JEEP YJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 281 of 2158

(9) After power steering pump has been tightened

into position, recheck belt tension. Adjust if neces-

sary.

BELT SERVICEÐXJ MODELS WITH RIGHT HAND

DRIVE

The automatic belt tensioner is used only on

XJ models equipped with a 4.0L 6-cylinder en-

gine with right hand drive steering system.

REMOVAL

(1) Attach a socket/wrench to the mounting bolt of

the automatic tensioner pulley (Fig. 7).

(2) Rotate the tensioner assembly clockwise (as

viewed from front) until tension has been relieved

from belt.

(3) Remove belt from idler pulley (Fig. 7) first. Re-

move belt from vehicle.

(4) Check condition and alignment of all pulleys.

INSTALLATION

(1) Position the drive belt over all pulleysexcept

the idler pulley (Fig. 7).

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump ro-

tating in the wrong direction. Refer to (Fig. 6) for

correct engine belt routing. The correct belt with

the correct length must be used

(2) Attach a socket/wrench to the pulley mounting

bolt of the automatic tensioner (Fig. 7).

(3) Rotate the socket/wrench clockwise (Fig. 7).

Place the belt over the idler pulley. Let tensioner ro-

tate back into place. Remove wrench. Be sure belt is

properly seated in the grooves of all pulleys.

AUTOMATIC BELT TENSIONERÐXJ MODELS WITH

RIGHT HAND DRIVE

The automatic belt tensioner is used only on

XJ models equipped with a 4.0L 6-cylinder en-

gine with right hand drive steering system.

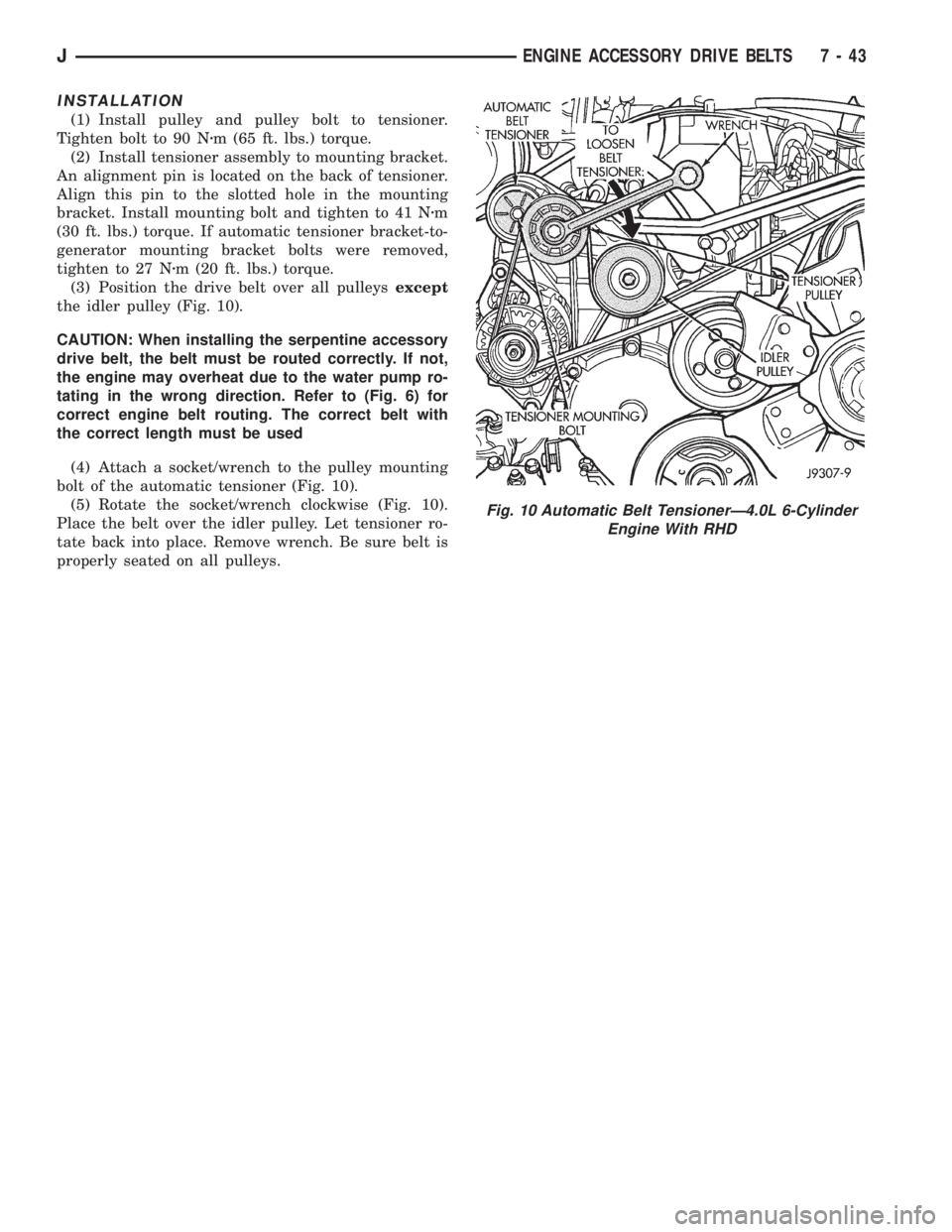

The drive belt is equipped with a spring loaded au-

tomatic belt tensioner (Fig. 10). This belt tensioner

will be used with all belt configurations such as with

or without air conditioning.

REMOVAL

(1) Attach a socket/wrench to the mounting bolt of

the automatic tensioner pulley (Fig. 10).

(2) Rotate the tensioner assembly clockwise (as

viewed from front) until tension has been relieved

from belt.

(3) Remove belt from idler pulley (Fig. 10) first.

Remove belt from automatic tensioner.

(4) Remove tensioner mounting bolt (Fig. 10) from

tensioner bracket. Remove tensioner from vehicle.

Note alignment pin on the back of tensioner.

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

(5) Remove tensioner pulley bolt. Remove pulley

from tensioner.

