steering column diagram JEEP YJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 380 of 2158

INSTRUMENT PANEL AND GAUGESÐYJ

CONTENTS

page page

INSTRUMENT PANEL AND GAUGESÐYJ..... 22

DIAGNOSIS............................ 23

GENERAL INFORMATION................. 20SERVICE PROCEDURES.................. 31

SPECIFICATIONS........................ 39

GENERAL INFORMATION

Following are general descriptions of major instru-

ment panel components. Refer to Group 8W - Wiring

Diagrams for complete circuit descriptions and dia-

grams.

INSTRUMENT PANEL

Modular instrument panel construction allows all

gauges and controls to be serviced from the front of

the panel. In addition, most instrument panel wiring

and heater components can be accessed without com-

plete instrument panel removal.

Removal of the left instrument cluster bezel allows

access to the main cluster assembly and most

switches. Removal of the center cluster bezel allows

access to the gauge package cluster assembly, the

heater controls, and the radio. Removal of the cluster

assemblies allows access to the individual gauges, il-

lumination and indicator lamp bulbs, printed cir-

cuits, and most wiring.

INSTRUMENT CLUSTERS

The instrument cluster used on YJ (Wrangler) mod-

els consists of two separate assemblies. The main

cluster assembly is located on the left side of the in-

strument panel, centered over the steering column

opening. The gauge package cluster assembly is lo-

cated near the center of the instrument panel. Each

cluster assembly is served by a separate printed cir-

cuit and wiring connector. Some variations of each

cluster exist due to optional equipment and regula-

tory requirements.

The main cluster assembly includes a speedometer/

odometer/trip odometer and a tachometer. It also in-

cludes provisions for the following indicator lamps:

²anti-lock brake system lamp

²brake warning lamp

²headlamp high beam indicator lamp

²malfunction indicator (Check Engine) lamp

²seat belt reminder lamp²turn signal indicator lamps

²upshift indicator lamp.

The gauge package cluster assembly includes a

four-wheel drive indicator lamp and the following

gauges:

²coolant temperature gauge

²fuel gauge

²oil pressure gauge

²voltmeter.

GAUGES

With the ignition switch in the ON or START posi-

tion, voltage is supplied to all gauges through the

two cluster printed circuits. With the ignition switch

in the OFF position, voltage is not supplied to the

gauges. A gauge pointer may remain within the

gauge scale after the ignition switch is OFF. How-

ever, the gauges do not accurately indicate any vehi-

cle condition unless the ignition switch is ON.

All gauges except the odometer are air core mag-

netic units. Two fixed electromagnetic coils are lo-

cated within the gauge. These coils are wrapped at

right angles to each other around a movable perma-

nent magnet. The movable magnet is suspended

within the coils on one end of a shaft. The gauge nee-

dle is attached to the other end of the shaft.

One of the coils has a fixed current flowing through

it to maintain a constant magnetic field strength.

Current flow through the second coil changes, which

causes changes in its magnetic field strength. The

current flowing through the second coil can be

changed by:

²a variable resistor-type sending unit (fuel level,

coolant temperature, or oil pressure)

²changes in electrical system voltage (voltmeter)

²electronic control circuitry (speedometer/odometer,

tachometer).

8E - 24 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 411 of 2158

HORNS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 3

SPECIFICATIONS......................... 5

GENERAL INFORMATION

Following are general descriptions of the major

components in the XJ (Cherokee)/YJ (Wrangler) horn

systems. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

HORN SWITCH

XJ

Two horn switches are installed in the steering

wheel, one on each side of the center-mounted driv-

er's airbag module. When either switch is depressed

it completes a circuit to ground for the coil side of the

horn relay. The steering wheel and steering column

must be properly grounded for the horn switches to

function. The horn switches are only serviced as a set

with their wiring. If either switch should fail, both

switches must be replaced.

YJ

A single switch is installed in the center of the

steering wheel, directly under the horn button. When

the horn button is depressed the switch completes a

circuit to ground for the coil side of the horn relay.

The steering wheel and steering column must be

properly grounded for the horn switch to function.

The horn switch is available for service.

