driver seat adjustment JEEP YJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1513 of 2158

CAUTION: Do not turn stub shaft any farther than

necessary. The recirculating balls will drop out of

the rack piston circuit and fall inside the rack pis-

ton chamber.

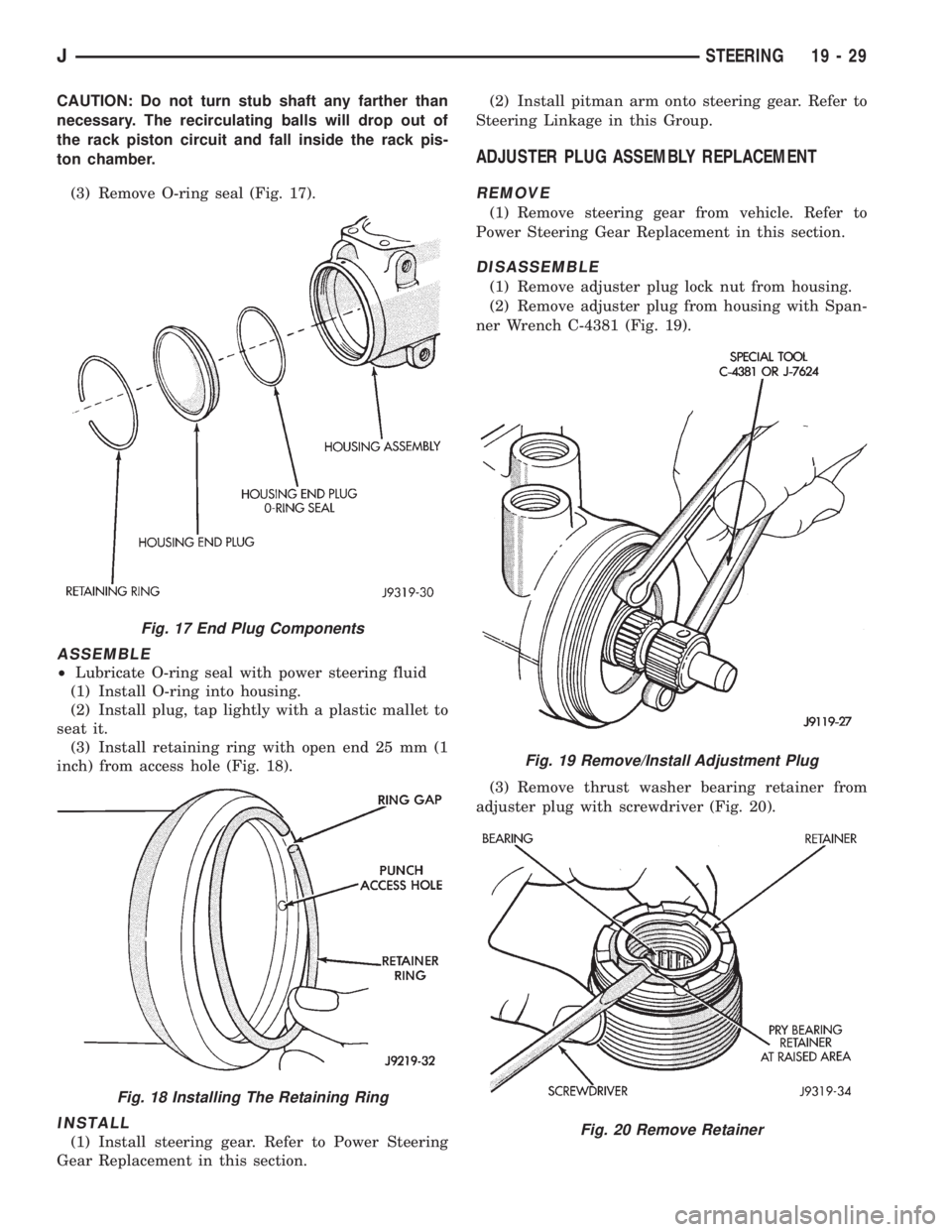

(3) Remove O-ring seal (Fig. 17).

ASSEMBLE

²Lubricate O-ring seal with power steering fluid

(1) Install O-ring into housing.

(2) Install plug, tap lightly with a plastic mallet to

seat it.

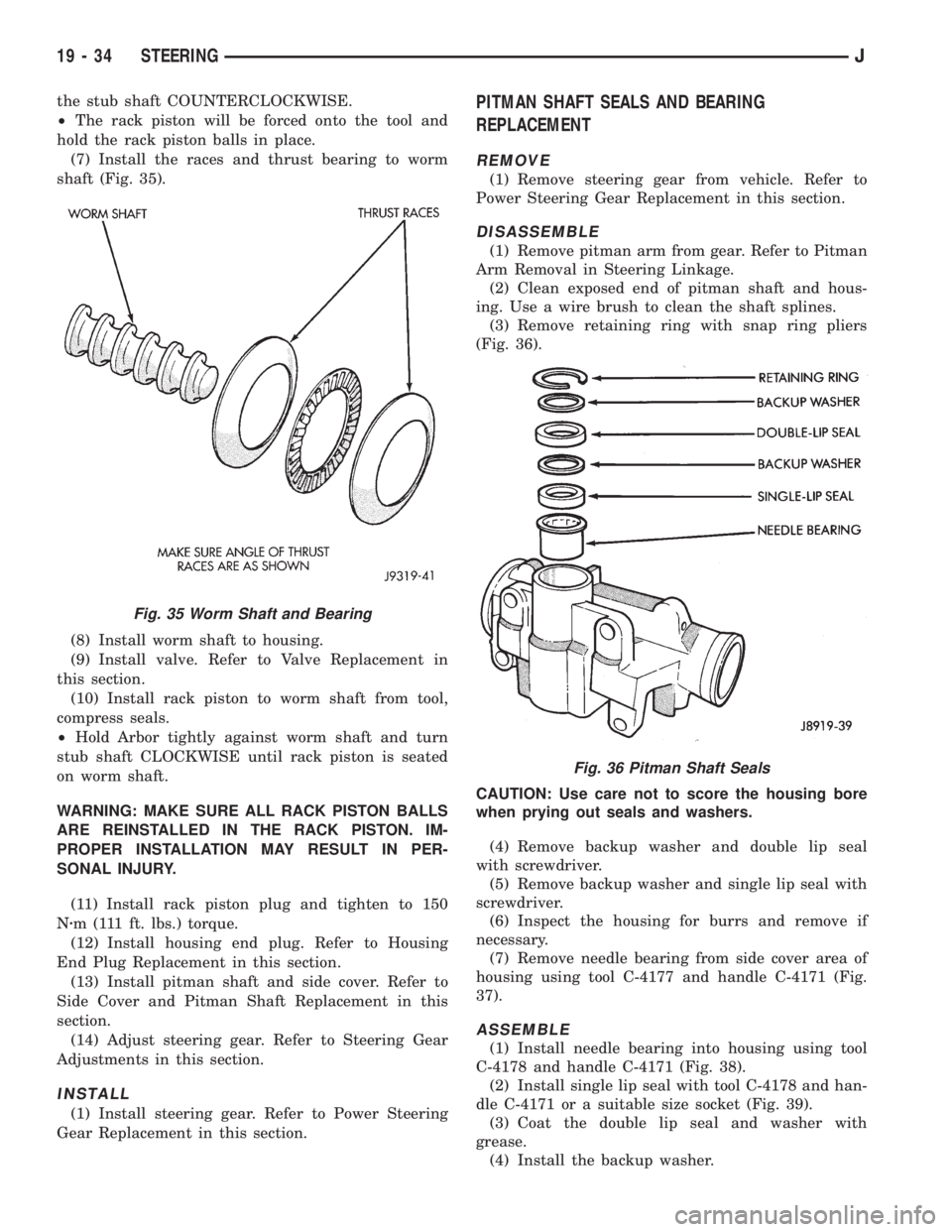

(3) Install retaining ring with open end 25 mm (1

inch) from access hole (Fig. 18).

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.(2) Install pitman arm onto steering gear. Refer to

Steering Linkage in this Group.

ADJUSTER PLUG ASSEMBLY REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove adjuster plug lock nut from housing.

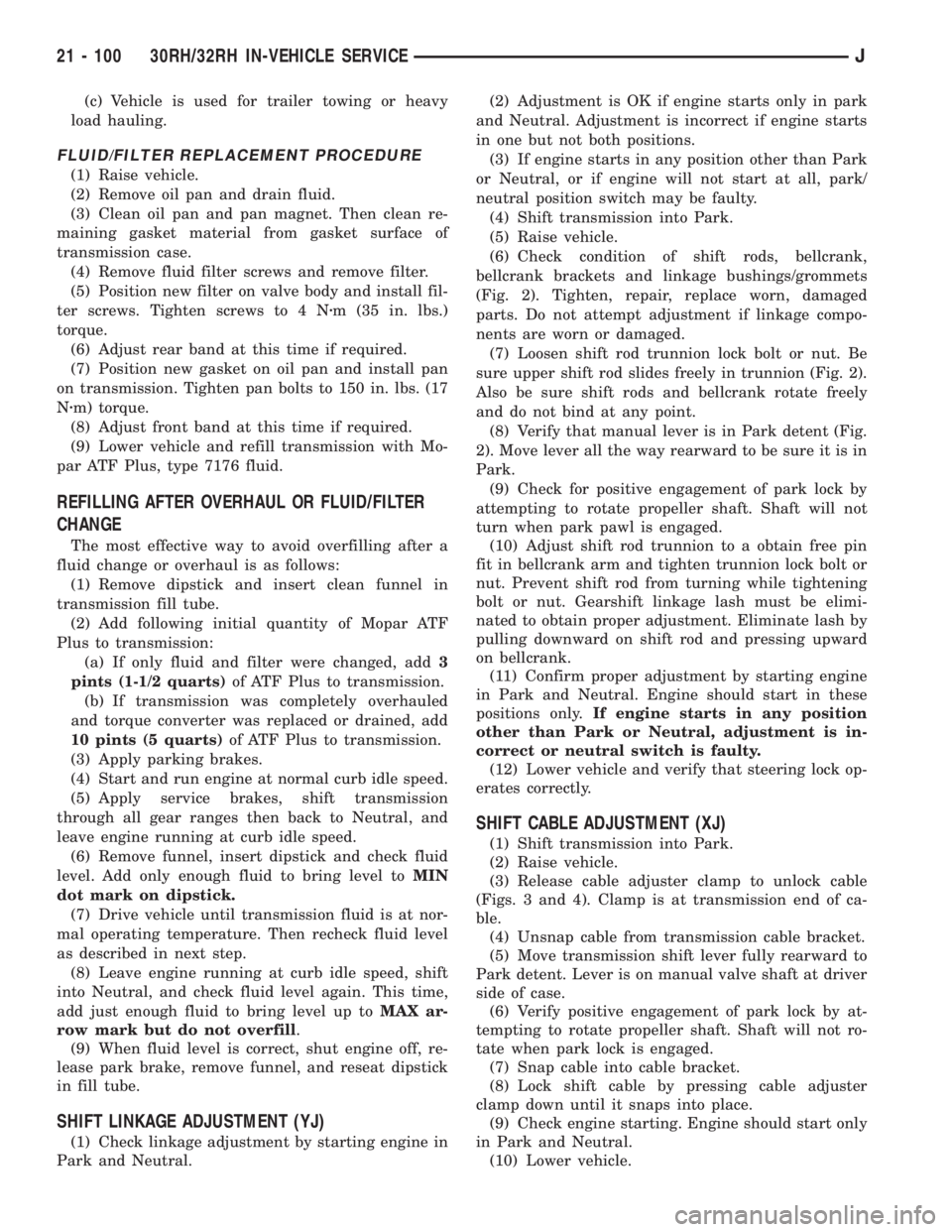

(2) Remove adjuster plug from housing with Span-

ner Wrench C-4381 (Fig. 19).

