spark plugs replace JEEP YJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1347 of 2158

(9) If equipped, disconnect the power steering

pump bracket. Set the pump and bracket aside. DO

NOT disconnect the hoses.

(10) Perform the Fuel System Pressure Release

procedure (refer to Group 14, Fuel System).

(11) Remove the fuel lines and vacuum advance

hose.

(12) Remove the intake and engine exhaust mani-

folds from the engine cylinder head (refer to Group

11, Exhaust System and Intake Manifold for the

proper procedures).

(13) Disconnect the ignition wires and remove the

spark plugs.

(14) Disconnect the temperature sending unit wire

connector.

(15) Remove the ignition coil and bracket assem-

bly.

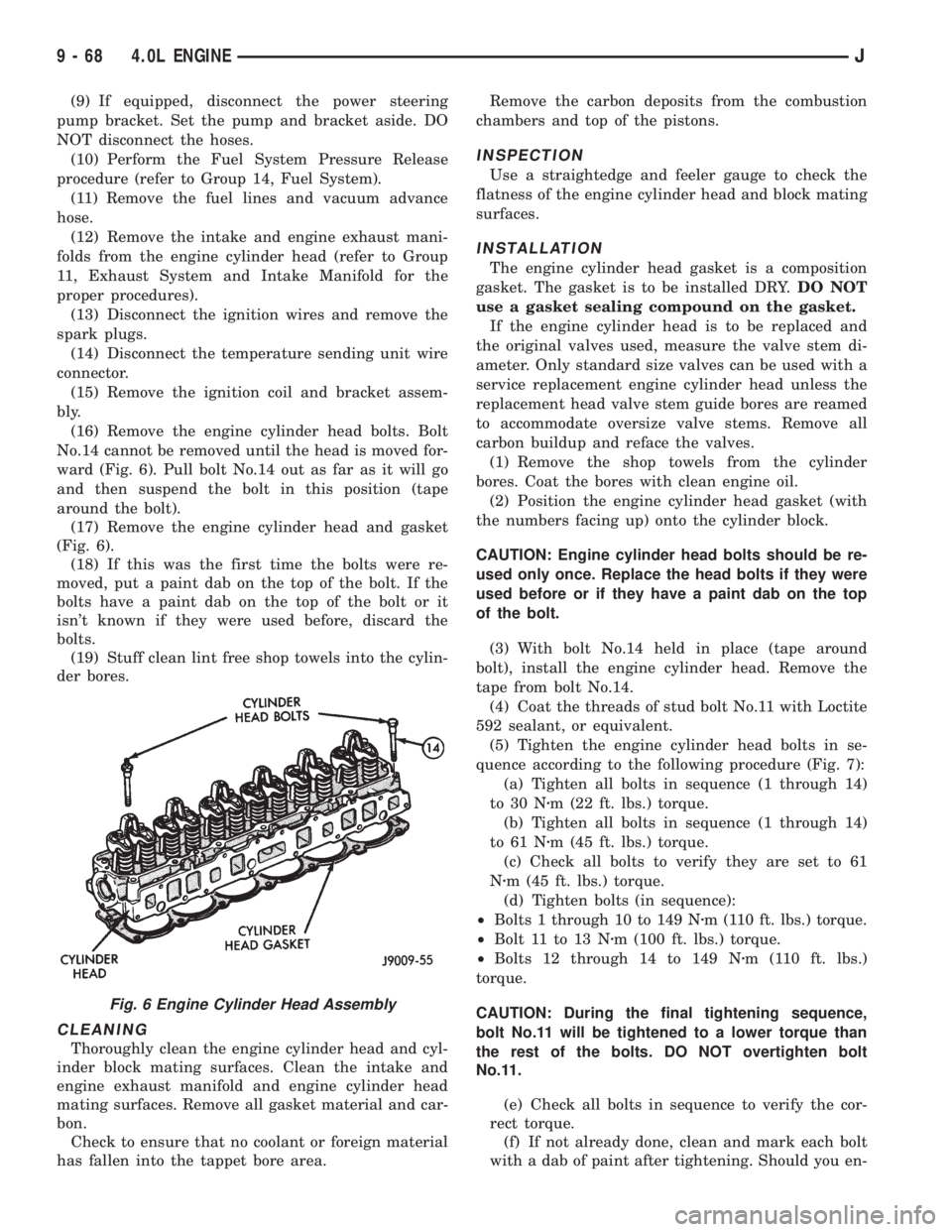

(16) Remove the engine cylinder head bolts. Bolt

No.14 cannot be removed until the head is moved for-

ward (Fig. 6). Pull bolt No.14 out as far as it will go

and then suspend the bolt in this position (tape

around the bolt).

(17) Remove the engine cylinder head and gasket

(Fig. 6).

(18) If this was the first time the bolts were re-

moved, put a paint dab on the top of the bolt. If the

bolts have a paint dab on the top of the bolt or it

isn't known if they were used before, discard the

bolts.

(19) Stuff clean lint free shop towels into the cylin-

der bores.

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

engine exhaust manifold and engine cylinder head

mating surfaces. Remove all gasket material and car-

bon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces.

INSTALLATION

The engine cylinder head gasket is a composition

gasket. The gasket is to be installed DRY.DO NOT

use a gasket sealing compound on the gasket.

If the engine cylinder head is to be replaced and

the original valves used, measure the valve stem di-

ameter. Only standard size valves can be used with a

service replacement engine cylinder head unless the

replacement head valve stem guide bores are reamed

to accommodate oversize valve stems. Remove all

carbon buildup and reface the valves.

(1) Remove the shop towels from the cylinder

bores. Coat the bores with clean engine oil.

(2) Position the engine cylinder head gasket (with

the numbers facing up) onto the cylinder block.

CAUTION: Engine cylinder head bolts should be re-

used only once. Replace the head bolts if they were

used before or if they have a paint dab on the top

of the bolt.

(3) With bolt No.14 held in place (tape around

bolt), install the engine cylinder head. Remove the

tape from bolt No.14.

(4) Coat the threads of stud bolt No.11 with Loctite

592 sealant, or equivalent.

