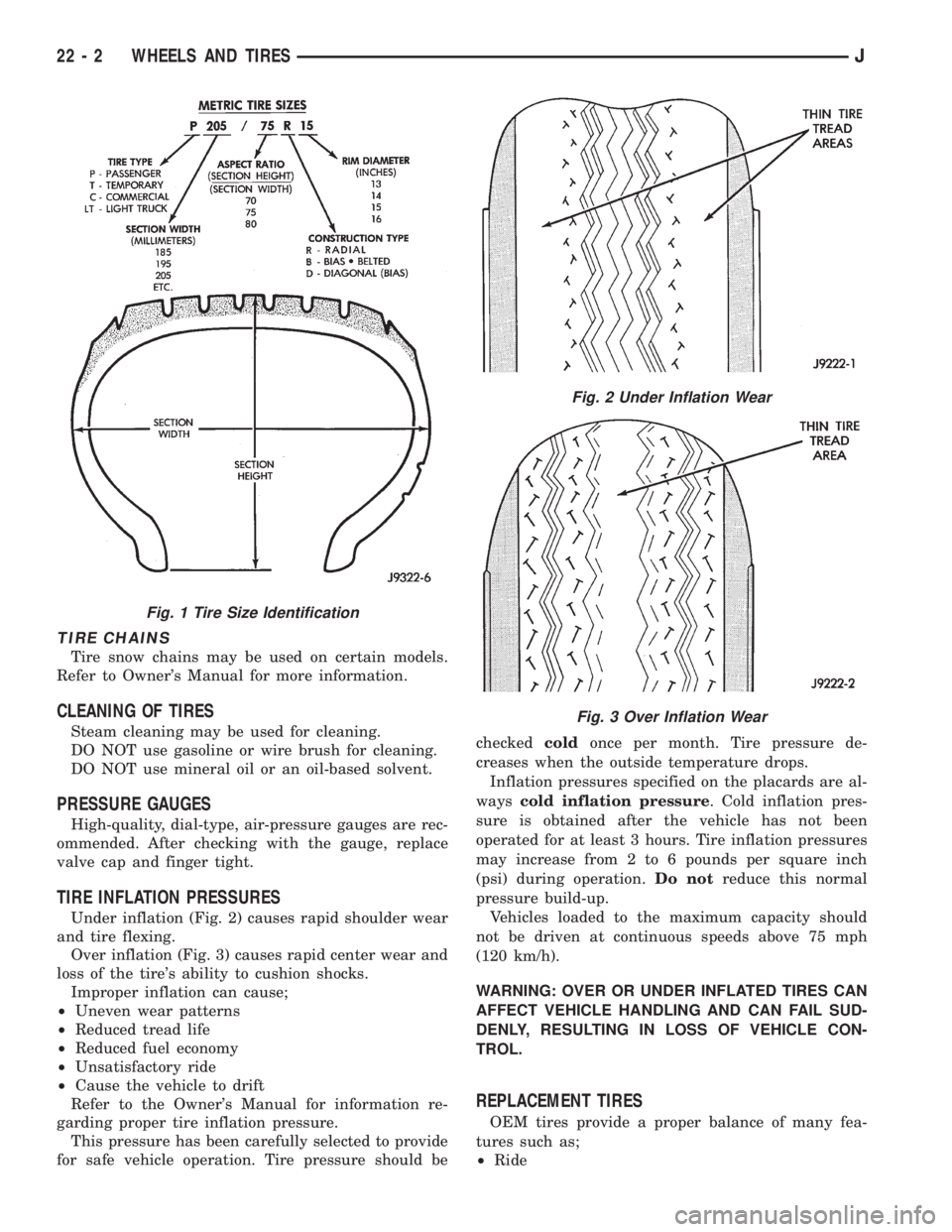

TRANSMISSION VALVE BODY COMPONENTS

Transmission operating pressure is supplied to the

clutch and brake apply circuits through the transmis-

sion valve body. The valve body consists of an upper

body, lower body, separator plate and upper and

lower gaskets (Fig. 9). The various spool valves,

sleeves, plugs and springs are located within the two

body sections.

Fig. 8 Component Application Chart

Fig. 9 Two-Section Transmission Valve Body

JAW-4 AUTOMATIC TRANSMISSION 21 - 169

Page 1908 of 2158

TIRE CHAINS

Tire snow chains may be used on certain models.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Steam cleaning may be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

PRESSURE GAUGES

High-quality, dial-type, air-pressure gauges are rec-

ommended. After checking with the gauge, replace

valve cap and finger tight.