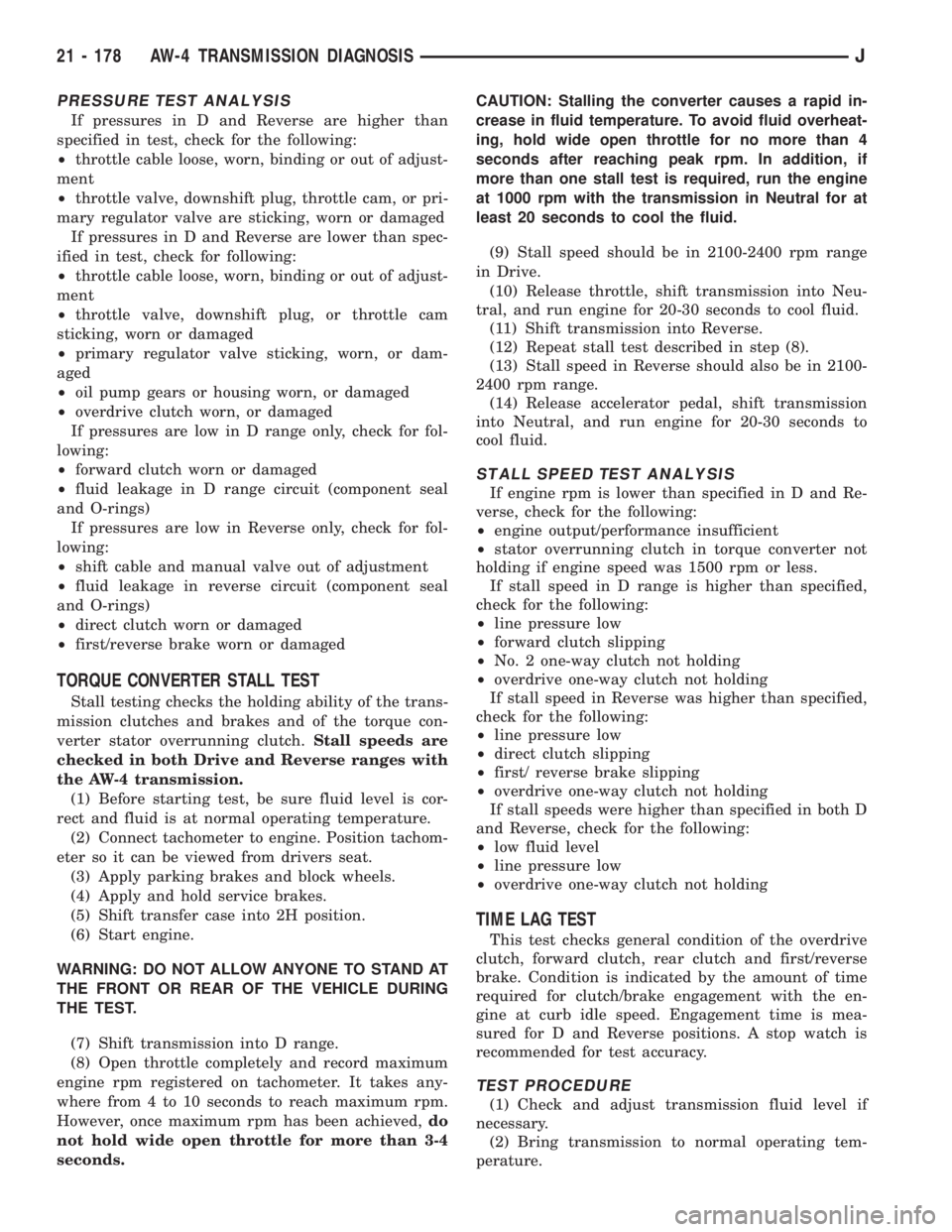

(3) Remove thrust washer bearing retainer from

adjuster plug with screwdriver (Fig. 20).

Fig. 17 End Plug Components

Fig. 18 Installing The Retaining Ring

Fig. 19 Remove/Install Adjustment Plug

Fig. 20 Remove Retainer

JSTEERING 19 - 29

Page 1518 of 2158

the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

(7) Install the races and thrust bearing to worm

shaft (Fig. 35).

(8) Install worm shaft to housing.

(9) Install valve. Refer to Valve Replacement in

this section.

(10) Install rack piston to worm shaft from tool,

compress seals.

²Hold Arbor tightly against worm shaft and turn

stub shaft CLOCKWISE until rack piston is seated

on worm shaft.

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.

(11) Install rack piston plug and tighten to 150

Nzm (111 ft. lbs.) torque.

(12) Install housing end plug. Refer to Housing

End Plug Replacement in this section.

(13) Install pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(14) Adjust steering gear. Refer to Steering Gear

Adjustments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

PITMAN SHAFT SEALS AND BEARING

REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove pitman arm from gear. Refer to Pitman

Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and hous-

ing. Use a wire brush to clean the shaft splines.

(3) Remove retaining ring with snap ring pliers

(Fig. 36).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary.

(7) Remove needle bearing from side cover area of

housing using tool C-4177 and handle C-4171 (Fig.

37).

ASSEMBLE

(1) Install needle bearing into housing using tool

C-4178 and handle C-4171 (Fig. 38).

(2) Install single lip seal with tool C-4178 and han-

dle C-4171 or a suitable size socket (Fig. 39).

(3) Coat the double lip seal and washer with

grease.

(4) Install the backup washer.

Fig. 35 Worm Shaft and Bearing

Fig. 36 Pitman Shaft Seals

19 - 34 STEERINGJ

Page 1662 of 2158

(c) Vehicle is used for trailer towing or heavy

load hauling.

FLUID/FILTER REPLACEMENT PROCEDURE

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Clean oil pan and pan magnet. Then clean re-

maining gasket material from gasket surface of

transmission case.

(4) Remove fluid filter screws and remove filter.

(5) Position new filter on valve body and install fil-

ter screws. Tighten screws to 4 Nzm (35 in. lbs.)

torque.

(6) Adjust rear band at this time if required.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 150 in. lbs. (17

Nzm) torque.

(8) Adjust front band at this time if required.

(9) Lower vehicle and refill transmission with Mo-

par ATF Plus, type 7176 fluid.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The most effective way to avoid overfilling after a

fluid change or overhaul is as follows:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of Mopar ATF

Plus to transmission:

(a) If only fluid and filter were changed, add3

pints (1-1/2 quarts)of ATF Plus to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of ATF Plus to transmission.

(3) Apply parking brakes.

(4) Start and run engine at normal curb idle speed.

(5) Apply service brakes, shift transmission

through all gear ranges then back to Neutral, and

leave engine running at curb idle speed.

(6) Remove funnel, insert dipstick and check fluid

level. Add only enough fluid to bring level toMIN

dot mark on dipstick.

(7) Drive vehicle until transmission fluid is at nor-

mal operating temperature. Then recheck fluid level

as described in next step.

(8) Leave engine running at curb idle speed, shift

into Neutral, and check fluid level again. This time,

add just enough fluid to bring level up toMAX ar-

row mark but do not overfill.

(9) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

SHIFT LINKAGE ADJUSTMENT (YJ)

(1) Check linkage adjustment by starting engine in

Park and Neutral.(2) Adjustment is OK if engine starts only in park

and Neutral. Adjustment is incorrect if engine starts

in one but not both positions.

(3) If engine starts in any position other than Park

or Neutral, or if engine will not start at all, park/

neutral position switch may be faulty.

(4) Shift transmission into Park.

(5) Raise vehicle.

(6) Check condition of shift rods, bellcrank,

bellcrank brackets and linkage bushings/grommets

(Fig. 2). Tighten, repair, replace worn, damaged

parts. Do not attempt adjustment if linkage compo-

nents are worn or damaged.

(7) Loosen shift rod trunnion lock bolt or nut. Be

sure upper shift rod slides freely in trunnion (Fig. 2).

Also be sure shift rods and bellcrank rotate freely

and do not bind at any point.

(8) Verify that manual lever is in Park detent (Fig.

2). Move lever all the way rearward to be sure it is in

Park.

(9) Check for positive engagement of park lock by

attempting to rotate propeller shaft. Shaft will not

turn when park pawl is engaged.

(10) Adjust shift rod trunnion to a obtain free pin

fit in bellcrank arm and tighten trunnion lock bolt or

nut. Prevent shift rod from turning while tightening

bolt or nut. Gearshift linkage lash must be elimi-

nated to obtain proper adjustment. Eliminate lash by

pulling downward on shift rod and pressing upward

on bellcrank.

(11) Confirm proper adjustment by starting engine

in Park and Neutral. Engine should start in these

positions only.If engine starts in any position

other than Park or Neutral, adjustment is in-

correct or neutral switch is faulty.

(12) Lower vehicle and verify that steering lock op-

erates correctly.

SHIFT CABLE ADJUSTMENT (XJ)

(1) Shift transmission into Park.

(2) Raise vehicle.

(3) Release cable adjuster clamp to unlock cable

(Figs. 3 and 4). Clamp is at transmission end of ca-

ble.

(4) Unsnap cable from transmission cable bracket.

(5) Move transmission shift lever fully rearward to

Park detent. Lever is on manual valve shaft at driver

side of case.

(6) Verify positive engagement of park lock by at-

tempting to rotate propeller shaft. Shaft will not ro-

tate when park lock is engaged.

(7) Snap cable into cable bracket.

(8) Lock shift cable by pressing cable adjuster

clamp down until it snaps into place.

(9) Check engine starting. Engine should start only

in Park and Neutral.

(10) Lower vehicle.

21 - 100 30RH/32RH IN-VEHICLE SERVICEJ

Page 1740 of 2158

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified in test, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified in test, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, or throttle cam

sticking, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn, or damaged

²overdrive clutch worn, or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.Stall speeds are

checked in both Drive and Reverse ranges with

the AW-4 transmission.