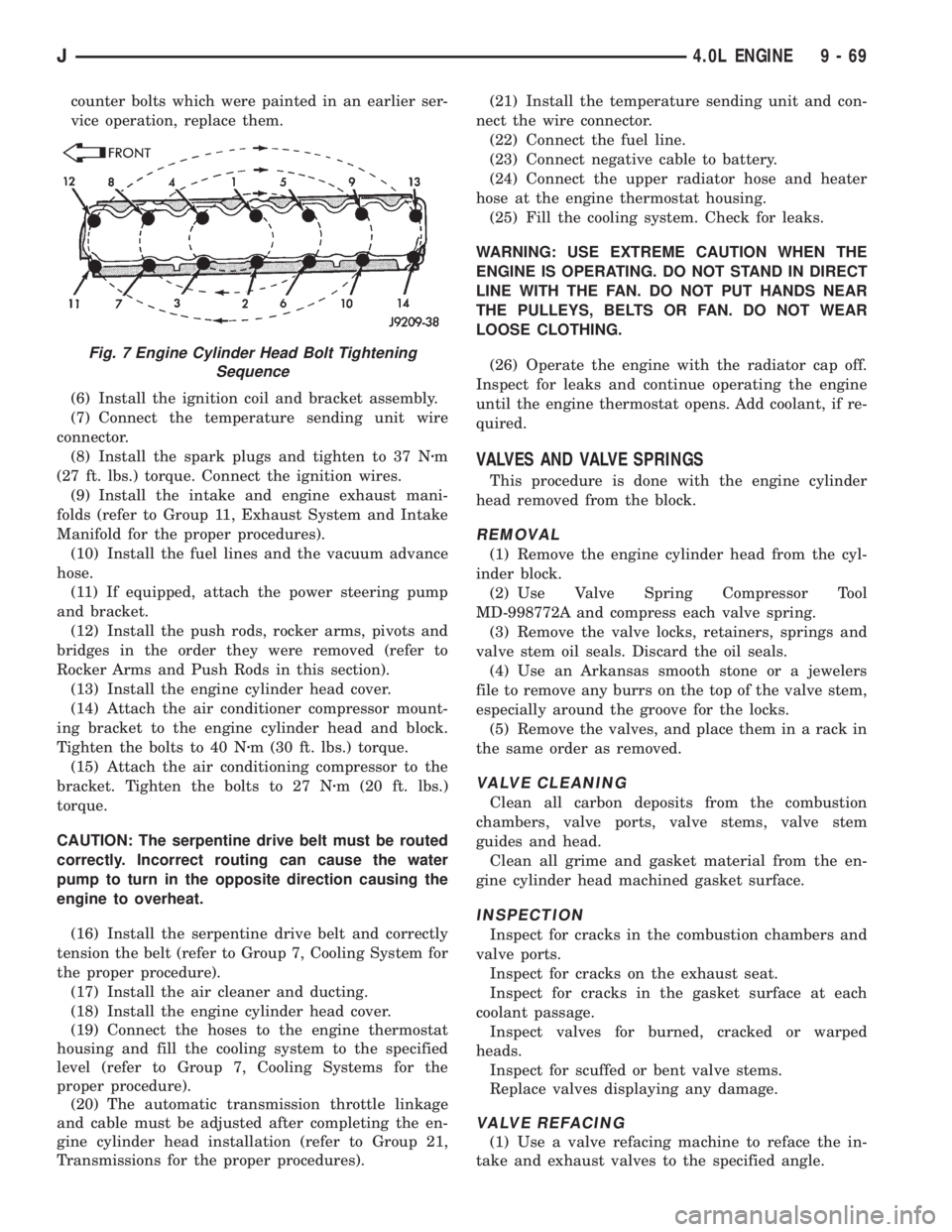

(5) Tighten the engine cylinder head bolts in se-

quence according to the following procedure (Fig. 7):

(a) Tighten all bolts in sequence (1 through 14)

to 30 Nzm (22 ft. lbs.) torque.

(b) Tighten all bolts in sequence (1 through 14)

to 61 Nzm (45 ft. lbs.) torque.

(c) Check all bolts to verify they are set to 61

Nzm (45 ft. lbs.) torque.

(d) Tighten bolts (in sequence):

²Bolts 1 through 10 to 149 Nzm (110 ft. lbs.) torque.

²Bolt 11 to 13 Nzm (100 ft. lbs.) torque.

²Bolts 12 through 14 to 149 Nzm (110 ft. lbs.)

torque.

CAUTION: During the final tightening sequence,

bolt No.11 will be tightened to a lower torque than

the rest of the bolts. DO NOT overtighten bolt

No.11.

(e) Check all bolts in sequence to verify the cor-

rect torque.

(f) If not already done, clean and mark each bolt

with a dab of paint after tightening. Should you en-

Fig. 6 Engine Cylinder Head Assembly

9 - 68 4.0L ENGINEJ

Page 1348 of 2158

counter bolts which were painted in an earlier ser-

vice operation, replace them.

(6) Install the ignition coil and bracket assembly.

(7) Connect the temperature sending unit wire

connector.

(8) Install the spark plugs and tighten to 37 Nzm

(27 ft. lbs.) torque. Connect the ignition wires.

(9) Install the intake and engine exhaust mani-

folds (refer to Group 11, Exhaust System and Intake

Manifold for the proper procedures).

(10) Install the fuel lines and the vacuum advance

hose.

(11) If equipped, attach the power steering pump

and bracket.

(12) Install the push rods, rocker arms, pivots and

bridges in the order they were removed (refer to

Rocker Arms and Push Rods in this section).

(13) Install the engine cylinder head cover.

(14) Attach the air conditioner compressor mount-

ing bracket to the engine cylinder head and block.

Tighten the bolts to 40 Nzm (30 ft. lbs.) torque.

(15) Attach the air conditioning compressor to the

bracket. Tighten the bolts to 27 Nzm (20 ft. lbs.)

torque.

CAUTION: The serpentine drive belt must be routed

correctly. Incorrect routing can cause the water

pump to turn in the opposite direction causing the

engine to overheat.

(16) Install the serpentine drive belt and correctly

tension the belt (refer to Group 7, Cooling System for

the proper procedure).

(17) Install the air cleaner and ducting.

(18) Install the engine cylinder head cover.

(19) Connect the hoses to the engine thermostat

housing and fill the cooling system to the specified

level (refer to Group 7, Cooling Systems for the

proper procedure).

(20) The automatic transmission throttle linkage

and cable must be adjusted after completing the en-

gine cylinder head installation (refer to Group 21,

Transmissions for the proper procedures).(21) Install the temperature sending unit and con-

nect the wire connector.

(22) Connect the fuel line.

(23) Connect negative cable to battery.

(24) Connect the upper radiator hose and heater

hose at the engine thermostat housing.

(25) Fill the cooling system. Check for leaks.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

(26) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the engine thermostat opens. Add coolant, if re-

quired.

VALVES AND VALVE SPRINGS

This procedure is done with the engine cylinder

head removed from the block.

REMOVAL

(1) Remove the engine cylinder head from the cyl-

inder block.

(2) Use Valve Spring Compressor Tool

MD-998772A and compress each valve spring.

(3) Remove the valve locks, retainers, springs and

valve stem oil seals. Discard the oil seals.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

VALVE CLEANING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

Clean all grime and gasket material from the en-

gine cylinder head machined gasket surface.

INSPECTION

Inspect for cracks in the combustion chambers and

valve ports.

Inspect for cracks on the exhaust seat.

Inspect for cracks in the gasket surface at each

coolant passage.

Inspect valves for burned, cracked or warped

heads.

Inspect for scuffed or bent valve stems.

Replace valves displaying any damage.

VALVE REFACING

(1) Use a valve refacing machine to reface the in-

take and exhaust valves to the specified angle.

Fig. 7 Engine Cylinder Head Bolt Tightening

Sequence

J4.0L ENGINE 9 - 69

Page 1350 of 2158

ments differ by more than 0.0635 mm (0.0025 in.),

ream the guide bore to accommodate an oversize

valve stem.

(7) Compare the measured valve guide bore diam-

eter with specifications (7.95-7.97 mm or 0.313-0.314

inch). If the measurement differs from specification

by more than 0.076 mm (0.003 inch), ream the guide

bore to accommodate an oversize valve stem.

