sensor JEEP YJ 1995 Service And Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1124 of 2158

²Circuit K60 connects to cavity 60 of the PCM.

VEHICLE SPEED SENSOR

Circuit K7 supplies 8 volts from the Powertrain

Control Module (PCM) to the vehicle speed sensor.

The K7 circuit connects to cavity 7 of the PCM.

Circuit G7 from the vehicle speed sensor provides

an input signal to the PCM. The G7 circuit connects

to cavity 47 of the PCM.

The PCM provides a ground for the vehicle speed

sensor signal (circuit G7) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit G7 splices to the speedometer, and Day-

time Running Lamp module (DRL).

²Circuit K7 splices to supply 8 volts to the camshaft

position sensor and crankshaft position sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Intake air temperature sensor

HEATED OXYGEN SENSOR

When the Automatic Shut Down (ASD) relay con-

tacts close, they connect circuits A14 and A142. Cir-

cuit A142 splices to supply voltage to the heated

oxygen sensor.

Circuit K41 delivers the signal from the heated ox-

ygen sensor to the Powertrain Control Module

(PCM). Circuit K41 connects to cavity 41 of the PCM.

The PCM provides a ground for the heated oxygen

sensor signal (circuit K41) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM connector.

Circuit Z1 provides a ground for the heater circuit

in the sensor. Circuit Z1 terminates at the rear of the

engine.

HELPFUL INFORMATION

²Along with supplying voltage to the ASD relay

contacts, circuit A14 supplies voltage to the contact

side of the fuel pump relay.

²Circuit A142 splices to supply voltage to the fuel

injectors, ignition coil, and heated oxygen sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

CAMSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor (in distributor)

on circuit K7. Circuit K7 connects to cavity 7 of the

PCM.

The PCM receives the camshaft position sensor sig-

nal on circuit K44. Circuit K44 connects to cavity 44

of the PCM.

The PCM provides a ground for the camshaft posi-

tion sensor signal (circuit K44) through circuit K4.

Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit K7 splices to supply 8 volts to the crank-

shaft position sensor and the vehicle speed sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

CRANKSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 8

volts to the crankshaft position sensor on circuit K7.

Circuit K7 connects to cavity 7 of the PCM.

The PCM receives the crankshaft position sensor

signal on circuit K24. Circuit K24 connects to cavity

24 of the PCM.

The PCM provides a ground for the crankshaft po-

sition sensor (circuit K24) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit K7 splices to supply 8 volts to the crank-

shaft position sensor and the vehicle speed sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor provides an

input to the Powertrain Control Module (PCM) on

circuit K2. From circuit K2, the engine coolant tem-

perature sensor draws up to 5 volts from the PCM.

The sensor is a variable resistor. As coolant temper-

ature changes, the resistance in the sensor changes,

causing a change in current draw. The K2 circuit

connects to cavity 2 of the PCM.

J8W-30 FUEL/IGNITIONÐYJ VEHICLES 8W - 30 - 3

Page 1125 of 2158

The PCM provides a ground for the engine coolant

temperature sensor signal (circuit K2) through circuit

K4. Circuit K4 connects to cavity 4 of the PCM con-

nector.

HELPFUL INFORMATION

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Vehicle speed sensor

THROTTLE POSITION SENSOR

From the Powertrain Control Module (PCM), cir-

cuit K6 supplies 5 volts to the Throttle Position Sen-

sor (TPS). Circuit K6 connects to cavity 6 of the

PCM.

Circuit K22 delivers the TPS signal to the PCM.

Circuit K22 connects to cavity 22 of the PCM.

The PCM provides a ground for the throttle posi-

tion sensor signal (circuit K22) through circuit K4.

Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

Refer to Group 14 for throttle position sensor oper-

ation.

Circuit K6 splices to supply 5 volts to the Manifold

Absolute Pressure (MAP) sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

From the Powertrain Control Module (PCM), cir-

cuit K6 supplies 5 volts to the Manifold Absolute

Pressure (MAP) sensor. Circuit K6 connects to cavity

6 of the PCM.

Circuit K1 delivers the MAP signal to the PCM.

Circuit K1 connects to cavity 1 of the PCM.

The PCM provides a ground for the MAP sensor

signal (circuit K1) through circuit K4. Circuit K4 con-

nects to cavity 4 of the PCM.

HELPFUL INFORMATION

Refer to Group 14 for MAP sensor operation.

Circuit K6 splices to supply 5 volts to the throttle

position sensor.Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor provides an in-

put to the Powertrain Control Module (PCM) on cir-

cuit K21. Circuit K21 connects to cavity 21 of the

PCM.

From circuit K21, the intake air temperature sen-

sor draws voltage from the PCM. The sensor is a

variable resistor. As intake air temperature changes,

the resistance in the sensor changes, causing a

change in current draw.

The PCM provides a ground for the intake air tem-

perature sensor signal (circuit K21) through circuit

K4. Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

PARK/NEUTRAL POSITION SWITCH

When closed, the case-grounded park/neutral posi-

tion switch provides a ground path on circuit T41 for

the coil side of the starter motor relay. Circuit A41

from the ignition switch provides battery voltage to

the coil side of the relay.

Circuit T41 splices to cavity 30 of the Powertrain

Control Module (PCM). The park/neutral position

switch provides an input to the (PCM).

HELPFUL INFORMATION

²In the START position, the ignition switch con-

nects circuit A1 from the Power Distribution Center

(PDC) to circuit A41. Fuse 4 in the fuse block pro-

tects circuits A1 and A41.

²The Park/Neutral position switch and back-up

lamp switch are molded together.

POWER STEERING PRESSURE SWITCH

The Powertrain Control Module (PCM) supplies

voltage to the power steering pressure switch on cir-

cuit K10. Circuit Z1 provides ground for the switch.

When the switch closes, voltage flows through the

8W - 30 - 4 8W-30 FUEL/IGNITIONÐYJ VEHICLESJ

Page 1126 of 2158

switch to ground on circuit Z1. The switch closes dur-

ing periods of high power steering pump load and

low engine speed; such as parking maneuvers. Cir-

cuit K10 connects to cavity 10 of the PCM.