(1) Before starting test, be sure fluid level is cor-

rect and fluid is at normal operating temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Open throttle completely and record maximum

engine rpm registered on tachometer. It takes any-

where from 4 to 10 seconds to reach maximum rpm.

However, once maximum rpm has been achieved,do

not hold wide open throttle for more than 3-4

seconds.CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 4

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(9) Stall speed should be in 2100-2400 rpm range

in Drive.

(10) Release throttle, shift transmission into Neu-

tral, and run engine for 20-30 seconds to cool fluid.

(11) Shift transmission into Reverse.

(12) Repeat stall test described in step (8).

(13) Stall speed in Reverse should also be in 2100-

2400 rpm range.

(14) Release accelerator pedal, shift transmission

into Neutral, and run engine for 20-30 seconds to

cool fluid.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

21 - 178 AW-4 TRANSMISSION DIAGNOSISJ

Page 1745 of 2158

(6) Let engine run at normal curb idle speed, apply

service brakes. Then shift transmission through all

gear ranges and back to PARK (leave engine run-

ning).

(7) Remove dipstick and check fluid level. Add only

enough fluid to bring level to Full mark on dipstick.

Do not overfill.If too much fluid is added, excess

amount can be removed with suction gun and

plastic tubing. Tubing only has to be long

enough to extend into oil pan.

(8) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

TRANSMISSION CONTROL MODULE (TCM)

SERVICE

Use the DRB scan tool to diagnose transmission

control module function whenever a fault is sus-

pected. Replace the module only when the scan tool

indicates the module is actually faulty.

TRANSMISSION CONTROL MODULE

REPLACEMENT

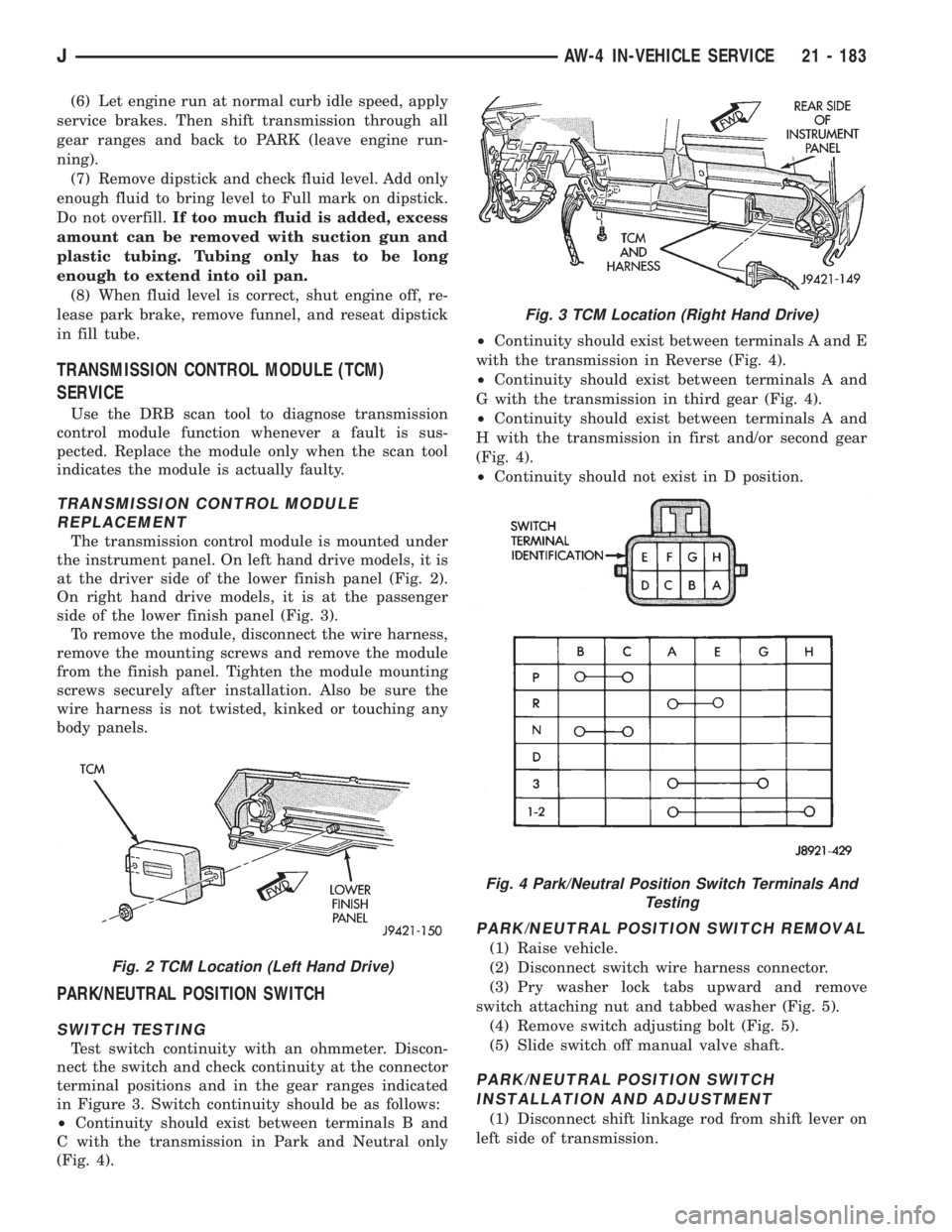

The transmission control module is mounted under

the instrument panel. On left hand drive models, it is

at the driver side of the lower finish panel (Fig. 2).

On right hand drive models, it is at the passenger

side of the lower finish panel (Fig. 3).

To remove the module, disconnect the wire harness,

remove the mounting screws and remove the module

from the finish panel. Tighten the module mounting

screws securely after installation. Also be sure the

wire harness is not twisted, kinked or touching any

body panels.

PARK/NEUTRAL POSITION SWITCH

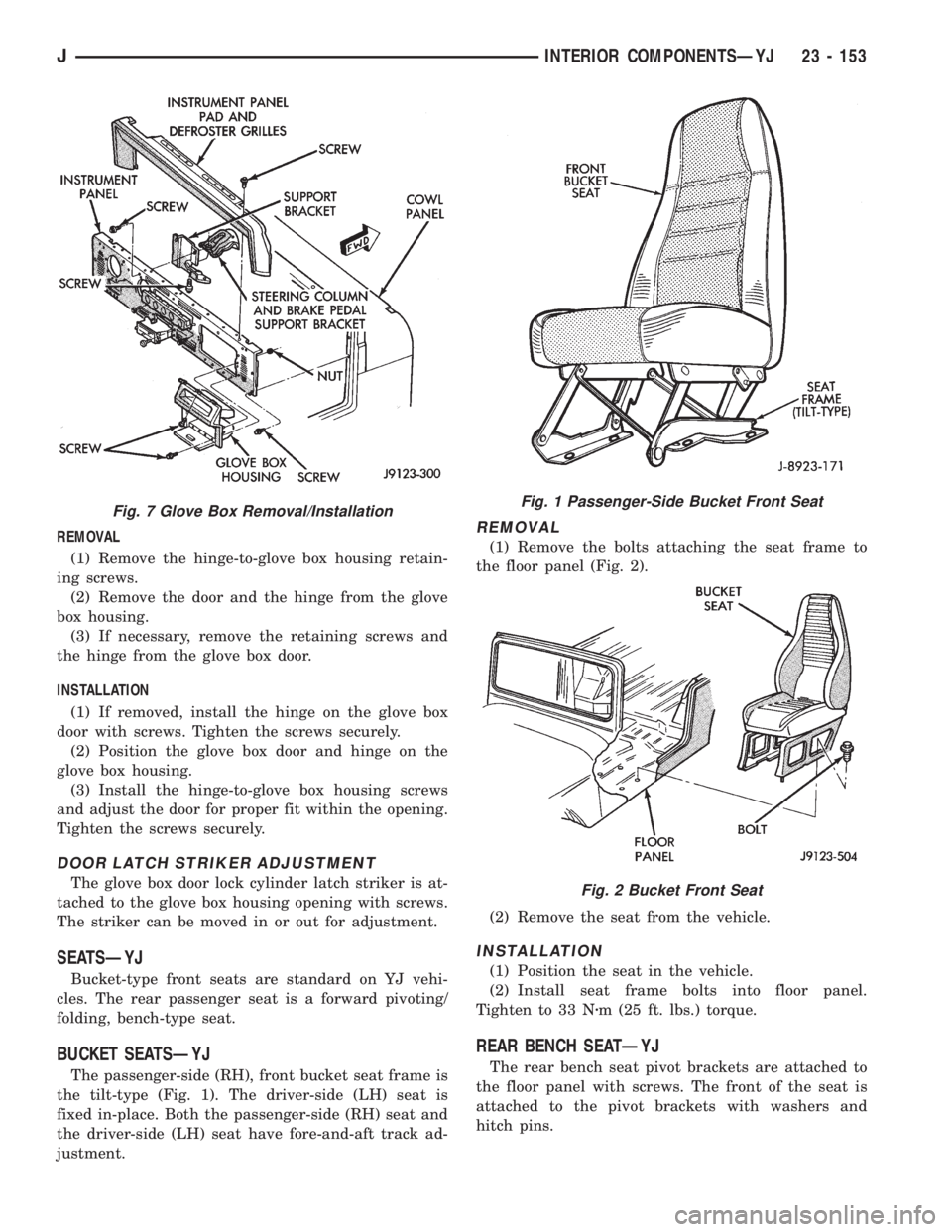

SWITCH TESTING

Test switch continuity with an ohmmeter. Discon-

nect the switch and check continuity at the connector

terminal positions and in the gear ranges indicated

in Figure 3. Switch continuity should be as follows:

²Continuity should exist between terminals B and

C with the transmission in Park and Neutral only

(Fig. 4).²Continuity should exist between terminals A and E

with the transmission in Reverse (Fig. 4).

²Continuity should exist between terminals A and

G with the transmission in third gear (Fig. 4).

²Continuity should exist between terminals A and

H with the transmission in first and/or second gear

(Fig. 4).

²Continuity should not exist in D position.

PARK/NEUTRAL POSITION SWITCH REMOVAL

(1) Raise vehicle.

(2) Disconnect switch wire harness connector.

(3) Pry washer lock tabs upward and remove

switch attaching nut and tabbed washer (Fig. 5).

(4) Remove switch adjusting bolt (Fig. 5).

(5) Slide switch off manual valve shaft.

PARK/NEUTRAL POSITION SWITCH

INSTALLATION AND ADJUSTMENT

(1) Disconnect shift linkage rod from shift lever on

left side of transmission.

