washer fluid JEEP XJ 1995 Service And Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1701 of 2158

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLING REAR CLUTCH

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

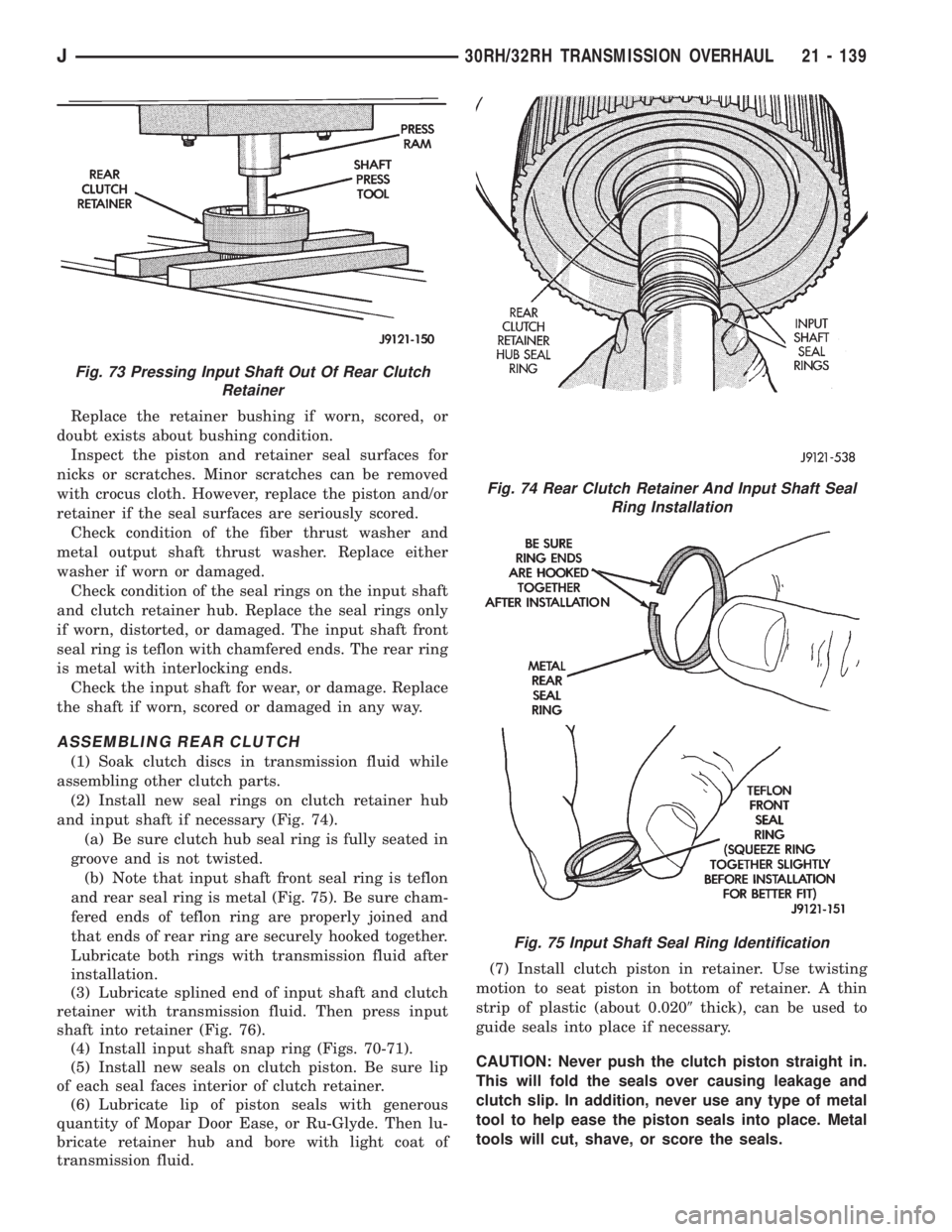

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary (Fig. 74).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(b) Note that input shaft front seal ring is teflon

and rear seal ring is metal (Fig. 75). Be sure cham-

fered ends of teflon ring are properly joined and

that ends of rear ring are securely hooked together.

Lubricate both rings with transmission fluid after

installation.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 76).

(4) Install input shaft snap ring (Figs. 70-71).

(5) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(6) Lubricate lip of piston seals with generous

