recommended oil JEEP XJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1629 of 2158

30RH/32RH AUTOMATIC TRANSMISSION

GENERAL INFORMATION

INDEX

page page

Recommended Fluid....................... 67

Torque Converter......................... 67

Transmission Application.................... 67

Transmission Changes and Parts Interchangeability.. 67

Transmission Controls and Components........ 67

Transmission Identification.................. 67

TRANSMISSION APPLICATION

Chrysler 30RH and 32RH automatic transmissions

are used in XJ/YJ models. Both are 3-speed auto-

matic transmissions with a gear-type oil pump, two

clutches and bands and a planetary gear system (Fig.

1).

The 30RH is used in XJ/YJ models with a 2.5L en-

gine. The 32RH is used in YJ models with a 4.0L en-

gine.

TORQUE CONVERTER

A three element, torque converter is used for all

applications. The converter consists of an impeller,

stator, and turbine.

The converter used with 30RH/32RH transmissions

has a converter clutch. The clutch is engaged by an

electrical solenoid and mechanical module on the

valve body. The solenoid is operated by the power-

train control module.

The torque converter is a welded assembly and is

not a repairable component. The converter is serviced

as an assembly.

RECOMMENDED FLUID

The recommended and preferred fluid for 30RH/

32RH transmissions is Mopar ATF Plus, Type 7176.

Dexron II is not really recommended and should

only be used when ATF Plus is not available.

TRANSMISSION IDENTIFICATION

The transmission identification numbers are

stamped on the left side of the case just above the oil

pan gasket surface (Fig. 2). The first set of numbers

is the transmission part number. The next set of code

numbers set is the date of build. The final set of code

numbers represents the transmission serial number.

TRANSMISSION CHANGES AND PARTS

INTERCHANGEABILITY

1995 transmissions are similar to previous models

but only in appearance. Current transmissions are

dimensionally different. Do not interchange new/oldparts. Different dimensions, fluid passages, input/

output shafts, cases, bands, valve bodies and gover-

nor assemblies are just a few of the changed items.

CAUTION: Special bolts are used to attach the

driveplate to the crankshaft on models with a 2.5L

engine and 30RH transmission,. These bolts have a

smaller hex head for torque converter clearance.

DO NOT interchange these bolts with similar size

bolts for any reason.

Different governor weight assemblies are used in

30RH/32RH transmissions. The 30RH weight assem-

bly is much the same as in previous years. However,

the 32RH has a three stage governor weight assem-

bly consisting of the outer weight, a smaller weight

spring, and a new intermediate weight. Refer to the

overhaul and in-vehicle service sections for more de-

tailed information.

Plastic check balls are now used in many 30RH/

32RH valve bodies. The new check balls entered pro-

duction as a running change. Plastic and steel check

balls are not interchangeable.

A converter drainback check valve has been added

to the fluid cooler system. The one-way valve is lo-

cated in the transmission outlet (pressure) line. The

valve prevents fluid drainback when the vehicle is

parked for lengthy periods.

TRANSMISSION CONTROLS AND COMPONENTS

The transmission hydraulic control system per-

forms five basic functions, which are:

²pressure supply

²pressure regulation

²flow control

²clutch/band apply and release

²lubrication

Pressure Supply And Regulation

The oil pump generates the fluid working pressure

needed for operation and lubrication. The pump is

J30RH/32RH AUTOMATIC TRANSMISSION 21 - 67

Page 1639 of 2158

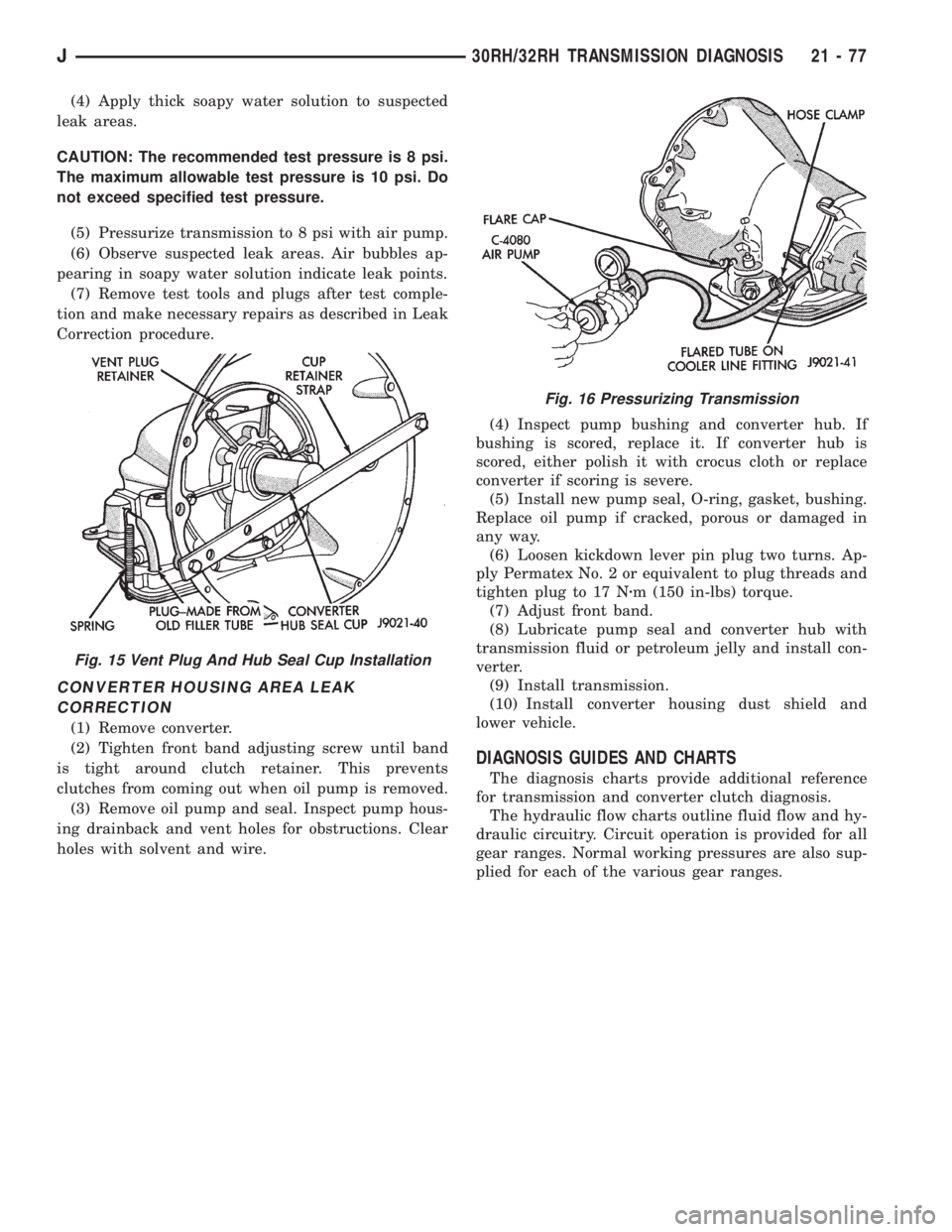

(4) Apply thick soapy water solution to suspected

leak areas.

CAUTION: The recommended test pressure is 8 psi.

The maximum allowable test pressure is 10 psi. Do

not exceed specified test pressure.

(5) Pressurize transmission to 8 psi with air pump.

(6) Observe suspected leak areas. Air bubbles ap-

pearing in soapy water solution indicate leak points.

(7) Remove test tools and plugs after test comple-

tion and make necessary repairs as described in Leak

Correction procedure.

CONVERTER HOUSING AREA LEAK

CORRECTION

(1) Remove converter.

(2) Tighten front band adjusting screw until band

is tight around clutch retainer. This prevents

clutches from coming out when oil pump is removed.

(3) Remove oil pump and seal. Inspect pump hous-

ing drainback and vent holes for obstructions. Clear

holes with solvent and wire.(4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is

scored, either polish it with crocus cloth or replace

converter if scoring is severe.

(5) Install new pump seal, O-ring, gasket, bushing.

Replace oil pump if cracked, porous or damaged in

any way.

(6) Loosen kickdown lever pin plug two turns. Ap-

ply Permatex No. 2 or equivalent to plug threads and

tighten plug to 17 Nzm (150 in-lbs) torque.

(7) Adjust front band.

(8) Lubricate pump seal and converter hub with

transmission fluid or petroleum jelly and install con-

verter.

(9) Install transmission.

(10) Install converter housing dust shield and

lower vehicle.

DIAGNOSIS GUIDES AND CHARTS

The diagnosis charts provide additional reference

for transmission and converter clutch diagnosis.

The hydraulic flow charts outline fluid flow and hy-

draulic circuitry. Circuit operation is provided for all

gear ranges. Normal working pressures are also sup-

plied for each of the various gear ranges.

Fig. 15 Vent Plug And Hub Seal Cup Installation

Fig. 16 Pressurizing Transmission

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 77

Page 1661 of 2158

30RH/32RH IN-VEHICLE SERVICE

INDEX

page page

Converter Drainback Check Valve Service...... 113

Fluid and Filter Replacement................. 99

Fluid Level Check......................... 99

Front Band Adjustment.................... 102

Governor and Park Gear Service............. 105

Oil Filter Replacement..................... 103

Park Interlock Cable Adjustment (XJ).......... 101

Park Lock Component Replacement.......... 108

Park/Neutral Position Switch Service.......... 109

Rear Band Adjustment.................... 103

Recommended Fluid....................... 99Refilling After Overhaul or Fluid/Filter Change . . . 100

Shift Cable Adjustment (XJ)................. 100

Shift Linkage Adjustment (YJ)............... 100

Speedometer Service..................... 109

Throttle Valve Cable Adjustment (XJ/YJ)....... 101

Transmission Cooler Flow Testing............ 113

Transmission Cooler Line and Fitting Service.... 111

Transmission Cooler Reverse Flushing......... 114

Valve Body Installation.................... 104

Valve Body Removal...................... 104

Valve Body Service....................... 104

RECOMMENDED FLUID

Recommended (and preferred) fluid for 30RH/32RH

transmissions is Mopar ATF Plus, type 7176.

Dexron II is not really recommended and should

only be used when ATF Plus is not available.

FLUID LEVEL CHECK

Transmission fluid level should be checked monthly

under normal operation. If the vehicle is used for

trailer towing or similar heavy load hauling, check

fluid level and condition weekly.

Fluid level is checked with the engine running at

curb idle speed, the transmission in Neutral and the

transmission fluid at normal operating temperature.

FLUID LEVEL CHECK PROCEDURE

(1) Transmission fluid must be at normal operating

temperature for accurate fluid level check. Drive ve-

hicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface. This is ex-

tremely important for accurate fluid level check.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to Neutral.

(6) Clean top of filler tube and dipstick to keep dirt

from entering tube.

(7) Remove dipstick and check fluid level as fol-

lows:

(a) Dipstick has three fluid level indicator levels

(Fig. 1) which are a MIN dot, an OK crosshatch

area, and a MAX fill arrow.

(b) Correct maximum level is to MAX arrow

mark. Correct acceptable level is to OK mark in

crosshatch area.

(c) Incorrect level is at or below MIN dot.