TIRE INFLATION PRESSURES

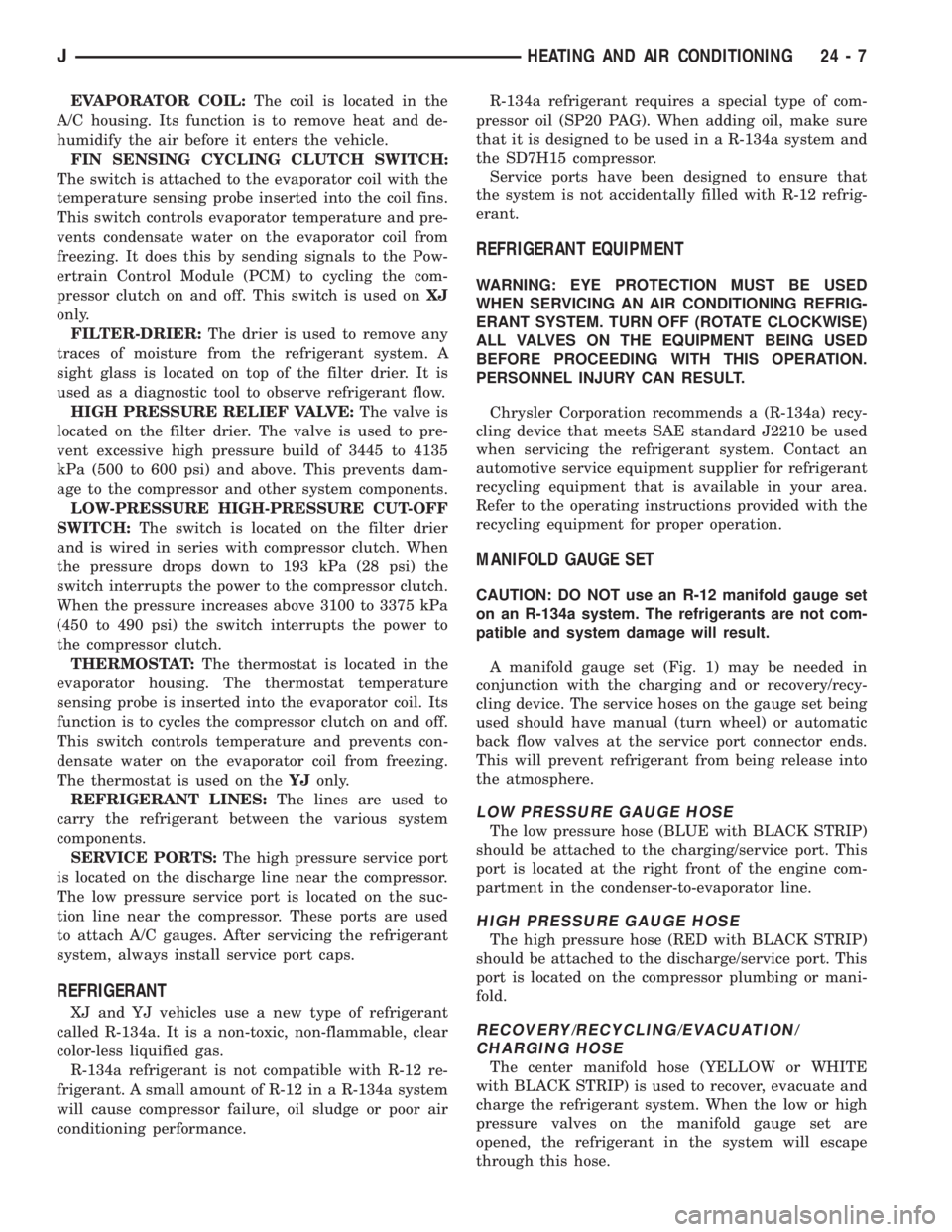

Under inflation (Fig. 2) causes rapid shoulder wear

and tire flexing.

Over inflation (Fig. 3) causes rapid center wear and

loss of the tire's ability to cushion shocks.

Improper inflation can cause;

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²Cause the vehicle to drift

Refer to the Owner's Manual for information re-

garding proper tire inflation pressure.