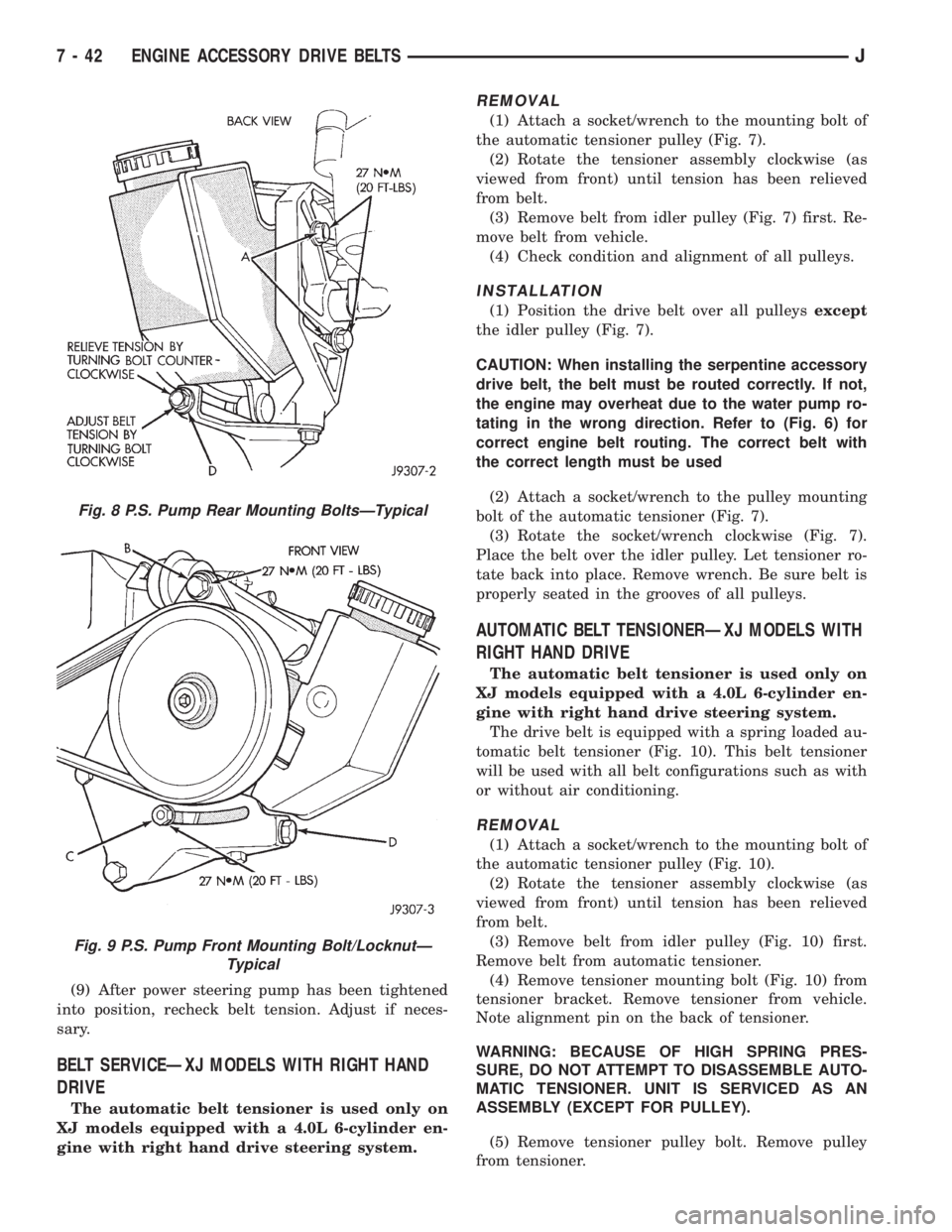

Fig. 8 P.S. Pump Rear Mounting BoltsÐTypical

Fig. 9 P.S. Pump Front Mounting Bolt/LocknutÐ

Typical

7 - 42 ENGINE ACCESSORY DRIVE BELTSJ

Page 282 of 2158

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 90 Nzm (65 ft. lbs.) torque.

(2) Install tensioner assembly to mounting bracket.

An alignment pin is located on the back of tensioner.

Align this pin to the slotted hole in the mounting

bracket. Install mounting bolt and tighten to 41 Nzm

(30 ft. lbs.) torque. If automatic tensioner bracket-to-

generator mounting bracket bolts were removed,

tighten to 27 Nzm (20 ft. lbs.) torque.

(3) Position the drive belt over all pulleysexcept

the idler pulley (Fig. 10).

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump ro-

tating in the wrong direction. Refer to (Fig. 6) for

correct engine belt routing. The correct belt with

the correct length must be used

(4) Attach a socket/wrench to the pulley mounting

bolt of the automatic tensioner (Fig. 10).

(5) Rotate the socket/wrench clockwise (Fig. 10).

Place the belt over the idler pulley. Let tensioner ro-

tate back into place. Remove wrench. Be sure belt is

properly seated on all pulleys.

Fig. 10 Automatic Belt TensionerÐ4.0L 6-Cylinder

Engine With RHD

JENGINE ACCESSORY DRIVE BELTS 7 - 43

Page 283 of 2158

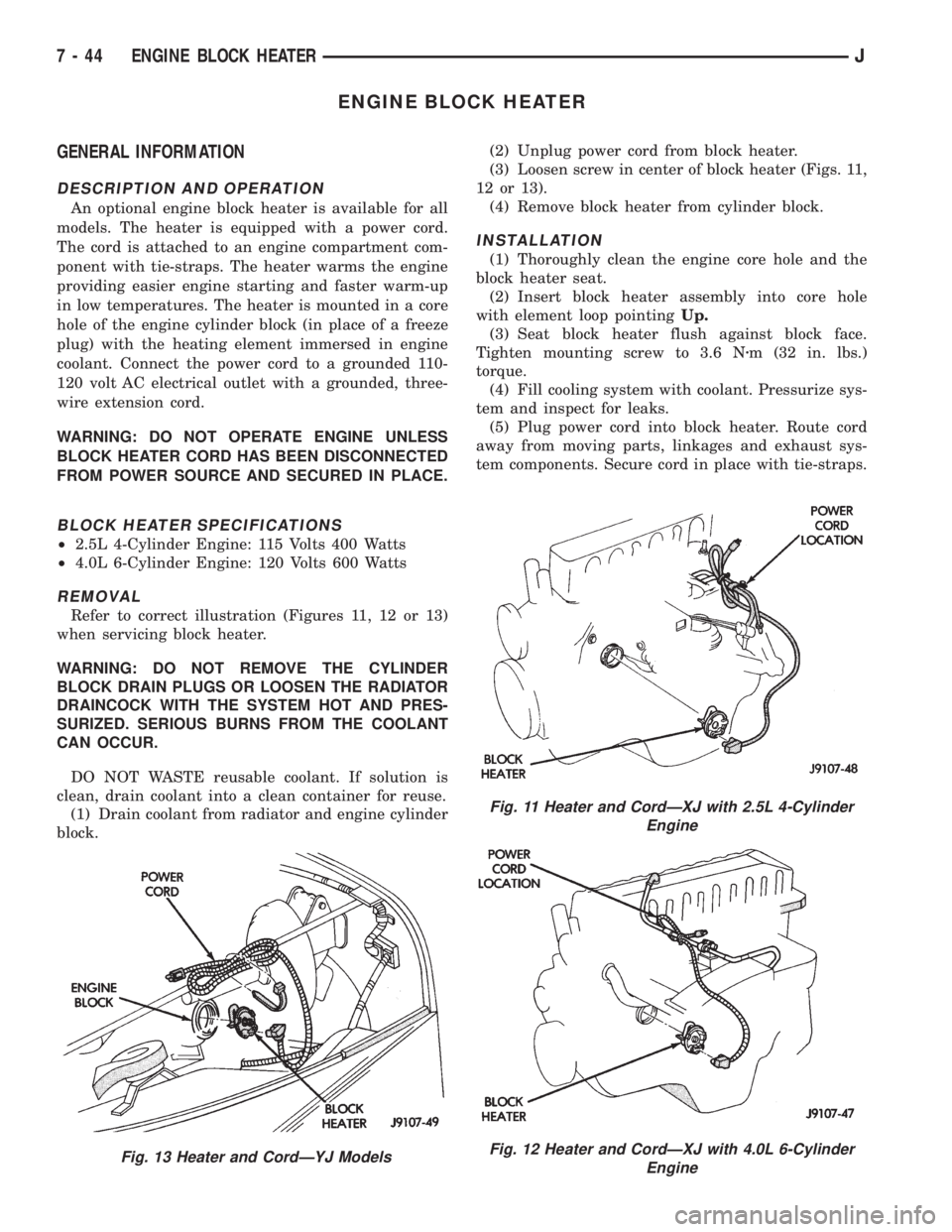

ENGINE BLOCK HEATER

GENERAL INFORMATION

DESCRIPTION AND OPERATION

An optional engine block heater is available for all

models. The heater is equipped with a power cord.