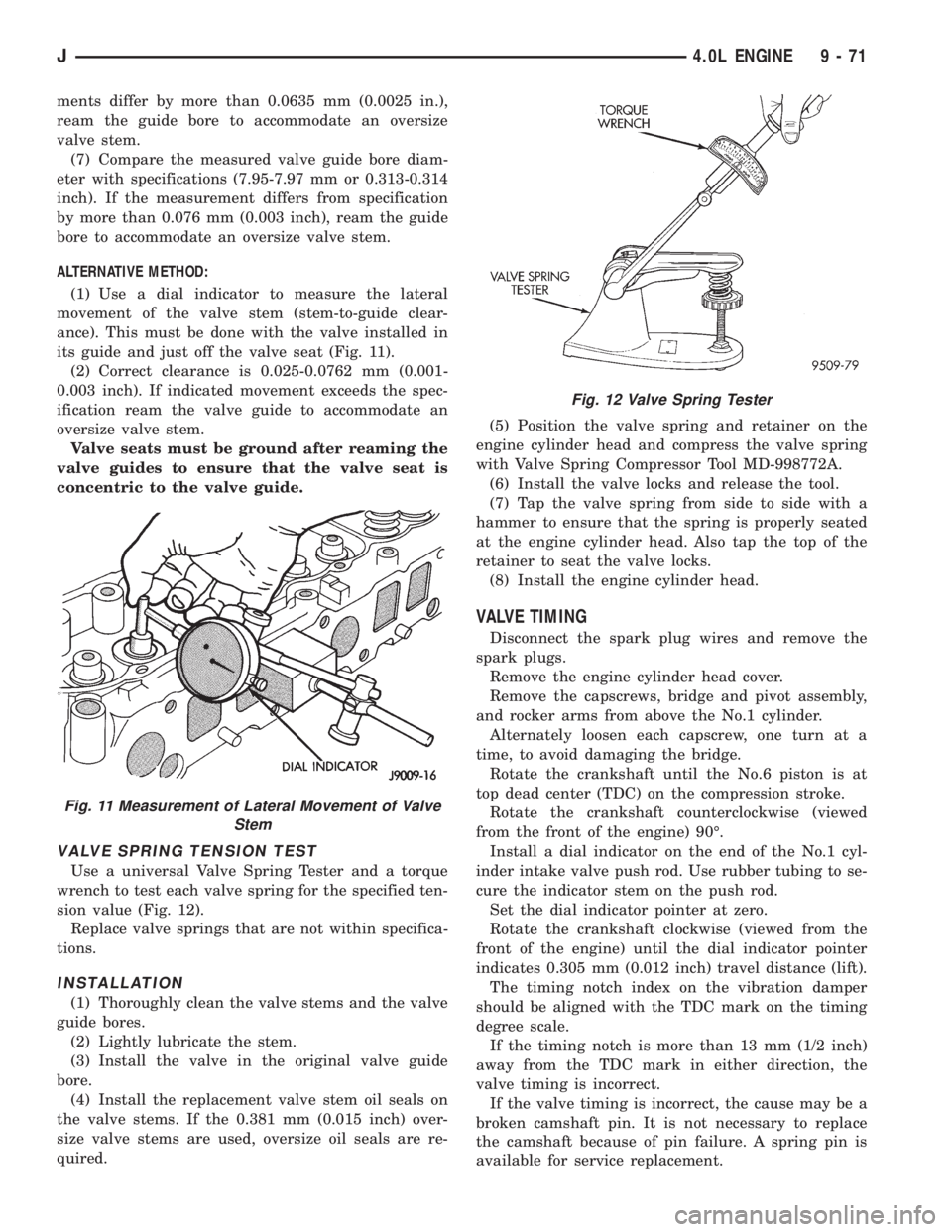

ALTERNATIVE METHOD:

(1) Use a dial indicator to measure the lateral

movement of the valve stem (stem-to-guide clear-

ance). This must be done with the valve installed in

its guide and just off the valve seat (Fig. 11).

(2) Correct clearance is 0.025-0.0762 mm (0.001-

0.003 inch). If indicated movement exceeds the spec-

ification ream the valve guide to accommodate an

oversize valve stem.

Valve seats must be ground after reaming the

valve guides to ensure that the valve seat is

concentric to the valve guide.

VALVE SPRING TENSION TEST

Use a universal Valve Spring Tester and a torque

wrench to test each valve spring for the specified ten-

sion value (Fig. 12).

Replace valve springs that are not within specifica-

tions.

INSTALLATION

(1) Thoroughly clean the valve stems and the valve

guide bores.

(2) Lightly lubricate the stem.

(3) Install the valve in the original valve guide

bore.

(4) Install the replacement valve stem oil seals on

the valve stems. If the 0.381 mm (0.015 inch) over-

size valve stems are used, oversize oil seals are re-

quired.(5) Position the valve spring and retainer on the

engine cylinder head and compress the valve spring

with Valve Spring Compressor Tool MD-998772A.

(6) Install the valve locks and release the tool.

(7) Tap the valve spring from side to side with a

hammer to ensure that the spring is properly seated

at the engine cylinder head. Also tap the top of the

retainer to seat the valve locks.

(8) Install the engine cylinder head.

VALVE TIMING

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridge.

Rotate the crankshaft until the No.6 piston is at

top dead center (TDC) on the compression stroke.

Rotate the crankshaft counterclockwise (viewed

from the front of the engine) 90É.

Install a dial indicator on the end of the No.1 cyl-

inder intake valve push rod. Use rubber tubing to se-

cure the indicator stem on the push rod.

Set the dial indicator pointer at zero.

Rotate the crankshaft clockwise (viewed from the

front of the engine) until the dial indicator pointer

indicates 0.305 mm (0.012 inch) travel distance (lift).

The timing notch index on the vibration damper

should be aligned with the TDC mark on the timing

degree scale.

If the timing notch is more than 13 mm (1/2 inch)

away from the TDC mark in either direction, the

valve timing is incorrect.

If the valve timing is incorrect, the cause may be a

broken camshaft pin. It is not necessary to replace

the camshaft because of pin failure. A spring pin is

available for service replacement.

Fig. 11 Measurement of Lateral Movement of Valve

Stem

Fig. 12 Valve Spring Tester

J4.0L ENGINE 9 - 71

Page 1366 of 2158

(8) Lower the vehicle.

(9) Install the engine cylinder head, push rods,

rocker arms, bridges, pivots and engine cylinder head

cover.

(10) Fill the crankcase with engine oil.

CRANKSHAFT MAIN BEARINGS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the spark plugs.

(3) Raise the vehicle.

(4) Remove the oil pan and oil pump.