This pressure has been carefully selected to provide

for safe vehicle operation. Tire pressure should becheckedcoldonce per month. Tire pressure de-

creases when the outside temperature drops.

Inflation pressures specified on the placards are al-

wayscold inflation pressure. Cold inflation pres-

sure is obtained after the vehicle has not been

operated for at least 3 hours. Tire inflation pressures

may increase from 2 to 6 pounds per square inch

(psi) during operation.Do notreduce this normal

pressure build-up.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND CAN FAIL SUD-

DENLY, RESULTING IN LOSS OF VEHICLE CON-

TROL.

REPLACEMENT TIRES

OEM tires provide a proper balance of many fea-

tures such as;

²Ride

Fig. 1 Tire Size Identification

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

22 - 2 WHEELS AND TIRESJ

Page 2087 of 2158

EVAPORATOR COIL:The coil is located in the

A/C housing. Its function is to remove heat and de-

humidify the air before it enters the vehicle.

FIN SENSING CYCLING CLUTCH SWITCH:

The switch is attached to the evaporator coil with the

temperature sensing probe inserted into the coil fins.

This switch controls evaporator temperature and pre-

vents condensate water on the evaporator coil from

freezing. It does this by sending signals to the Pow-

ertrain Control Module (PCM) to cycling the com-

pressor clutch on and off. This switch is used onXJ

only.

FILTER-DRIER:The drier is used to remove any

traces of moisture from the refrigerant system. A

sight glass is located on top of the filter drier. It is

used as a diagnostic tool to observe refrigerant flow.

HIGH PRESSURE RELIEF VALVE:The valve is

located on the filter drier. The valve is used to pre-

vent excessive high pressure build of 3445 to 4135

kPa (500 to 600 psi) and above. This prevents dam-

age to the compressor and other system components.

LOW-PRESSURE HIGH-PRESSURE CUT-OFF

SWITCH:The switch is located on the filter drier

and is wired in series with compressor clutch. When

the pressure drops down to 193 kPa (28 psi) the

switch interrupts the power to the compressor clutch.

When the pressure increases above 3100 to 3375 kPa

(450 to 490 psi) the switch interrupts the power to

the compressor clutch.

THERMOSTAT:The thermostat is located in the

evaporator housing. The thermostat temperature

sensing probe is inserted into the evaporator coil. Its

function is to cycles the compressor clutch on and off.

This switch controls temperature and prevents con-

densate water on the evaporator coil from freezing.

The thermostat is used on theYJonly.

REFRIGERANT LINES:The lines are used to

carry the refrigerant between the various system

components.

SERVICE PORTS:The high pressure service port

is located on the discharge line near the compressor.

The low pressure service port is located on the suc-

tion line near the compressor. These ports are used

to attach A/C gauges. After servicing the refrigerant

system, always install service port caps.

REFRIGERANT

XJ and YJ vehicles use a new type of refrigerant

called R-134a. It is a non-toxic, non-flammable, clear

color-less liquified gas.

R-134a refrigerant is not compatible with R-12 re-

frigerant. A small amount of R-12 in a R-134a system

will cause compressor failure, oil sludge or poor air

conditioning performance.R-134a refrigerant requires a special type of com-

pressor oil (SP20 PAG). When adding oil, make sure

that it is designed to be used in a R-134a system and

the SD7H15 compressor.

Service ports have been designed to ensure that

the system is not accidentally filled with R-12 refrig-

erant.

REFRIGERANT EQUIPMENT

WARNING: EYE PROTECTION MUST BE USED

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE PROCEEDING WITH THIS OPERATION.

PERSONNEL INJURY CAN RESULT.

Chrysler Corporation recommends a (R-134a) recy-

cling device that meets SAE standard J2210 be used

when servicing the refrigerant system. Contact an

automotive service equipment supplier for refrigerant

recycling equipment that is available in your area.

Refer to the operating instructions provided with the

recycling equipment for proper operation.

MANIFOLD GAUGE SET

CAUTION: DO NOT use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

A manifold gauge set (Fig. 1) may be needed in

conjunction with the charging and or recovery/recy-

cling device. The service hoses on the gauge set being

used should have manual (turn wheel) or automatic

back flow valves at the service port connector ends.

This will prevent refrigerant from being release into

the atmosphere.

LOW PRESSURE GAUGE HOSE

The low pressure hose (BLUE with BLACK STRIP)

should be attached to the charging/service port. This

port is located at the right front of the engine com-

partment in the condenser-to-evaporator line.