TACHOMETER SIGNAL

The Powertrain Control Module (PCM) supplies the

signal for the tachometer on circuit G21. Circuit G21

connects to cavity 43 of the PCM.

MALFUNCTION INDICATOR LAMP (MIL)

The Powertrain Control Module (PCM) provides

ground for the instrument cluster malfunction indica-

tor lamp on circuit G3. The MIL displays the mes-

sage CHECK ENGINE when illuminated. Circuit G5

provides voltage for the lamp.

DATA LINK CONNECTOR

Circuit G50 supplies battery voltage to the data

link connector. Circuit G50 originates at fuse 5 in the

fuse block. Circuit G50 is double crimped at the data

link connector and connects to cavity 9 of the Power-

train Control Module (PCM).

Circuit A21 from the ignition switch powers fuse 5

when the switch is in the START or RUN positions.

In the START or RUN position the ignition switch

connects circuit A1 from fuse 4 in the Power Distri-

bution Center (PDC) with circuit A21.

Circuit D20 connects to cavity 45 of the PCM. Cir-

cuit D20 is the SCI receive circuit for the PCM.

Circuit D21 connects to cavity 25 of the PCM. Cir-

cuit D21 is the SCI transmit circuit for the PCM.

Circuit Z11 provides ground for the data link con-

nector. Circuit Z11 splices to circuit Z1 which termi-

nates at the right rear of the engine. Circuit Z11 also

connects to cavity 5 of the PCM.

HELPFUL INFORMATION

²Circuit Z1 also supplies a ground for the PCM

high current drivers.

²If the system loses ground for the Z1 and Z11 cir-

cuits at the right rear of the engine, the vehicle will

not operate. Check the connection at the ganged-

ground circuit eyelet.

BRAKE SWITCH INPUT

Circuit V40 provides the brake switch input to the

Powertrain Control Module (PCM). Circuit V40 con-

nects to cavity 29 of the PCM.

POWER (DEVICE) GROUND

Circuit Z11 connects to cavities 11 and 12 of the

Powertrain Control Module (PCM). The Z1 circuit

provides ground for PCM internal drivers that oper-

ate high current devices like the injectors and igni-

tion coil.

Internal to the PCM, the power (device) ground cir-

cuit connects to the PCM sensor return circuit (from

circuit K4).

HELPFUL INFORMATION

²The grounding point for circuit Z1 is the right rear

of the engine.

²If the system loses ground for the Z1 circuits at

the rear of the engine, the vehicle will not operate.

Check the connection at the ganged-ground circuit

eyelet.

DIAGRAM INDEX

Component Page

Automatic Shut Down Relay...............8W-30-6, 14

Camshaft Position Sensor................8W-30-10, 16

Crankshaft Position Sensor...............8W-30-10, 16

Data Link Connector...................8W-30-11, 17

Daytime Running Lamps (DRL) Module.......8W-30-11, 17

Engine Coolant Temperature Sensor..........8W-30-9, 18

Fuel Pump Relay........................8W-30-20

Fuel Tank Level Unit......................8W-30-21

Fuse 1 (PDC)........................8W-30-6, 14

Fuse 4 (PDC)........................8W-30-6, 14

Fuse 5 (Fuse Block).................8W-30-6, 14, 20

Heated Oxygen Sensor..................8W-30-7, 15

Idle Air Control Motor..................8W-30-12, 18

Ignition Switch.....................8W-30-6, 14, 20

Ignition Coil........................8W-30-12, 18

Injectors (4.0L).........................8W-30-13

Injectors (2.5L)..........................8W-30-8

Instrument Cluster....................8W-30-11, 17

Intake Air Temperature Sensor.............8W-30-9, 18

MAP Sensor.........................8W-30-9, 18

Power Steering Pressure Switch..............8W-30-12

Powertrain Control Module.............8W-30-6 thru 21

Throttle Position Sensor.................8W-30-9, 18

Vehicle Speed Sensor..................8W-30-11, 17

J8W-30 FUEL/IGNITIONÐYJ VEHICLES 8W - 30 - 5

Page 1146 of 2158

ANTI-LOCK BRAKES

GENERAL INFORMATION

Three fuses supply power for the Anti-Lock Brake

System (ABS); fuses 9 and 10 in the PDC and fuse

13 in the fuse block. Fuses 9 and 10 in the Power

Distribution Center (PDC) are connected directly to

battery voltage and are HOT all times. Fuse 13 is

HOT when the ignition switch is the RUN position.

In the RUN position, the ignition switch connects

circuit A1 from fuse 4 in the PDC with circuit A22.

Circuit A22 connects to a bus bar in the fuse block.

The bus bar feeds circuit F15 through fuse 13. Fuse

13 is a 2 amp fuse.

Circuit F15 splices to the coil side of the ABS

power relay and cavity 53 of the ABS control module.

Circuit Z1 provides ground for the ABS control

module. Circuit Z1 connects to cavities 1 and 19 of

the ABS control module.

Refer to group 5, Brakes for operational descrip-

tions of ABS system components.

WHEEL SPEED SENSORS

The all wheel anti-lock system uses four wheel

speed sensors; one for each wheel. Each sensor con-

verts wheel speed into an electrical signal that it

transmits to the ABS control module. A pair of

twisted wires connect to each sensor to provide sig-

nals to the ABS control module.

Circuits B6 and B7 provide signals to ABS control

module from the right front wheel speed sensor. Cir-

cuit B6, which provides the LOW signal, connects to

cavity 29 of the ABS control module. Circuit B7 con-

nects to cavity 47 of the module and provides the

HIGH signal.

Circuits B8 and B9 provide signals to ABS control

module from the left front wheel speed sensor. Cir-

cuit B8, which provides the LOW signal, connects to

cavity 30 of the ABS control module. Circuit B9 con-

nects to cavity 48 of the module and provides the

HIGH signal.