HORN RELAY

On XJ models, the horn relay is a mini-relay in-

stalled in the relay center, which is mounted to the

lower instrument panel reinforcement inboard of thesteering column. On YJ models, the horn relay is a

ISO relay installed in the Power Distribution Center

(PDC) near the battery tray. Refer to underside of

PDC cover for relay identification.

One side of the horn relay electromagnetic coil re-

ceives battery voltage at all times. When a horn

switch is depressed, the other side of the relay coil is

grounded. The energized relay coil causes the nor-

mally open relay contacts to close, providing battery

voltage to the horn.

If a problem is encountered with a continuously

sounding horn, it can usually be quickly resolved by

removing the horn relay until further diagnosis is

completed.

HORNS

On YJ models, a standard single, low-note, dia-

phragm-type horn is mounted and grounded to the

left inner fender shield under the hood. Dual horns

are standard equipment on XJ models. The high-note

diaphragm-type horn is mounted and grounded to

the left radiator closure panel brace behind the front

bumper. The low-note diaphragm-type horn is con-

nected in parallel with the high-note horn and is

mounted and grounded to the right radiator closure

panel brace behind the front bumper.

On XJ models, a cadmium-plated screw is

used to attach the horns to the body. Do not

substitute other types of screws as they may be-

come corroded and cause a loss of ground.

JHORNS 8G - 1

Page 427 of 2158

TURN SIGNAL AND HAZARD WARNING SYSTEMS

CONTENTS

page page

DIAGNOSIS............................. 3

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 5

GENERAL INFORMATION

Following are general descriptions of the major

components in the XJ (Cherokee)/YJ (Wrangler)

model turn signal and hazard warning systems. Refer

to Group 8W - Wiring Diagrams for complete circuit

descriptions and diagrams.

TURN SIGNAL SYSTEM

With the ignition switch in the ON or ACCESSORY

position and the turn signal switch lever (YJ) or

multi-function switch control lever (XJ) moved up

(right turn) or down (left turn), the turn signal sys-

tem is activated.

When the turn signal system is activated, the se-

lected (right or left) turn signal indicator lamp, front

park/turn signal lamp and rear tail/stop/turn signal

lamp bulb filaments will flash. With the headlamp

switch in the OFF position, the turn and front side

marker lamps flash in unison. With the headlamp

switch in the ON position, the turn and front side

marker lamps flash alternately.

HAZARD WARNING SYSTEM

The hazard warning is activated by a switch button

located below the ignition lock cylinder (YJ) or on the

top of the steering column (XJ) between the steering

wheel and the instrument panel. The hazard warning

flasher (YJ) or combination flasher (XJ) receives bat-

tery feed at all times, and the system is functional

regardless of ignition switch position. The hazard

warning switch button is identified with a double

triangle. On YJ models, push the switch button in to

activate the hazard warning system and pull the

button out to turn system off. On XJ models, push in

on the switch button to latch the switch and activate

the hazard warning system, and push in on the

switch button again to unlatch the switch and turn

the system off.

When the hazard warning system is activated, all

(right and left) turn signal indicator, front park/turn

signal lamp and rear tail/stop/turn signal lamp bulb

filaments will flash.

TURN SIGNAL FLASHER (YJ ONLY)

The turn signal flasher is located in the fuseblock

module. It contains one fixed contact point and one

contact point attached to a flexible bimetal arm. The

contact points are normally closed. When a turn sig-

nal is activated, current flows through the flasher. As

current flows through the bimetal arm it heats and

flexes to pull the contact points open, stopping cur-

rent flow. As the bimetal arm cools it straightens,

until the contact points close and the cycle repeats.

The standard flasher is designed to handle the cur-

rent flow requirements of the factory installed light-

ing. If supplemental lighting is added to the turn

signal circuits such as when towing a trailer with

lights, the current flow through the flasher increases.

This causes the flash rate to increase. It is recom-

mended that the standard flasher be replaced with a

heavy-duty (hazard warning) flasher when supple-

mental lighting is added.

However, when a turn signal bulb fails with a stan-

dard flasher, the remaining bulbs in that circuit will

light, but not flash. This will give the driver an indi-

cation to check the turn signal bulbs. Because a

heavy-duty flasher has different internal circuitry, a

failed bulb will not prevent the remaining bulbs in

the circuit from flashing. Therefore, it is recom-

mended that an occasional visual inspection of exte-

rior turn signal lamp operation be performed when a

heavy-duty flasher is installed.