HIGH PRESSURE GAUGE HOSE

The high pressure hose (RED with BLACK STRIP)

should be attached to the discharge/service port. This

port is located on the compressor plumbing or mani-

fold.

RECOVERY/RECYCLING/EVACUATION/

CHARGING HOSE

The center manifold hose (YELLOW or WHITE

with BLACK STRIP) is used to recover, evacuate and

charge the refrigerant system. When the low or high

pressure valves on the manifold gauge set are

opened, the refrigerant in the system will escape

through this hose.

JHEATING AND AIR CONDITIONING 24 - 7

Page 2089 of 2158

WARNINGS, CAUTIONS AND SERVICE PRECAUTIONS

WARNINGS

WARNING: THE AIR CONDITIONING SYSTEM CON-

TAINS REFRIGERANT UNDER HIGH PRESSURE.

SEVERE PERSONAL INJURY MAY RESULT FROM

IMPROPER SERVICE PROCEDURES. REPAIRS

SHOULD ONLY BE PERFORMED BY QUALIFIED

SERVICE PERSONNEL.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND/OR THROAT. WEAR

EYE PROTECTION WHEN SERVICING THE AIR

CONDITIONING REFRIGERANT SYSTEM. SERIOUS

EYE INJURY CAN RESULT FROM EYE CONTACT

WITH REFRIGERANT. IF EYE CONTACT IS MADE,

SEEK MEDICAL ATTENTION IMMEDIATELY.

WARNING: DO NOT EXPOSE REFRIGERANT TO

OPEN FLAME. POISONOUS GAS IS CREATED

WHEN REFRIGERANT IS BURNED. AN ELEC-

TRONIC TYPE LEAK DETECTOR IS RECOM-

MENDED.

WARNING: IF ACCIDENTAL SYSTEM DISCHARGE

OCCURS, VENTILATE THE WORK AREA BEFORE

RESUMING SERVICE. LARGE AMOUNTS OF RE-

FRIGERANT RELEASED IN A CLOSED WORK AREA

WILL DISPLACE THE OXYGEN AND CAUSE SUFFO-

CATION.

WARNING: THE EVAPORATION RATE OF (R-134A)

REFRIGERANT AT AVERAGE TEMPERATURE AND

ALTITUDE IS EXTREMELY HIGH. AS A RESULT,

ANYTHING THAT COMES IN CONTACT WITH THE

REFRIGERANT WILL FREEZE. ALWAYS PROTECT

SKIN OR DELICATE OBJECTS FROM DIRECT CON-

TACT WITH REFRIGERANT.

WARNING: R-134A SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. SOME MIXTURES OF AIR AND R-134A HAVE

BEEN SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR EX-

PLOSION CAUSING INJURY OR PROPERTY DAM-

AGE.

CAUTIONS

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with equipment being used.

CAUTION: DO NOT use R-12 equipment or parts on

the R-134a system. Damage to the system will re-

sult.

CAUTION: Never add R-12 to a system designed to

use R-134a. Damage to the system will result.

CAUTION: R-12 compressor oil can not be mixed

with the R-134a compressor oil. They ARE NOT

compatible.

CAUTION: Do not over charge refrigerant system.

This will cause excessive compressor head pres-

sure and can cause noise and system failure.

SERVICE PRECAUTIONS

Recover the refrigerant before opening any fitting

or connection. Open fittings with caution even after

the system has been discharged. Never open or

loosen a connection before recovering the refrigerant.

The A/C system must always be evacuated before

charging.

DO NOT open the refrigerant system or uncap a

replacement component until you are ready to service

the system. This will prevent contamination in the

system.

Before disconnecting a component clean the outside

of the fittings thoroughly to prevent contamination

entering the system.

Immediately after disconnecting a component from

the system, seal the open fittings with a cap or plug.

Before connecting an open fitting always install a

new seal/gasket. Coat the fitting and seal with clean

refrigerant oil before connecting.

When installing a refrigerant line avoid sharp

bends. Position the lines away from the exhaust or

any sharp edges which may chafe the line.

Tighten fittings only to the specified torque. The

aluminum fittings used in the A/C system will not

tolerate over tightening.

When disconnecting a fitting use a wrench on both

halves of the fitting. This will prevent twisting of the

refrigerant lines or tubes.