Circuits B1 and B2 provide signals to ABS control

module from the right rear wheel speed sensor. Cir-

cuit B1 which provides the LOW signal, connects to

cavity 27 of the ABS control module. Circuit B2 con-

nects to cavity 45 of the module and provides the

HIGH signal.

Circuits B4 and B3 provide signals to ABS control

module from the left rear wheel speed sensor. Circuit

B3, which provides the LOW signal, connects to cav-

ity 28 of the ABS control module. Circuit B4 connects

to cavity 46 of the module and provides the HIGH

signal.

ACCELERATION SWITCH

During four-wheel drive operation, the acceleration

switch provides deceleration data to the ABS control

module. Refer to Group 5, Brakes for additional in-

formation.

Circuits B21, B22, and B23 connect the accelera-

tion sensor to the ABS control module. Circuits B21

and B22 provide switch states while circuit B23 pro-

vides ground. At the ABS control module circuit B21

connects to cavity 25, circuit B22 connects to cavity

43 and circuit B23 connects to cavity 26.

ABS POWER RELAY

The ABS power relay is located in the Power Dis-

tribution Center (PDC). When the ABS module

grounds the ABS power relay on circuit B20, the re-

lay switches to connect circuit B15 and circuit A20

from PDC fuse 10. Circuit F15 from fuse 13 in the

fuse block splices to feed the coil side of the ABS

power relay. Circuit B20 connects to cavity 34 of the

ABS control module.

Circuit B15 is double crimped at the ABS power re-

lay. One branch of circuit B15 supplies power to the

coil side of the ABS pump motor relay. The other

branch of circuit B15 splices to cavities 3 and 33 of

the ABS control module and to the hydraulic control

unit.

ABS PUMP MOTOR RELAY

The ABS pump motor relay in the Power Distribu-

tion Center (PDC) supplies voltage to the ABS pump

motor. When the ABS power relay energizes, circuit

B15 supplies battery voltage to the coil side of the

ABS pump motor relay. The ABS control module pro-

vides ground for the relay on circuit B116. Circuit

B116 connects to cavity 15 of the ABS control mod-

ule.

When the ABS pump motor energizes, it connects

circuit A10 from PDC fuse 9 to circuit B25. Circuit

B25 supplies battery voltage to the pump motor. Cir-

cuit Z12 provides ground for the pump motor.

PUMP MOTOR SPEED SENSOR

The input from the pump motor speed sensor tells

the ABS control module that the pump is operating.

Circuit B17 and B16 from the control module connect

to the speed sensor.

BRAKE PEDAL TRAVEL SENSOR

The brake pedal travel sensor provides the ABS

control module with data regarding brake pedal posi-

tion. The sensor is a variable resistor that the ABS

J8W-32 ANTI-LOCK BRAKESÐYJ VEHICLES 8W - 32 - 1

Page 1147 of 2158

module provides voltage to and receives input from.

Circuit B210 from cavity 41 of the ABS control mod-

ule provides voltage to the sensor. Circuit B258 car-

ries the signal from the sensor to cavity 16 of the

ABS module.

BRAKE SWITCH INPUT

Circuit L50 from the stop lamp provides the brake

switch input to the ABS control module. When the

brake pedal is pressed, the stop lamp switch closes to

supply battery voltage from circuit F32 to circuit

L50. Circuit L50 connects to cavity 32 of the ABS

control module. Circuit F32 originates at fuse 3 in

the fuse block.

Circuit A6 from Power Distribution Center (PDC)

fuse 3 supplies voltage to the fuse block for circuit

F32.

HYDRAULIC CONTROL UNIT

When the ABS power relay energizes, two branches

of circuit B15 splice to supply voltage to the isolation

and decay solenoids in the hydraulic control unit.

The hydraulic control unit contains three separate

isolation solenoids and three separate decay sole-

noids. The ABS control module activates the decay

and isolation solenoids by providing separate ground

paths for each.

The ABS module provides a ground path for the

rear isolation solenoid on circuit B251. Circuit B251

connects to cavity 54 of the ABS control module.

For the right front isolation solenoid, the ABS mod-

ule provides a ground path on circuit B249. Circuit

B249 connects to cavity 38 of the ABS control mod-

ule.

On circuit B245, the ABS module provides ground

for the left front isolation solenoid. Circuit B245 con-

nects to cavity 20 of the ABS control module.

The ABS module provides a ground path for the

rear decay solenoid on circuit B254. Circuit B254

connects to cavity 36 of the ABS control module.

For the right front decay solenoid, the ABS module

provides a ground path on circuit B248. Circuit B248

connects to cavity 21 of the ABS control module.

On circuit B243, the ABS module provides ground

for the left decay solenoid. Circuit B243 connects to

cavity 2 of the ABS control module.

ABS WARNING LAMP

Circuit G5 provides power for the ABS warning

lamp at the instrument cluster. Ground for the ABS

warning lamp is provided by either the ABS control

module or by the ABS power relay when the relay is

not energized. The ABS control module illuminates

the lamp by providing ground on circuit G19.

Circuit G19 splices to connect to circuit B15

through a diode. When the ABS power relay is notenergized, it connects circuit B15 to circuit Z12. The

ground path for the warning lamp is through the di-

ode to circuit B15, through the ABS power relay to

ground on circuit Z12.

The diode between circuit G19 and B15 prevents

voltage from flowing to the ABS control module when

the ABS power relay switches to supply power on cir-

cuit B15.

DATA LINK CONNECTOR

Circuit D11 from cavity 23 of the ABS control mod-

ule receives data from the DRB scan tool through the

data link connector. The ABS control module trans-

mits data to the scan tool through the connector on

circuit D12. Circuit D12 originates at cavity 42 of the

ABS control module.

Through the data link connector, circuit Z12 pro-

vides ground for the DRB scan tool. Circuit Z12 ter-

minates at the right rear of the dash panel.

Circuit A4 from fuse 8 in the Power Distribution

Center (PDC) supplies power to fuse 16 in the PDC.

Fuse 16 powers circuit M1 which supplies battery

voltage to the scan tool through the diagnostic con-

nector.