Fig. 2 TCM Location (Left Hand Drive)

Fig. 3 TCM Location (Right Hand Drive)

Fig. 4 Park/Neutral Position Switch Terminals And

Testing

JAW-4 IN-VEHICLE SERVICE 21 - 183

Page 2071 of 2158

REMOVAL

(1) Remove the hinge-to-glove box housing retain-

ing screws.

(2) Remove the door and the hinge from the glove

box housing.

(3) If necessary, remove the retaining screws and

the hinge from the glove box door.

INSTALLATION

(1) If removed, install the hinge on the glove box

door with screws. Tighten the screws securely.

(2) Position the glove box door and hinge on the

glove box housing.

(3) Install the hinge-to-glove box housing screws

and adjust the door for proper fit within the opening.

Tighten the screws securely.

DOOR LATCH STRIKER ADJUSTMENT

The glove box door lock cylinder latch striker is at-

tached to the glove box housing opening with screws.

The striker can be moved in or out for adjustment.

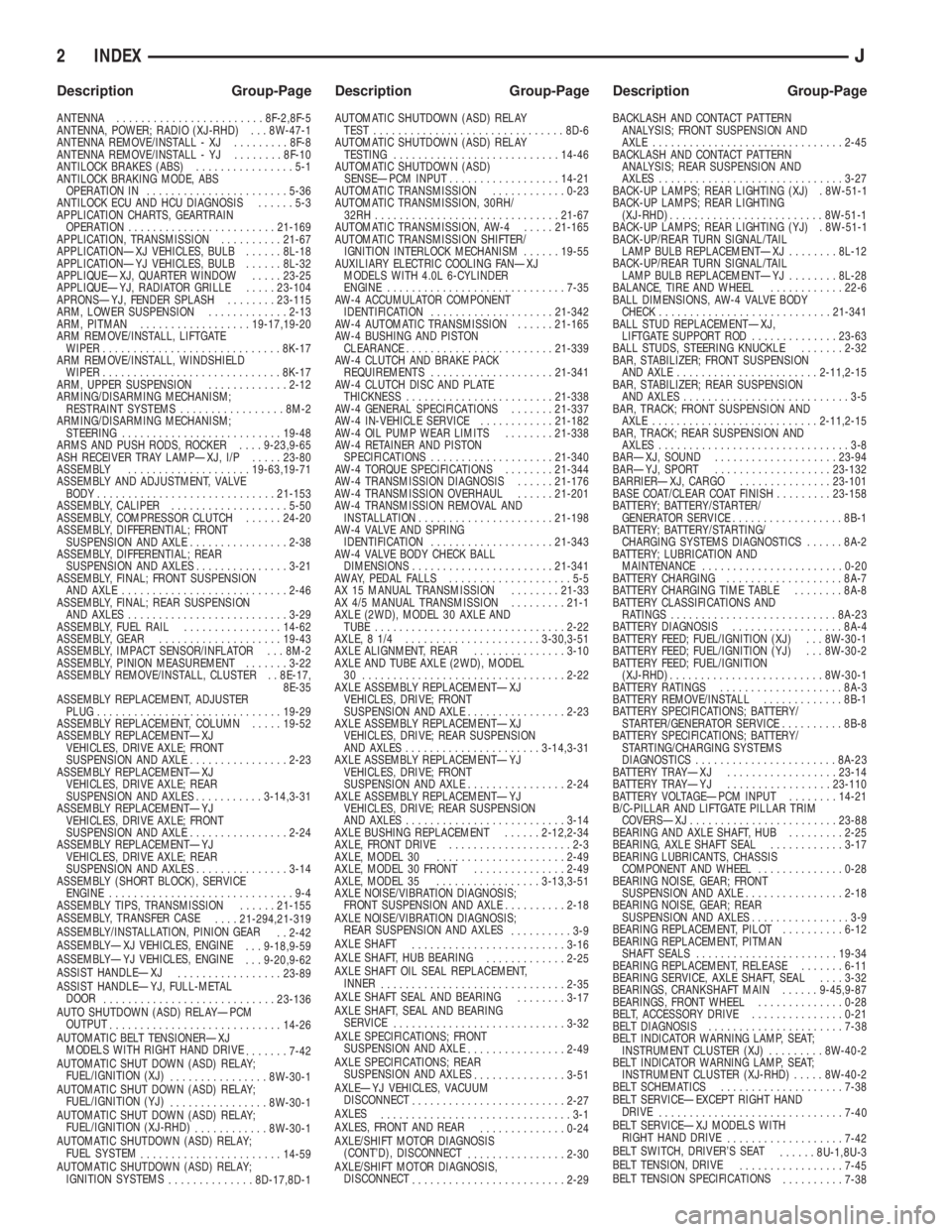

SEATSÐYJ

Bucket-type front seats are standard on YJ vehi-

cles. The rear passenger seat is a forward pivoting/

folding, bench-type seat.

BUCKET SEATSÐYJ

The passenger-side (RH), front bucket seat frame is

the tilt-type (Fig. 1). The driver-side (LH) seat is

fixed in-place. Both the passenger-side (RH) seat and

the driver-side (LH) seat have fore-and-aft track ad-

justment.

REMOVAL

(1) Remove the bolts attaching the seat frame to

the floor panel (Fig. 2).

(2) Remove the seat from the vehicle.

INSTALLATION

(1) Position the seat in the vehicle.

(2) Install seat frame bolts into floor panel.

Tighten to 33 Nzm (25 ft. lbs.) torque.

REAR BENCH SEATÐYJ

The rear bench seat pivot brackets are attached to

the floor panel with screws. The front of the seat is

attached to the pivot brackets with washers and

hitch pins.

Fig. 7 Glove Box Removal/InstallationFig. 1 Passenger-Side Bucket Front Seat

Fig. 2 Bucket Front Seat

JINTERIOR COMPONENTSÐYJ 23 - 153

Page 2126 of 2158

ANTENNA........................8F-2,8F-5

ANTENNA, POWER; RADIO (XJ-RHD) . . . 8W-47-1

ANTENNA REMOVE/INSTALL - XJ.........8F-8

ANTENNA REMOVE/INSTALL - YJ........8F-10

ANTILOCK BRAKES (ABS)................5-1

ANTILOCK BRAKING MODE, ABS

OPERATION IN.......................5-36

ANTILOCK ECU AND HCU DIAGNOSIS......5-3

APPLICATION CHARTS, GEARTRAIN

OPERATION........................21-169

APPLICATION, TRANSMISSION..........21-67

APPLICATIONÐXJ VEHICLES, BULB......8L-18

APPLICATIONÐYJ VEHICLES, BULB......8L-32

APPLIQUEÐXJ, QUARTER WINDOW.....23-25

APPLIQUEÐYJ, RADIATOR GRILLE.....23-104

APRONSÐYJ, FENDER SPLASH........23-115

ARM, LOWER SUSPENSION.............2-13

ARM, PITMAN..................19-17,19-20

ARM REMOVE/INSTALL, LIFTGATE

WIPER.............................8K-17

ARM REMOVE/INSTALL, WINDSHIELD

WIPER.............................8K-17

ARM, UPPER SUSPENSION.............2-12

ARMING/DISARMING MECHANISM;

RESTRAINT SYSTEMS.................8M-2

ARMING/DISARMING MECHANISM;

STEERING..........................19-48

ARMS AND PUSH RODS, ROCKER....9-23,9-65

ASH RECEIVER TRAY LAMPÐXJ, I/P.....23-80

ASSEMBLY....................19-63,19-71

ASSEMBLY AND ADJUSTMENT, VALVE

BODY.............................21-153

ASSEMBLY, CALIPER...................5-50

ASSEMBLY, COMPRESSOR CLUTCH......24-20

ASSEMBLY, DIFFERENTIAL; FRONT

SUSPENSION AND AXLE................2-38

ASSEMBLY, DIFFERENTIAL; REAR

SUSPENSION AND AXLES...............3-21

ASSEMBLY, FINAL; FRONT SUSPENSION

AND AXLE...........................2-46

ASSEMBLY, FINAL; REAR SUSPENSION

AND AXLES..........................3-29

ASSEMBLY, FUEL RAIL................14-62

ASSEMBLY, GEAR....................19-43

ASSEMBLY, IMPACT SENSOR/INFLATOR . . . 8M-2

ASSEMBLY, PINION MEASUREMENT.......3-22

ASSEMBLY REMOVE/INSTALL, CLUSTER . . 8E-17,

8E-35

ASSEMBLY REPLACEMENT, ADJUSTER

PLUG..............................19-29

ASSEMBLY REPLACEMENT, COLUMN.....19-52

ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE AXLE; FRONT

SUSPENSION AND AXLE................2-23

ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE AXLE; REAR

SUSPENSION AND AXLES...........3-14,3-31

ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE AXLE; FRONT

SUSPENSION AND AXLE................2-24

ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE AXLE; REAR

SUSPENSION AND AXLES...............3-14

ASSEMBLY (SHORT BLOCK), SERVICE

ENGINE..............................9-4

ASSEMBLY TIPS, TRANSMISSION......21-155

ASSEMBLY, TRANSFER CASE

....21-294,21-319

ASSEMBLY/INSTALLATION, PINION GEAR

. . 2-42

ASSEMBLYÐXJ VEHICLES, ENGINE

. . . 9-18,9-59

ASSEMBLYÐYJ VEHICLES, ENGINE

. . . 9-20,9-62

ASSIST HANDLEÐXJ

.................23-89

ASSIST HANDLEÐYJ, FULL-METAL

DOOR

............................23-136

AUTO SHUTDOWN (ASD) RELAYÐPCM

OUTPUT

............................14-26

AUTOMATIC BELT TENSIONERÐXJ

MODELS WITH RIGHT HAND DRIVE

.......7-42

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL/IGNITION (XJ)

................8W-30-1

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL/IGNITION (YJ)

................8W-30-1

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL/IGNITION (XJ-RHD)

............8W-30-1

AUTOMATIC SHUTDOWN (ASD) RELAY;

FUEL SYSTEM

.......................14-59

AUTOMATIC SHUTDOWN (ASD) RELAY;

IGNITION SYSTEMS

..............8D-17,8D-1AUTOMATIC SHUTDOWN (ASD) RELAY

TEST...............................8D-6

AUTOMATIC SHUTDOWN (ASD) RELAY

TESTING...........................14-46

AUTOMATIC SHUTDOWN (ASD)