The cord is attached to an engine compartment com-

ponent with tie-straps. The heater warms the engine

providing easier engine starting and faster warm-up

in low temperatures. The heater is mounted in a core

hole of the engine cylinder block (in place of a freeze

plug) with the heating element immersed in engine

coolant. Connect the power cord to a grounded 110-

120 volt AC electrical outlet with a grounded, three-

wire extension cord.

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

BLOCK HEATER SPECIFICATIONS

²2.5L 4-Cylinder Engine: 115 Volts 400 Watts

²4.0L 6-Cylinder Engine: 120 Volts 600 Watts

REMOVAL

Refer to correct illustration (Figures 11, 12 or 13)

when servicing block heater.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

(1) Drain coolant from radiator and engine cylinder

block.(2) Unplug power cord from block heater.

(3) Loosen screw in center of block heater (Figs. 11,

12 or 13).

(4) Remove block heater from cylinder block.

INSTALLATION

(1) Thoroughly clean the engine core hole and the

block heater seat.

(2) Insert block heater assembly into core hole

with element loop pointingUp.

(3) Seat block heater flush against block face.

Tighten mounting screw to 3.6 Nzm (32 in. lbs.)

torque.

(4) Fill cooling system with coolant. Pressurize sys-

tem and inspect for leaks.

(5) Plug power cord into block heater. Route cord

away from moving parts, linkages and exhaust sys-

tem components. Secure cord in place with tie-straps.

Fig. 13 Heater and CordÐYJ Models

Fig. 11 Heater and CordÐXJ with 2.5L 4-Cylinder

Engine

Fig. 12 Heater and CordÐXJ with 4.0L 6-Cylinder

Engine

7 - 44 ENGINE BLOCK HEATERJ

Page 284 of 2158

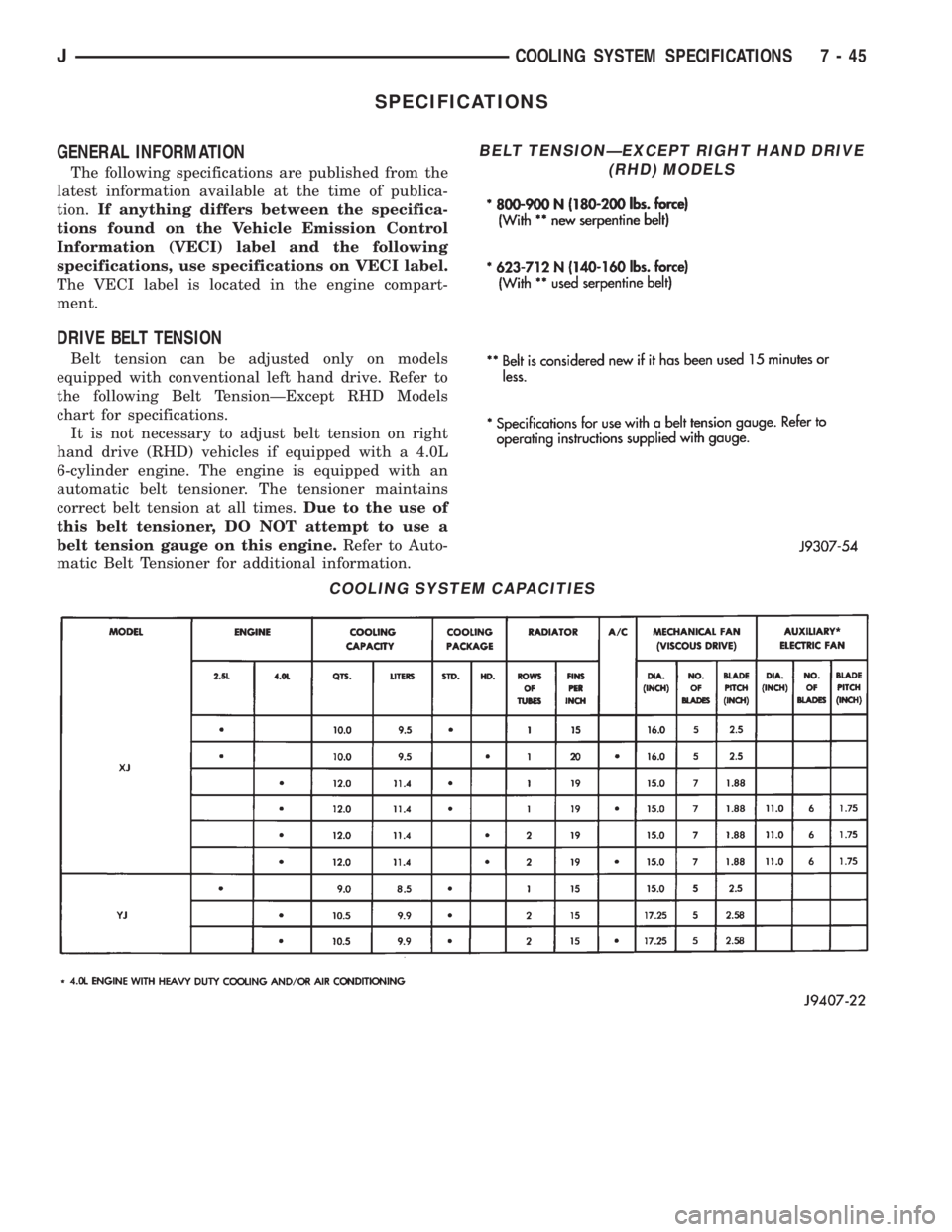

SPECIFICATIONS

GENERAL INFORMATION

The following specifications are published from the

latest information available at the time of publica-

tion.If anything differs between the specifica-

tions found on the Vehicle Emission Control

Information (VECI) label and the following

specifications, use specifications on VECI label.

The VECI label is located in the engine compart-

ment.

DRIVE BELT TENSION

Belt tension can be adjusted only on models

equipped with conventional left hand drive. Refer to

the following Belt TensionÐExcept RHD Models

chart for specifications.

It is not necessary to adjust belt tension on right

hand drive (RHD) vehicles if equipped with a 4.0L

6-cylinder engine. The engine is equipped with an

automatic belt tensioner. The tensioner maintains

correct belt tension at all times.Due to the use of

this belt tensioner, DO NOT attempt to use a

belt tension gauge on this engine.Refer to Auto-

matic Belt Tensioner for additional information.