Refrigerant oil absorbs moisture from the atmo-

sphere if left uncapped. DO NOT open a container of

JHEATING AND AIR CONDITIONING 24 - 9

Page 2155 of 2158

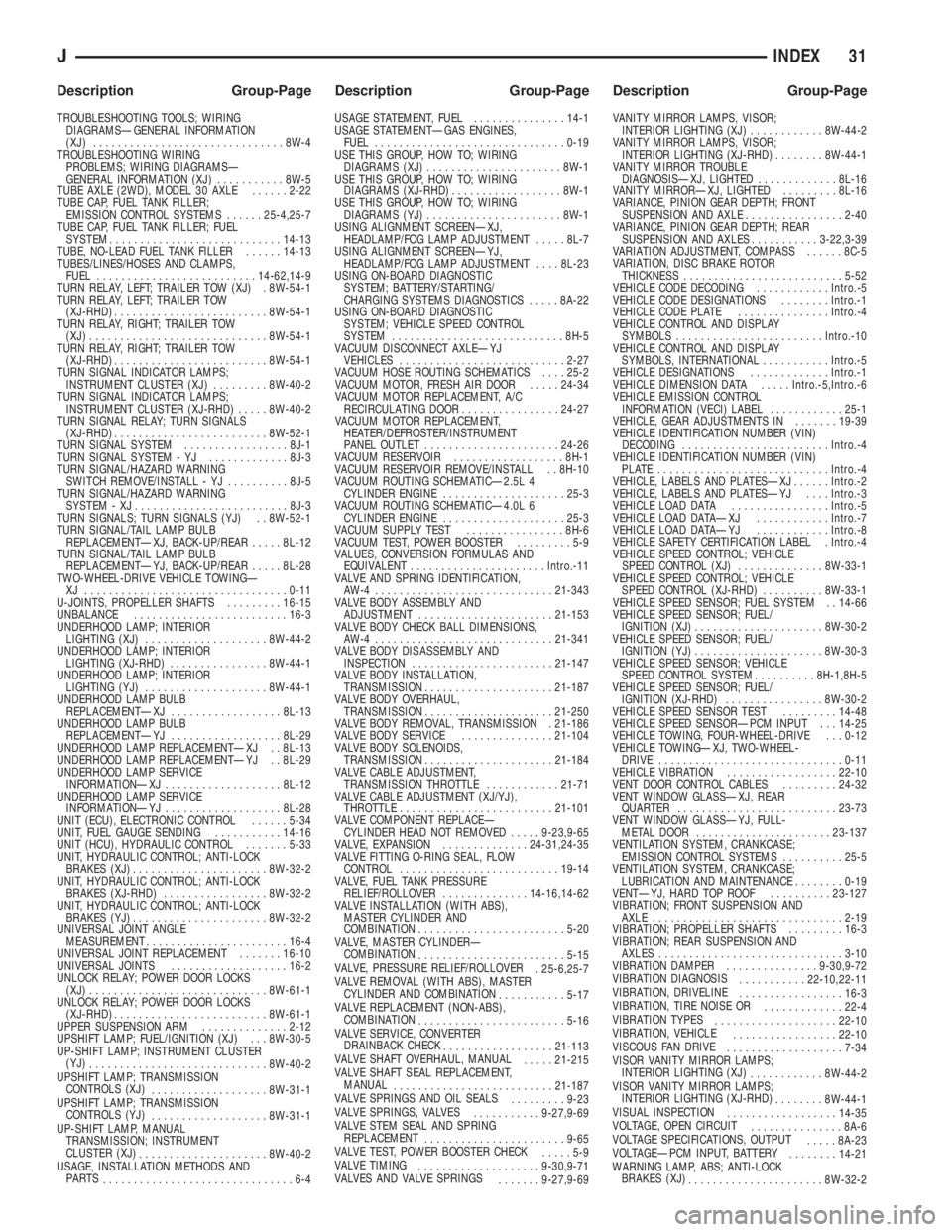

TROUBLESHOOTING TOOLS; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-4

TROUBLESHOOTING WIRING

PROBLEMS; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-5

TUBE AXLE (2WD), MODEL 30 AXLE......2-22

TUBE CAP, FUEL TANK FILLER;