(d) If fluid is low, add only enough Mopar ATF

Plus restore correct level. Do not overfill.CAUTION: Do not overfill the transmission. Overfill-

ing may cause leakage out the pump vent which

can be mistaken for a pump seal leak. Overfilling

will also cause fluid aeration and foaming as the ex-

cess fluid is picked up and churned by the gear

train. This will reduce fluid life significantly.

FLUID AND FILTER REPLACEMENT

NORMAL CHANGE INTERVAL

The fluid and filter should be changed (and the

bands adjusted) at recommended maintenance inter-

vals, or whenever the transmission has been disas-

sembled for any reason.

Refer to the Driveline section in Group O, Lubrica-

tion and Maintenance for recommended change inter-

vals. Refer to the fluid/filter replacement and band

adjustment procedures in this section.

SEVERE USAGE CHANGE INTERVAL

Under severe usage, the fluid and filter should be

changed and the bands adjusted at 12,000 mile (19

000 Km) intervals.

Severe usage is defined as:

(a) More than half of vehicle operation occurs in

heavy city traffic during hot weather (above 90É F).

(b) Vehicle is used for taxi, police, limousine, or

similar commercial operation.

Fig. 1 Fluid Level Marks On Transmission Dipstick

J30RH/32RH IN-VEHICLE SERVICE 21 - 99

Page 1687 of 2158

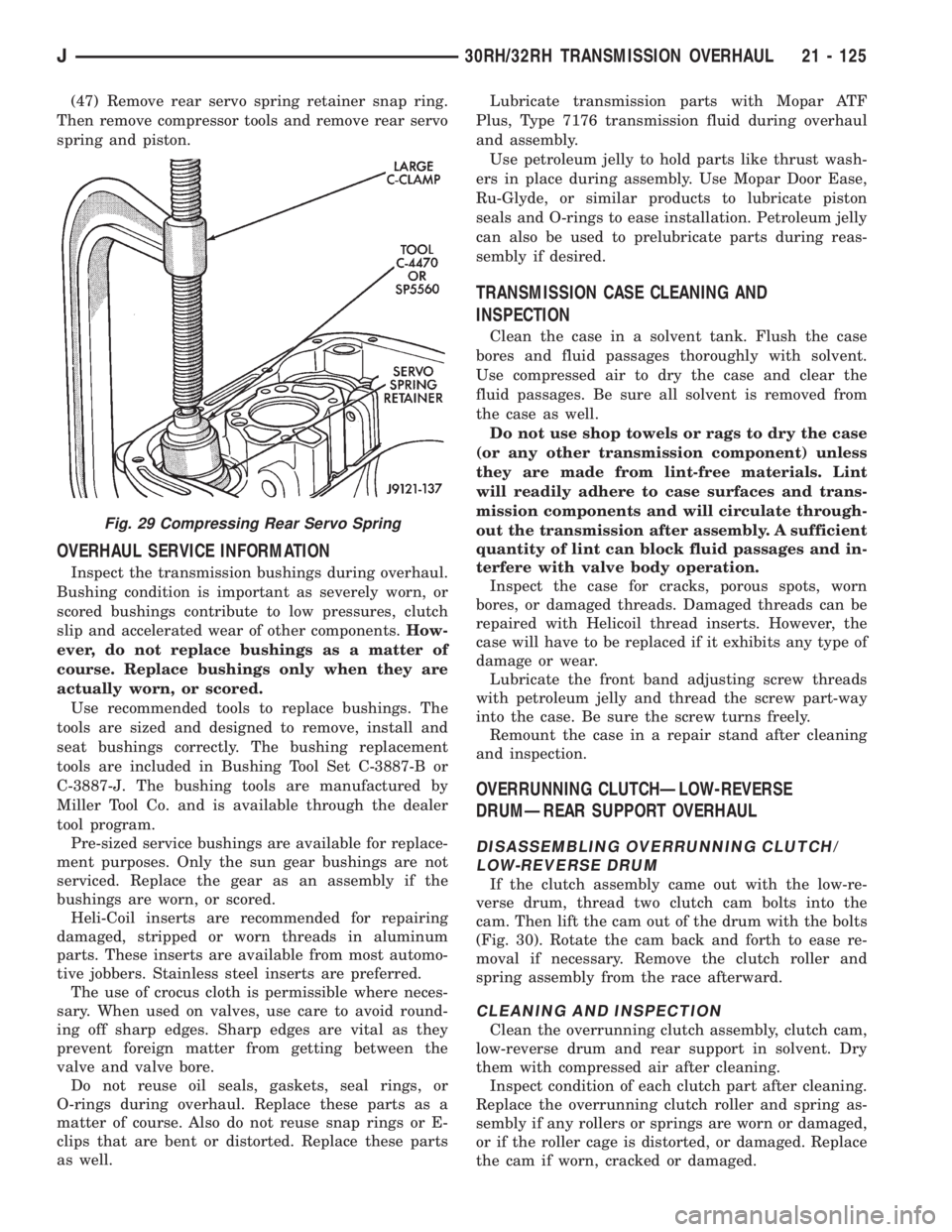

(47) Remove rear servo spring retainer snap ring.

Then remove compressor tools and remove rear servo

spring and piston.

OVERHAUL SERVICE INFORMATION

Inspect the transmission bushings during overhaul.

Bushing condition is important as severely worn, or

scored bushings contribute to low pressures, clutch

slip and accelerated wear of other components.How-

ever, do not replace bushings as a matter of

course. Replace bushings only when they are

actually worn, or scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B or

C-3887-J. The bushing tools are manufactured by

Miller Tool Co. and is available through the dealer

tool program.

Pre-sized service bushings are available for replace-

ment purposes. Only the sun gear bushings are not

serviced. Replace the gear as an assembly if the

bushings are worn, or scored.

Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts. These inserts are available from most automo-

tive jobbers. Stainless steel inserts are preferred.

The use of crocus cloth is permissible where neces-

sary. When used on valves, use care to avoid round-

ing off sharp edges. Sharp edges are vital as they

prevent foreign matter from getting between the

valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or E-

clips that are bent or distorted. Replace these parts

as well.Lubricate transmission parts with Mopar ATF

Plus, Type 7176 transmission fluid during overhaul

and assembly.

Use petroleum jelly to hold parts like thrust wash-

ers in place during assembly. Use Mopar Door Ease,

Ru-Glyde, or similar products to lubricate piston

seals and O-rings to ease installation. Petroleum jelly

can also be used to prelubricate parts during reas-

sembly if desired.

TRANSMISSION CASE CLEANING AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Use compressed air to dry the case and clear the

fluid passages. Be sure all solvent is removed from

the case as well.

Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint

will readily adhere to case surfaces and trans-

mission components and will circulate through-

out the transmission after assembly. A sufficient

quantity of lint can block fluid passages and in-

terfere with valve body operation.

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Remount the case in a repair stand after cleaning

and inspection.

OVERRUNNING CLUTCHÐLOW-REVERSE

DRUMÐREAR SUPPORT OVERHAUL

DISASSEMBLING OVERRUNNING CLUTCH/

LOW-REVERSE DRUM

If the clutch assembly came out with the low-re-

verse drum, thread two clutch cam bolts into the

cam. Then lift the cam out of the drum with the bolts

(Fig. 30). Rotate the cam back and forth to ease re-

moval if necessary. Remove the clutch roller and

spring assembly from the race afterward.

CLEANING AND INSPECTION

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum and rear support in solvent. Dry

them with compressed air after cleaning.

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring as-

sembly if any rollers or springs are worn or damaged,

or if the roller cage is distorted, or damaged. Replace

the cam if worn, cracked or damaged.

Fig. 29 Compressing Rear Servo Spring

J30RH/32RH TRANSMISSION OVERHAUL 21 - 125

Page 1727 of 2158

AW-4 AUTOMATIC TRANSMISSION

CONTENTS

page page

AW-4 AUTOMATIC TRANSMISSION........ 165

AW-4 IN-VEHICLE SERVICE.............. 182

AW-4 TRANSMISSION DIAGNOSIS......... 176

AW-4 TRANSMISSION OVERHAUL......... 201AW-4 TRANSMISSION REMOVAL AND

INSTALLATION....................... 198

GENERAL INFORMATION................ 165

GENERAL INFORMATION

INDEX

page page

Components and Operation................. 166

Description............................. 165

First/Second/Third/Reverse Components....... 168

Fourth Gear Overdrive Components.......... 167

Geartrain Operation and Application Charts..... 169Hydraulic System........................ 169