COOLING SYSTEM CAPACITIES

BELT TENSIONÐEXCEPT RIGHT HAND DRIVE

(RHD) MODELS

JCOOLING SYSTEM SPECIFICATIONS 7 - 45

Page 285 of 2158

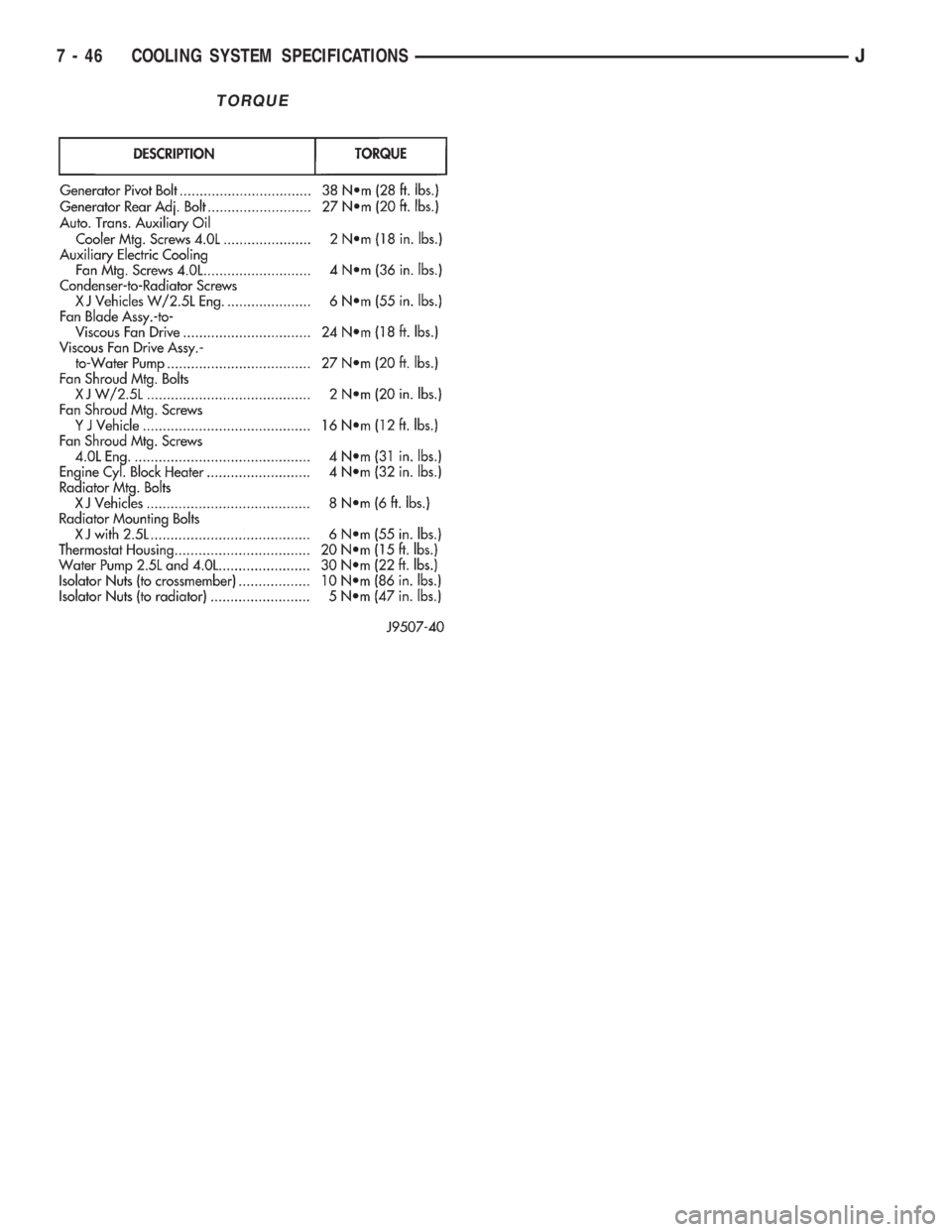

TORQUE

7 - 46 COOLING SYSTEM SPECIFICATIONSJ

Page 286 of 2158

ELECTRICAL

GROUP INDEX

Group Group

AUDIO SYSTEMS........................ 8F

BATTERY/STARTER/GENERATOR SERVICE.... 8B

BATTERY/STARTING/CHARGING SYSTEMS

DIAGNOSTICS......................... 8A

CHIME/BUZZER WARNING SYSTEMS........ 8U

HORNS................................ 8G

IGNITION SYSTEMS...................... 8D

INSTRUMENT PANEL AND GAUGES......... 8E

LAMPS................................ 8L

OVERHEAD CONSOLE.................... 8C

POWER LOCKS.......................... 8P

POWER MIRRORS....................... 8TPOWER SEATS.......................... 8R

POWER WINDOWS....................... 8S

REAR WINDOW DEFOGGER............... 8N

RESTRAINT SYSTEMS................... 8M

TURN SIGNAL AND HAZARD WARNING

SYSTEMS............................. 8J

VEHICLE SPEED CONTROL SYSTEM......... 8H

WIPER AND WASHER SYSTEMS............ 8K

XJ WIRING DIAGRAMS-LEFT HAND DRIVE . . . 8W

XJ WIRING DIAGRAMS-RIGHT HAND DRIVE . 8W

YJ WIRING DIAGRAMS.................. 8W

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS

CONTENTS

page page

BATTERY............................... 2

CHARGING SYSTEM..................... 17

IGNITION-OFF DRAW.................... 10SPECIFICATIONS........................ 23

STARTING SYSTEM...................... 11

USING ON-BOARD DIAGNOSTIC SYSTEM.... 22

GENERAL INFORMATION

The battery, starting, and charging systems operate

with one another; therefore, they must be tested as a

complete system. In order for the vehicle to start and

charge properly, all of the components involved in

these systems must perform within specifications.