EMISSION CONTROL SYSTEMS......25-4,25-7

TUBE CAP, FUEL TANK FILLER; FUEL

SYSTEM............................14-13

TUBE, NO-LEAD FUEL TANK FILLER......14-13

TUBES/LINES/HOSES AND CLAMPS,

FUEL..........................14-62,14-9

TURN RELAY, LEFT; TRAILER TOW (XJ) . 8W-54-1

TURN RELAY, LEFT; TRAILER TOW

(XJ-RHD).........................8W-54-1

TURN RELAY, RIGHT; TRAILER TOW

(XJ).............................8W-54-1

TURN RELAY, RIGHT; TRAILER TOW

(XJ-RHD).........................8W-54-1

TURN SIGNAL INDICATOR LAMPS;

INSTRUMENT CLUSTER (XJ).........8W-40-2

TURN SIGNAL INDICATOR LAMPS;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

TURN SIGNAL RELAY; TURN SIGNALS

(XJ-RHD).........................8W-52-1

TURN SIGNAL SYSTEM.................8J-1

TURN SIGNAL SYSTEM - YJ.............8J-3

TURN SIGNAL/HAZARD WARNING

SWITCH REMOVE/INSTALL - YJ..........8J-5

TURN SIGNAL/HAZARD WARNING

SYSTEM - XJ..........................8J-3

TURN SIGNALS; TURN SIGNALS (YJ) . . 8W-52-1

TURN SIGNAL/TAIL LAMP BULB

REPLACEMENTÐXJ, BACK-UP/REAR.....8L-12

TURN SIGNAL/TAIL LAMP BULB

REPLACEMENTÐYJ, BACK-UP/REAR.....8L-28

TWO-WHEEL-DRIVE VEHICLE TOWINGÐ

XJ .................................0-11

U-JOINTS, PROPELLER SHAFTS.........16-15

UNBALANCE.........................16-3

UNDERHOOD LAMP; INTERIOR

LIGHTING (XJ)....................8W-44-2

UNDERHOOD LAMP; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

UNDERHOOD LAMP; INTERIOR

LIGHTING (YJ)....................8W-44-1

UNDERHOOD LAMP BULB

REPLACEMENTÐXJ..................8L-13

UNDERHOOD LAMP BULB

REPLACEMENTÐYJ..................8L-29

UNDERHOOD LAMP REPLACEMENTÐXJ . . 8L-13

UNDERHOOD LAMP REPLACEMENTÐYJ . . 8L-29

UNDERHOOD LAMP SERVICE

INFORMATIONÐXJ...................8L-12

UNDERHOOD LAMP SERVICE

INFORMATIONÐYJ...................8L-28

UNIT (ECU), ELECTRONIC CONTROL......5-34

UNIT, FUEL GAUGE SENDING...........14-16

UNIT (HCU), HYDRAULIC CONTROL.......5-33

UNIT, HYDRAULIC CONTROL; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

UNIT, HYDRAULIC CONTROL; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

UNIT, HYDRAULIC CONTROL; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

UNIVERSAL JOINT ANGLE

MEASUREMENT.......................16-4

UNIVERSAL JOINT REPLACEMENT.......16-10

UNIVERSAL JOINTS...................16-2

UNLOCK RELAY; POWER DOOR LOCKS

(XJ).............................8W-61-1

UNLOCK RELAY; POWER DOOR LOCKS

(XJ-RHD).........................8W-61-1

UPPER SUSPENSION ARM..............2-12

UPSHIFT LAMP; FUEL/IGNITION (XJ) . . . 8W-30-5

UP-SHIFT LAMP; INSTRUMENT CLUSTER

(YJ)

.............................8W-40-2

UPSHIFT LAMP; TRANSMISSION

CONTROLS (XJ)

...................8W-31-1

UPSHIFT LAMP; TRANSMISSION

CONTROLS (YJ)