Recommended Fluid and Capacity........... 166

Torque Converter........................ 167

Transmission Identification.................. 166

Transmission Ranges and Shift Lever Positions . . 166

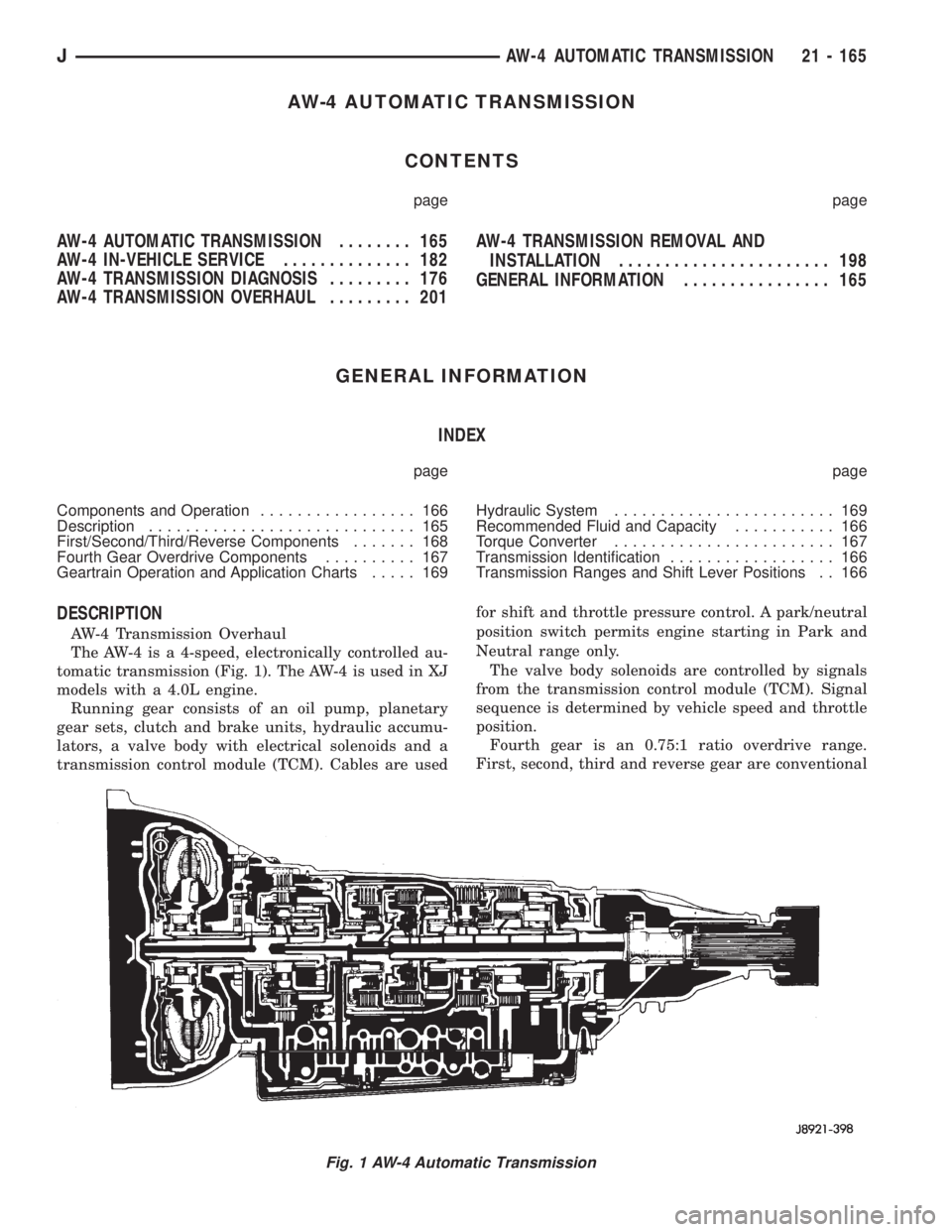

DESCRIPTION

AW-4 Transmission Overhaul

The AW-4 is a 4-speed, electronically controlled au-

tomatic transmission (Fig. 1). The AW-4 is used in XJ

models with a 4.0L engine.

Running gear consists of an oil pump, planetary

gear sets, clutch and brake units, hydraulic accumu-

lators, a valve body with electrical solenoids and a

transmission control module (TCM). Cables are usedfor shift and throttle pressure control. A park/neutral

position switch permits engine starting in Park and

Neutral range only.

The valve body solenoids are controlled by signals

from the transmission control module (TCM). Signal

sequence is determined by vehicle speed and throttle

position.

Fourth gear is an 0.75:1 ratio overdrive range.

First, second, third and reverse gear are conventional

Fig. 1 AW-4 Automatic Transmission

JAW-4 AUTOMATIC TRANSMISSION 21 - 165

Page 1740 of 2158

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified in test, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified in test, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, or throttle cam

sticking, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn, or damaged

²overdrive clutch worn, or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.Stall speeds are

checked in both Drive and Reverse ranges with

the AW-4 transmission.

(1) Before starting test, be sure fluid level is cor-

rect and fluid is at normal operating temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Open throttle completely and record maximum

engine rpm registered on tachometer. It takes any-

where from 4 to 10 seconds to reach maximum rpm.

However, once maximum rpm has been achieved,do

not hold wide open throttle for more than 3-4

seconds.CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 4

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(9) Stall speed should be in 2100-2400 rpm range

in Drive.

(10) Release throttle, shift transmission into Neu-

tral, and run engine for 20-30 seconds to cool fluid.

(11) Shift transmission into Reverse.

(12) Repeat stall test described in step (8).

(13) Stall speed in Reverse should also be in 2100-

2400 rpm range.

(14) Release accelerator pedal, shift transmission

into Neutral, and run engine for 20-30 seconds to

cool fluid.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

21 - 178 AW-4 TRANSMISSION DIAGNOSISJ

Page 1744 of 2158

AW-4 IN-VEHICLE SERVICE

INDEX

page page

Accumulator Pistons and Springs............. 189

Adapter Housing Seal Replacement........... 191

Checking Fluid Level and Condition........... 182

Manual Valve Shaft Seal Replacement......... 187

Park Interlock Cable Adjustment............. 195

Park Rod and Pawl Service................. 190

Park/Neutral Position Switch................ 183

Refilling After Overhaul or Fluid/Filter Change . . . 182

Second Coast Brake Servo................. 190

Shift Cable Adjustment.................... 195

Speed Sensor........................... 192Speed Sensor RotorÐSpeedometer Drive Gear . . 193