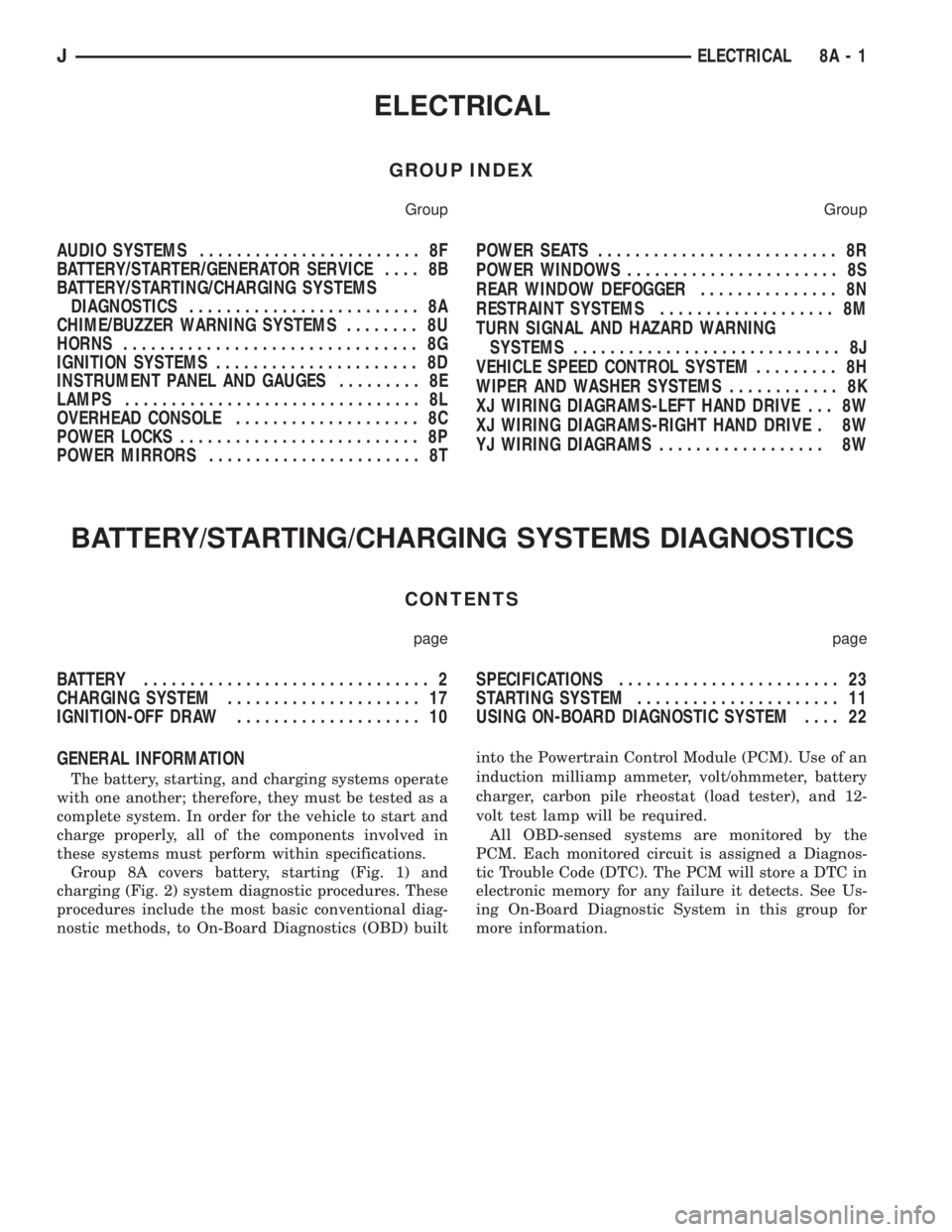

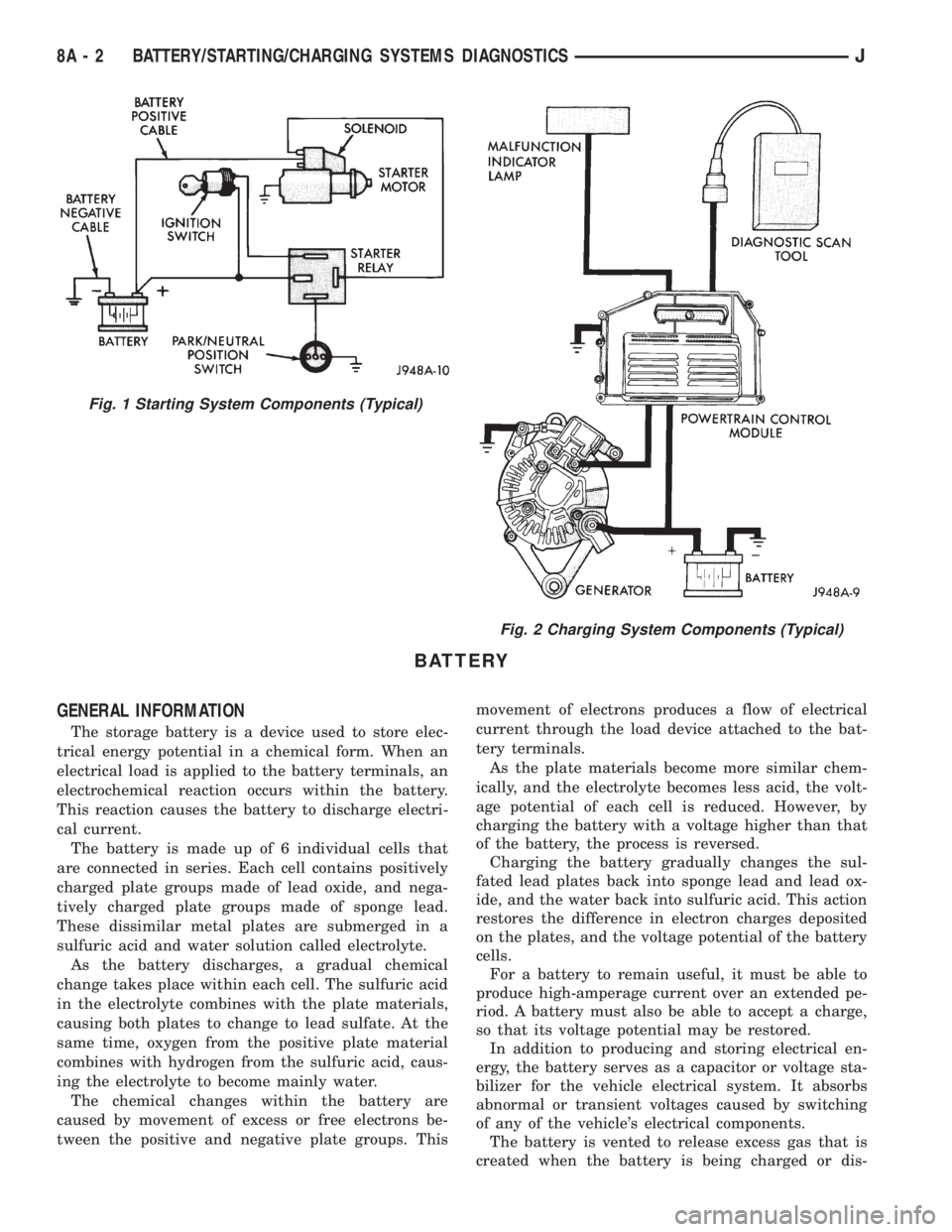

Group 8A covers battery, starting (Fig. 1) and

charging (Fig. 2) system diagnostic procedures. These

procedures include the most basic conventional diag-

nostic methods, to On-Board Diagnostics (OBD) builtinto the Powertrain Control Module (PCM). Use of an

induction milliamp ammeter, volt/ohmmeter, battery

charger, carbon pile rheostat (load tester), and 12-

volt test lamp will be required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See Us-

ing On-Board Diagnostic System in this group for

more information.

JELECTRICAL 8A - 1

Page 287 of 2158

BATTERY

GENERAL INFORMATION

The storage battery is a device used to store elec-

trical energy potential in a chemical form. When an

electrical load is applied to the battery terminals, an

electrochemical reaction occurs within the battery.