SENSEÐPCM INPUT..................14-21

AUTOMATIC TRANSMISSION............0-23

AUTOMATIC TRANSMISSION, 30RH/

32RH..............................21-67

AUTOMATIC TRANSMISSION, AW-4.....21-165

AUTOMATIC TRANSMISSION SHIFTER/

IGNITION INTERLOCK MECHANISM......19-55

AUXILIARY ELECTRIC COOLING FANÐXJ

MODELS WITH 4.0L 6-CYLINDER

ENGINE.............................7-35

AW-4 ACCUMULATOR COMPONENT

IDENTIFICATION....................21-342

AW-4 AUTOMATIC TRANSMISSION......21-165

AW-4 BUSHING AND PISTON

CLEARANCE........................21-339

AW-4 CLUTCH AND BRAKE PACK

REQUIREMENTS....................21-341

AW-4 CLUTCH DISC AND PLATE

THICKNESS........................21-338

AW-4 GENERAL SPECIFICATIONS.......21-337

AW-4 IN-VEHICLE SERVICE............21-182

AW-4 OIL PUMP WEAR LIMITS........21-338

AW-4 RETAINER AND PISTON

SPECIFICATIONS....................21-340

AW-4 TORQUE SPECIFICATIONS........21-344

AW-4 TRANSMISSION DIAGNOSIS......21-176

AW-4 TRANSMISSION OVERHAUL......21-201

AW-4 TRANSMISSION REMOVAL AND

INSTALLATION......................21-198

AW-4 VALVE AND SPRING

IDENTIFICATION....................21-343

AW-4 VALVE BODY CHECK BALL

DIMENSIONS.......................21-341

AWAY, PEDAL FALLS....................5-5

AX 15 MANUAL TRANSMISSION........21-33

AX 4/5 MANUAL TRANSMISSION.........21-1

AXLE (2WD), MODEL 30 AXLE AND

TUBE...............................2-22

AXLE, 8 1/4......................3-30,3-51

AXLE ALIGNMENT, REAR...............3-10

AXLE AND TUBE AXLE (2WD), MODEL

30 .................................2-22

AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE; FRONT

SUSPENSION AND AXLE................2-23

AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES......................3-14,3-31

AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE; FRONT

SUSPENSION AND AXLE................2-24

AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES..........................3-14

AXLE BUSHING REPLACEMENT......2-12,2-34

AXLE, FRONT DRIVE....................2-3

AXLE, MODEL 30.....................2-49

AXLE, MODEL 30 FRONT...............2-49

AXLE, MODEL 35.................3-13,3-51

AXLE NOISE/VIBRATION DIAGNOSIS;

FRONT SUSPENSION AND AXLE..........2-18

AXLE NOISE/VIBRATION DIAGNOSIS;

REAR SUSPENSION AND AXLES

..........3-9

AXLE SHAFT

.........................3-16

AXLE SHAFT, HUB BEARING

.............2-25

AXLE SHAFT OIL SEAL REPLACEMENT,

INNER

..............................2-35

AXLE SHAFT SEAL AND BEARING

........3-17

AXLE SHAFT, SEAL AND BEARING

SERVICE

............................3-32

AXLE SPECIFICATIONS; FRONT

SUSPENSION AND AXLE

................2-49

AXLE SPECIFICATIONS; REAR

SUSPENSION AND AXLES

...............3-51

AXLEÐYJ VEHICLES, VACUUM

DISCONNECT

.........................2-27

AXLES

...............................3-1

AXLES, FRONT AND REAR

..............0-24

AXLE/SHIFT MOTOR DIAGNOSIS

(CONT'D), DISCONNECT

................2-30

AXLE/SHIFT MOTOR DIAGNOSIS,

DISCONNECT

.........................2-29BACKLASH AND CONTACT PATTERN

ANALYSIS; FRONT SUSPENSION AND

AXLE...............................2-45

BACKLASH AND CONTACT PATTERN

ANALYSIS; REAR SUSPENSION AND

AXLES..............................3-27

BACK-UP LAMPS; REAR LIGHTING (XJ) . 8W-51-1

BACK-UP LAMPS; REAR LIGHTING

(XJ-RHD).........................8W-51-1

BACK-UP LAMPS; REAR LIGHTING (YJ) . 8W-51-1

BACK-UP/REAR TURN SIGNAL/TAIL

LAMP BULB REPLACEMENTÐXJ........8L-12

BACK-UP/REAR TURN SIGNAL/TAIL

LAMP BULB REPLACEMENTÐYJ........8L-28

BALANCE, TIRE AND WHEEL............22-6

BALL DIMENSIONS, AW-4 VALVE BODY

CHECK............................21-341

BALL STUD REPLACEMENTÐXJ,

LIFTGATE SUPPORT ROD..............23-63

BALL STUDS, STEERING KNUCKLE.......2-32

BAR, STABILIZER; FRONT SUSPENSION

AND AXLE.......................2-11,2-15

BAR, STABILIZER; REAR SUSPENSION

AND AXLES...........................3-5

BAR, TRACK; FRONT SUSPENSION AND

AXLE...........................2-11,2-15

BAR, TRACK; REAR SUSPENSION AND

AXLES...............................3-8

BARÐXJ, SOUND....................23-94

BARÐYJ, SPORT...................23-132

BARRIERÐXJ, CARGO...............23-101

BASE COAT/CLEAR COAT FINISH.........23-158

BATTERY; BATTERY/STARTER/

GENERATOR SERVICE..................8B-1

BATTERY; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS......8A-2

BATTERY; LUBRICATION AND

MAINTENANCE.......................0-20

BATTERY CHARGING...................8A-7

BATTERY CHARGING TIME TABLE........8A-8

BATTERY CLASSIFICATIONS AND

RATINGS...........................8A-23

BATTERY DIAGNOSIS..................8A-4

BATTERY FEED; FUEL/IGNITION (XJ) . . . 8W-30-1

BATTERY FEED; FUEL/IGNITION (YJ) . . . 8W-30-2

BATTERY FEED; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

BATTERY RATINGS....................8A-3

BATTERY REMOVE/INSTALL.............8B-1

BATTERY SPECIFICATIONS; BATTERY/

STARTER/GENERATOR SERVICE..........8B-8

BATTERY SPECIFICATIONS; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS.......................8A-23

BATTERY TRAYÐXJ..................23-14

BATTERY TRAYÐYJ.................23-110

BATTERY VOLTAGEÐPCM INPUT........14-21

B/C-PILLAR AND LIFTGATE PILLAR TRIM

COVERSÐXJ........................23-88

BEARING AND AXLE SHAFT, HUB.........2-25

BEARING, AXLE SHAFT SEAL............3-17

BEARING LUBRICANTS, CHASSIS

COMPONENT AND WHEEL..............0-28

BEARING NOISE, GEAR; FRONT

SUSPENSION AND AXLE................2-18

BEARING NOISE, GEAR; REAR

SUSPENSION AND AXLES................3-9

BEARING REPLACEMENT, PILOT..........6-12

BEARING REPLACEMENT, PITMAN

SHAFT SEALS.......................19-34

BEARING REPLACEMENT, RELEASE.......6-11

BEARING SERVICE, AXLE SHAFT, SEAL....3-32

BEARINGS, CRANKSHAFT MAIN......9-45,9-87

BEARINGS, FRONT WHEEL..............0-28

BELT, ACCESSORY DRIVE...............0-21

BELT DIAGNOSIS......................7-38

BELT INDICATOR WARNING LAMP, SEAT;

INSTRUMENT CLUSTER (XJ).........8W-40-2

BELT INDICATOR WARNING LAMP, SEAT;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

BELT SCHEMATICS....................7-38

BELT SERVICEÐEXCEPT RIGHT HAND

DRIVE

..............................7-40

BELT SERVICEÐXJ MODELS WITH

RIGHT HAND DRIVE

...................7-42

BELT SWITCH, DRIVER'S SEAT

......8U-1,8U-3

BELT TENSION, DRIVE

.................7-45

BELT TENSION SPECIFICATIONS

..........7-38

2 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2132 of 2158

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-2

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (YJ)...............8W-42-1,8W-42-2

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ).............................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ-RHD).........................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(YJ).............................8W-32-2

DIAGRAM INDEX; CHARGING SYSTEM

(XJ).............................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(XJ-RHD).........................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(YJ).............................8W-20-1

DIAGRAM INDEX; FRONT LIGHTING (XJ) . 8W-50-2

DIAGRAM INDEX; FRONT LIGHTING

(XJ-RHD).........................8W-50-3

DIAGRAM INDEX; FRONT LIGHTING (YJ) . 8W-50-2

DIAGRAM INDEX; FUEL/IGNITION (YJ) . . 8W-30-5

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ).............................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ-RHD).........................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(YJ).............................8W-10-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ)................8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (YJ)..................8W-15-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ).....................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ-RHD).................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (YJ).....................8W-48-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER . . . 8E-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ).............8W-40-1,8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (YJ).....................8W-40-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ).............................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(YJ).............................8W-44-2

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ).............................8W-49-1

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ-RHD).........................8W-49-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ).............................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ-RHD).........................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(YJ).............................8W-11-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ)

.............................8W-61-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ-RHD)

.........................8W-61-1

DIAGRAM INDEX; POWER MIRRORS

(XJ)

.............................8W-62-1

DIAGRAM INDEX; POWER MIRRORS

(XJ-RHD)

.........................8W-62-1

DIAGRAM INDEX; POWER SEAT (XJ)

. . . 8W-63-1

DIAGRAM INDEX; POWER SEAT

(XJ-RHD)

.........................8W-63-1

DIAGRAM INDEX; POWER WINDOWS

(XJ)

.............................8W-60-2

DIAGRAM INDEX; POWER WINDOWS

(XJ-RHD)

.........................8W-60-2

DIAGRAM INDEX; REAR LIGHTING (XJ)

. 8W-51-1

DIAGRAM INDEX; REAR LIGHTING

(XJ-RHD)

.........................8W-51-1

DIAGRAM INDEX; REAR LIGHTING (YJ)

. 8W-51-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ)

.............................8W-21-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ-RHD)

.........................8W-21-1DIAGRAM INDEX; STARTING SYSTEM

(YJ).............................8W-21-1

DIAGRAM INDEX; TRAILER TOW (XJ) . . 8W-54-1

DIAGRAM INDEX; TRAILER TOW

(XJ-RHD).........................8W-54-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ-RHD)...............8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (YJ)...................8W-31-1

DIAGRAM INDEX; TURN SIGNALS (XJ) . 8W-52-1

DIAGRAM INDEX; TURN SIGNALS

(XJ-RHD).........................8W-52-1

DIAGRAM INDEX; TURN SIGNALS (YJ) . 8W-52-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ)....................8W-33-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ-RHD)................8W-33-1

DIAGRAM INDEX; WIPERS (XJ).......8W-53-2

DIAGRAM INDEX; WIPERS (XJ-RHD) . . . 8W-53-2

DIAGRAM INDEX; WIPERS (YJ).......8W-53-2

DIAGRAM INDEX; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

DIAGRAM INDEXÐ2.5L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIAGRAM INDEXÐ4.0L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIFFERENTIAL AND PINION