...................8W-31-1

UP-SHIFT LAMP, MANUAL

TRANSMISSION; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-2

USAGE, INSTALLATION METHODS AND

PARTS

...............................6-4USAGE STATEMENT, FUEL...............14-1

USAGE STATEMENTÐGAS ENGINES,

FUEL...............................0-19

USE THIS GROUP, HOW TO; WIRING

DIAGRAMS (XJ)......................8W-1

USE THIS GROUP, HOW TO; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

USE THIS GROUP, HOW TO; WIRING

DIAGRAMS (YJ)......................8W-1

USING ALIGNMENT SCREENÐXJ,

HEADLAMP/FOG LAMP ADJUSTMENT.....8L-7

USING ALIGNMENT SCREENÐYJ,

HEADLAMP/FOG LAMP ADJUSTMENT....8L-23

USING ON-BOARD DIAGNOSTIC

SYSTEM; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS.....8A-22

USING ON-BOARD DIAGNOSTIC

SYSTEM; VEHICLE SPEED CONTROL

SYSTEM............................8H-5

VACUUM DISCONNECT AXLEÐYJ

VEHICLES...........................2-27

VACUUM HOSE ROUTING SCHEMATICS....25-2

VACUUM MOTOR, FRESH AIR DOOR.....24-34

VACUUM MOTOR REPLACEMENT, A/C

RECIRCULATING DOOR................24-27

VACUUM MOTOR REPLACEMENT,

HEATER/DEFROSTER/INSTRUMENT

PANEL OUTLET......................24-26

VACUUM RESERVOIR..................8H-1

VACUUM RESERVOIR REMOVE/INSTALL . . 8H-10

VACUUM ROUTING SCHEMATICÐ2.5L 4

CYLINDER ENGINE....................25-3

VACUUM ROUTING SCHEMATICÐ4.0L 6

CYLINDER ENGINE....................25-3

VACUUM SUPPLY TEST................8H-6

VACUUM TEST, POWER BOOSTER.........5-9

VALUES, CONVERSION FORMULAS AND

EQUIVALENT......................Intro.-11

VALVE AND SPRING IDENTIFICATION,

AW-4 .............................21-343

VALVE BODY ASSEMBLY AND

ADJUSTMENT......................21-153

VALVE BODY CHECK BALL DIMENSIONS,

AW-4 .............................21-341

VALVE BODY DISASSEMBLY AND

INSPECTION.......................21-147

VALVE BODY INSTALLATION,

TRANSMISSION.....................21-187

VALVE BODY OVERHAUL,

TRANSMISSION.....................21-250

VALVE BODY REMOVAL, TRANSMISSION . 21-186

VALVE BODY SERVICE...............21-104

VALVE BODY SOLENOIDS,

TRANSMISSION.....................21-184

VALVE CABLE ADJUSTMENT,

TRANSMISSION THROTTLE............21-71

VALVE CABLE ADJUSTMENT (XJ/YJ),

THROTTLE.........................21-101

VALVE COMPONENT REPLACEÐ

CYLINDER HEAD NOT REMOVED.....9-23,9-65

VALVE, EXPANSION..............24-31,24-35

VALVE FITTING O-RING SEAL, FLOW

CONTROL..........................19-14

VALVE, FUEL TANK PRESSURE

RELIEF/ROLLOVER..............14-16,14-62

VALVE INSTALLATION (WITH ABS),

MASTER CYLINDER AND

COMBINATION........................5-20

VALVE, MASTER CYLINDERÐ

COMBINATION

........................5-15

VALVE, PRESSURE RELIEF/ROLLOVER

. 25-6,25-7

VALVE REMOVAL (WITH ABS), MASTER

CYLINDER AND COMBINATION

...........5-17

VALVE REPLACEMENT (NON-ABS),

COMBINATION

........................5-16

VALVE SERVICE, CONVERTER

DRAINBACK CHECK

..................21-113

VALVE SHAFT OVERHAUL, MANUAL

.....21-215

VALVE SHAFT SEAL REPLACEMENT,

MANUAL

..........................21-187

VALVE SPRINGS AND OIL SEALS

.........9-23

VALVE SPRINGS, VALVES

...........9-27,9-69

VALVE STEM SEAL AND SPRING

REPLACEMENT

.......................9-65

VALVE TEST, POWER BOOSTER CHECK

.....5-9

VALVE TIMING

....................9-30,9-71

VALVES AND VALVE SPRINGS

.......9-27,9-69VANITY MIRROR LAMPS, VISOR;