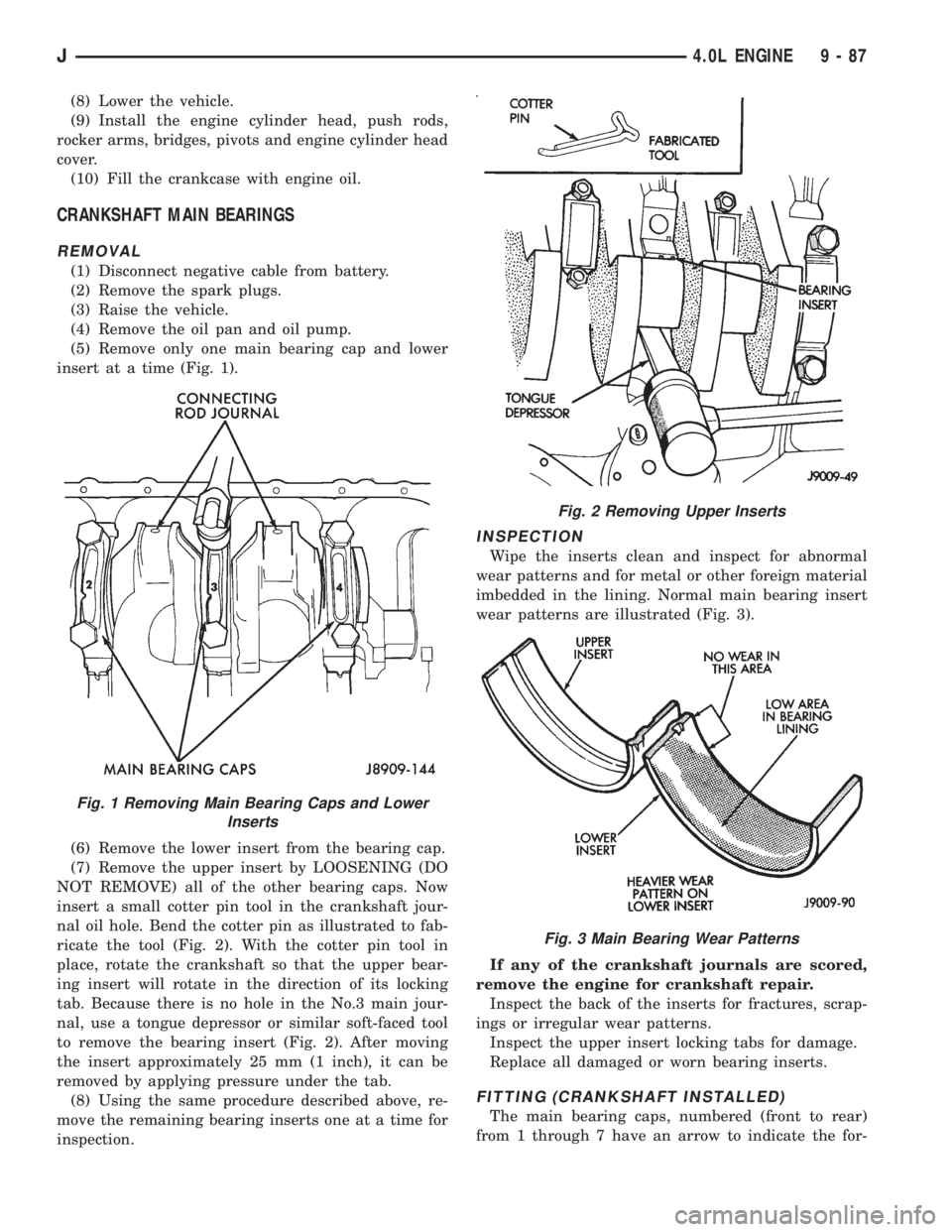

(5) Remove only one main bearing cap and lower

insert at a time (Fig. 1).

(6) Remove the lower insert from the bearing cap.

(7) Remove the upper insert by LOOSENING (DO

NOT REMOVE) all of the other bearing caps. Now

insert a small cotter pin tool in the crankshaft jour-

nal oil hole. Bend the cotter pin as illustrated to fab-

ricate the tool (Fig. 2). With the cotter pin tool in

place, rotate the crankshaft so that the upper bear-

ing insert will rotate in the direction of its locking

tab. Because there is no hole in the No.3 main jour-

nal, use a tongue depressor or similar soft-faced tool

to remove the bearing insert (Fig. 2). After moving

the insert approximately 25 mm (1 inch), it can be

removed by applying pressure under the tab.

(8) Using the same procedure described above, re-

move the remaining bearing inserts one at a time for

inspection.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 3).

If any of the crankshaft journals are scored,

remove the engine for crankshaft repair.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

FITTING (CRANKSHAFT INSTALLED)

The main bearing caps, numbered (front to rear)

from 1 through 7 have an arrow to indicate the for-

Fig. 1 Removing Main Bearing Caps and Lower

Inserts

Fig. 2 Removing Upper Inserts

Fig. 3 Main Bearing Wear Patterns

J4.0L ENGINE 9 - 87

Page 1368 of 2158

If the clearance exceeds specification using a pair

of 0.051 mm (0.002 inch) undersize bearing inserts,

measure crankshaft journal diameter with a mi-

crometer. If the journal diameter is correct, the

crankshaft bore in the cylinder block may be mis-

aligned, which requires cylinder block replacement or

machining to true bore.

Replace the crankshaft or grind to accept the ap-

propriate undersize bearing inserts if:

²Journal diameters 1 through 6 are less than

63.4517 mm (2.4981 inches)

²Journal 7 diameter is less than 63.4365 mm

(2.4975 inches).

Once the proper clearances have been obtained,

proceed to Crankshaft Main BearingÐInstallation.

MAIN BEARING JOURNAL DIAMETER (CRANKSHAFT

REMOVED)

Remove the crankshaft from the cylinder block (re-

fer to Cylinder Block - Disassemble).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper and out of round is

0.013 mm (0.0005 inch). Compare the measured di-

ameter with the journal diameter specification (Main

Bearing Fitting Chart). Select inserts required to ob-

tain the specified bearing-to-journal clearance.

Install the crankshaft into the cylinder block (refer

to Cylinder Block - Assemble and Crankshaft Main

Bearings - Installation).

INSTALLATION

(1) Lubricate the bearing surface of each insert

with engine oil.

(2) Loosen all the main bearing caps. Install the

main bearing upper inserts.

(3) Install the lower bearing inserts into the main

bearing caps.

(4) Install the main bearing cap(s) and lower in-

sert(s).

(5) Tighten the bolts of caps 1, 2, 4, 5, 6, and 7 to

54 Nzm (40 ft. lbs.) torque. Now tighten these bolts to

95 Nzm (70 ft. lbs.) torque. Finally, tighten these

bolts to 108 Nzm (80 ft. lbs.) torque.

(6) Push the crankshaft forward and backward.

Load the crankshaft front or rear and tighten cap

bolt No.3 to 54 Nzm (40 ft. lbs.) torque. Then tighten

to 95 Nzm (70 ft. lbs.) torque and finally tighten to

108 Nzm (80 ft. lbs.) torque.

(7) Rotate the crankshaft after tightening each

main bearing cap to ensure the crankshaft rotates

freely.

(8) Check crankshaft end play. Crankshaft end

play is controlled by the thrust bearing which is

flange and installed at the No.2 main bearing posi-

tion.(a) Attach a magnetic base dial indicator to the

cylinder block at either the front or rear of the en-

gine.

(b) Position the dial indicator rod so that it is

parallel to the center line of the crankshaft.

(c) Pry the crankshaft forward, position the dial

indicator to zero.

(d) Pry the crankshaft forward and backward.

Note the dial indicator readings. End play is the

difference between the high and low measurements

(Fig. 6). Correct end play is 0.038-0.165 mm

(0.0015-0.0065 inch). The desired specifications are

0.051-0.064 mm (0.002-0.0025 inch).