MEASUREMENT.......................2-40

DIFFERENTIAL ASSEMBLY; FRONT

SUSPENSION AND AXLE.................2-38

DIFFERENTIAL ASSEMBLY; REAR

SUSPENSION AND AXLES...............3-21

DIFFERENTIAL DISASSEMBLY; FRONT

SUSPENSION AND AXLE................2-35

DIFFERENTIAL DISASSEMBLY; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL INSTALLATION............2-44

DIFFERENTIAL, LIMITED SLIP............3-10

DIFFERENTIAL MEASUREMENT AND

INSTALLATION........................3-25

DIFFERENTIAL OVERHAUL..............3-46

DIFFERENTIAL REMOVAL; FRONT

SUSPENSION AND AXLE................2-34

DIFFERENTIAL REMOVAL; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL SERVICE................3-34

DIFFERENTIAL SHIM PACK

MEASUREMENT AND ADJUSTMENT.......2-43

DIFFERENTIAL, TRAC-LOK..............3-45

DIMENSION DATA, VEHICLE.....Intro.-5,Intro.-6

DIMENSIONS, AW-4 VALVE BODY CHECK

BALL.............................21-341

DIMENSIONS, DESIGNATIONS,

LABELS/PLATES, CODES..............Intro.-1

DIMENSIONS, FRAME.............13-13,13-1

DIMMER SWITCH REMOVE/INSTALL,

HEADLAMP OR PANEL................8E-42

DIMMER SWITCH REPLACEMENTÐYJ,

HEADLAMP.........................8L-26

DIMMING MODULE; FRONT LIGHTING

(XJ-RHD).........................8W-50-1

DIODE REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-8

DIRECT CLUTCH OVERHAUL...........21-228

DISASSEMBLY AND INSPECTION, VALVE

BODY.............................21-147

DISASSEMBLY AND OVERHAUL,

TRANSFER CASE..............21-289,21-310

DISASSEMBLY AND OVERHAUL,

TRANSMISSION.................21-37,21-5

DISASSEMBLY, CALIPER................5-48

DISASSEMBLY, DIFFERENTIAL; FRONT

SUSPENSION AND AXLE................2-35

DISASSEMBLY, DIFFERENTIAL; REAR

SUSPENSION AND AXLES...............3-18

DISASSEMBLY, TRANSMISSION . . 21-119,21-201

DISASSEMBLYÐCOLUMN OR CONSOLE

SHIFT..............................19-60

DISC AND PLATE THICKNESS, AW-4

CLUTCH...........................21-338

DISC BRAKE ROTOR REFINISHING

........5-53

DISC BRAKE ROTOR RUNOUT

...........5-52

DISC BRAKE ROTOR THICKNESS

.........5-52

DISC BRAKES

........................5-45

DISC BRAKESHOE INSTALLATION

.........5-47DISC BRAKESHOE REMOVAL............5-46

DISC INSTALLATION, CLUTCH COVER.....6-10

DISC REMOVAL, CLUTCH COVER.........6-10

DISC RUNOUT, CLUTCH COVER...........6-3

DISCHARGE (ESD) SENSITIVE DEVICES,

ELECTROSTATIC; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

DISCONNECT AXLEÐYJ VEHICLES,

VACUUM............................2-27

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS..........................2-29

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS (CONT'D)..................2-30

DISPLAY, ABS WARNING LIGHT...........5-3

DISPLAY SYMBOLS, INTERNATIONAL

VEHICLE CONTROL..................Intro.-5

DISPLAY SYMBOLS, VEHICLE CONTROL . Intro.-10

DISPOSALÐXJ, LIFTGATE SUPPORT

ROD CYLINDER......................23-63

DISTRIBUTOR.......................8D-19

DISTRIBUTOR CAP....................8D-7

DISTRIBUTOR CAP AND ROTOR,

IGNITION CABLES.....................0-20

DISTRIBUTOR ROTOR.................8D-8

DISTRIBUTORS.......................8D-4

DOME LAMP, CARGO LAMP; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

DOME LAMP, CARGO LAMP, COURTESY

LAMPS; INTERIOR LIGHTING (XJ).....8W-44-1

DOME LAMP REPLACEMENTÐXJ.........8L-17

DOME LAMPÐXJ....................23-93

DOME LAMPS, COURTESY LAMPS;

INTERIOR LIGHTING (YJ)............8W-44-1

DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES,

HARDTOP..........................8L-31

DOME/COURTESY LAMP SERVICE

INFORMATIONÐXJ...................8L-16

DOME/COURTESY LAMP SERVICE

INFORMATIONÐYJ...................8L-31

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐXJ.....................8L-16

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐYJ.....................8L-31

DOOR ALIGNMENT ADJUSTMENTÐ

MAJOR............................23-41

DOOR ALIGNMENT ADJUSTMENTÐ

MINOR.............................23-37

DOOR ASSIST HANDLEÐYJ, FULL-

METAL............................23-136

DOOR BUMPERSÐXJ, FUEL FILLER.....23-27

DOOR CONTROL CABLES, VENT.........24-32

DOOR EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ.........................23-54

DOOR EXTERNAL HANDLEÐXJ.........23-48

DOOR FRAME GLASS CHANNEL

REPLACEMENTÐYJ.................23-142

DOOR HINGE/HINGE PIN

REPLACEMENTÐXJ..................23-52

DOOR HINGESÐYJ, FULL-METAL.......23-140

DOOR INSIDE LATCH RELEASE AND

LOCK RODSÐXJ.....................23-50

DOOR JAMB SWITCH, DRIVER'S.....8U-1,8U-2

DOOR KEY LOCK CYLINDERÐXJ........23-47

DOOR KEY LOCK CYLINDERÐYJ,

FULL-METAL.......................23-139

DOOR LATCH ADJUSTMENTÐXJ........23-48

DOOR LATCH EXTERNAL RELEASE

HANDLEÐYJ, FULL-METAL............23-140

DOOR LATCH INSIDE RELEASE AND

LOCK HANDLEÐYJ, FULL-METAL.......23-137

DOOR LATCH STRIKERÐYJ, HALF-

METAL............................23-135

DOOR LATCHÐXJ....................23-49

DOOR LATCHÐYJ, FULL-METAL........23-140

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ).......................8W-61-1

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ-RHD)

..................8W-61-1

DOOR MIRROR (EXTERNAL)ÐYJ, HALF

METAL

............................23-121

DOOR MOTOR SWITCH REPLACEMENT,

BLOWER MOTOR/AIR

.................24-32

DOOR OPENER STORAGE, REMOTE

GARAGE

............................8C-1

DOOR OPENING WEATHERSTRIP

SEALSÐXJ, DOOR WINDOW GLASS

.....23-55

8 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2133 of 2158

DOOR REMOVAL/INSTALLATIONÐXJ.....23-35

DOOR RESTRAINT REPLACEMENTÐXJ . . . 23-41

DOOR SERVICEÐYJ, FULL-METAL......23-142

DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES, FRONT....................23-53

DOOR STATIONARY WINDOW

GLASSÐXJ, REAR...................23-46

DOOR TRIM PANELÐXJ...............23-31

DOOR TRIM PANELÐYJ, FULL-METAL . . . 23-137

DOOR VACUUM MOTOR, FRESH AIR.....24-34

DOOR VACUUM MOTOR REPLACEMENT,

A/C RECIRCULATING..................24-27

DOOR VENT WINDOW GLASSÐYJ,

FULL-METAL.......................23-137

DOOR WATERDAMÐYJ, FULL-METAL . . . 23-137

DOOR WEATHERSTRIP SEAL

REPLACEMENTÐYJ.................23-142

DOOR WEATHERSTRIP SEALSÐYJ,

FULL-METAL.......................23-141

DOOR WINDOW EXTERIOR

MOLDINGSÐXJ.....................23-54

DOOR WINDOW GLASS AND DOOR

OPENING WEATHERSTRIP SEALSÐXJ....23-55

DOOR WINDOW GLASS REGULATOR

HANDLEÐYJ, FULL-METAL............23-136

DOOR WINDOW GLASS REGULATORÐ

XJ, FRONT..........................23-42

DOOR WINDOW GLASS REGULATORÐ

XJ, REAR...........................23-44

DOOR WINDOW GLASS REGULATORÐ

YJ, FULL-METAL....................23-138

DOOR WINDOW GLASSÐXJ, FRONT.....23-43

DOOR WINDOW GLASSÐXJ, REAR......23-45

DOOR WINDOW GLASSÐYJ, FULL-

METAL............................23-139

DOORÐYJ, HALF-METAL SOFT TOP.....23-134

DOUBLE CARDAN (CV)................16-11

DRAG LINK....................19-16,19-20

DRAINING COOLING SYSTEM............7-21

DRAW FUSE, IGNITION-OFF.............8F-1

DRAW, IGNITION-OFF.................8A-10

DRB SCAN TOOL; BRAKES...............5-3

DRB SCAN TOOL; COOLING SYSTEM.......7-5

DRB SCAN TOOL; EMISSION CONTROL

SYSTEMS...........................25-2

DRB SCAN TOOL; FUEL SYSTEM........14-54

DRB SCAN TOOL; IGNITION SYSTEMS....8D-8

DRIERÐ2.5L ENGINES, CONDENSER

FILTER.............................24-27

DRIERÐ4.0L ENGINES, FILTER.........24-28

DRIP RAIL MOLDINGÐXJ.............23-25

DRIVE (4WD) SWITCH, FOUR-WHEEL;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

DRIVE (4WD) SWITCH, FOUR-WHEEL;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

DRIVE, AUTOMATIC BELT TENSIONERÐ

XJ MODELS WITH RIGHT HAND..........7-42

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-23

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; REAR

SUSPENSION AND AXLES...........3-14,3-31

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-24

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; REAR

SUSPENSION AND AXLES

...............3-14

DRIVE AXLE, FRONT

....................2-3

DRIVE BELT, ACCESSORY

...............0-21

DRIVE BELT DIAGNOSIS (CONT.),

SERPENTINE

.........................7-40

DRIVE BELT DIAGNOSIS, SERPENTINE

.....7-39

DRIVE, BELT SERVICEÐEXCEPT RIGHT

HAND

...............................7-40

DRIVE, BELT SERVICEÐXJ MODELS

WITH RIGHT HAND

....................7-42

DRIVE BELT TENSION

..................7-45

DRIVE BELTS, ENGINE ACCESSORY

.......7-38

DRIVE GEAR, SPEED SENSOR

ROTORÐSPEEDOMETER

.............21-193

DRIVE, GENERATOR REMOVE/INSTALLÐ

LEFT-HAND

..........................8B-6

DRIVE, GENERATOR REMOVE/INSTALLÐ

RIGHT-HAND

.........................8B-7

DRIVE PULLEY REPLACEMENT

..........19-13DRIVE (RHD), BELT TENSIONÐEXCEPT

RIGHT HAND.........................7-38

DRIVE (RHD), BELT TENSIONÐRIGHT

HAND...............................7-38

DRIVE (RHD) MODELS, BELT TENSIONÐ

EXCEPT RIGHT HAND..................7-45

DRIVE SHAFTS.......................0-26

DRIVE VEHICLES, RIGHT HAND..........23-1

DRIVE, VISCOUS FAN..................7-34

DRIVELINE SNAP; FRONT SUSPENSION

AND AXLE...........................2-19

DRIVELINE SNAP; REAR SUSPENSION

AND AXLES..........................3-10

DRIVELINE VIBRATION.................16-3

DRIVER'S DOOR JAMB SWITCH.....8U-1,8U-2

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (LHD).........................8P-3