This reaction causes the battery to discharge electri-

cal current.

The battery is made up of 6 individual cells that

are connected in series. Each cell contains positively

charged plate groups made of lead oxide, and nega-

tively charged plate groups made of sponge lead.

These dissimilar metal plates are submerged in a

sulfuric acid and water solution called electrolyte.

As the battery discharges, a gradual chemical

change takes place within each cell. The sulfuric acid

in the electrolyte combines with the plate materials,

causing both plates to change to lead sulfate. At the

same time, oxygen from the positive plate material

combines with hydrogen from the sulfuric acid, caus-

ing the electrolyte to become mainly water.

The chemical changes within the battery are

caused by movement of excess or free electrons be-

tween the positive and negative plate groups. Thismovement of electrons produces a flow of electrical

current through the load device attached to the bat-

tery terminals.

As the plate materials become more similar chem-

ically, and the electrolyte becomes less acid, the volt-

age potential of each cell is reduced. However, by

charging the battery with a voltage higher than that

of the battery, the process is reversed.

Charging the battery gradually changes the sul-

fated lead plates back into sponge lead and lead ox-

ide, and the water back into sulfuric acid. This action

restores the difference in electron charges deposited

on the plates, and the voltage potential of the battery

cells.

For a battery to remain useful, it must be able to

produce high-amperage current over an extended pe-

riod. A battery must also be able to accept a charge,

so that its voltage potential may be restored.

In addition to producing and storing electrical en-

ergy, the battery serves as a capacitor or voltage sta-

bilizer for the vehicle electrical system. It absorbs

abnormal or transient voltages caused by switching

of any of the vehicle's electrical components.

The battery is vented to release excess gas that is

created when the battery is being charged or dis-

Fig. 1 Starting System Components (Typical)

Fig. 2 Charging System Components (Typical)

8A - 2 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 288 of 2158

charged. However, even with these vents, hydrogen

gas can collect in or around the battery. If hydrogen

gas is exposed to flame or sparks, it can ignite.

If the electrolyte level is low, the battery could arc

internally and explode. If the battery is equipped

with removable cell caps, add distilled water when-

ever the electrolyte level is below the top of the

plates. If the battery cell caps cannot be removed, the

battery must be replaced when the electrolyte level is

low.

WARNING: DO NOT ATTEMPT TO ASSIST BOOST,

CHARGE, OR TEST BATTERY WHEN ELECTRO-

LYTE LEVEL IS BELOW THE TOP OF THE PLATES.

PERSONAL INJURY MAY OCCUR.

BATTERY RATINGS

Currently, there are 2 commonly accepted methods

for rating and comparing battery performance. These

ratings are called Cold Cranking Amperage (CCA),

and Reserve Capacity (RC). Be certain that a replace-

ment battery has CCA and RC ratings that equal or

exceed the original equipment specification for the

vehicle being serviced. See Battery Classifications

and Ratings charts in Specifications at the back of

this group.

COLD CRANKING AMPERAGE

The Cold Cranking Amperage (CCA) rating speci-

fies how much current (in amperes) the battery can

deliver for 30 seconds at -17.7ÉC (0ÉF). Terminal volt-

age must not fall below 7.2 volts during or after the

30 second discharge. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

RESERVE CAPACITY

The Reserve Capacity (RC) rating specifies the

time (in minutes) it takes for battery terminal volt-

age to fall below 10.2 volts at a discharge rate of 25

amps. RC is determined with the battery fully-

charged at 26.7ÉC (80ÉF). This rating estimates how

long the battery might last after a charging system

failure, under minimum electrical load.

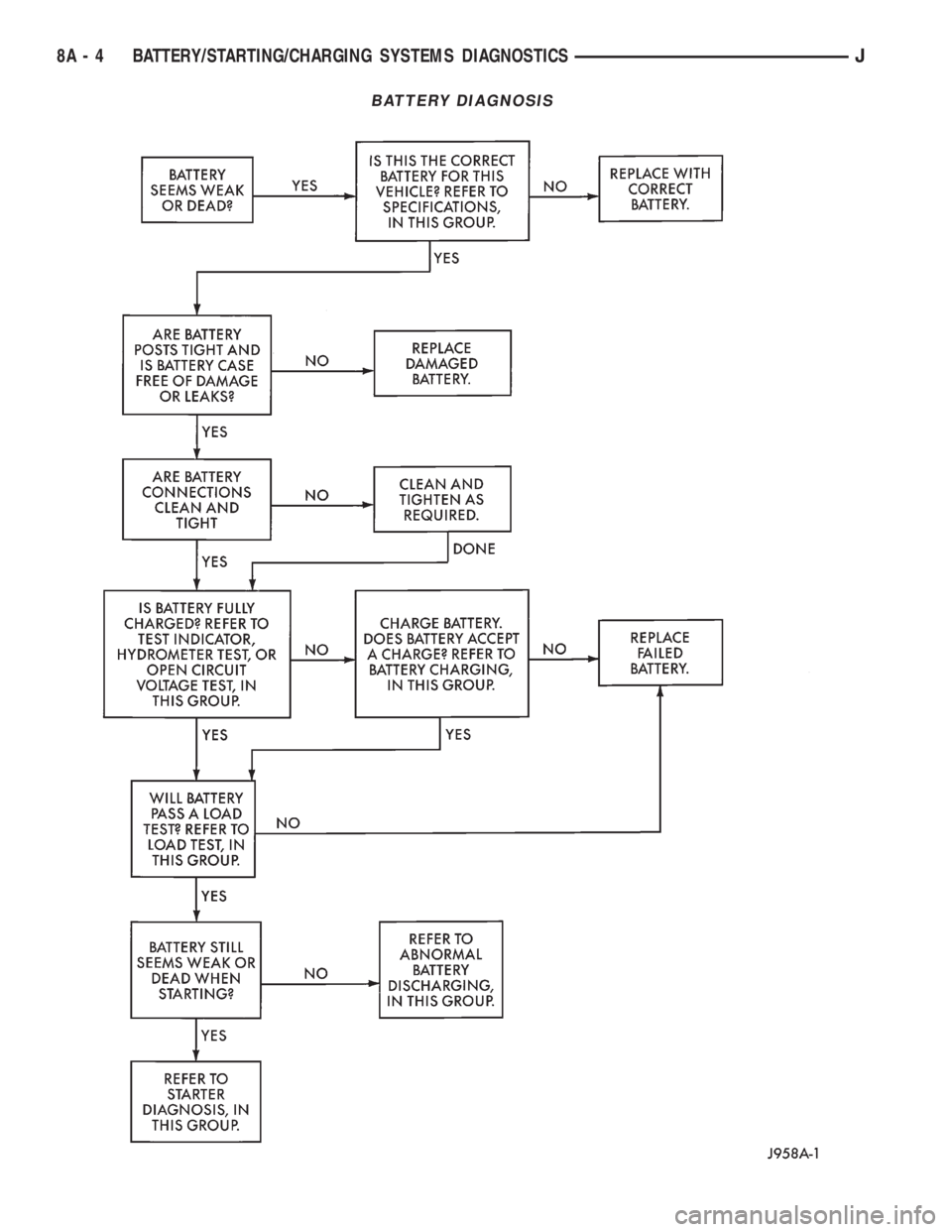

DIAGNOSIS

The battery must be completely charged and the

top, posts, and terminal clamps should be properly

cleaned before diagnostic procedures are performed.