HELPFUL INFORMATION

²Check fuses 4, 9 and 10 in the PDC

²Check fuse 13 in the fuse block

DIAGRAM INDEX

Component Page

ABS Power Relay........................8W-32-4

ABS Pump Motor/Sensor...................8W-32-5

ABS Warning Lamp.......................8W-32-4

ABS Control Module..................8W-32-3 thru 7

ABS Pump Motor Relay....................8W-32-5

Brake Pedal Travel Sensor...................8W-32-6

Data Link Connector......................8W-32-6

Fuse 1 Fuse Block........................8W-32-4

Fuse 3 Fuse Block........................8W-32-6

Fuse 3 (PDC)...........................8W-32-6

Fuse 4 (PDC)...........................8W-32-4

Fuse 8 (PDC)...........................8W-32-6

Fuse 10 (PDC)..........................8W-32-4

Fuse 12 Fuse Block.......................8W-32-4

Fuse 12 (PDC)..........................8W-32-6

Fuse 13 (PDC)..........................8W-32-4

Hydraulic Actuation Unit....................8W-32-3

Ignition Switch..........................8W-32-4

Powertrain Control Module (PCM)..............8W-32-6

Stop Lamp Switch........................8W-32-6

Wheel Speed Sensors......................8W-32-7

8W - 32 - 2 8W-32 ANTI-LOCK BRAKESÐYJ VEHICLESJ

Page 1154 of 2158

INSTRUMENT CLUSTER

INSTRUMENT CLUSTER

The instrument cluster contains the gauges and

warning lamps. All gauges have magnetic move-

ments.

When the ignition switch is in either the START or

RUN position, circuit A1 from fuse 4 in the Power

Distribution Center (PDC) connects to circuit A21.

Circuit A21 powers fuse 9 in the fuse block. Fuse 9

powers circuit G5. One branch of circuit G5 connects

directly to the combination buzzer. The other branch

of circuit G5 splices to power the gauges, speedome-

ter, tachometer, voltmeter, indicator lamps, and

warning lamps in the instrument cluster.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit F33 to circuit L7.

Circuit L7 splices to the dimmer switch. Circuit E1

from the dimmer switch powers fuse 10 in the fuse

block when the parking lamps or headlamps are ON.

Circuit E2 from fuse 10 in the fuse block feeds the

illumination lamps in the instrument cluster.

Circuit Z1 provides ground the instrument cluster

illumination lamps, gauges and warning lamps.

HELPFUL INFORMATION

²Circuit G5 also powers the heated rear window,

A/C compressor clutch relay. On Canadian vehicles,

circuit G5 powers the Daytime Running Lamps

(DRL) module.

²Circuit F33 originates at fuse 8 in the fuse block.

Circuit A6 from fuse 3 in the PDC powers fuse 8 in

the fuse block.

ENGINE COOLANT TEMPERATURE GAUGE

Circuit G20 connects the engine coolant tempera-

ture gauge to the engine coolant temperature sensor.

The sensor is a variable resistor and case grounded

to the engine. Circuit G5 connects to the instrument

cluster and supplies voltage for the gauge.

The gauge uses two coils. The first coil has fixed

current flowing through it to maintain magnetic field

strength. Circuit Z1 provides ground for the fixed

current coil. The current level passing through the

second coil is controlled by the variable resistor in

the engine coolant temperature sender. The changing

current varies the magnetic field in the second coil.

Refer to group 8E, Instrument Panel and Gauges

for gauge operation.

FUEL GAUGE

Circuit G4 connects the fuel level sensor to the fuel

gauge in the instrument cluster. Circuit G5 supplies

voltage to the fuel gauge. The fuel level sensor draws

voltage from circuit G5 through the fuel gauge on cir-

cuit G4.The gauge uses two coils. The first coil has fixed

current flowing through it to maintain magnetic field

strength. Circuit Z1 provides ground for the fixed

current coil. The current level passing through the

second coil is controlled by the variable resistor in

the fuel level sensor. The changing current varies the

magnetic field in the second coil.

Circuit Z2 provides the ground path for the fuel

level sensor.

Refer to group 8E, Instrument Panel and Gauges

for gauge operation.

OIL PRESSURE GAUGE

The case grounded oil pressure sending unit is a

variable resistor. The sending unit connects to the oil

pressure gauge on circuit G60.

Circuit G5 connects to the instrument cluster and

supplies battery voltage to the oil pressure gauge.

The gauge uses two coils. The first coil has fixed cur-

rent flowing through it to maintain magnetic field

strength. Circuit Z1 provides ground for the fixed

current coil. The current level passing through the

second coil is controlled by the variable resistor in

the oil pressure sending unit. The changing current

varies the magnetic field in the second coil.

Refer to group 8E, Instrument Panel and Gauges

for gauge operation.

TACHOMETER

The Powertrain Control Module (PCM) provides

the tachometer signal to the electronic tachometer on

circuit G21. Circuit G21 originates at cavity 43 of the

PCM. Circuit Z1 provides ground for the tachometer's

internal logic circuits.

SPEEDOMETER

The electronic speedometer and odometer receive a

signal from the vehicle speed sensor on circuit G7.

Circuit G5 connects to the instrument cluster and

supplies battery voltage to the speedometer. Circuit

Z1 provides ground for the speedometer internal logic

circuits.

Circuit G7 splices to connect to the Powertrain

Control Module (PCM) and if equipped, the Daytime

Running Lamps (DRL) module.

FOUR-WHEEL DRIVE (4WD) INDICATOR LAMP

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

panel. Circuit G5 connects to the instrument cluster

and supplies battery voltage to the 4WD indicator

lamp. Circuit G1 connects the indicator lamp to the

4WD switch.

J8W-40 INSTRUMENT CLUSTERÐYJ VEHICLES 8W - 40 - 1

Page 1155 of 2158

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMP

The Powertrain Control Module (PCM) provides

ground for the malfunction indicator (Check Engine)

lamp on circuit G3. Circuit G3 connects to cavity 32

of the PCM. Circuit G5 connects to the instrument

cluster and supplies battery voltage for the malfunc-

tion indicator lamp. When illuminated, the malfunc-

tion indicator lamp displays the message CHECK

ENGINE.