quantity of Mopar Door Ease, or Ru-Glyde. Then lu-

bricate retainer hub and bore with light coat of

transmission fluid.(7) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

Fig. 73 Pressing Input Shaft Out Of Rear Clutch

Retainer

Fig. 74 Rear Clutch Retainer And Input Shaft Seal

Ring Installation

Fig. 75 Input Shaft Seal Ring Identification

J30RH/32RH TRANSMISSION OVERHAUL 21 - 139

Page 1704 of 2158

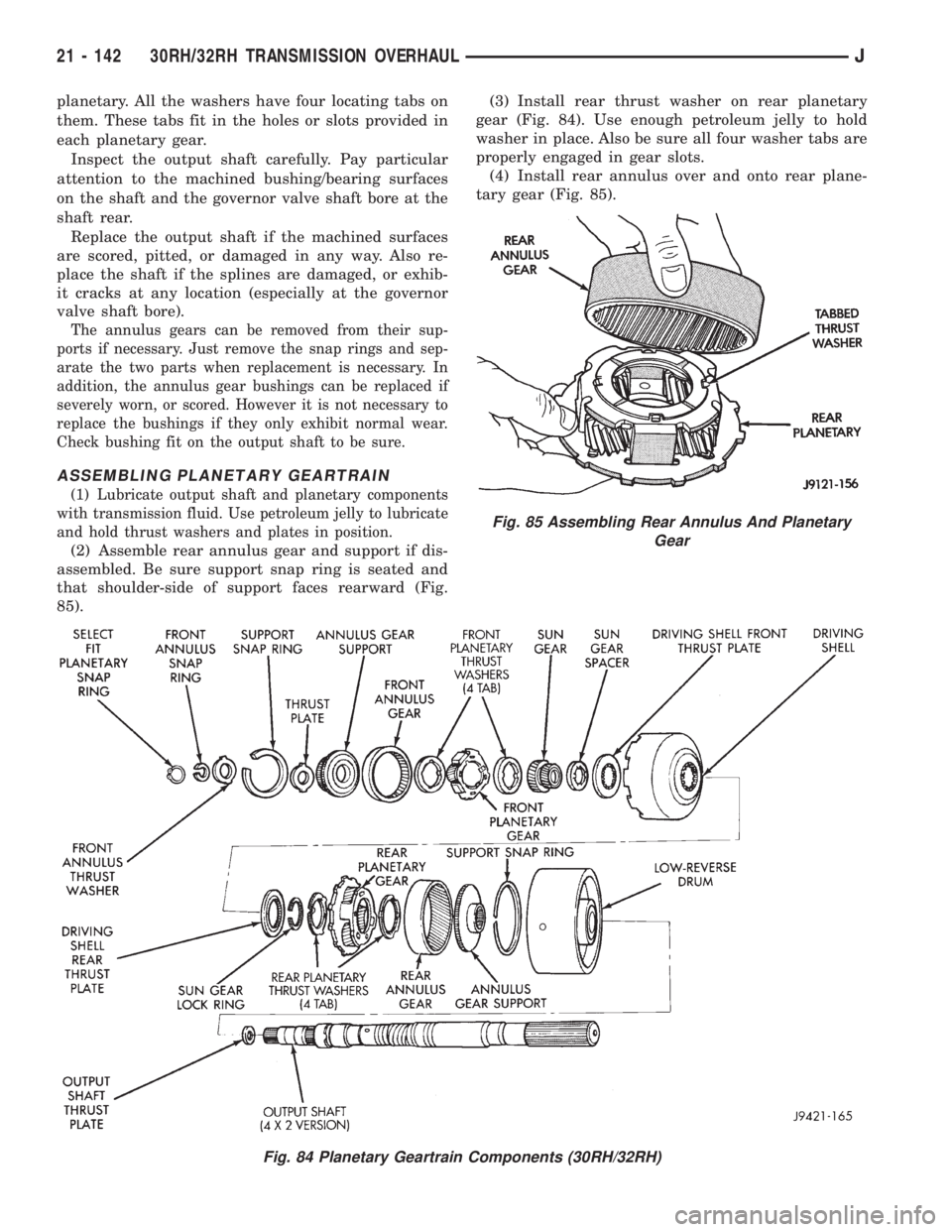

planetary. All the washers have four locating tabs on

them. These tabs fit in the holes or slots provided in

each planetary gear.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also re-

place the shaft if the splines are damaged, or exhib-

it cracks at any location (especially at the governor

valve shaft bore).

The annulus gears can be removed from their sup-

ports if necessary. Just remove the snap rings and sep-

arate the two parts when replacement is necessary. In

addition, the annulus gear bushings can be replaced if

severely worn, or scored. However it is not necessary to

replace the bushings if they only exhibit normal wear.

Check bushing fit on the output shaft to be sure.

ASSEMBLING PLANETARY GEARTRAIN

(1) Lubricate output shaft and planetary components

with transmission fluid. Use petroleum jelly to lubricate

and hold thrust washers and plates in position.

(2) Assemble rear annulus gear and support if dis-

assembled. Be sure support snap ring is seated and

that shoulder-side of support faces rearward (Fig.

85).(3) Install rear thrust washer on rear planetary

gear (Fig. 84). Use enough petroleum jelly to hold

washer in place. Also be sure all four washer tabs are

properly engaged in gear slots.

(4) Install rear annulus over and onto rear plane-

tary gear (Fig. 85).

Fig. 84 Planetary Geartrain Components (30RH/32RH)