Throttle Position Sensor (TPS) Service........ 193

Transmission Control Module (TCM) Service.... 183

Transmission Cooler Line Fittings............ 197

Transmission Cooler Service................ 196

Transmission Throttle Cable Adjustment........ 194

Transmission Throttle Cable Replacement...... 193

Transmission Valve Body Installation.......... 187

Transmission Valve Body Removal........... 186

Transmission Valve Body Solenoids........... 184

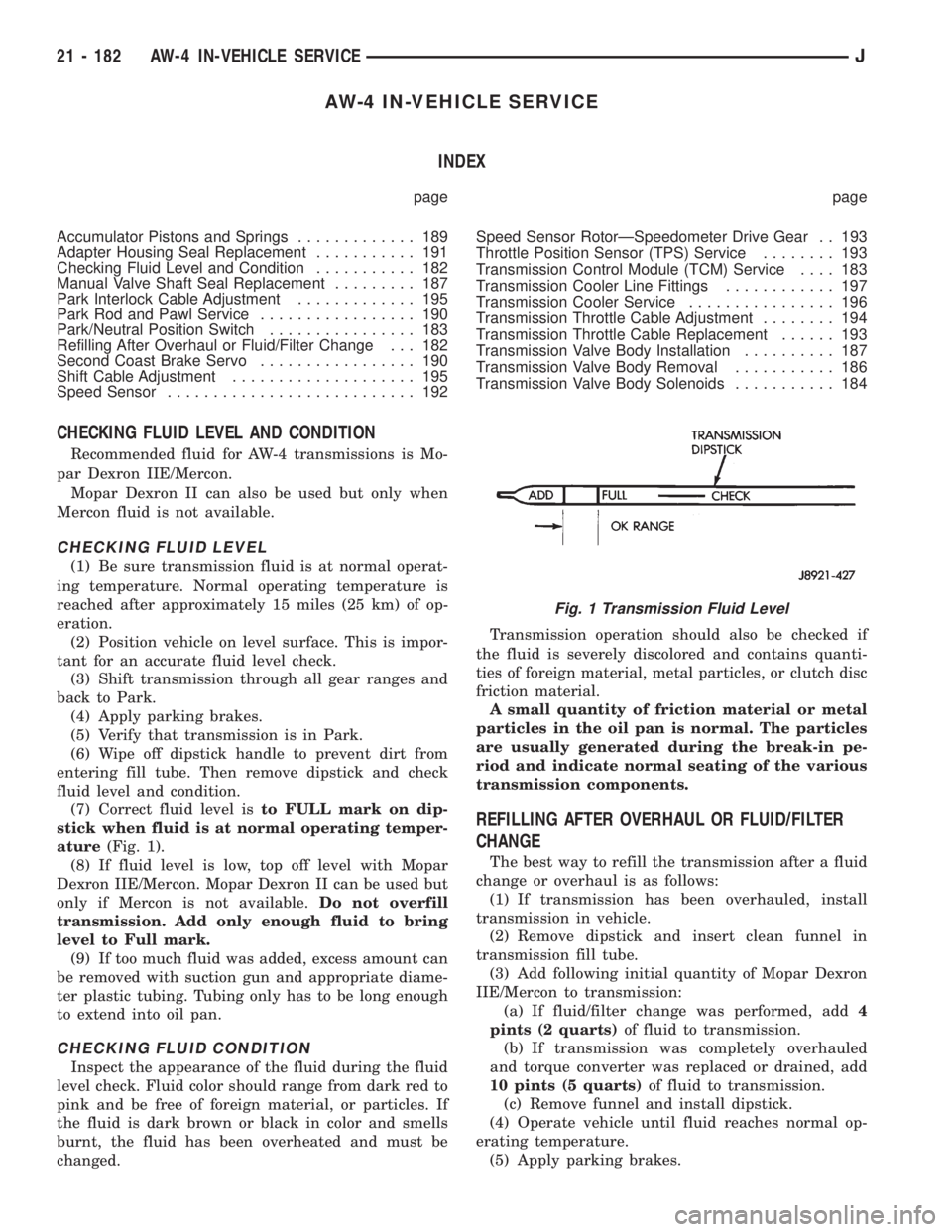

CHECKING FLUID LEVEL AND CONDITION

Recommended fluid for AW-4 transmissions is Mo-

par Dexron IIE/Mercon.

Mopar Dexron II can also be used but only when

Mercon fluid is not available.

CHECKING FLUID LEVEL

(1) Be sure transmission fluid is at normal operat-

ing temperature. Normal operating temperature is

reached after approximately 15 miles (25 km) of op-

eration.

(2) Position vehicle on level surface. This is impor-

tant for an accurate fluid level check.

(3) Shift transmission through all gear ranges and

back to Park.

(4) Apply parking brakes.

(5) Verify that transmission is in Park.

(6) Wipe off dipstick handle to prevent dirt from

entering fill tube. Then remove dipstick and check

fluid level and condition.

(7) Correct fluid level isto FULL mark on dip-

stick when fluid is at normal operating temper-

ature(Fig. 1).

(8) If fluid level is low, top off level with Mopar

Dexron IIE/Mercon. Mopar Dexron II can be used but

only if Mercon is not available.Do not overfill

transmission. Add only enough fluid to bring

level to Full mark.

(9) If too much fluid was added, excess amount can

be removed with suction gun and appropriate diame-

ter plastic tubing. Tubing only has to be long enough

to extend into oil pan.

CHECKING FLUID CONDITION

Inspect the appearance of the fluid during the fluid

level check. Fluid color should range from dark red to

pink and be free of foreign material, or particles. If

the fluid is dark brown or black in color and smells

burnt, the fluid has been overheated and must be

changed.Transmission operation should also be checked if

the fluid is severely discolored and contains quanti-

ties of foreign material, metal particles, or clutch disc

friction material.

A small quantity of friction material or metal

particles in the oil pan is normal. The particles

are usually generated during the break-in pe-

riod and indicate normal seating of the various

transmission components.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The best way to refill the transmission after a fluid

change or overhaul is as follows:

(1) If transmission has been overhauled, install

transmission in vehicle.

(2) Remove dipstick and insert clean funnel in

transmission fill tube.

(3) Add following initial quantity of Mopar Dexron

IIE/Mercon to transmission:

(a) If fluid/filter change was performed, add4

pints (2 quarts)of fluid to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of fluid to transmission.

(c) Remove funnel and install dipstick.

(4) Operate vehicle until fluid reaches normal op-

erating temperature.

(5) Apply parking brakes.