(e) If end play is not within specification, inspect

crankshaft thrust faces for wear. If no wear is ap-

parent, replace the thrust bearing and measure

end play. If end play is still not within specifica-

tion, replace the crankshaft.

If the crankshaft was removed, install the crank-

shaft into the cylinder block (refer to Cylinder Block -

Assemble).

(9) Install the oil pan.

(10) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(11) Lower the vehicle.

(12) Install the spark plugs. Tighten the plugs to

37 Nzm (27 ft. lbs.) torque.

(13) Fill the oil pan with engine oil to the full

mark on the dipstick level.

(14) Connect negative cable to battery.

REAR MAIN OIL SEALS

The crankshaft rear main bearing oil seal consists

of two half pieces of viton with a single lip that ef-

fectively seals the rear of the crankshaft. Replace the

upper and lower seal halves as a unit to ensure leak-

free operation.

Fig. 6 Crankshaft End Play Measurement

J4.0L ENGINE 9 - 89

Page 2144 of 2158

PANEL (GOP)ÐXJ, GRILLE AND GRILLE

OPENING............................23-3

PANEL ILLUMINATION LAMPS,

INSTRUMENT; INTERIOR LIGHTING

(XJ).............................8W-44-1

PANEL ILLUMINATION LAMPS,

INSTRUMENT; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-1

PANEL, INSTRUMENT.............8E-24,8E-1

PANEL INSULATOR PANELÐXJ, DASH....23-12

PANEL LAMP, ACCESSORY LAMP AND

HEATER CONTROL; INTERIOR

LIGHTING (YJ)....................8W-44-1

PANEL OUTLET VACUUM MOTOR

REPLACEMENT, HEATER/DEFROSTER/

INSTRUMENT.......................24-26

PANEL REMOVE/INSTALL, INSTRUMENT . . 8E-20

PANELÐXJ, DASH PANEL INSULATOR....23-12

PANELÐXJ, DOOR TRIM..............23-31

PANELÐXJ, FRONT INNER SCUFF

PLATE/COWL SIDE TRIM...............23-86

PANELÐXJ, LIFTGATE TRIM............23-59

PANELÐYJ, FULL-METAL DOOR TRIM . . . 23-137

PANELÐYJ, HOOD INSULATOR........23-107

PANELÐYJ, INSTRUMENT............23-151

PANELS AND SCUFF PLATESÐXJ,

INTERIOR TRIM......................23-84

PANELSÐXJ, QUARTER AND

WHEELHOUSE TRIM..................23-87

PARK GEAR OVERHAUL, GOVERNOR....21-127

PARK GEAR SERVICE, GOVERNOR......21-105

PARK INTERLOCK CABLE ADJUSTMENT . 21-195

PARK INTERLOCK CABLE ADJUSTMENT

(XJ)..............................21-101

PARK LOCK COMPONENT OVERHAUL,

ADAPTER/EXTENSION HOUSING

INSPECTION.......................21-127

PARK LOCK COMPONENT

REPLACEMENT.....................21-108

PARK NEUTRAL SWITCH..............14-63

PARK ROD AND PAWL SERVICE........21-190

PARKING BRAKE CABLE TENSIONER

ADJUSTMENT (XJ/YJ)..................5-69

PARKING BRAKE CABLE TENSIONER

REPLACEMENT (XJ)...................5-66

PARKING BRAKE FRONT CABLE

REPLACEMENT (YJ)...................5-67

PARKING BRAKE HANDLE COVERÐXJ....23-94

PARKING BRAKE LEVER INSTALLATION

(XJ WITH FULL CONSOLE)..............5-64

PARKING BRAKE LEVER INSTALLATION

(XJ WITH MINI CONSOLE)..............5-63

PARKING BRAKE LEVER INSTALLATION

(XJ WITHOUT CONSOLE)...............5-65

PARKING BRAKE LEVER REMOVAL (XJ

WITH FULL CONSOLE).................5-63

PARKING BRAKE LEVER REMOVAL (XJ

WITH MINI CONSOLE).................5-62

PARKING BRAKE LEVER REMOVAL (XJ

WITHOUT CONSOLE)...................5-64

PARKING BRAKE MALFUNCTIONS,

DIAGNOSING..........................5-8

PARKING BRAKE OPERATION............5-60

PARKING BRAKE PEDAL INSTALLATION

(YJ)................................5-66

PARKING BRAKE PEDAL REMOVAL (YJ) . . . 5-66

PARKING BRAKE REAR CABLE

REPLACEMENT (XJ)...................5-67

PARKING BRAKE REAR CABLE

REPLACEMENT (YJ)...................5-68

PARKING BRAKE SWITCH...............5-68

PARKING BRAKES.....................5-60

PARKING LAMPS; FRONT LIGHTING

(XJ).............................8W-50-1

PARKING LAMPS; FRONT LIGHTING

(XJ-RHD).........................8W-50-2

PARKING LAMPS; FRONT LIGHTING

(YJ).............................8W-50-1

PARK/NEUTRAL POSITION SWITCH;

FUEL/IGNITION (XJ)

................8W-30-4

PARK/NEUTRAL POSITION SWITCH;

FUEL/IGNITION (YJ)

................8W-30-4

PARK/NEUTRAL POSITION SWITCH;

TRANSMISSION AND TRANSFER CASE

. . 21-183

PARK/NEUTRAL POSITION SWITCH;

FUEL/IGNITION (XJ-RHD)

............8W-30-4

PARK/NEUTRAL POSITION SWITCH

SERVICE

..........................21-109PARK/NEUTRAL SWITCHÐPCM INPUT . . . 14-24

PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐXJ, FRONT.............8L-9

PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐYJ, FRONT............8L-25

PARTS INTERCHANGEABILITY,

TRANSMISSION CHANGES.............21-67

PARTS RECOMMENDATION,

LUBRICATION AND REPLACEMENT........0-2

PASSENGER'S POWER LOCK SWITCH.....8P-6

PASSENGER'S POWER WINDOW

SWITCH.............................8S-6

PATTERN ANALYSIS, BACKLASH AND

CONTACT; FRONT SUSPENSION AND

AXLE...............................2-45

PATTERN ANALYSIS, BACKLASH AND

CONTACT; REAR SUSPENSION AND

AXLES..............................3-27

PATTERN, SHIFT......................21-2

PATTERN, TRANSMISSION SHIFT........21-34

PATTERNS, TIRE WEAR................22-4

PAWL SERVICE, PARK ROD...........21-190

PCM SYSTEM SCHEMATICS............14-41

PEDAL, ACCELERATOR................14-17

PEDAL AND THROTTLE CABLE,

ACCELERATOR.................14-17,14-58

PEDAL BUSHINGS, CLUTCH AND BRAKE . . . 0-22

PEDAL INSTALLATION, BRAKE...........5-31

PEDAL INSTALLATION, CLUTCH..........6-15

PEDAL INSTALLATION (YJ), PARKING

BRAKE...............................5-66

PEDAL REMOVAL, BRAKE...............5-31

PEDAL REMOVAL, CLUTCH..............6-15

PEDAL REMOVAL (YJ), PARKING BRAKE . . . 5-66

PEDAL TRAVEL SENSOR, BRAKE;