Fig. 85 Assembling Rear Annulus And Planetary

Gear

21 - 142 30RH/32RH TRANSMISSION OVERHAULJ

Page 1712 of 2158

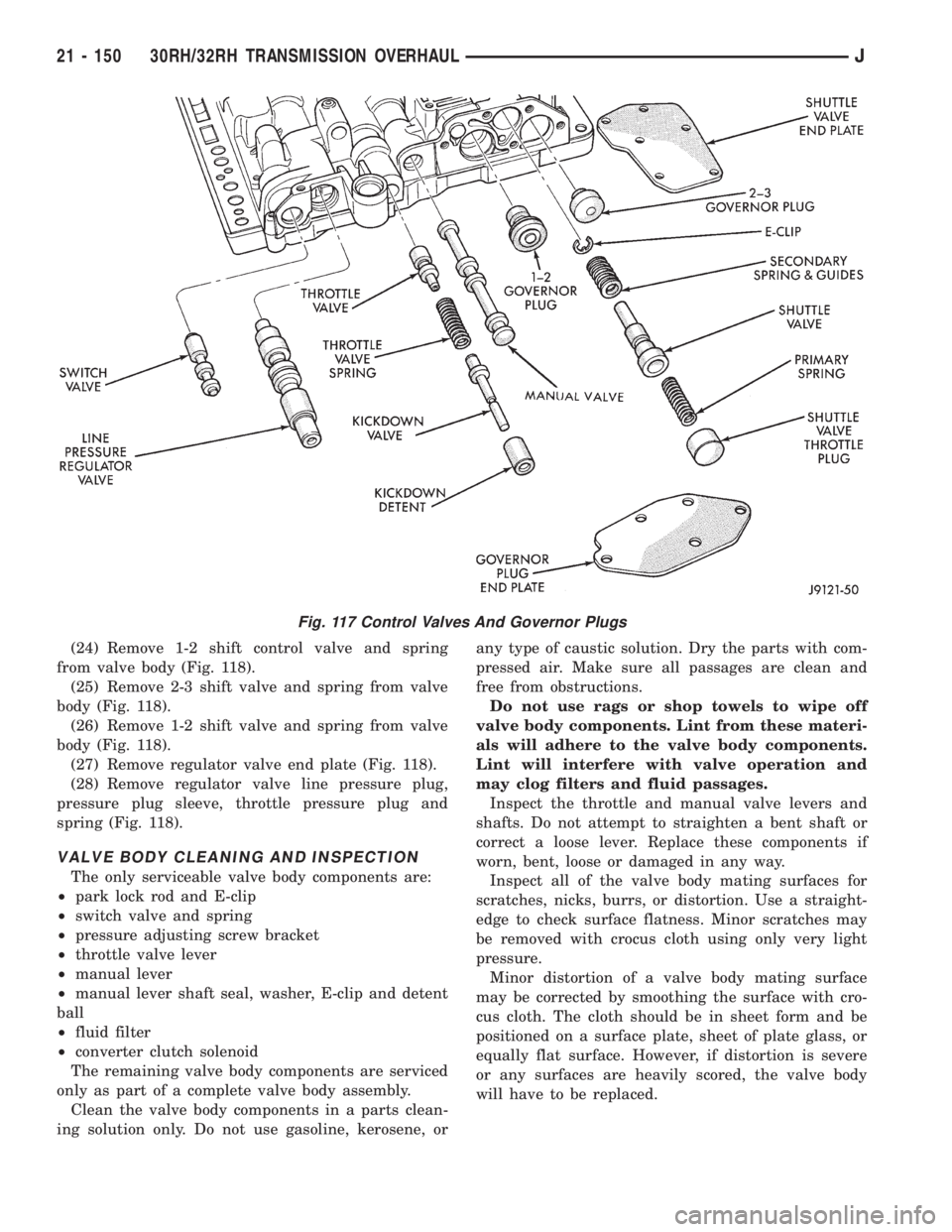

(24) Remove 1-2 shift control valve and spring

from valve body (Fig. 118).

(25) Remove 2-3 shift valve and spring from valve

body (Fig. 118).

(26) Remove 1-2 shift valve and spring from valve

body (Fig. 118).

(27) Remove regulator valve end plate (Fig. 118).

(28) Remove regulator valve line pressure plug,

pressure plug sleeve, throttle pressure plug and

spring (Fig. 118).

VALVE BODY CLEANING AND INSPECTION

The only serviceable valve body components are:

²park lock rod and E-clip

²switch valve and spring

²pressure adjusting screw bracket

²throttle valve lever

²manual lever

²manual lever shaft seal, washer, E-clip and detent

ball

²fluid filter

²converter clutch solenoid

The remaining valve body components are serviced

only as part of a complete valve body assembly.

Clean the valve body components in a parts clean-

ing solution only. Do not use gasoline, kerosene, orany type of caustic solution. Dry the parts with com-

pressed air. Make sure all passages are clean and

free from obstructions.

Do not use rags or shop towels to wipe off

valve body components. Lint from these materi-

als will adhere to the valve body components.

Lint will interfere with valve operation and

may clog filters and fluid passages.

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with cro-

cus cloth. The cloth should be in sheet form and be

positioned on a surface plate, sheet of plate glass, or

equally flat surface. However, if distortion is severe

or any surfaces are heavily scored, the valve body

will have to be replaced.

Fig. 117 Control Valves And Governor Plugs

21 - 150 30RH/32RH TRANSMISSION OVERHAULJ

Page 1717 of 2158

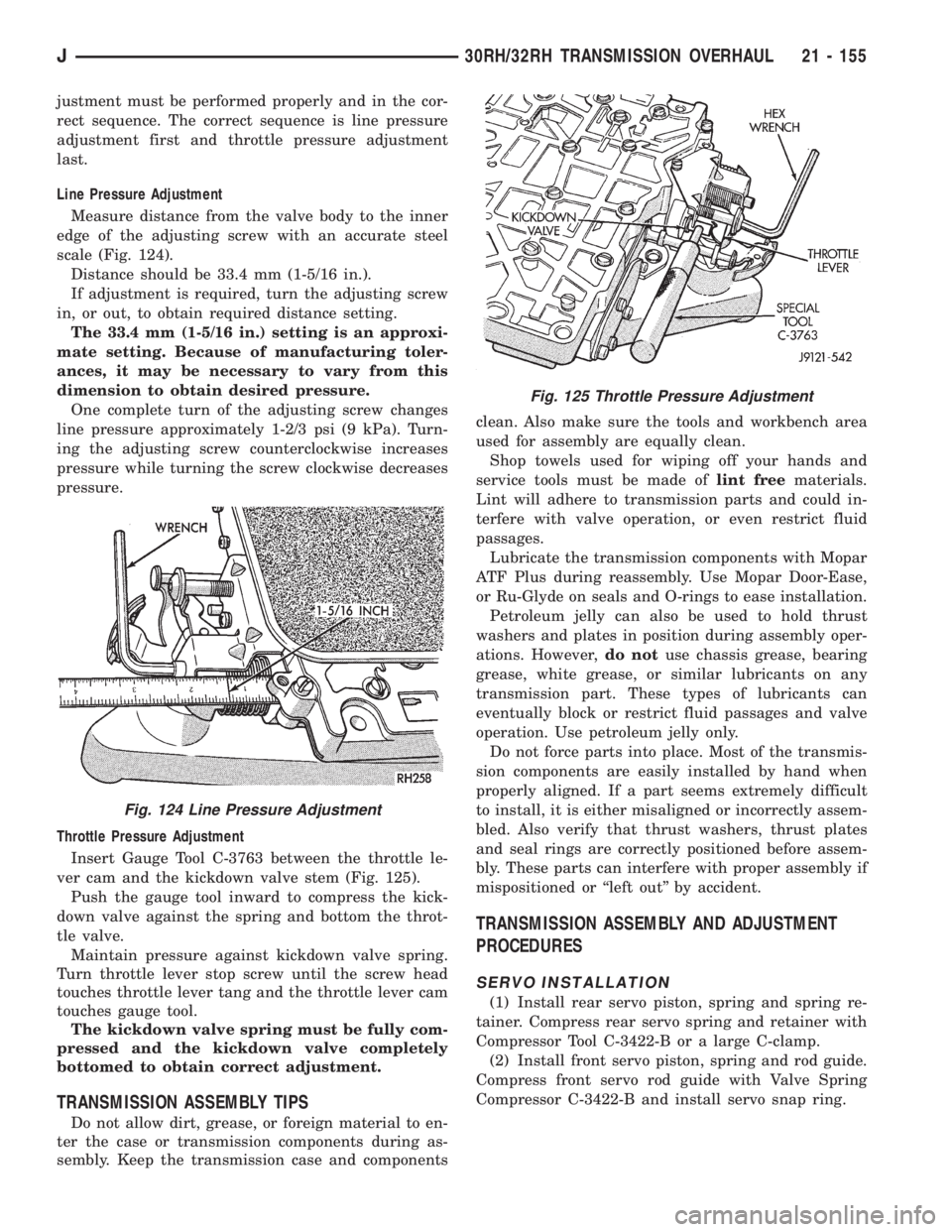

justment must be performed properly and in the cor-

rect sequence. The correct sequence is line pressure

adjustment first and throttle pressure adjustment

last.