For information regarding diagnostic trouble code

access using the malfunction indicator lamp, refer to

Group 14, Fuel Systems.

UP-SHIFT LAMP

On vehicles equipped with a manual transmission,

the Powertrain Control Module (PCM) provides

ground for the Up-Shift lamp on circuit K54. Circuit

G5 provides battery voltage for the lamp.

ABS WARNING LAMP

Circuit G5 provides power for the ABS warning

lamp at the instrument cluster. Ground for the ABS

warning lamp is provided by either the ABS control

module or by the ABS power relay when the relay is

not energized. The ABS control module illuminates

the lamp by providing ground on circuit G19.

Circuit G19 splices to connect to circuit B15

through a diode. When the ABS power relay is not

energized, it connects circuit B15 to circuit Z12. The

ground path for the warning lamp is provided

through the diode to circuit B15, through the ABS

power relay to ground on circuit Z12.

The diode between circuit G19 and B15 prevents

voltage from flowing to the ABS control module when

the ABS power relay switches to supply power on cir-

cuit B15.

BRAKE WARNING LAMP

Circuit G5 provides battery voltage for the brake

warning lamp. Circuit G11 can provide ground for

the lamp in 3 ways. The first ground path is through

the ignition switch when the key is in the START po-

sition.

The second ground path for the brake warning

lamp on circuit G11 is through the case grounded

brake warning switch. When the switch closes it pro-

vides a ground.

The third ground path on circuit G11 is through

the case grounded park brake switch. When the

switch closes it provides ground.

HIGH BEAM INDICATOR LAMP

Circuit G34 supplies power for the high-beam indi-

cator lamp when the operator either flashes the opti-

cal horn (high beams) or selects high beam operation.

Circuit Z1 provides the ground path for the lamp.

Circuit L3 from the headlamp switch powers the

high beam circuits of the headlamps. On vehicles not

equipped with Daytime Running Lamps (DRL), cir-

cuit G34 double crimps to circuit L3 at the bulkhead

connector.

On vehicles equipped with DRL, circuit L3 splices

to the DRL module. The DRL module powers circuit

G34.

TURN SIGNAL INDICATOR LAMPS

Circuit L61 supplies battery voltage to the left turn

signal indicator lamp. The right turn signal indicator

lamp receives battery voltage from circuit L60. The

turn signal/hazard flasher switch powers circuits L60

and L61. Circuit Z1 provides ground for the lamps.

HELPFUL INFORMATION

²If the warning lamps, gauges and indicator lamps

don't operate, check fuse 4 in the PDC and fuse 9 in

the fuse block.

²If the illumination lamps don't operate, check fuse

10 in the fuse block.

DIAGRAM INDEX

Component Page

4WD Switch............................8W-40-9

ABS Control Module......................8W-40-5

Brake Warning Switch.....................8W-40-5

Combination Buzzer.....................8W-40-7, 8

Daytime Running Lamp (DRL) Module.........8W-40-4, 6

Engine Coolant Temperature Sensor...........8W-40-7, 8

Engine Oil Pressure Sensor..................8W-40-9

Fuse 3 (PDC).......................8W-40-3, 7, 8

Fuse 4 (PDC).......................8W-40-4, 7, 8

Fuse 7 (PDC)...........................8W-40-6

Fuse 8 (Fuse Block)...................8W-40-3, 7, 8

Fuse 9 (Fuse Block).......................8W-40-8

Fuse 10 (Fuse Block).................8W-40-3, 7, 10

Gauge Package......................8W-40-7, 8, 9

Headlamp Switch...................8W-40-3, 6, 7, 8

Headlamp Dimmer Switch...................8W-40-6

Ignition Switch......................8W-40-4, 5, 8

Instrument Cluster...................8W-40-3 thru 9

Panel Lamp Dimmer Switch..............8W-40-3, 7, 8

Park Brake Switch........................8W-40-5

Powertrain Control Module.................8W-40-4, 5

8W - 40 - 2 8W-40 INSTRUMENT CLUSTERÐYJ VEHICLESJ

Page 1191 of 2158

When the park lamp relay energizes, the relay con-

tacts close and connect circuit F81 from fuse 6 in the

fuse block to circuit L36. Circuit L36 connects to the

contact side of the high beam relay. The contacts in

the high beam relay are normally closed. Battery

voltage flows through high beam relay to the fog

lamps on circuit L39. Circuit L39 also splices to the

lamp in the fog lamp switch.

Circuit L3 from the dimmer switch provides power

for the high beams of the headlamps and connects to

Circuit G34. Circuit G34 powers the coil side of the

high beam relay. Circuit Z1 provides ground for the

coil. When the operator selects high beam operation

or flashes the optical horn, circuit G34 energizes the

high beam relay. When energized, the normally

closed contacts in the relay open, shutting off battery

voltage to the fog lamps on circuit L39.

HELPFUL INFORMATION

²Circuit A6 from fuse 3 in the PDC supplies voltage

to the fuse block for fuses in cavities 3 and 6. Fuse 6

in the fuse block protects circuit F81 which powers

the contact side of the park lamp relay.

²In the high beam position, the dimmer switch con-

nects circuit L20 from the headlamp switch to circuit

L3. The headlamp switch connects circuit A3 from

fuse 7 in the PDC with circuit L20. Circuits A3 and

L20 are HOT at all times.

DAYTIME RUNNING LAMP (DRL) MODULEÐ

CANADIAN VEHICLES ONLY

On Canadian vehicles, the low-beam headlamps op-

erate when the ignition switch is in the RUN position

and the headlamp switch is OFF.

When the ignition switch is in the START or RUN

positions, circuit A1 from fuse 4 in the Power Distri-

bution Center (PDC) connects to circuit A21. Circuit

A21 supplies voltage to circuit G5 through fuse 9 in

the fuse block. Circuit G5 splices to supply battery

voltage to the DRL module.

Circuit L20 from the headlamp switch connects to

the DRL module. Circuit L20 is HOT at all times.