ANTI-LOCK BRAKES (YJ)............8W-32-1

PEDALÐBRAKELIGHT SWITCH, POWER

BRAKE BOOSTERÐBRAKE..............5-22

PERFORMANCE, ENGINE.................9-2

PERFORMANCE TEMPERATURE AND

PRESSURE CHART, XJ................24-13

PERFORMANCE TEMPERATURE AND

PRESSURE CHART, YJ................24-13

PERFORMANCE TEST, REFRIGERANT

SERVICE...........................24-11

PERFORMANCE TESTS, AIR

CONDITIONING......................24-12

PILLAR TRIM COVERSÐXJ, B/C-PILLAR

AND LIFTGATE.......................23-88

PILOT BEARING REPLACEMENT..........6-12

PIN REPLACEMENT, CAMSHAFT......9-34,9-75

PIN REPLACEMENTÐXJ, DOOR

HINGE/HINGE.......................23-52

PINION GEAR ASSEMBLY/INSTALLATION . . . 2-42

PINION GEAR DEPTH INFORMATION;

FRONT SUSPENSION AND AXLE..........2-39

PINION GEAR DEPTH INFORMATION;

REAR SUSPENSION AND AXLES..........3-21

PINION GEAR DEPTH VARIANCE; FRONT

SUSPENSION AND AXLE................2-40

PINION GEAR DEPTH VARIANCE; REAR

SUSPENSION AND AXLES...........3-22,3-39

PINION MEASUREMENT AND ASSEMBLY . . . 3-22

PINION MEASUREMENT, DIFFERENTIAL....2-40

PINION REMOVAL/DISASSEMBLY; FRONT

SUSPENSION AND AXLE................2-36

PINION REMOVAL/DISASSEMBLY; REAR

SUSPENSION AND AXLES...............3-19

PINION SEAL REPLACEMENT; FRONT

SUSPENSION AND AXLE................2-25

PINION SEAL REPLACEMENT; REAR

SUSPENSION AND AXLES...............3-33

PINION SHAFT SEAL REPLACEMENT......3-15

PIPEÐXJ VEHICLES, EXHAUST..........11-3

PIPEÐYJ VEHICLES, EXHAUST..........11-4

PISTON AND TRANSMISSION CASE

OVERHAUL, FIRST-REVERSE BRAKE....21-247

PISTON AND WORM SHAFT

REPLACEMENT, RACK.................19-32

PISTON CLEARANCE, AW-4 BUSHING . . . 21-339

PISTON SPECIFICATIONS, AW-4

RETAINER.........................21-340

PISTONS AND CONNECTING RODS

. . . 9-39,9-81

PISTONS AND SPRINGS, ACCUMULATOR

. 21-189

PITMAN ARM

..................19-17,19-20

PITMAN SHAFT AND SIDE COVER

REPLACEMENT

......................19-28

PITMAN SHAFT SEAL REPLACEMENT

.....19-37PITMAN SHAFT SEALS AND BEARING

REPLACEMENT......................19-34

PITMAN SHAFT SEALSÐIN CAR

REPLACEMENT......................19-23

PIVOTS REMOVE/INSTALL, WINDSHIELD

WIPER LINKAGE.....................8K-17

PLANETARY GEAR AND CLUTCH

OVERHAUL, OVERDRIVE..............21-218

PLANETARY GEAR OVERHAUL, FRONT . . . 21-237

PLANETARY GEAR TRAIN OVERHAUL . . . 21-141

PLASTIC COMPONENT INSPECTION,

RUBBER............................0-20

PLASTIC HOSES/TUBING, RUBBER........0-26

PLASTIC INSERTÐXJ, REAR QUARTER

WINDOW GLASS/REAR QUARTER.......23-73

PLASTIGAGE, MEASURING WITH..........9-3

PLATE, FRONT SKID...................13-1

PLATE, FUEL TANK SKID...........13-15,13-3

PLATE LAMP HOUSINGÐXJ, LIFTGATE

LICENSE...........................23-65

PLATE LAMPÐXJ, LICENSE............8L-12

PLATE LAMPS, TAIL LAMPS AND

LICENSE.........................8W-51-1

PLATE LAMPS, TAIL LAMPS AND REAR

LICENSE; REAR LIGHTING (XJ).......8W-51-1

PLATE LAMPS, TAIL LAMPS AND REAR

LICENSE; REAR LIGHTING (XJ-RHD) . . . 8W-51-1

PLATE REPLACEMENT, SUPPORT.........5-58

PLATE SCREW ANCHOR AND BUMPERÐ

XJ, LIFTGATE LICENSE................23-65

PLATE SERVICE, CONVERTERÐPUMP

SEALÐDRIVE......................21-116

PLATE SPECIFICATIONS, 30RH/32RH

SNAP RING/THRUST WASHER/THRUST . . 21-335

PLATE THICKNESS, AW-4 CLUTCH DISC . 21-338

PLATE, TRANSFER CASE SKID......13-15,13-3

PLATE, VEHICLE CODE...............Intro.-4

PLATE, VEHICLE IDENTIFICATION

NUMBER (VIN).....................Intro.-4

PLATE/COWL SIDE TRIM PANELÐXJ,

FRONT INNER SCUFF.................23-86

PLATESÐXJ, INTERIOR TRIM PANELS

AND SCUFF.........................23-84

PLATESÐXJ, OUTER SCUFF............23-89

PLATESÐXJ, VEHICLE, LABELS........Intro.-2

PLATESÐYJ, VEHICLE, LABELS........Intro.-3

PLATFORMÐXJ, BUCKET SEAT.........23-82

PLUG ASSEMBLY REPLACEMENT,

ADJUSTER..........................19-29

PLUG CABLE RESISTANCE, SPARK......8D-14

PLUG, HOUSING END.................19-28

PLUG LOCATIONS, TRANSMISSION

SWITCH............................21-34

PLUG SECONDARY CABLES, SPARK.....8D-14,

8D-24

PLUGS, SPARK; IGNITION SYSTEMS....8D-12,

8D-23,8D-32

PLUGS, SPARK; LUBRICATION AND

MAINTENANCE.......................0-20

POLISHING, WET SANDING,BUFFING....23-158

POOR CONNECTIONS, INTERMITTENT;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)

...................8W-4

POSITION SENSOR, CAMSHAFT; FUEL

SYSTEM

............................14-60

POSITION SENSOR, CAMSHAFT;

FUEL/IGNITION (XJ)

................8W-30-3

POSITION SENSOR, CAMSHAFT;

FUEL/IGNITION (YJ)

................8W-30-3

POSITION SENSOR, CAMSHAFT;

IGNITION SYSTEMS

..............8D-17,8D-2

POSITION SENSOR, CAMSHAFT;

FUEL/IGNITION (XJ-RHD)

............8W-30-3

POSITION SENSOR, CRANKSHAFT; FUEL

SYSTEM

............................14-60

POSITION SENSOR, CRANKSHAFT;

FUEL/IGNITION (XJ)

................8W-30-3

POSITION SENSOR, CRANKSHAFT;

FUEL/IGNITION (YJ)

................8W-30-3

POSITION SENSOR, CRANKSHAFT;

IGNITION SYSTEMS

..............8D-17,8D-3

POSITION SENSOR, CRANKSHAFT;