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (RHD).........................8P-4

DRIVER'S POWER LOCK SWITCHÐ4-

DOOR..............................8P-5

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (LHD).......................8S-4

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (RHD).......................8S-5

DRIVER'S POWER WINDOW SWITCHÐ

4-DOOR.............................8S-3

DRIVER'S SEAT BELT SWITCH.......8U-1,8U-3

DRIVETRAIN.........................0-22

DRL MODULE REPLACEMENTÐXJ.......8L-15

DRL MODULE REPLACEMENTÐYJ........8L-30

DRUM BRAKE ADJUSTMENT............5-57

DRUM BRAKES.......................5-55

DRUM BRAKESHOE INSTALLATION.......5-55

DRUM BRAKESHOE REMOVAL...........5-55

DRUM REFINISHING, BRAKE............5-58

DRUMÐREAR SUPPORT OVERHAUL,

OVERRUNNING CLUTCHÐLOW-

REVERSE..........................21-125

DUCT, DEFROSTER NOZZLE............24-33

DUCT, FRESH AIR INTAKE..............24-34

ECU AND HCU DIAGNOSIS, ANTILOCK......5-3

ECU INSTALLATION (XJ MODELS)........5-40

ECU OPERATION......................5-37

ECU REMOVAL (XJ MODELS)............5-40

ECU REMOVAL/INSTALLATION (YJ

MODELS)............................5-41

EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ, DOOR....................23-54

EFFECTS OF INCORRECT FLUID LEVEL....21-71

EFFORT, HARD PEDAL OR HIGH PEDAL.....5-6

ELECTRIC COOLING FANÐXJ MODELS

WITH 4.0L 6-CYLINDER ENGINE,

AUXILIARY..........................7-35

ELECTRICAL CONTROL, FUEL PUMP......14-5

ELECTRONIC CONTROL UNIT (ECU).......5-34

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

ELEMENT, AIR CLEANER; EMISSION

CONTROL SYSTEMS...................25-7

ELEMENT, AIR CLEANER; FUEL SYSTEM . . 14-59

ELEMENT, AIR CLEANER; LUBRICATION

AND MAINTENANCE...................0-18

ELEMENT TEST, OXYGEN SENSOR (O2S)

HEATING...........................14-48

ELEMENTS, HEATER; POWER MIRRORS

(XJ-RHD).........................8W-62-1

EMISSION CONTROL INFORMATION

(VECI) LABEL, VEHICLE.................25-1

EMISSION CONTROL SYSTEM...........0-20

EMISSION CONTROL SYSTEM

MAINTENANCE........................0-4

EMISSION CONTROLS..................25-4

EMR LAMPÐPCM OUTPUT............14-27

ENGINE ACCESSORY DRIVE BELTS.......7-38

ENGINE AND TRANSMISSION/TRANSFER

CASE IDENTIFICATION...............Intro.-5

ENGINE ASSEMBLY (SHORT BLOCK),

SERVICE.............................9-4

ENGINE ASSEMBLYÐXJ VEHICLES

. . . 9-18,9-59

ENGINE ASSEMBLYÐYJ VEHICLES

. . . 9-20,9-62

ENGINE, AUXILIARY ELECTRIC COOLING

FANÐXJ MODELS WITH 4.0L

6-CYLINDER

.........................7-35

ENGINE BLOCK HEATER

................7-44

ENGINE BREAK-IN

.....................0-15ENGINE COOLANT TEMPERATURE

GAUGE; INSTRUMENT CLUSTER (XJ) . . 8W-40-1

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL SYSTEM...............14-60

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (YJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; IGNITION SYSTEMS......8D-19,8D-5

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ-RHD)....8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR TEST; FUEL SYSTEM..........14-46

ENGINE COOLANT TEMPERATURE

SENSOR TEST; IGNITION SYSTEMS.......8D-9

ENGINE COOLANT TEMPERATURE

SENSORÐPCM INPUT................14-23

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

ENGINE COOLING SYSTEM..............0-18

ENGINE CYLINDER HEAD...........9-25,9-67

ENGINE CYLINDER HEAD COVER.....9-22,9-64

ENGINE CYLINDER HEAD GASKET

FAILURE DIAGNOSIS....................9-5

ENGINE DAMPER.....................9-17

ENGINE DIAGNOSIS....................9-5

ENGINE, DIAGRAM INDEXÐ2.5L;

FUEL/IGNITION (XJ)..................8W-30-6

ENGINE, DIAGRAM INDEXÐ4.0L;

FUEL/IGNITION (XJ)................8W-30-6

ENGINE, ENGINE EXHAUST MANIFOLDÐ

2.5L................................11-7

ENGINE, ENGINE EXHAUST MANIFOLDÐ

4.0L................................11-7

ENGINE, ENGINE FIRING ORDERÐ2.5L

4-CYLINDER........................8D-32

ENGINE, ENGINE FIRING ORDERÐ4.0L

6-CYLINDER........................8D-32

ENGINE EXHAUST MANIFOLDÐ2.5L

ENGINE.............................11-7

ENGINE EXHAUST MANIFOLDÐ4.0L

ENGINE.............................11-7

ENGINE FIRING ORDERÐ2.5L

4-CYLINDER ENGINE.................8D-32

ENGINE FIRING ORDERÐ4.0L

6-CYLINDER ENGINE.................8D-32

ENGINE, INTAKE MANIFOLDÐ2.5L........11-7

ENGINE, INTAKE MANIFOLDÐ4.0L........11-8

ENGINE MAINTENANCE.................0-15

ENGINE MOUNTÐREAR............9-16,9-57

ENGINE MOUNTSÐFRONT..........9-14,9-56

ENGINE OIL..........................0-15

ENGINE OIL CHANGE AND FILTER

REPLACEMENT.......................0-16

ENGINE OIL FILTER....................0-17

ENGINE OIL PRESSURE.................9-7

ENGINE ONLY, POWER STEERING

PRESSURE SWITCHÐ2.5L.............14-63

ENGINE ONLY, TORQUE CONVERTER

CLUTCH (TCC) SOLENOID AND

RELAYÐ2.5L; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

ENGINE ONLY, TRANSMISSION

CONTROL MODULEÐ4.0L;

TRANSMISSION CONTROLS (XJ)......8W-31-1

ENGINE PERFORMANCE.................9-2

ENGINE SERVICE PROCEDURES, 2.5L.....9-13

ENGINE SERVICE PROCEDURES, 4.0L.....9-55

ENGINE SPECIFICATIONS...........9-52,9-93

ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4 CYLINDER..........25-3

ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6 CYLINDER..........25-3

ENGINES, CONDENSER FILTER

DRIERÐ2.5L........................24-27

ENGINES, CONDENSERÐ4.0L..........24-28

ENGINES, FILTER DRIERÐ4.0L

.........24-28

ENGINES, FUEL USAGE STATEMENTÐ

GAS

................................0-19

ENGLISH/SAE CONVERSION, METRIC

. . Intro.-11

ENTRY MODULE, KEYLESS

.........8P-1,8P-7

ENTRY MODULE, REMOTE KEYLESS;

POWER DOOR LOCKS (XJ)