The DRL module receives the vehicle speed sensor

input from circuit G7. Circuit G34 from the DRLmodule provides power for the high beam indicator

lamp in the instrument cluster.

Circuit L4 feeds the low beams of the headlamps.

When the headlamp switch is in the OFF position,

the DRL module powers the left and right headlamps

on circuit L4. When the headlamps are ON, the dim-

mer switch powers the low beams on circuit L4.

Circuit L3 feeds the high beams of the headlamps.

When the operator flashes the high beams with the

turn signal stalk, the DRL senses voltage on circuit

L3. When it senses voltage on circuit L3, the DRL

module stops supplying power to the low beams on

circuit L4.

Circuit Z1 provides ground for the DRL module.

Circuit Z1 terminates at the radiator left side sup-

port.

DIAGRAM INDEX

Component Page

Daytime Running Lamp (DRL) Module. . . .8W-50-3, 7, 9, 11

Fog Lamps.............................8W-50-9

Fog Lamp Switch........................8W-50-9

Fuse 3 (PDC)...........................8W-50-3

Fuse 4 (PDC)..........................8W-50-10

Fuse 6 (Fuse Block).......................8W-50-8

Fuse 7 (PDC)........................8W-50-3, 10

Fuse 8 (Fuse Block).......................8W-50-3

Fuse 9 (Fuse Block)......................8W-50-10

Headlamp Switch....................8W-50-3, 8, 10

Headlamp Dimmer Switch.................8W-50-3, 8

High Beam Relay.........................8W-50-9

Ignition Switch.........................8W-50-10

Instrument Cluster..................8W-50-3 thru 10

Left Headlamp.........................8W-50-4, 6

Left Park, Turn Signal Lamp...............8W-50-4, 6

Left Side Marker Lamp...................8W-50-4, 6

Park Lamp Relay.........................8W-50-8

Powertrain Control Module..................8W-50-11

Right Headlamp........................8W-50-5, 7

Right Park, Turn Signal Lamp..............8W-50-5, 7

Right Side Marker Lamp..................8W-50-5, 7

8W - 50 - 2 8W-50 FRONT LIGHTINGÐYJ VEHICLESJ

Page 1262 of 2158

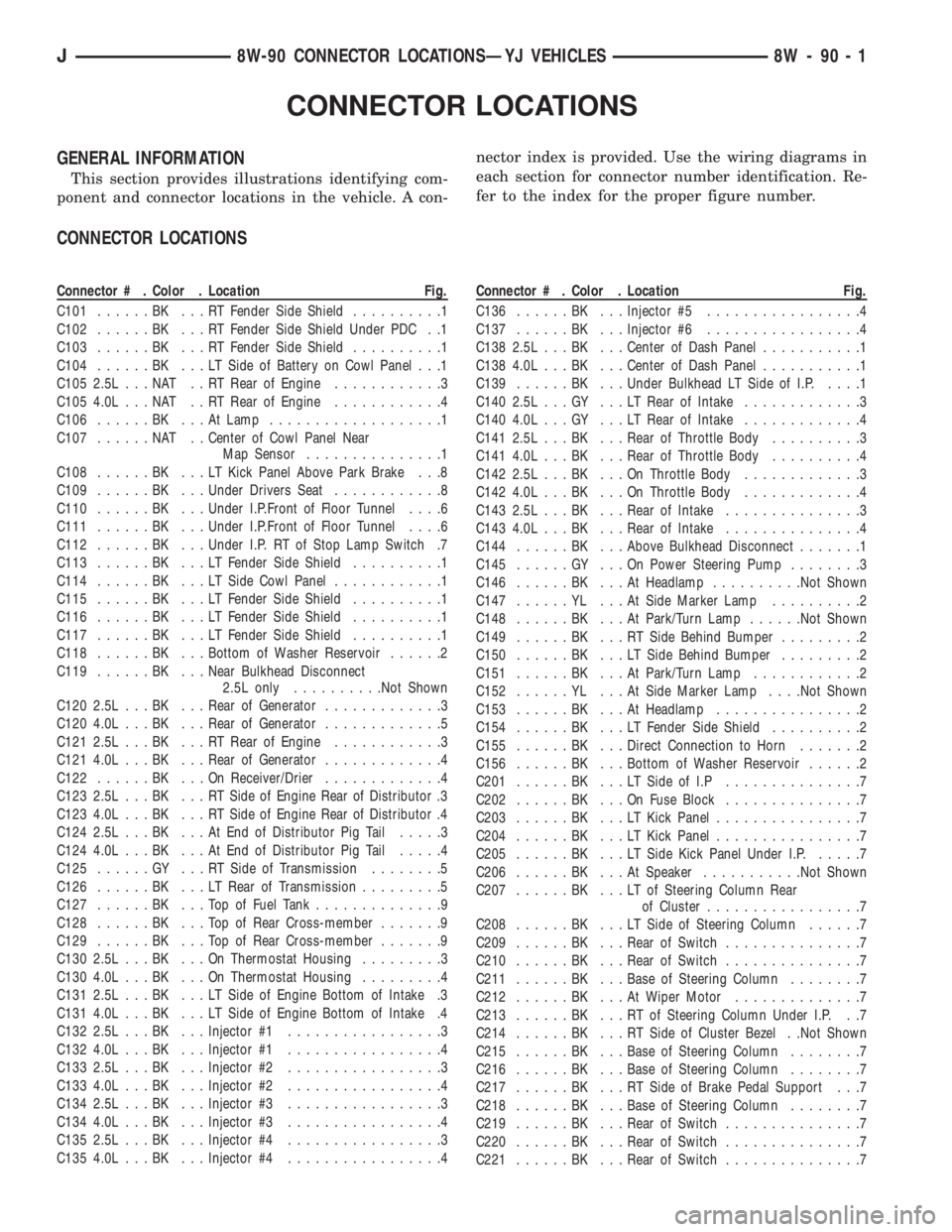

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # . Color . Location Fig.