FUEL/IGNITION (XJ-RHD)

............8W-30-3

POSITION SENSOR TEST, CAMSHAFT;

FUEL SYSTEM

.......................14-46

POSITION SENSOR TEST, CAMSHAFT;

IGNITION SYSTEMS

...................8D-6

20 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2150 of 2158

SHUTDOWN (ASD) RELAY, AUTOMATIC;

FUEL SYSTEM.......................14-59

SHUTDOWN (ASD) RELAY, AUTOMATIC;

IGNITION SYSTEMS..............8D-17,8D-1

SHUTDOWN (ASD) RELAY TEST,

AUTOMATIC.........................8D-6

SHUTDOWN (ASD) RELAY TESTING,

AUTOMATIC.........................14-46

SHUTDOWN (ASD) RELAYÐPCM

OUTPUT, AUTO......................14-26

SHUTDOWN (ASD) SENSEÐPCM INPUT,

AUTOMATIC.........................14-21

SIDE COVER REPLACEMENT, PITMAN

SHAFT.............................19-28

SIDE MARKER LAMP BULB

REPLACEMENTÐXJ..................8L-10

SIDE MARKER LAMP BULB

REPLACEMENTÐYJ..................8L-25

SIDE MOLDING/CLADDINGÐXJ, BODY . . . 23-20

SIDE MOLDINGÐXJ, WINDSHIELD......23-86

SIDE STEP MOLDINGÐYJ, BODY.......23-115

SIDE TRIM PANELÐXJ, FRONT INNER

SCUFF PLATE/COWL..................23-86

SIGNAL INDICATOR LAMPS, TURN;

INSTRUMENT CLUSTER (XJ).........8W-40-2

SIGNAL INDICATOR LAMPS, TURN;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

SIGNAL LAMP BULB REPLACEMENTÐ

XJ, FRONT PARK/TURN.................8L-9

SIGNAL LAMP BULB REPLACEMENTÐ

YJ, FRONT PARK/TURN................8L-25

SIGNAL RELAY, TURN; TURN SIGNALS

(XJ-RHD)..........................8W-52-1

SIGNAL SYSTEM - YJ, TURN............8J-3

SIGNAL SYSTEM, TURN................8J-1

SIGNAL, TACHOMETER; FUEL/IGNITION

(XJ).............................8W-30-5

SIGNAL, TACHOMETER; FUEL/IGNITION

(YJ).............................8W-30-5

SIGNAL, TACHOMETER; FUEL/IGNITION

(XJ-RHD).........................8W-30-4

SIGNAL/HAZARD WARNING SWITCH

REMOVE/INSTALL - YJ, TURN............8J-5

SIGNAL/HAZARD WARNING SYSTEM -

XJ, TURN............................8J-3

SIGNALS, TURN; TURN SIGNALS (YJ) . . 8W-52-1

SIGNALS, WHEEL/TIRE SIZE AND INPUT....5-3

SIGNAL/TAIL LAMP BULB

REPLACEMENTÐXJ, BACK-UP/REAR

TURN..............................8L-12

SIGNAL/TAIL LAMP BULB

REPLACEMENTÐYJ, BACK-UP/REAR

TURN..............................8L-28

SINGLE CARDAN.....................16-10

SIZE AND INPUT SIGNALS, WHEEL/TIRE....5-3

SKID PLATE, FRONT...................13-1

SKID PLATE, FUEL TANK...........13-15,13-3

SKID PLATE, TRANSFER CASE......13-15,13-3

SLIP DIFFERENTIAL, LIMITED............3-10

SNAP, DRIVELINE; FRONT SUSPENSION

AND AXLE...........................2-19

SNAP, DRIVELINE; REAR SUSPENSION

AND AXLES..........................3-10

SNAP RING CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE...........21-334

SNAP RING/THRUST WASHER/THRUST

PLATE SPECIFICATIONS, 30RH/32RH....21-335

SOFT TOP DOORÐYJ, HALF-METAL.....23-134

SOFT TOP SERVICE INFORMATIONÐYJ . . 23-127

SOFT TOP SERVICEÐYJ..............23-129

SOLENOID AND RELAY, TORQUE

CONVERTER CLUTCH (TCC);

FUEL/IGNITION (XJ)................8W-30-4

SOLENOID AND RELAY, TORQUE

CONVERTER CLUTCH (TCC);

TRANSMISSION CONTROLS (YJ)......8W-31-1

SOLENOID AND RELAYÐ2.5L ENGINE

ONLY, TORQUE CONVERTER CLUTCH

(TCC); TRANSMISSION CONTROLS

(XJ)

.............................8W-31-1

SOLENOID TESTING SPECIFICATIONS,

2.5L STARTER

.......................8A-23

SOLENOID TESTING SPECIFICATIONS,

4.0L STARTER

.......................8A-23

SOLENOIDS, TRANSMISSION VALVE

BODY

.............................21-184

SOLVENTS, BRAKE FLUID/LUBRICANTS/

CLEANING

............................5-2SOUND BAR REMOVE/INSTALL - XJ.......8F-8

SOUND BAR REMOVE/INSTALL - YJ......8F-10

SOUND BARÐXJ....................23-94

SPACER BLOCKSÐTWO-DOOR

VEHICLES, FRONT DOOR..............23-53

SPARE TIRE/WHEEL HOLDDOWN AND

FLOOR BRACKETSÐXJ................23-98

SPARE/WHEEL TIRE CARRIERÐYJ,

EXTERNAL.........................23-133

SPARK PLUG CABLE RESISTANCE.......8D-14

SPARK PLUG SECONDARY CABLES . 8D-14,8D-24

SPARK PLUGS; IGNITION SYSTEMS.....8D-12,

8D-23,8D-32

SPARK PLUGS; LUBRICATION AND

MAINTENANCE.......................0-20

SPEAKERS; AUDIO SYSTEMS........8F-1,8F-2

SPEAKERS; RADIO (XJ).............8W-47-1

SPEAKERS; RADIO (XJ-RHD).........8W-47-1

SPEAKERS; RADIO (YJ).............8W-47-1

SPEAKERS REMOVE/INSTALL - XJ........8F-6

SPEAKERS REMOVE/INSTALL - YJ........8F-9

SPECIFICATION NOTATIONS..........Intro.-11

SPECIFICATIONS; BATTERY/STARTER/

GENERATOR SERVICE..................8B-8

SPECIFICATIONS; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS.....8A-23

SPECIFICATIONS; BRAKES..............5-70

SPECIFICATIONS; COOLING SYSTEM......7-45

SPECIFICATIONS; ENGINES...........9-52,9-93

SPECIFICATIONS; FUEL SYSTEM........14-67

SPECIFICATIONS; HORNS...............8G-5

SPECIFICATIONS; IGNITION SYSTEMS....8D-32

SPECIFICATIONS; INSTRUMENT PANEL

AND GAUGESÐXJ..............8E-23,8E-43

SPECIFICATIONS; WHEELS AND TIRES....22-12

SPECIFICATIONS, 2.5L STARTER AND

SOLENOID TESTING..................8A-23

SPECIFICATIONS, 2.5L STARTING

SYSTEM COLD CRANKING.............8A-23

SPECIFICATIONS, 30RH/32RH GENERAL . 21-335

SPECIFICATIONS, 30RH/32RH PRESSURE

TEST.............................21-336

SPECIFICATIONS, 30RH/32RH TORQUE . . 21-336

SPECIFICATIONS, 4.0L STARTER AND

SOLENOID TESTING..................8A-23

SPECIFICATIONS, 4.0L STARTING

SYSTEM COLD CRANKING.............8A-23

SPECIFICATIONS, AW-4 GENERAL......21-337

SPECIFICATIONS, AW-4 TORQUE.......21-344

SPECIFICATIONS, AXLE; FRONT

SUSPENSION AND AXLE................2-49

SPECIFICATIONS, AXLE; REAR

SUSPENSION AND AXLES...............3-51

SPECIFICATIONS, BATTERY; BATTERY/

STARTER/GENERATOR SERVICE..........8B-8

SPECIFICATIONS, BATTERY; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS.......................8A-23