Line Pressure Adjustment

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 124).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

The 33.4 mm (1-5/16 in.) setting is an approxi-

mate setting. Because of manufacturing toler-

ances, it may be necessary to vary from this

dimension to obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa). Turn-

ing the adjusting screw counterclockwise increases

pressure while turning the screw clockwise decreases

pressure.

Throttle Pressure Adjustment

Insert Gauge Tool C-3763 between the throttle le-

ver cam and the kickdown valve stem (Fig. 125).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

The kickdown valve spring must be fully com-

pressed and the kickdown valve completely

bottomed to obtain correct adjustment.

TRANSMISSION ASSEMBLY TIPS

Do not allow dirt, grease, or foreign material to en-

ter the case or transmission components during as-

sembly. Keep the transmission case and componentsclean. Also make sure the tools and workbench area

used for assembly are equally clean.

Shop towels used for wiping off your hands and

service tools must be made oflint freematerials.

Lint will adhere to transmission parts and could in-

terfere with valve operation, or even restrict fluid

passages.

Lubricate the transmission components with Mopar

ATF Plus during reassembly. Use Mopar Door-Ease,

or Ru-Glyde on seals and O-rings to ease installation.

Petroleum jelly can also be used to hold thrust

washers and plates in position during assembly oper-

ations. However,do notuse chassis grease, bearing

grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and valve

operation. Use petroleum jelly only.

Do not force parts into place. Most of the transmis-

sion components are easily installed by hand when

properly aligned. If a part seems extremely difficult

to install, it is either misaligned or incorrectly assem-

bled. Also verify that thrust washers, thrust plates

and seal rings are correctly positioned before assem-

bly. These parts can interfere with proper assembly if

mispositioned or ``left out'' by accident.

TRANSMISSION ASSEMBLY AND ADJUSTMENT

PROCEDURES

SERVO INSTALLATION

(1) Install rear servo piston, spring and spring re-

tainer. Compress rear servo spring and retainer with

Compressor Tool C-3422-B or a large C-clamp.

(2) Install front servo piston, spring and rod guide.

Compress front servo rod guide with Valve Spring

Compressor C-3422-B and install servo snap ring.