Refer to Group 8B - Battery/Starter/Generator Ser-

vice for more information.

The condition of a battery is determined by two cri-

teria:

(1)State-Of-ChargeThis can be determined by

viewing the built-in test indicator, by checking spe-

cific gravity of the electrolyte (hydrometer test), or by

checking battery voltage (open circuit voltage test).(2)Cranking CapacityThis can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

If the battery has a built-in test indicator, use this

test first. If it has no test indicator, but has remov-

able cell caps, perform the hydrometer test first. If

cell caps are not removable, or a hydrometer is not

available, perform the open circuit voltage test first.

The battery must be charged before proceeding

with a load test if:

²the built-in test indicator has a black or dark color

visible

²the temperature corrected specific gravity is less

than 1.235

²the open circuit voltage is less than 12.4 volts.

A battery that will not accept a charge is faulty

and further testing is not required. A battery that is

fully-charged, but does not pass the load test is

faulty and must be replaced.

Completely discharged batteries may take

several hours to accept a charge. See Charging

Completely Discharged Battery.

A battery is fully-charged when:

²all cells are gassing freely during charging

²a green color is visible in the sight glass of the

built-in test indicator

²three corrected specific gravity tests, taken at

1-hour intervals, indicate no increase in specific grav-

ity

²open circuit voltage is 12.4 volts or greater.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging:

(1) Corroded battery posts and terminals.

(2) Loose or worn generator drive belt.

(3) Electrical loads that exceed the output of the

charging system, possibly due to equipment installed

after manufacture or repeated short trip use.

(4) Slow driving speeds (heavy traffic conditions) or

prolonged idling with high-amperage draw systems

in use.

(5) Faulty circuit or component causing excessive

ignition-off draw. See Ignition-Off Draw in this group

for diagnosis.

(6) Faulty charging system.

(7) Faulty or incorrect battery.