C101......BK ...RTFender Side Shield..........1

C102......BK ...RTFender Side Shield Under PDC . .1

C103......BK ...RTFender Side Shield..........1

C104......BK ...LTSide of Battery on Cowl Panel . . .1

C105 2.5L . . . NAT . . RT Rear of Engine............3

C105 4.0L . . . NAT . . RT Rear of Engine............4

C106......BK ...AtLamp...................1

C107......NAT ..Center of Cowl Panel Near

Map Sensor...............1

C108......BK ...LTKick Panel Above Park Brake . . .8

C109......BK ...Under Drivers Seat............8

C110......BK ...Under I.P.Front of Floor Tunnel....6

C111......BK ...Under I.P.Front of Floor Tunnel....6

C112......BK ...Under I.P. RT of Stop Lamp Switch .7

C113......BK ...LTFender Side Shield..........1

C114......BK ...LTSide Cowl Panel............1

C115......BK ...LTFender Side Shield..........1

C116......BK ...LTFender Side Shield..........1

C117......BK ...LTFender Side Shield..........1

C118......BK ...Bottom of Washer Reservoir......2

C119......BK ...Near Bulkhead Disconnect

2.5L only..........Not Shown

C120 2.5L . . . BK . . . Rear of Generator.............3

C120 4.0L . . . BK . . . Rear of Generator.............5

C121 2.5L . . . BK . . . RT Rear of Engine............3

C121 4.0L . . . BK . . . Rear of Generator.............4

C122......BK ...OnReceiver/Drier.............4

C123 2.5L . . . BK . . . RT Side of Engine Rear of Distributor .3

C123 4.0L . . . BK . . . RT Side of Engine Rear of Distributor .4

C124 2.5L . . . BK . . . At End of Distributor Pig Tail.....3

C124 4.0L . . . BK . . . At End of Distributor Pig Tail.....4

C125......GY ...RTSide of Transmission........5

C126......BK ...LTRear of Transmission.........5

C127......BK ...TopofFuel Tank..............9

C128......BK ...TopofRear Cross-member.......9

C129......BK ...TopofRear Cross-member.......9

C130 2.5L . . . BK . . . On Thermostat Housing.........3

C130 4.0L . . . BK . . . On Thermostat Housing.........4

C131 2.5L . . . BK . . . LT Side of Engine Bottom of Intake .3

C131 4.0L . . . BK . . . LT Side of Engine Bottom of Intake .4

C132 2.5L . . . BK . . . Injector #1.................3

C132 4.0L . . . BK . . . Injector #1.................4

C133 2.5L . . . BK . . . Injector #2.................3

C133 4.0L . . . BK . . . Injector #2.................4

C134 2.5L . . . BK . . . Injector #3.................3

C134 4.0L . . . BK . . . Injector #3.................4

C135 2.5L . . . BK . . . Injector #4.................3

C135 4.0L . . . BK . . . Injector #4.................4Connector # . Color . Location Fig.