Fig. 124 Line Pressure Adjustment

Fig. 125 Throttle Pressure Adjustment

J30RH/32RH TRANSMISSION OVERHAUL 21 - 155

Page 1725 of 2158

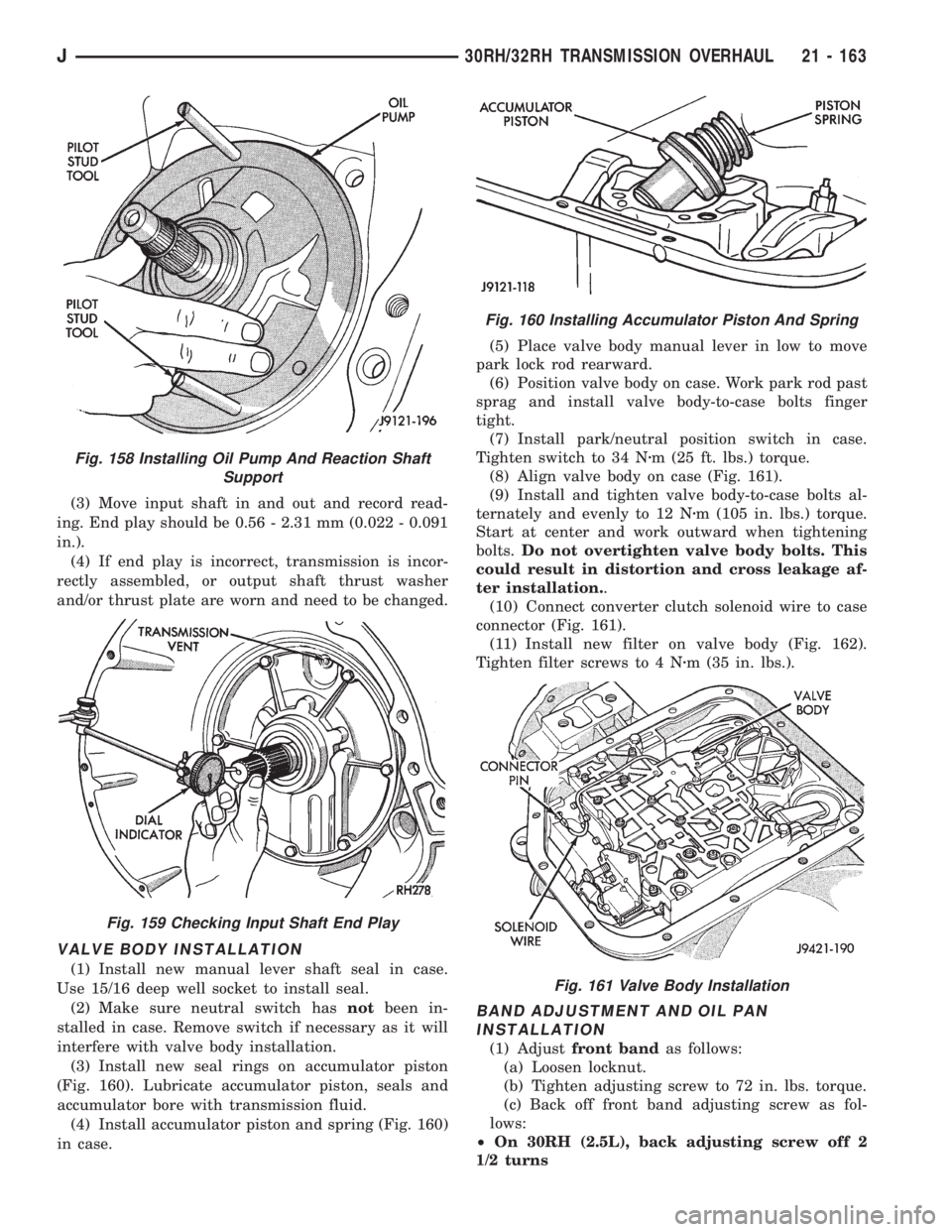

(3) Move input shaft in and out and record read-

ing. End play should be 0.56 - 2.31 mm (0.022 - 0.091

in.).

(4) If end play is incorrect, transmission is incor-

rectly assembled, or output shaft thrust washer

and/or thrust plate are worn and need to be changed.

VALVE BODY INSTALLATION

(1) Install new manual lever shaft seal in case.

Use 15/16 deep well socket to install seal.

(2) Make sure neutral switch hasnotbeen in-

stalled in case. Remove switch if necessary as it will

interfere with valve body installation.

(3) Install new seal rings on accumulator piston

(Fig. 160). Lubricate accumulator piston, seals and

accumulator bore with transmission fluid.

(4) Install accumulator piston and spring (Fig. 160)

in case.(5) Place valve body manual lever in low to move

park lock rod rearward.

(6) Position valve body on case. Work park rod past

sprag and install valve body-to-case bolts finger

tight.

(7) Install park/neutral position switch in case.

Tighten switch to 34 Nzm (25 ft. lbs.) torque.

(8) Align valve body on case (Fig. 161).

(9) Install and tighten valve body-to-case bolts al-

ternately and evenly to 12 Nzm (105 in. lbs.) torque.

Start at center and work outward when tightening

bolts.Do not overtighten valve body bolts. This

could result in distortion and cross leakage af-

ter installation..

(10) Connect converter clutch solenoid wire to case

connector (Fig. 161).

(11) Install new filter on valve body (Fig. 162).

Tighten filter screws to 4 Nzm (35 in. lbs.).

BAND ADJUSTMENT AND OIL PAN

INSTALLATION

(1) Adjustfront bandas follows:

(a) Loosen locknut.

(b) Tighten adjusting screw to 72 in. lbs. torque.

(c) Back off front band adjusting screw as fol-

lows:

²On 30RH (2.5L), back adjusting screw off 2

1/2 turns

Fig. 158 Installing Oil Pump And Reaction Shaft

Support

Fig. 159 Checking Input Shaft End Play

Fig. 160 Installing Accumulator Piston And Spring

Fig. 161 Valve Body Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 163

Page 1745 of 2158

(6) Let engine run at normal curb idle speed, apply

service brakes. Then shift transmission through all

gear ranges and back to PARK (leave engine run-

ning).

(7) Remove dipstick and check fluid level. Add only

enough fluid to bring level to Full mark on dipstick.

Do not overfill.If too much fluid is added, excess

amount can be removed with suction gun and

plastic tubing. Tubing only has to be long

enough to extend into oil pan.

(8) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

TRANSMISSION CONTROL MODULE (TCM)

SERVICE

Use the DRB scan tool to diagnose transmission

control module function whenever a fault is sus-

pected. Replace the module only when the scan tool

indicates the module is actually faulty.

TRANSMISSION CONTROL MODULE

REPLACEMENT

The transmission control module is mounted under

the instrument panel. On left hand drive models, it is

at the driver side of the lower finish panel (Fig. 2).

On right hand drive models, it is at the passenger

side of the lower finish panel (Fig. 3).

To remove the module, disconnect the wire harness,

remove the mounting screws and remove the module

from the finish panel. Tighten the module mounting

screws securely after installation. Also be sure the

wire harness is not twisted, kinked or touching any

body panels.

PARK/NEUTRAL POSITION SWITCH

SWITCH TESTING

Test switch continuity with an ohmmeter. Discon-

nect the switch and check continuity at the connector

terminal positions and in the gear ranges indicated

in Figure 3. Switch continuity should be as follows:

²Continuity should exist between terminals B and

C with the transmission in Park and Neutral only

(Fig. 4).²Continuity should exist between terminals A and E

with the transmission in Reverse (Fig. 4).

²Continuity should exist between terminals A and

G with the transmission in third gear (Fig. 4).

²Continuity should exist between terminals A and

H with the transmission in first and/or second gear

(Fig. 4).

²Continuity should not exist in D position.

PARK/NEUTRAL POSITION SWITCH REMOVAL

(1) Raise vehicle.

(2) Disconnect switch wire harness connector.

(3) Pry washer lock tabs upward and remove

switch attaching nut and tabbed washer (Fig. 5).

(4) Remove switch adjusting bolt (Fig. 5).

(5) Slide switch off manual valve shaft.

PARK/NEUTRAL POSITION SWITCH

INSTALLATION AND ADJUSTMENT

(1) Disconnect shift linkage rod from shift lever on

left side of transmission.

Fig. 2 TCM Location (Left Hand Drive)

Fig. 3 TCM Location (Right Hand Drive)

Fig. 4 Park/Neutral Position Switch Terminals And

Testing

JAW-4 IN-VEHICLE SERVICE 21 - 183

Page 1746 of 2158

(2) Rotate manual shift lever all the way rearward.

Then rotate lever forward two detent positions to

Neutral.

(3) Install switch on manual valve shaft and in-

stall switch adjusting bolt finger tight. Do not tighten

bolt at this time.

(4) Install tabbed washer on manual valve shaft

and install switch attaching nut. Tighten nut to 6.9

Nzm (61 in. lbs.) torque but do not bend washer lock

tabs over nut at this time.

(5) Verify that transmission is in Neutral.

(6) Rotate switch to align neutral standard line

with vertical groove on manual valve shaft (Fig. 6).