Fig. 1 Transmission Fluid Level

21 - 182 AW-4 IN-VEHICLE SERVICEJ

Page 1856 of 2158

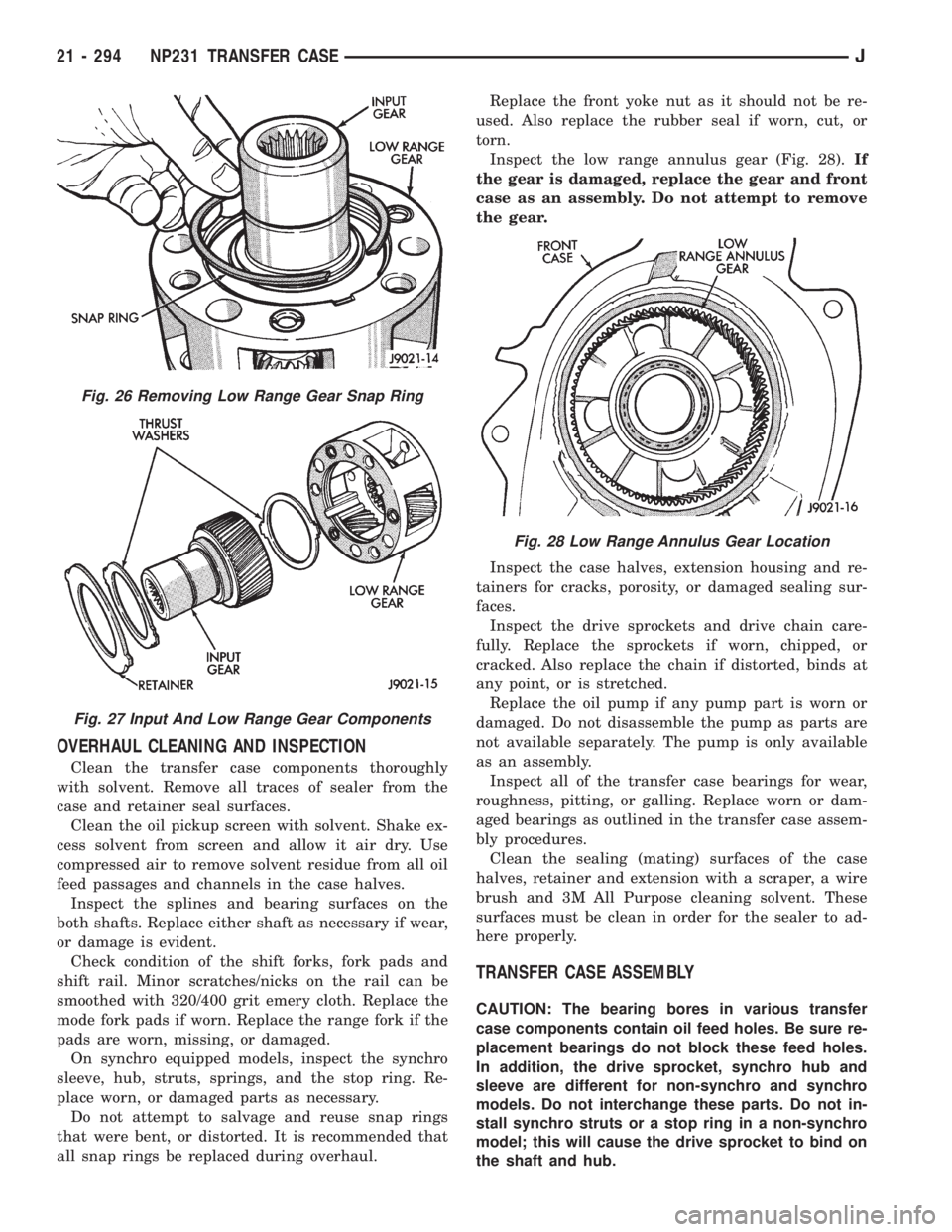

OVERHAUL CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.

Clean the oil pickup screen with solvent. Shake ex-

cess solvent from screen and allow it air dry. Use

compressed air to remove solvent residue from all oil

feed passages and channels in the case halves.

Inspect the splines and bearing surfaces on the

both shafts. Replace either shaft as necessary if wear,

or damage is evident.

Check condition of the shift forks, fork pads and

shift rail. Minor scratches/nicks on the rail can be

smoothed with 320/400 grit emery cloth. Replace the

mode fork pads if worn. Replace the range fork if the

pads are worn, missing, or damaged.

On synchro equipped models, inspect the synchro

sleeve, hub, struts, springs, and the stop ring. Re-

place worn, or damaged parts as necessary.

Do not attempt to salvage and reuse snap rings

that were bent, or distorted. It is recommended that

all snap rings be replaced during overhaul.Replace the front yoke nut as it should not be re-

used. Also replace the rubber seal if worn, cut, or

torn.

Inspect the low range annulus gear (Fig. 28).If

the gear is damaged, replace the gear and front

case as an assembly. Do not attempt to remove

the gear.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces.

Inspect the drive sprockets and drive chain care-

fully. Replace the sprockets if worn, chipped, or

cracked. Also replace the chain if distorted, binds at

any point, or is stretched.

Replace the oil pump if any pump part is worn or

damaged. Do not disassemble the pump as parts are

not available separately. The pump is only available

as an assembly.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the transfer case assem-

bly procedures.

Clean the sealing (mating) surfaces of the case

halves, retainer and extension with a scraper, a wire

brush and 3M All Purpose cleaning solvent. These

surfaces must be clean in order for the sealer to ad-

here properly.

TRANSFER CASE ASSEMBLY

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

In addition, the drive sprocket, synchro hub and

sleeve are different for non-synchro and synchro

models. Do not interchange these parts. Do not in-

stall synchro struts or a stop ring in a non-synchro

model; this will cause the drive sprocket to bind on

the shaft and hub.