INTERIOR LIGHTING (XJ)............8W-44-2

VANITY MIRROR LAMPS, VISOR;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

VANITY MIRROR TROUBLE

DIAGNOSISÐXJ, LIGHTED.............8L-16

VANITY MIRRORÐXJ, LIGHTED.........8L-16

VARIANCE, PINION GEAR DEPTH; FRONT

SUSPENSION AND AXLE................2-40

VARIANCE, PINION GEAR DEPTH; REAR

SUSPENSION AND AXLES...........3-22,3-39

VARIATION ADJUSTMENT, COMPASS......8C-5

VARIATION, DISC BRAKE ROTOR

THICKNESS..........................5-52

VEHICLE CODE DECODING............Intro.-5

VEHICLE CODE DESIGNATIONS........Intro.-1

VEHICLE CODE PLATE...............Intro.-4

VEHICLE CONTROL AND DISPLAY

SYMBOLS........................Intro.-10

VEHICLE CONTROL AND DISPLAY

SYMBOLS, INTERNATIONAL...........Intro.-5

VEHICLE DESIGNATIONS.............Intro.-1

VEHICLE DIMENSION DATA.....Intro.-5,Intro.-6

VEHICLE EMISSION CONTROL

INFORMATION (VECI) LABEL............25-1

VEHICLE, GEAR ADJUSTMENTS IN.......19-39

VEHICLE IDENTIFICATION NUMBER (VIN)

DECODING........................Intro.-4

VEHICLE IDENTIFICATION NUMBER (VIN)

PLATE ............................Intro.-4

VEHICLE, LABELS AND PLATESÐXJ......Intro.-2

VEHICLE, LABELS AND PLATESÐYJ....Intro.-3

VEHICLE LOAD DATA................Intro.-5

VEHICLE LOAD DATAÐXJ............Intro.-7

VEHICLE LOAD DATAÐYJ............Intro.-8

VEHICLE SAFETY CERTIFICATION LABEL . Intro.-4

VEHICLE SPEED CONTROL; VEHICLE

SPEED CONTROL (XJ)..............8W-33-1

VEHICLE SPEED CONTROL; VEHICLE

SPEED CONTROL (XJ-RHD)..........8W-33-1

VEHICLE SPEED SENSOR; FUEL SYSTEM . . 14-66

VEHICLE SPEED SENSOR; FUEL/

IGNITION (XJ).....................8W-30-2

VEHICLE SPEED SENSOR; FUEL/

IGNITION (YJ).....................8W-30-3

VEHICLE SPEED SENSOR; VEHICLE

SPEED CONTROL SYSTEM..........8H-1,8H-5

VEHICLE SPEED SENSOR; FUEL/

IGNITION (XJ-RHD)................8W-30-2

VEHICLE SPEED SENSOR TEST.........14-48

VEHICLE SPEED SENSORÐPCM INPUT . . . 14-25

VEHICLE TOWING, FOUR-WHEEL-DRIVE . . . 0-12

VEHICLE TOWINGÐXJ, TWO-WHEEL-

DRIVE..............................0-11

VEHICLE VIBRATION..................22-10

VENT DOOR CONTROL CABLES.........24-32

VENT WINDOW GLASSÐXJ, REAR

QUARTER..........................23-73

VENT WINDOW GLASSÐYJ, FULL-

METAL DOOR......................23-137

VENTILATION SYSTEM, CRANKCASE;

EMISSION CONTROL SYSTEMS..........25-5

VENTILATION SYSTEM, CRANKCASE;

LUBRICATION AND MAINTENANCE........0-19

VENTÐYJ, HARD TOP ROOF..........23-127

VIBRATION; FRONT SUSPENSION AND

AXLE...............................2-19

VIBRATION; PROPELLER SHAFTS.........16-3

VIBRATION; REAR SUSPENSION AND

AXLES..............................3-10

VIBRATION DAMPER...............9-30,9-72

VIBRATION DIAGNOSIS

...........22-10,22-11

VIBRATION, DRIVELINE

.................16-3

VIBRATION, TIRE NOISE OR

.............22-4

VIBRATION TYPES

....................22-10

VIBRATION, VEHICLE

.................22-10

VISCOUS FAN DRIVE

...................7-34

VISOR VANITY MIRROR LAMPS;

INTERIOR LIGHTING (XJ)

............8W-44-2

VISOR VANITY MIRROR LAMPS;

INTERIOR LIGHTING (XJ-RHD)

........8W-44-1

VISUAL INSPECTION

..................14-35

VOLTAGE, OPEN CIRCUIT

...............8A-6

VOLTAGE SPECIFICATIONS, OUTPUT

.....8A-23

VOLTAGEÐPCM INPUT, BATTERY

........14-21

WARNING LAMP, ABS; ANTI-LOCK

BRAKES (XJ)

......................8W-32-2

JINDEX 31

Description Group-Page Description Group-Page Description Group-Page