(7) Align switch standard line with groove or flat

on manual valve shaft.

(8) Tighten switch adjusting bolt to 13 Nzm(9ft.

lbs.) torque.

(9) Bend at least two washer lock tabs over switch

attaching nut to secure it.

(10) Connect shift linkage rod to shift lever on left

side of case.

(11) Connect switch wires to harness and lower ve-

hicle.

(12) Check switch operation. Engine should start

in Park and Neutral only.

TRANSMISSION VALVE BODY SOLENOIDS

SOLENOID REMOVAL

(1) Remove transmission oil pan drain plug and

drain fluid.

(2) Remove pan bolts and remove oil pan.(3) Remove oil screen bolts and remove screen (Fig.

7) and gasket. Discard the gasket.

(4) Disconnect solenoid wire connector (Fig. 8).

(5) If all solenoids are being removed, mark or tag

wires for assembly reference before disconnecting

them.

(6) Remove bolt attaching solenoids to valve body

and remove solenoids (Fig. 9). Do not allow any valve

body components to fall out when solenoids are re-

moved.

(7) Clean oil filter and pan with solvent and dry

with compressed air.

(8) Remove old sealer material from oil pan and

transmission case.

Fig. 5 Park/Neutral Position Switch Removal/

Installation

Fig. 6 Park/Neutral Position Switch Adjustment

Fig. 7 Oil Screen Removal/Installation

21 - 184 AW-4 IN-VEHICLE SERVICEJ

Page 1776 of 2158

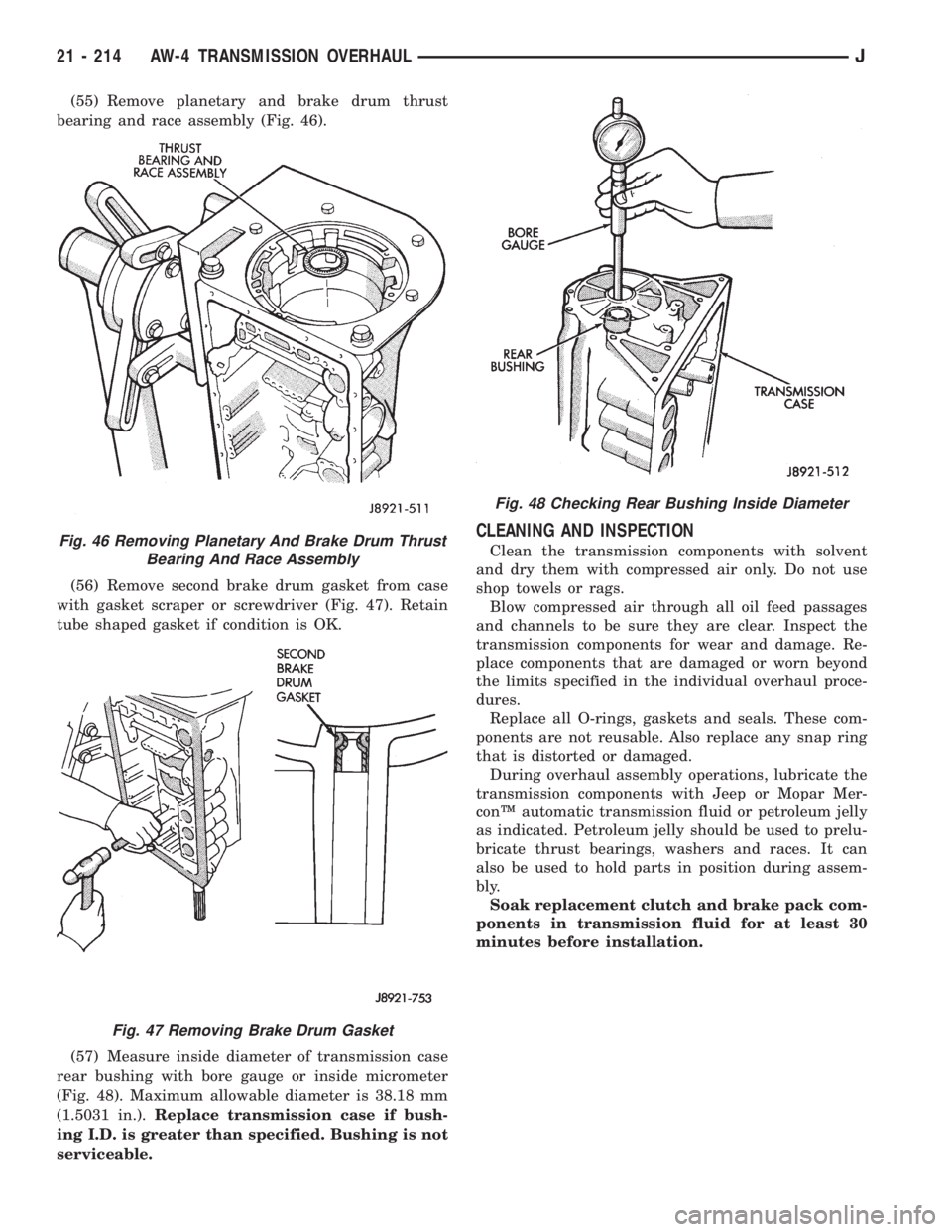

(55) Remove planetary and brake drum thrust

bearing and race assembly (Fig. 46).

(56) Remove second brake drum gasket from case

with gasket scraper or screwdriver (Fig. 47). Retain

tube shaped gasket if condition is OK.

(57) Measure inside diameter of transmission case

rear bushing with bore gauge or inside micrometer

(Fig. 48). Maximum allowable diameter is 38.18 mm

(1.5031 in.).Replace transmission case if bush-

ing I.D. is greater than specified. Bushing is not

serviceable.

CLEANING AND INSPECTION

Clean the transmission components with solvent

and dry them with compressed air only. Do not use

shop towels or rags.

Blow compressed air through all oil feed passages

and channels to be sure they are clear. Inspect the

transmission components for wear and damage. Re-

place components that are damaged or worn beyond

the limits specified in the individual overhaul proce-

dures.