C136......BK ...Injector #5.................4

C137......BK ...Injector #6.................4

C138 2.5L . . . BK . . . Center of Dash Panel...........1

C138 4.0L . . . BK . . . Center of Dash Panel...........1

C139......BK ...Under Bulkhead LT Side of I.P.....1

C140 2.5L . . . GY . . . LT Rear of Intake.............3

C140 4.0L . . . GY . . . LT Rear of Intake.............4

C141 2.5L . . . BK . . . Rear of Throttle Body..........3

C141 4.0L . . . BK . . . Rear of Throttle Body..........4

C142 2.5L . . . BK . . . On Throttle Body.............3

C142 4.0L . . . BK . . . On Throttle Body.............4

C143 2.5L . . . BK . . . Rear of Intake...............3

C143 4.0L . . . BK . . . Rear of Intake...............4

C144......BK ...Above Bulkhead Disconnect.......1

C145......GY ...OnPower Steering Pump........3

C146......BK ...AtHeadlamp..........Not Shown

C147......YL ...AtSide Marker Lamp..........2

C148......BK ...AtPark/Turn Lamp......Not Shown

C149......BK ...RTSide Behind Bumper.........2

C150......BK ...LTSide Behind Bumper.........2

C151......BK ...AtPark/Turn Lamp............2

C152......YL ...AtSide Marker Lamp. . . .Not Shown

C153......BK ...AtHeadlamp................2

C154......BK ...LTFender Side Shield..........2

C155......BK ...Direct Connection to Horn.......2

C156......BK ...Bottom of Washer Reservoir......2

C201......BK ...LTSide of I.P...............7

C202......BK ...OnFuse Block...............7

C203......BK ...LTKick Panel................7

C204......BK ...LTKick Panel................7

C205......BK ...LTSide Kick Panel Under I.P......7

C206......BK ...AtSpeaker...........Not Shown

C207......BK ...LTofSteering Column Rear

of Cluster.................7

C208......BK ...LTSide of Steering Column......7

C209......BK ...Rear of Switch...............7

C210......BK ...Rear of Switch...............7

C211......BK ...Base of Steering Column........7

C212......BK ...AtWiper Motor..............7

C213......BK ...RTofSteering Column Under I.P. . .7

C214......BK ...RTSide of Cluster Bezel . .Not Shown

C215......BK ...Base of Steering Column........7

C216......BK ...Base of Steering Column........7

C217......BK ...RTSide of Brake Pedal Support . . .7

C218......BK ...Base of Steering Column........7

C219......BK ...Rear of Switch...............7

C220......BK ...Rear of Switch...............7

C221......BK ...Rear of Switch...............7

J8W-90 CONNECTOR LOCATIONSÐYJ VEHICLES 8W - 90 - 1

Page 1273 of 2158

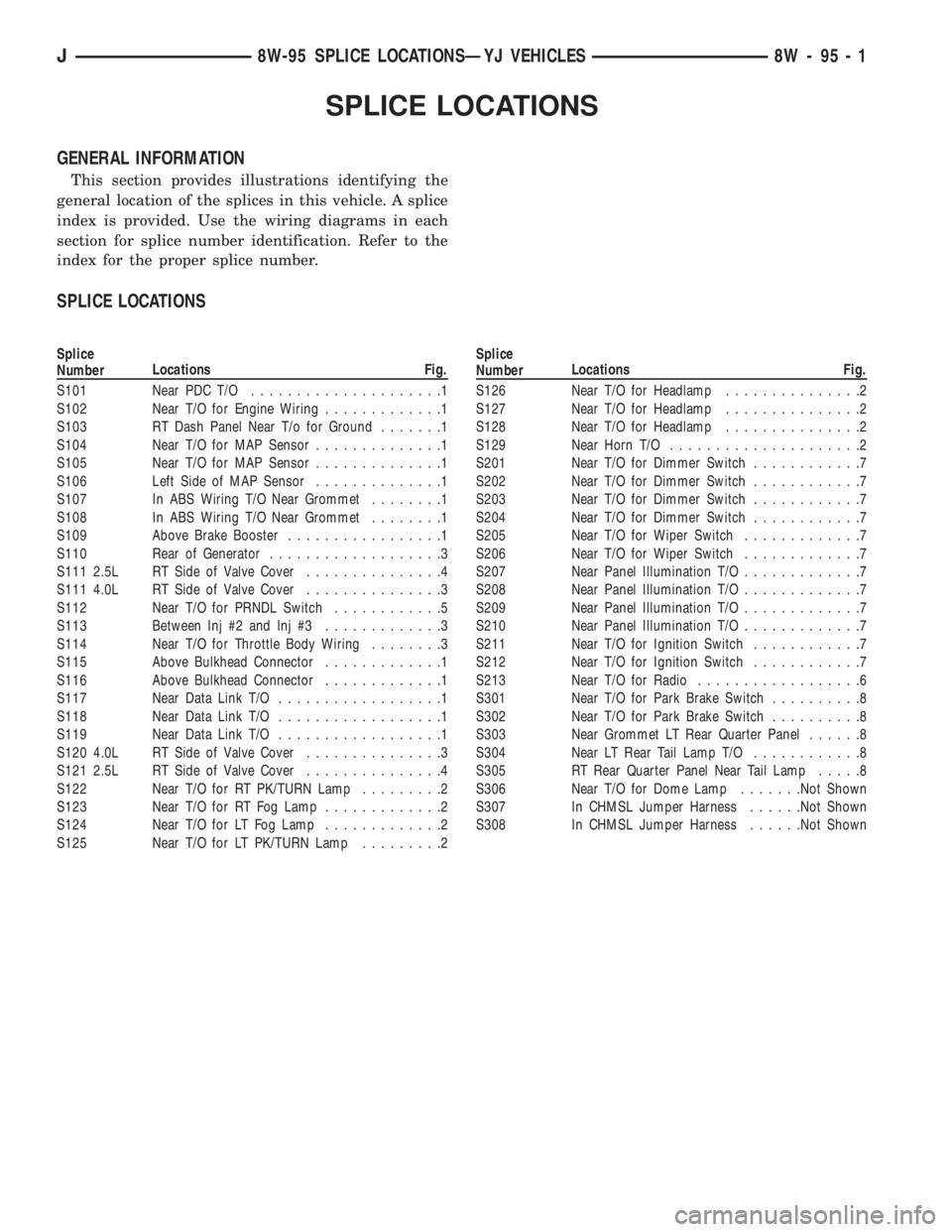

SPLICE LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for the proper splice number.

SPLICE LOCATIONS

Splice

NumberLocations Fig.

S101 Near PDC T/O.....................1

S102 Near T/O for Engine Wiring.............1

S103 RT Dash Panel Near T/o for Ground.......1

S104 Near T/O for MAP Sensor..............1

S105 Near T/O for MAP Sensor..............1

S106 Left Side of MAP Sensor..............1

S107 In ABS Wiring T/O Near Grommet........1

S108 In ABS Wiring T/O Near Grommet........1

S109 Above Brake Booster.................1

S110 Rear of Generator...................3

S111 2.5L RT Side of Valve Cover...............4

S111 4.0L RT Side of Valve Cover...............3

S112 Near T/O for PRNDL Switch............5

S113 Between Inj #2 and Inj #3.............3

S114 Near T/O for Throttle Body Wiring........3

S115 Above Bulkhead Connector.............1

S116 Above Bulkhead Connector.............1

S117 Near Data Link T/O..................1

S118 Near Data Link T/O..................1

S119 Near Data Link T/O..................1

S120 4.0L RT Side of Valve Cover...............3

S121 2.5L RT Side of Valve Cover...............4

S122 Near T/O for RT PK/TURN Lamp.........2

S123 Near T/O for RT Fog Lamp.............2

S124 Near T/O for LT Fog Lamp.............2

S125 Near T/O for LT PK/TURN Lamp.........2Splice

NumberLocations Fig.

S126 Near T/O for Headlamp...............2

S127 Near T/O for Headlamp...............2

S128 Near T/O for Headlamp...............2

S129 Near Horn T/O.....................2

S201 Near T/O for Dimmer Switch............7

S202 Near T/O for Dimmer Switch............7

S203 Near T/O for Dimmer Switch............7

S204 Near T/O for Dimmer Switch............7

S205 Near T/O for Wiper Switch.............7

S206 Near T/O for Wiper Switch.............7

S207 Near Panel Illumination T/O.............7

S208 Near Panel Illumination T/O.............7

S209 Near Panel Illumination T/O.............7

S210 Near Panel Illumination T/O.............7

S211 Near T/O for Ignition Switch............7

S212 Near T/O for Ignition Switch............7

S213 Near T/O for Radio..................6

S301 Near T/O for Park Brake Switch..........8

S302 Near T/O for Park Brake Switch..........8

S303 Near Grommet LT Rear Quarter Panel......8

S304 Near LT Rear Tail Lamp T/O............8

S305 RT Rear Quarter Panel Near Tail Lamp.....8

S306 Near T/O for Dome Lamp.......Not Shown

S307 In CHMSL Jumper Harness......Not Shown

S308 In CHMSL Jumper Harness......Not Shown

J8W-95 SPLICE LOCATIONSÐYJ VEHICLES 8W - 95 - 1