Fig. 26 Removing Low Range Gear Snap Ring

Fig. 27 Input And Low Range Gear Components

Fig. 28 Low Range Annulus Gear Location

21 - 294 NP231 TRANSFER CASEJ

Page 1881 of 2158

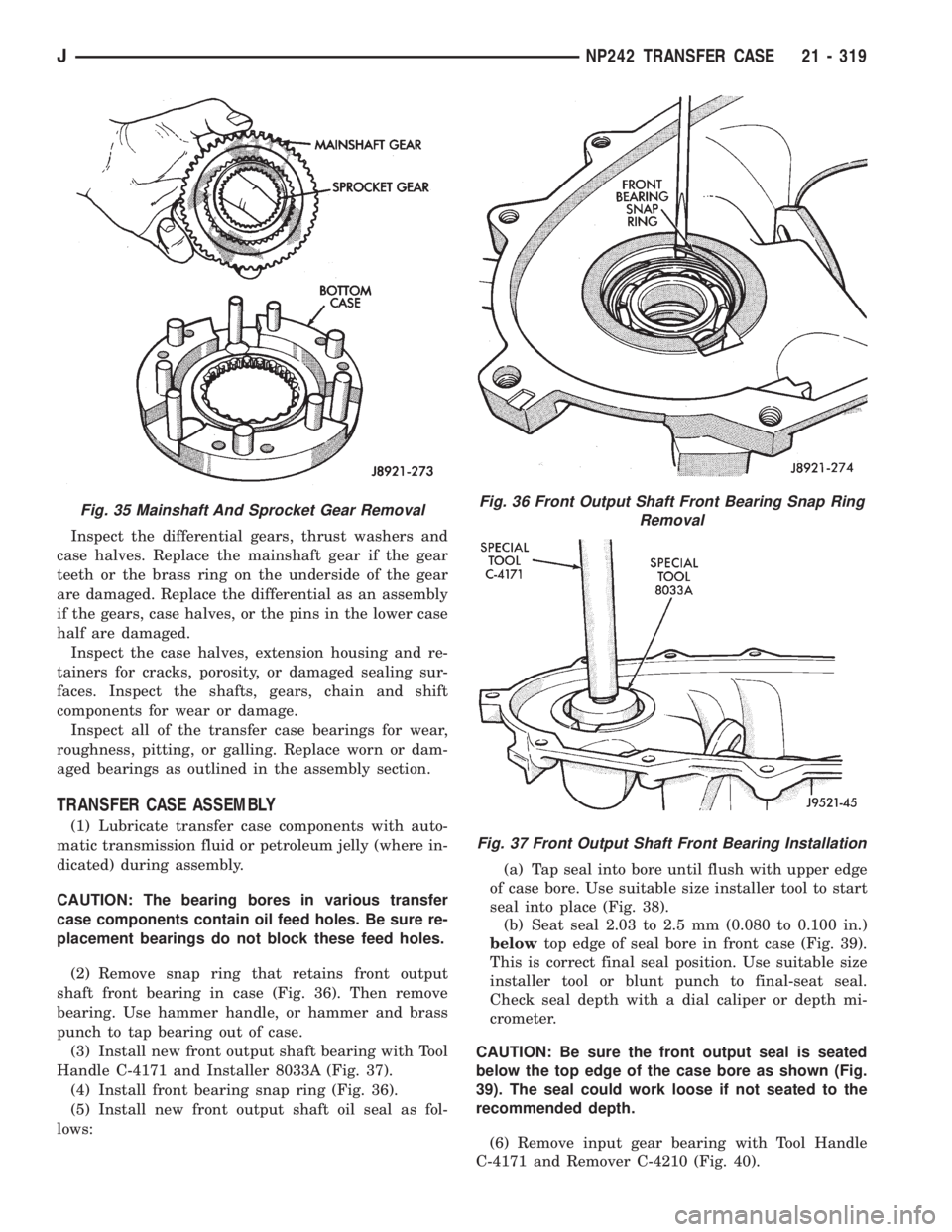

Inspect the differential gears, thrust washers and

case halves. Replace the mainshaft gear if the gear

teeth or the brass ring on the underside of the gear

are damaged. Replace the differential as an assembly

if the gears, case halves, or the pins in the lower case

half are damaged.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces. Inspect the shafts, gears, chain and shift

components for wear or damage.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the assembly section.

TRANSFER CASE ASSEMBLY

(1) Lubricate transfer case components with auto-

matic transmission fluid or petroleum jelly (where in-

dicated) during assembly.

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

(2) Remove snap ring that retains front output

shaft front bearing in case (Fig. 36). Then remove

bearing. Use hammer handle, or hammer and brass

punch to tap bearing out of case.

(3) Install new front output shaft bearing with Tool

Handle C-4171 and Installer 8033A (Fig. 37).

(4) Install front bearing snap ring (Fig. 36).

(5) Install new front output shaft oil seal as fol-

lows:(a) Tap seal into bore until flush with upper edge

of case bore. Use suitable size installer tool to start

seal into place (Fig. 38).

(b) Seat seal 2.03 to 2.5 mm (0.080 to 0.100 in.)

belowtop edge of seal bore in front case (Fig. 39).

This is correct final seal position. Use suitable size

installer tool or blunt punch to final-seat seal.

Check seal depth with a dial caliper or depth mi-

crometer.

CAUTION: Be sure the front output seal is seated

below the top edge of the case bore as shown (Fig.

39). The seal could work loose if not seated to the

recommended depth.

(6) Remove input gear bearing with Tool Handle

C-4171 and Remover C-4210 (Fig. 40).

Fig. 35 Mainshaft And Sprocket Gear RemovalFig. 36 Front Output Shaft Front Bearing Snap Ring

Removal

Fig. 37 Front Output Shaft Front Bearing Installation

JNP242 TRANSFER CASE 21 - 319

Page 1912 of 2158

WHEELS

GENERAL INFORMATION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well.

Initial inflation of the tire forces the bead over

these raised sections. In case of tire failure, the

raised sections hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in se-

quence to 129 Nzm (95 ft. lbs.) torque (Fig. 2).Never

use oil or grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they have:²Excessive runout

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re-

placement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

Refer to the Specifications Chart for informa-

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING: HANDLE ALL WHEEL ORNAMENTATION

WITH EXTREME CARE DURING REMOVAL AND IN-

STALLATION. SHARP EDGES ON THE COVERS OR

CAPS CAN CAUSE PERSONAL INJURY.

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly re-

quire balancing. Static should be used only when a

two plane balancer is not available.

For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

Fig. 1 Wheel Safety Rim

Fig. 2 Lug Nut Tightening Pattern

22 - 6 WHEELS AND TIRESJ