Replace all O-rings, gaskets and seals. These com-

ponents are not reusable. Also replace any snap ring

that is distorted or damaged.

During overhaul assembly operations, lubricate the

transmission components with Jeep or Mopar Mer-

conŸ automatic transmission fluid or petroleum jelly

as indicated. Petroleum jelly should be used to prelu-

bricate thrust bearings, washers and races. It can

also be used to hold parts in position during assem-

bly.

Soak replacement clutch and brake pack com-

ponents in transmission fluid for at least 30

minutes before installation.Fig. 46 Removing Planetary And Brake Drum Thrust

Bearing And Race Assembly

Fig. 47 Removing Brake Drum Gasket

Fig. 48 Checking Rear Bushing Inside Diameter

21 - 214 AW-4 TRANSMISSION OVERHAULJ

Page 1816 of 2158

use shop towels or rags. Lint or foreign material from

towels or rags can interfere with valve operation.

(13) Inspect condition of lower body components.

Replace lower body if any bores are scored or cor-

roded. Replace valves, plugs or sleeves that are

scored or worn. Replace oil strainers if cut, torn or

damaged in any way.

(14) Inspect valve body springs. Replace any spring

having rusted, distorted, or collapsed coils. Measure

length of each valve body spring. Replace any spring

if free length is less than length specified in following

chart (Fig. 11).

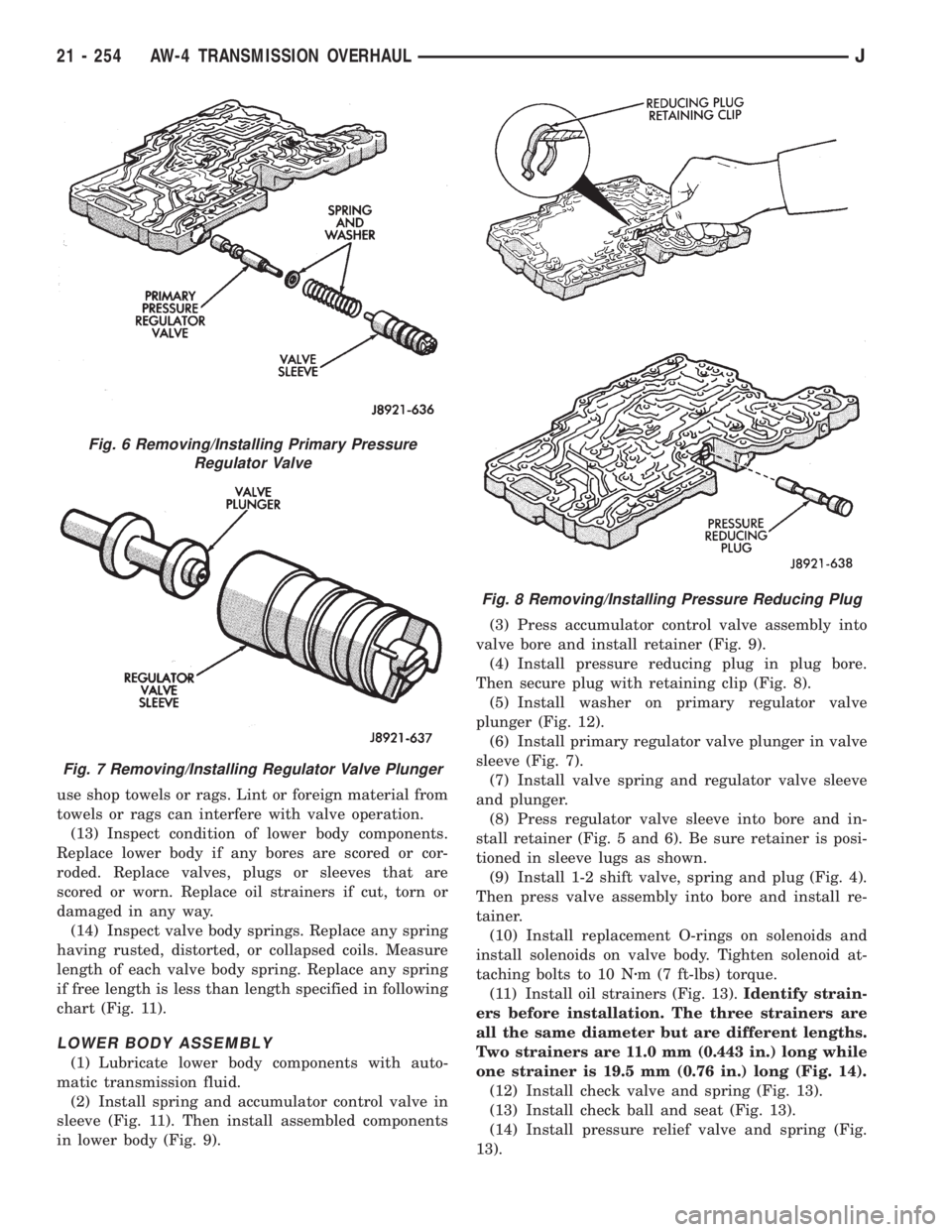

LOWER BODY ASSEMBLY

(1) Lubricate lower body components with auto-

matic transmission fluid.

(2) Install spring and accumulator control valve in

sleeve (Fig. 11). Then install assembled components

in lower body (Fig. 9).(3) Press accumulator control valve assembly into

valve bore and install retainer (Fig. 9).

(4) Install pressure reducing plug in plug bore.

Then secure plug with retaining clip (Fig. 8).

(5) Install washer on primary regulator valve

plunger (Fig. 12).

(6) Install primary regulator valve plunger in valve

sleeve (Fig. 7).

(7) Install valve spring and regulator valve sleeve

and plunger.

(8) Press regulator valve sleeve into bore and in-

stall retainer (Fig. 5 and 6). Be sure retainer is posi-

tioned in sleeve lugs as shown.

(9) Install 1-2 shift valve, spring and plug (Fig. 4).

Then press valve assembly into bore and install re-

tainer.

(10) Install replacement O-rings on solenoids and

install solenoids on valve body. Tighten solenoid at-

taching bolts to 10 Nzm (7 ft-lbs) torque.