...........8W-61-1

JINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 2148 of 2158

REPLACEMENTÐXJ VEHICLES, DRIVE

AXLE ASSEMBLY; REAR SUSPENSION

AND AXLES......................3-14,3-31

REPLACEMENTÐXJ, WINDSHIELD

GLASS.............................23-69

REPLACEMENTÐYJ, BACK-UP/REAR

TURN SIGNAL/TAIL LAMP BULB.........8L-28

REPLACEMENTÐYJ, DOOR FRAME

GLASS CHANNEL...................23-142

REPLACEMENTÐYJ, DOOR

WEATHERSTRIP SEAL................23-142

REPLACEMENTÐYJ, DRL MODULE......8L-30

REPLACEMENTÐYJ, FOG LAMP.........8L-25

REPLACEMENTÐYJ, FOG LAMP SWITCH . 8L-26

REPLACEMENTÐYJ, FRONT PARK/TURN

SIGNAL LAMP BULB..................8L-25

REPLACEMENTÐYJ, HEADLAMP BULB . . . 8L-23

REPLACEMENTÐYJ, HEADLAMP

DIMMER SWITCH....................8L-26

REPLACEMENTÐYJ, LIFTGATE GLASS

WEATHERSTRIP SEAL................23-125

REPLACEMENTÐYJ, SIDE MARKER

LAMP BULB.........................8L-25

REPLACEMENTÐYJ, UNDERHOOD LAMP . 8L-29

REPLACEMENTÐYJ, UNDERHOOD LAMP

BULB..............................8L-29

REPLACEMENTÐYJ VEHICLES, DRIVE

AXLE ASSEMBLY; FRONT SUSPENSION

AND AXLE...........................2-24

REPLACEMENTÐYJ VEHICLES, DRIVE

AXLE ASSEMBLY; REAR SUSPENSION

AND AXLES..........................3-14

REPLACEMENTÐYJ VEHICLES,

HARDTOP DOME/CARGO LAMP BULB....8L-31

REQUIREMENTS, FUEL..................0-1

REQUIRING NO LUBRICATION,

COMPONENTS.........................0-2

RESERVE/OVERFLOW SYSTEM,

COOLANT............................7-24

RESERVOIR REPLACEMENT (2-PIECE

MASTER CYLINDER)...................5-19

RESERVOIR, VACUUM.................8H-1

RESISTANCE, IGNITION COIL............8D-9

RESISTANCE (OHMS)ÐCOOLANT

TEMPERATURE SENSOR/MANIFOLD

AIR TEMPERATURE, SENSOR...........14-46

RESISTANCE, SPARK PLUG CABLE......8D-14

RESISTORS REPLACEMENT, BLOWER

MOTOR............................24-31

RESTRAINT REPLACEMENTÐXJ, DOOR . . . 23-41

RETAINER AND PISTON

SPECIFICATIONS, AW-4...............21-340

RETAINING BRACKETÐYJ, REARVIEW

MIRROR..........................23-144

RETURNÐPCM INPUT, SENSOR.........14-25

REVEAL MOLDINGÐXJ, WINDSHIELD....23-66

REVEAL MOLDINGÐYJ, WINDSHIELD . . . 23-144

RHD, STEERING.....................19-74

RIGHT HAND DRIVE, AUTOMATIC BELT

TENSIONERÐXJ MODELS WITH.........7-42

RIGHT HAND DRIVE, BELT SERVICEÐ

EXCEPT.............................7-40

RIGHT HAND DRIVE, BELT SERVICEÐXJ

MODELS WITH.......................7-42

RIGHT HAND DRIVE (RHD), BELT

TENSIONÐEXCEPT....................7-38

RIGHT HAND DRIVE (RHD) MODELS,

BELT TENSIONÐEXCEPT...............7-45

RIGHT HAND DRIVE VEHICLES...........23-1

RIGHT TURN RELAY; TRAILER TOW

(XJ).............................8W-54-1

RIGHT TURN RELAY; TRAILER TOW

(XJ-RHD).........................8W-54-1

RING CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP......21-334

RING/THRUST WASHER/THRUST PLATE

SPECIFICATIONS, 30RH/32RH SNAP.....21-335

ROCKER ARMS AND PUSH RODS....9-23,9-65

ROD AND PAWL SERVICE, PARK.......21-190

ROD BALL STUD REPLACEMENTÐXJ,

LIFTGATE SUPPORT

..................23-63

ROD BEARING FITTING CHART,

CONNECTING

.....................9-41,9-83

ROD CYLINDER DISPOSALÐXJ,

LIFTGATE SUPPORT

..................23-63

ROD CYLINDERÐXJ, LIFTGATE

SUPPORT

..........................23-62

ROD, TIE

......................19-16,19-19RODS, PISTONS AND CONNECTING . . . 9-39,9-81

RODS, ROCKER ARMS AND PUSH....9-23,9-65

RODSÐXJ, DOOR INSIDE LATCH

RELEASE AND LOCK..................23-50

ROOF VENTÐYJ, HARD TOP..........23-127

ROTOR, DISTRIBUTOR.................8D-8

ROTOR, IGNITION CABLES,

DISTRIBUTOR CAP....................0-20

ROTOR INSTALLATION.................5-51

ROTOR REFINISHING, DISC BRAKE.......5-53

ROTOR REMOVAL.....................5-51

ROTOR RUNOUT, DISC BRAKE...........5-52

ROTOR THICKNESS, DISC BRAKE........5-52

ROTORÐSPEEDOMETER DRIVE GEAR,

SPEED SENSOR.....................21-193

ROUGH AND/OR HAS A MISS, INJECTOR

DIAGNOSISÐVEHICLE RUNS...........14-52

ROUTING SCHEMATICÐ2.5L 4

CYLINDER ENGINE, VACUUM............25-3

ROUTING SCHEMATICÐ4.0L 6

CYLINDER ENGINE, VACUUM............25-3

ROUTING SCHEMATICS, VACUUM HOSE . . . 25-2

ROUTING, SYSTEM COOLANT.............7-1

RUBBER AND PLASTIC COMPONENT

INSPECTION.........................0-20

RUBBER AND PLASTIC HOSES/TUBING....0-26

RUNNING LAMP (DRL) MODULE,

DAYTIME.........................8W-50-2

RUNNING LAMP (DRL) MODULEÐ

CANADIAN VEHICLES ONLY, DAYTIME. . . 8W-50-2

RUNNING LIGHTS (CANADA ONLY)ÐXJ,

DAYTIME...........................8L-15

RUNNING LIGHTS (CANADA ONLY)ÐYJ,

DAYTIME...........................8L-30

RUNOUT............................16-4

RUNOUT, CLUTCH COVER AND DISC.......6-3

RUNOUT, DISC BRAKE ROTOR...........5-52

RUNOUT, FLYWHEEL....................6-3

RUNOUT SPECIFICATIONS..............16-4

RUNOUT, TIRE AND WHEEL.............22-8

RUNS ROUGH AND/OR HAS A MISS,

INJECTOR DIAGNOSISÐVEHICLE........14-52

SAFETY CERTIFICATION LABEL, VEHICLE . Intro.-4

SAFETY LATCH STRIKER

REPLACEMENTÐXJ..................23-11

SAFETY LATCHÐYJ, HOOD............23-109

SAFETY PRECAUTIONS AND WARNINGS . . 13-10

SAFETY PRECAUTIONS, BRAKE...........5-2

SAFETY PRECAUTIONS, CLUTCH.........6-10

SANDING,BUFFING AND POLISHING,

WET..............................23-158

SCAN TOOL, DRB; BRAKES...............5-3

SCAN TOOL, DRB; COOLING SYSTEM......7-5

SCAN TOOL, DRB; EMISSION CONTROL

SYSTEMS...........................25-2

SCAN TOOL, DRB; FUEL SYSTEM........14-54

SCAN TOOL, DRB; IGNITION SYSTEMS....8D-8

SCHEDULES, MAINTENANCE.............0-4

SCHEMATIC - YJ, BUZZER MODULE......8U-4

SCHEMATICÐ2.5L 4 CYLINDER ENGINE,

VACUUM ROUTING....................25-3

SCHEMATICÐ4.0L 6 CYLINDER ENGINE,

VACUUM ROUTING....................25-3

SCHEMATICÐXJ, AIR CONDITIONING.....24-5

SCHEMATICÐXJ, HEATING..............24-2

SCHEMATICS, BELT....................7-38

SCHEMATICS, PCM SYSTEM............14-41

SCHEMATICS, VACUUM HOSE ROUTING . . . 25-2

SCI RECEIVEÐPCM INPUT.............14-24

SCI TRANSMITÐPCM OUTPUT.........14-29

SCREENÐXJ, COWL GRILLE...........23-12

SCREENÐXJ, HEADLAMP/FOG LAMP

ADJUSTMENT USING ALIGNMENT........8L-7

SCREENÐYJ, COWL GRILLE..........23-109

SCREENÐYJ, HEADLAMP/FOG LAMP

ADJUSTMENT USING ALIGNMENT.......8L-23

SCREW ANCHOR AND BUMPERÐXJ,

LIFTGATE LICENSE PLATE..............23-65

SCUFF PLATE/COWL SIDE TRIM

PANELÐXJ, FRONT INNER.............23-86

SCUFF PLATESÐXJ, INTERIOR TRIM

PANELS

............................23-84

SCUFF PLATESÐXJ, OUTER

............23-89

SEAL AND BEARING, AXLE SHAFT

........3-17

SEAL AND BEARING SERVICE, AXLE

SHAFT

..............................3-32

SEAL AND SPRING REPLACEMENT,

VALVE STEM

.........................9-65SEAL REPLACEMENT, INNER AXLE

SHAFT OIL...........................2-35

SEAL REPLACEMENT, MANUAL VALVE

SHAFT............................21-187

SEAL REPLACEMENT, OIL PUMP.......21-199

SEAL REPLACEMENT, PINION; FRONT

SUSPENSION AND AXLE................2-25

SEAL REPLACEMENT, PINION; REAR

SUSPENSION AND AXLES...............3-33

SEAL REPLACEMENT, PINION SHAFT......3-15

SEAL REPLACEMENT, PITMAN SHAFT....19-37

SEAL REPLACEMENT, TIMING CASE

COVER OIL......................9-30,9-73

SEAL REPLACEMENTÐYJ, DOOR

WEATHERSTRIP....................23-142

SEAL REPLACEMENTÐYJ, LIFTGATE

GLASS WEATHERSTRIP..............23-125

SEAL/CROSSMEMBER AIR

DEFLECTORÐXJ, COWL

WEATHERSTRIP.....................23-11

SEALÐDRIVE PLATE SERVICE,

CONVERTERÐPUMP.................21-116

SEALÐXJ, LIFTGATE OPENING

WEATHERSTRIP.....................23-64

SEALÐYJ, BELTLINE.................23-142

SEALÐYJ, COWL WEATHERSTRIP......23-109

SEALÐYJ, TAILGATE WEATHERSTRIP . . . 23-123

SEALÐYJ, WINDSHIELD FRAME

WEATHERSTRIP....................23-146

SEALS AND BEARING REPLACEMENT,

PITMAN SHAFT......................19-34

SEALS, REAR MAIN OIL..............9-49,9-89

SEALS, VALVE SPRINGS AND OIL........9-23

SEALSÐIN CAR REPLACEMENT, PITMAN

SHAFT.............................19-23

SEALSÐXJ, DOOR WINDOW GLASS

AND DOOR OPENING WEATHERSTRIP....23-55

SEALSÐYJ, FULL-METAL DOOR

WEATHERSTRIP....................23-141

SEAT ADJUSTER/MOTORS, POWER . . . 8R-1,8R-2

SEAT ADJUSTER/MOTORS REMOVE/

INSTALL, POWER.....................8R-3

SEAT BELT INDICATOR WARNING LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-2

SEAT BELT INDICATOR WARNING LAMP;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

SEAT BELT SWITCH, DRIVER'S......8U-1,8U-3

SEAT CUSHION AND COVERÐXJ,

BUCKET............................23-81

SEAT CUSHION COVERÐXJ, REAR......23-82

SEAT CUSHIONÐXJ, REAR.............23-82

SEAT PLATFORMÐXJ, BUCKET.........23-82

SEAT, POWER; POWER SEAT (XJ).....8W-63-1

SEAT, POWER; POWER SEAT (XJ-RHD) . 8W-63-1

SEAT SWITCH CONTINUITY, POWER......8R-2

SEAT SWITCH, POWER............8R-1,8R-2

SEAT SWITCH REMOVE/INSTALL,

POWER.............................8R-3

SEATBACK COVER AND FRAMEÐXJ,

BUCKET............................23-81

SEATBACK COVERÐXJ, REAR..........23-84

SEATBACK LATCH STRIKER AND

BUMPERÐXJ, REAR..................23-84

SEATBACKÐXJ, REAR................23-83

SEATÐYJ, REAR BENCH..............23-153

SEATSÐXJ, FRONT BUCKET............23-81

SEATSÐYJ........................23-153

SEATSÐYJ, BUCKET.................23-153

SECOND (2) RANGE, HYDRAULIC FLOW

IN MANUAL.........................21-96

SECOND BRAKE OVERHAUL...........21-241

SECONDARY CABLES, SPARK PLUG.....8D-14,

8D-24

SECONDARY CIRCUIT DIAGNOSIS,

IGNITION...........................8D-10

SECTION IDENTIFICATION; WIRING

DIAGRAMS (XJ)......................8W-1

SECTION IDENTIFICATION; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

SECTION IDENTIFICATION; WIRING

DIAGRAMS (YJ)

......................8W-1

SELECTIVE SNAP RING CHARTÐAX 15

MANUAL TRANSMISSION

.............21-334

SELF-DIAGNOSTIC TEST, COMPASS/

DISPLAY

............................8C-2

SENDING UNIT, FUEL GAUGE

...........14-16

SENSEÐPCM INPUT, AUTOMATIC

SHUTDOWN (ASD)

...................14-21

24 INDEXJ

Description Group-Page Description Group-Page Description Group-Page