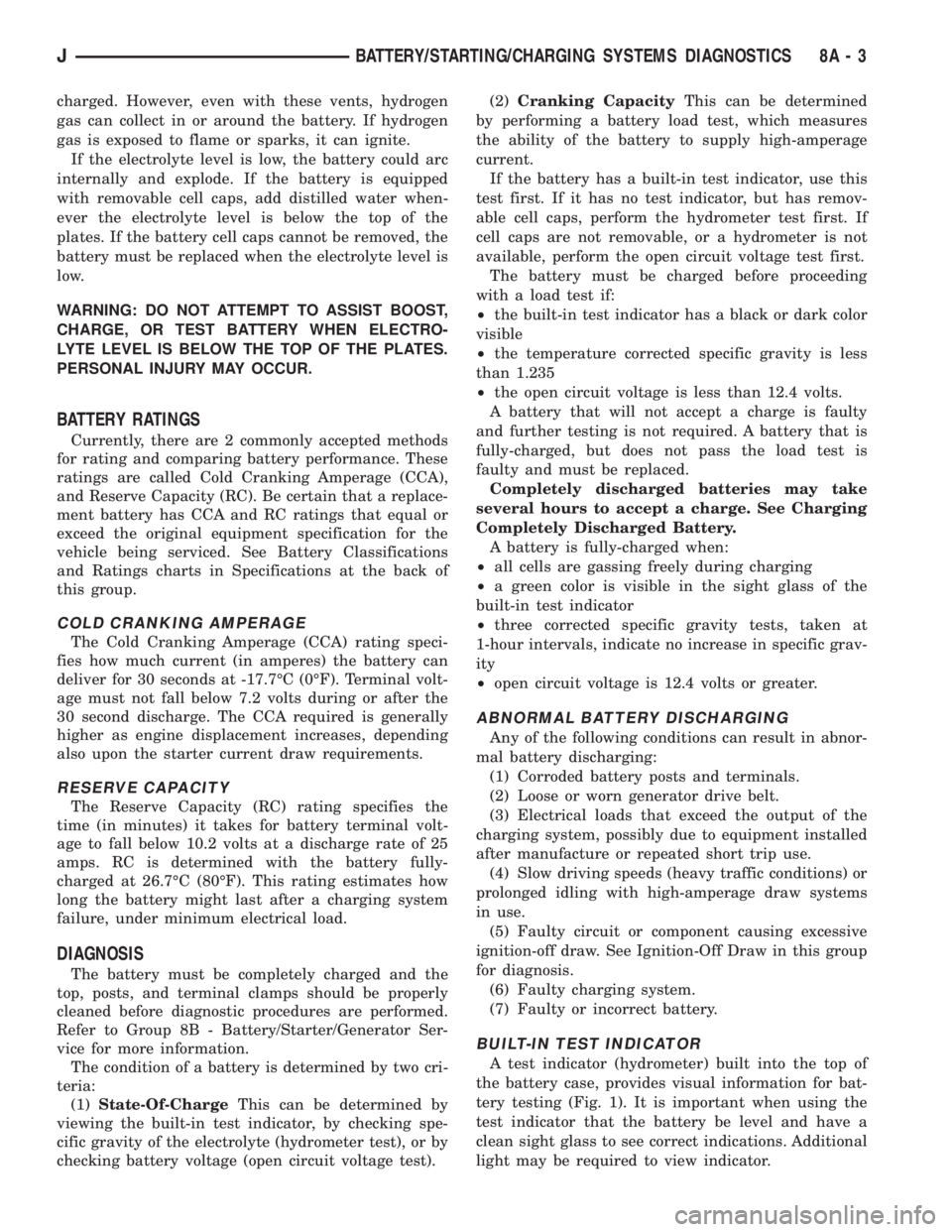

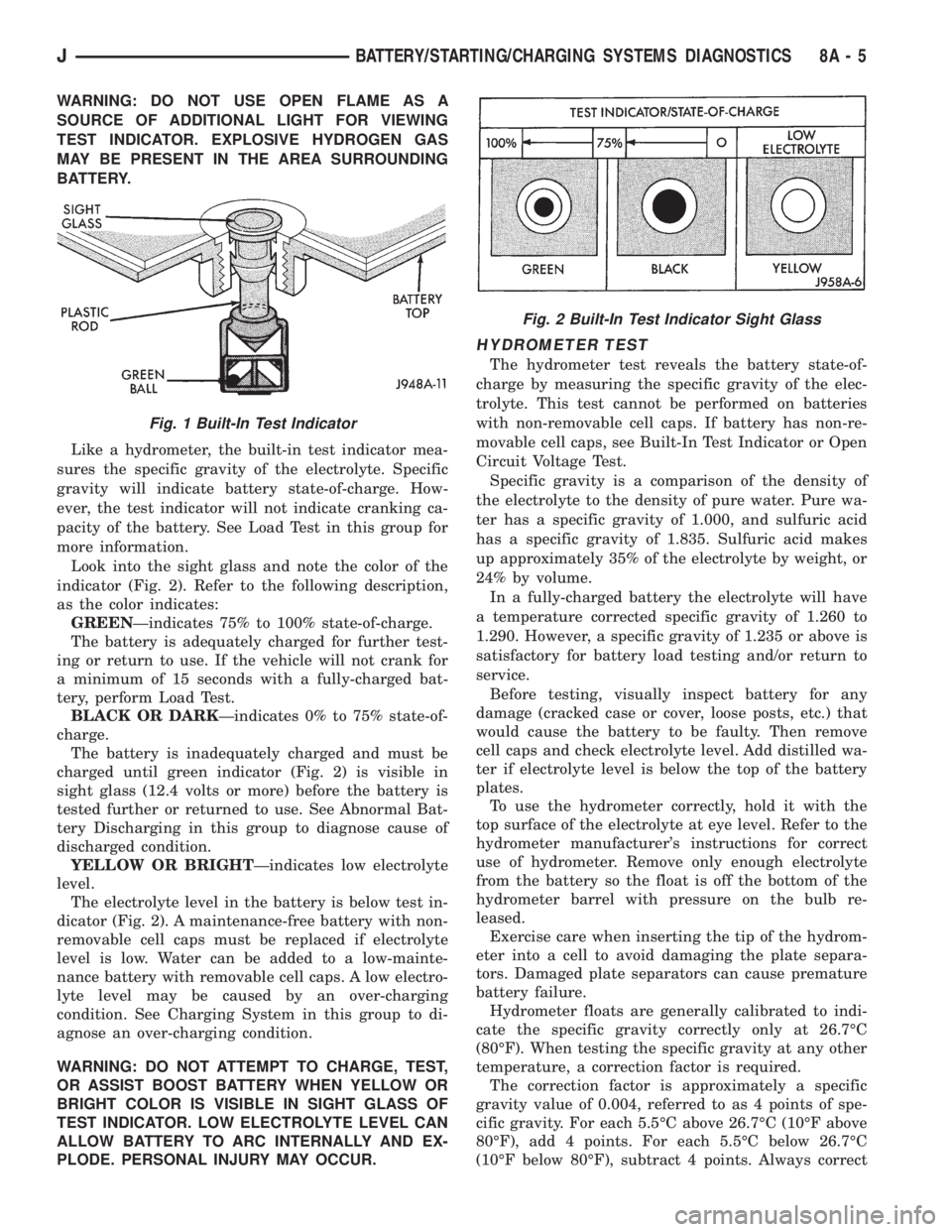

BUILT-IN TEST INDICATOR

A test indicator (hydrometer) built into the top of

the battery case, provides visual information for bat-

tery testing (Fig. 1). It is important when using the

test indicator that the battery be level and have a

clean sight glass to see correct indications. Additional

light may be required to view indicator.

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 3

Page 289 of 2158

BATTERY DIAGNOSIS

8A - 4 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 290 of 2158

WARNING: DO NOT USE OPEN FLAME AS A

SOURCE OF ADDITIONAL LIGHT FOR VIEWING

TEST INDICATOR. EXPLOSIVE HYDROGEN GAS

MAY BE PRESENT IN THE AREA SURROUNDING

BATTERY.

Like a hydrometer, the built-in test indicator mea-

sures the specific gravity of the electrolyte. Specific

gravity will indicate battery state-of-charge. How-

ever, the test indicator will not indicate cranking ca-

pacity of the battery. See Load Test in this group for

more information.

Look into the sight glass and note the color of the

indicator (Fig. 2). Refer to the following description,

as the color indicates:

GREENÐindicates 75% to 100% state-of-charge.

The battery is adequately charged for further test-

ing or return to use. If the vehicle will not crank for

a minimum of 15 seconds with a fully-charged bat-

tery, perform Load Test.

BLACK OR DARKÐindicates 0% to 75% state-of-

charge.

The battery is inadequately charged and must be

charged until green indicator (Fig. 2) is visible in

sight glass (12.4 volts or more) before the battery is

tested further or returned to use. See Abnormal Bat-

tery Discharging in this group to diagnose cause of

discharged condition.

YELLOW OR BRIGHTÐindicates low electrolyte

level.

The electrolyte level in the battery is below test in-

dicator (Fig. 2). A maintenance-free battery with non-

removable cell caps must be replaced if electrolyte

level is low. Water can be added to a low-mainte-

nance battery with removable cell caps. A low electro-

lyte level may be caused by an over-charging

condition. See Charging System in this group to di-

agnose an over-charging condition.

WARNING: DO NOT ATTEMPT TO CHARGE, TEST,

OR ASSIST BOOST BATTERY WHEN YELLOW OR

BRIGHT COLOR IS VISIBLE IN SIGHT GLASS OF

TEST INDICATOR. LOW ELECTROLYTE LEVEL CAN

ALLOW BATTERY TO ARC INTERNALLY AND EX-

PLODE. PERSONAL INJURY MAY OCCUR.

HYDROMETER TEST

The hydrometer test reveals the battery state-of-

charge by measuring the specific gravity of the elec-

trolyte. This test cannot be performed on batteries

with non-removable cell caps. If battery has non-re-

movable cell caps, see Built-In Test Indicator or Open

Circuit Voltage Test.

Specific gravity is a comparison of the density of

the electrolyte to the density of pure water. Pure wa-

ter has a specific gravity of 1.000, and sulfuric acid

has a specific gravity of 1.835. Sulfuric acid makes

up approximately 35% of the electrolyte by weight, or

24% by volume.

In a fully-charged battery the electrolyte will have

a temperature corrected specific gravity of 1.260 to

1.290. However, a specific gravity of 1.235 or above is

satisfactory for battery load testing and/or return to

service.

Before testing, visually inspect battery for any

damage (cracked case or cover, loose posts, etc.) that

would cause the battery to be faulty. Then remove

cell caps and check electrolyte level. Add distilled wa-

ter if electrolyte level is below the top of the battery

plates.

To use the hydrometer correctly, hold it with the

top surface of the electrolyte at eye level. Refer to the

hydrometer manufacturer's instructions for correct

use of hydrometer. Remove only enough electrolyte

from the battery so the float is off the bottom of the

hydrometer barrel with pressure on the bulb re-

leased.

Exercise care when inserting the tip of the hydrom-

eter into a cell to avoid damaging the plate separa-

tors. Damaged plate separators can cause premature

battery failure.

Hydrometer floats are generally calibrated to indi-

cate the specific gravity correctly only at 26.7ÉC

(80ÉF). When testing the specific gravity at any other

temperature, a correction factor is required.

The correction factor is approximately a specific

gravity value of 0.004, referred to as 4 points of spe-

cific gravity. For each 5.5ÉC above 26.7ÉC (10ÉF above

80ÉF), add 4 points. For each 5.5ÉC below 26.7ÉC

(10ÉF below 80ÉF), subtract 4 points. Always correct

Fig. 1 Built-In Test Indicator

Fig. 2 Built-In Test Indicator Sight Glass

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 5