(11) Install oil strainers (Fig. 13).Identify strain-

ers before installation. The three strainers are

all the same diameter but are different lengths.

Two strainers are 11.0 mm (0.443 in.) long while

one strainer is 19.5 mm (0.76 in.) long (Fig. 14).

(12) Install check valve and spring (Fig. 13).

(13) Install check ball and seat (Fig. 13).

(14) Install pressure relief valve and spring (Fig.

13).

Fig. 6 Removing/Installing Primary Pressure

Regulator Valve

Fig. 7 Removing/Installing Regulator Valve Plunger

Fig. 8 Removing/Installing Pressure Reducing Plug

21 - 254 AW-4 TRANSMISSION OVERHAULJ

Page 1862 of 2158

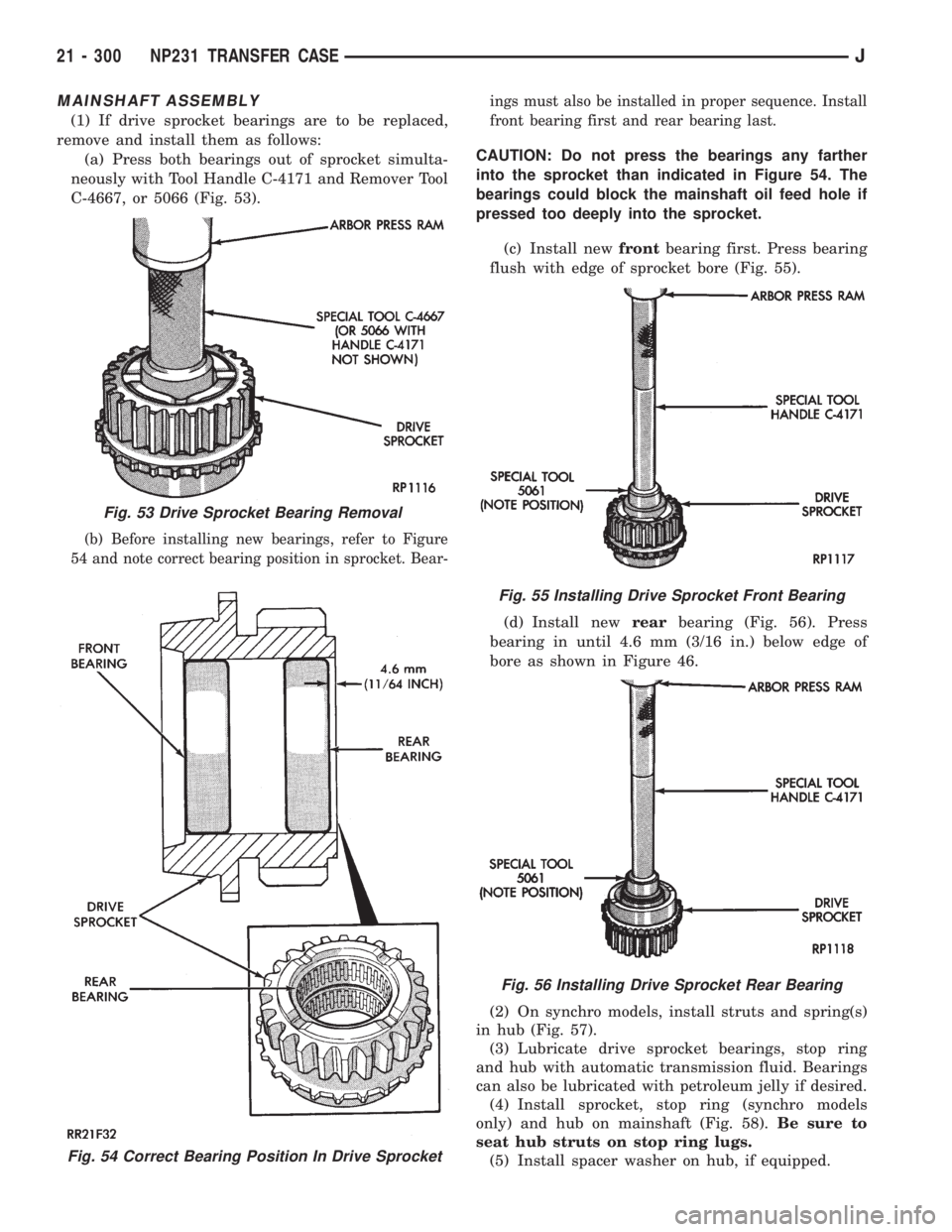

MAINSHAFT ASSEMBLY

(1) If drive sprocket bearings are to be replaced,

remove and install them as follows:

(a) Press both bearings out of sprocket simulta-

neously with Tool Handle C-4171 and Remover Tool

C-4667, or 5066 (Fig. 53).

(b) Before installing new bearings, refer to Figure

54 and note correct bearing position in sprocket. Bear-ings must also be installed in proper sequence. Install

front bearing first and rear bearing last.

CAUTION: Do not press the bearings any farther

into the sprocket than indicated in Figure 54. The

bearings could block the mainshaft oil feed hole if

pressed too deeply into the sprocket.

(c) Install newfrontbearing first. Press bearing

flush with edge of sprocket bore (Fig. 55).

(d) Install newrearbearing (Fig. 56). Press

bearing in until 4.6 mm (3/16 in.) below edge of

bore as shown in Figure 46.

(2) On synchro models, install struts and spring(s)

in hub (Fig. 57).

(3) Lubricate drive sprocket bearings, stop ring

and hub with automatic transmission fluid. Bearings

can also be lubricated with petroleum jelly if desired.

(4) Install sprocket, stop ring (synchro models

only) and hub on mainshaft (Fig. 58).Be sure to

seat hub struts on stop ring lugs.

(5) Install spacer washer on hub, if equipped.

Fig. 54 Correct Bearing Position In Drive Sprocket

Fig. 53 Drive Sprocket Bearing Removal

Fig. 55 Installing Drive Sprocket Front Bearing

Fig. 56 Installing Drive Sprocket Rear Bearing

21 - 300 NP231 TRANSFER CASEJ