SPECIFICATIONS, BELT TENSION.........7-38

SPECIFICATIONS, BODY LUBRICANT......0-33

SPECIFICATIONS, BRAKE TORQUE........5-70

SPECIFICATIONS, CHARGING SYSTEM....8A-23

SPECIFICATIONS (CONT.), ENGINE....9-53,9-54,

9-94,9-95

SPECIFICATIONS, ENGINE...........9-52,9-93

SPECIFICATIONS, GENERATOR...........8B-8

SPECIFICATIONS, LUBRICANT; FRONT

SUSPENSION AND AXLE................2-22

SPECIFICATIONS, LUBRICANT; REAR

SUSPENSION AND AXLES...........3-13,3-31

SPECIFICATIONS, MANUAL STEERING

GEAR..............................19-46

SPECIFICATIONS, MEASUREMENT AND

TORQUE.........................Intro.-11

SPECIFICATIONS, NP231/NP242 TORQUE . 21-344

SPECIFICATIONS, OUTPUT VOLTAGE.....8A-23

SPECIFICATIONS, POWER STEERING

GEAR..............................19-36

SPECIFICATIONS, PUMP OPERATING......19-3

SPECIFICATIONS, RUNOUT..............16-4

SPECIFICATIONS, STARTER.............8B-8

SPECIFICATIONS, STARTING SYSTEM

....8A-23

SPECIFICATIONS, TORQUE; CLUTCH

......6-17

SPECIFICATIONS, TORQUE; ENGINES

. . 9-54,9-95

SPECIFICATIONS, TORQUE; EXHAUST

SYSTEM AND INTAKE MANIFOLD

........11-10

SPECIFICATIONS, TORQUE; FRONT

SUSPENSION AND AXLE

................2-49SPECIFICATIONS, TORQUE; HEATING

AND AIR CONDITIONING...............24-37

SPECIFICATIONS, TORQUE;

INTRODUCTION............Intro.-11,Intro.-12

SPECIFICATIONS, TORQUE; PROPELLER

SHAFTS............................16-15

SPECIFICATIONS, TORQUE; REAR

SUSPENSION AND AXLES...............3-51

SPECIFICATIONS, TORQUE; STEERING....19-78

SPECIFICATIONS, TRAILER TOWING....Intro.-5,

Intro.-9

SPECIFICATIONS, TRANSMISSION/

TRANSFER CASE....................21-333

SPECIFICATIONSÐACCESSORIES,

TORQUE...........................23-162

SPECIFICATIONSÐMANUAL

TRANSMISSION, TORQUE.............21-333

SPECIFICATIONSÐXJ VEHICLES,

ALIGNMENT..........................2-10

SPECIFICATIONSÐXJ VEHICLES,

TORQUE...........................23-161

SPECIFICATIONSÐYJ VEHICLES,

ALIGNMENT..........................2-10

SPEED CONTROL DIAGNOSTIC TROUBLE

CODE...............................8H-5

SPEED CONTROL SERVO...........8H-1,8H-6

SPEED CONTROL SERVO REMOVE/

INSTALL............................8H-9

SPEED CONTROL SWITCH..........8H-1,8H-6

SPEED CONTROL SWITCH REMOVE/

INSTALL............................8H-9

SPEED CONTROL, VEHICLE; VEHICLE

SPEED CONTROL (XJ)................8W-33-1

SPEED CONTROL, VEHICLE; VEHICLE

SPEED CONTROL (XJ-RHD)..........8W-33-1

SPEED CONTROLÐPCM INPUT.........14-25

SPEED CONTROLÐPCM OUTPUT........14-29

SPEED KNOCK, LOW; FRONT

SUSPENSION AND AXLE................2-19

SPEED KNOCK, LOW; REAR

SUSPENSION AND AXLES...............3-10

SPEED SENSOR.....................21-192

SPEED SENSOR AIR GAP...............5-37

SPEED SENSOR OPERATION, WHEEL......5-37

SPEED SENSOR, PUMP MOTOR;

ANTI-LOCK BRAKES (XJ)............8W-32-2

SPEED SENSOR, PUMP MOTOR;

ANTI-LOCK BRAKES (XJ-RHD)........8W-32-2

SPEED SENSOR, PUMP MOTOR;

ANTI-LOCK BRAKES (YJ)............8W-32-1

SPEED SENSOR ROTORÐ

SPEEDOMETER DRIVE GEAR..........21-193

SPEED SENSOR TEST, VEHICLE.........14-48

SPEED SENSOR, VEHICLE; FUEL

SYSTEM............................14-66

SPEED SENSOR, VEHICLE; FUEL/

IGNITION (XJ).....................8W-30-2

SPEED SENSOR, VEHICLE; FUEL/

IGNITION (YJ).....................8W-30-3

SPEED SENSOR, VEHICLE; VEHICLE

SPEED CONTROL SYSTEM..........8H-1,8H-5

SPEED SENSOR, VEHICLE; FUEL/

IGNITION (XJ-RHD)................8W-30-2

SPEED SENSORÐPCM INPUT, VEHICLE . . 14-25

SPEED SENSORS, WHEEL; ANTI-LOCK

BRAKES (XJ)......................8W-32-1

SPEED SENSORS, WHEEL; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-1

SPEED SENSORS, WHEEL; ANTI-LOCK

BRAKES (YJ)

......................8W-32-1

SPEED SENSORS, WHEEL; BRAKES

.......5-34

SPEEDOMETER; INSTRUMENT CLUSTER

(XJ)

.............................8W-40-2

SPEEDOMETER; INSTRUMENT CLUSTER

(XJ-RHD)

.........................8W-40-1

SPEEDOMETER CABLE

.................0-33

SPEEDOMETER SERVICE

. . 21-109,21-287,21-309

SPLASH APRONSÐYJ, FENDER

........23-115

SPLASH LINERSÐYJ, WHEELHOUSE

....23-115

SPLASH SHIELD, GENERATOR

..........13-13

SPLASH SHIELDÐXJ VEHICLES, FUEL

FILLER HOSE

.........................13-4

SPLASH SHIELDSÐYJ, FENDER INNER

. . 23-116

SPLICE INDEX; SPLICE INFORMATION

(XJ)

.............................8W-70-1

SPLICE INDEX; SPLICE INFORMATION

(XJ-RHD)

.........................8W-70-1

26 INDEXJ

Description Group-Page Description Group-Page Description Group-Page