HAZARD WARNING FLASHER (YJ ONLY)

The hazard warning flasher is located in the fuse-

block module. The hazard warning flasher contains

two normally open contact points mounted to two

flexible arms. A bimetal strip is attached between the

two arms. When the hazard warning is activated,

current flows through the flasher. As the current

flows through the bimetal strip it heats and pulls the

flexible arms together until the contact points close,

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 1

Page 497 of 2158

REAR WINDOW DEFOGGER

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 3

GENERAL INFORMATION

The electrically-heated rear window defogger is an

available option on XJ (Cherokee), and YJ (Wrangler)

models equipped with the hardtop roof option. Fol-

lowing are general descriptions of the major compo-

nents in the rear window defogger system. Refer to

Group 8W - Wiring Diagrams for complete circuit de-

scriptions and diagrams.

REAR WINDOW GLASS GRID

The heated rear window glass has two electrically-

conductive vertical bus bars and a series of horizon-

tal grid lines made of a silver-ceramic material,

which is baked on and bonded to the inside surface of

the glass. The grid lines and bus bars comprise a

parallel electrical circuit.

When the rear window defogger switch is placed in

the ON position, current is directed to the rear win-

dow grid lines through the bus bars. The grid lines

heat the rear window to clear the surface of fog or

snow. Circuit protection for the heated grid circuit is

provided by fuse 18 (XJ) or fuse 6 (YJ) in the fuse-

block module.

The grid lines and bus bars are highly resistant to

abrasion. However, it is possible for an open to occur

in an individual grid line resulting in no current flow

through the line. The grid lines can be damaged or

scraped off with sharp instruments. Care should be

taken in cleaning the glass or removing foreign ma-

terials, decals or stickers. Normal glass cleaning sol-

vents or hot water used with rags or toweling is

recommended.A repair kit is available to repair the grid lines and

bus bars, or to reinstall the heated glass pigtail

wires.

DEFOGGER SWITCH

The rear window defogger switch is mounted in the

instrument panel left of the steering column for XJ,

or right of the steering column for YJ. The switch cir-

cuit is protected by fuse 8 (XJ) or fuse 9 (YJ) in the

fuseblock module. Actuating the switch energizes the

relay and electronic timer. A light-emitting diode

(LED) in the switch (XJ), or a indicator lamp in the

switch (YJ), illuminates to indicate when the system

is turned on. The defogger switch can not be re-

paired. If faulty, the switch must be replaced.

DEFOGGER RELAY/TIMER

The defogger relay/timer is located in the relay cen-

ter on XJ models, or taped to the instrument panel

wiring harness behind the parking brake pedal in the

left cowl side area on YJ models. When the rear de-

fogger switch is actuated, the rear defogger relay is

energized. This causes current to flow through the

grid circuit for approximately 10 minutes, or until

the rear window defogger switch or ignition switch

are turned off.

DIAGNOSIS

SYSTEM TESTS

Electrically-heated rear window defogger operation

can be confirmed in the following manner:

(1) Turn the ignition switch to the ON position.

(2) Turn rear window defogger control switch ON.

(3) Monitor vehicle voltmeter. With the control

switch ON, a distinct needle deflection should be

noted.(4) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected within 3 to 4 minutes of

operation.

(5) Using a DC voltmeter, contact terminal A (Fig.

1) (passenger side) with the negative lead, and termi-

JREAR WINDOW DEFOGGER 8N - 1

Page 501 of 2158

POWER LOCKS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 8

GENERAL INFORMATION

Power locks are optional equipment on XJ (Chero-

kee) models. Power windows and the keyless entry

system are included on vehicles equipped with the

power lock option. All doors and the liftgate can be

locked and unlocked electrically by operating the

switch on either front door panel, or by operating the

lock and unlock buttons of the remote keyless entry

transmitter. The power lock and keyless entry sys-

tems operate with battery power supplied indepen-

dent of the ignition switch.

Following are general descriptions of the major

components in the power lock system. Refer to Group

8W - Wiring Diagrams for complete circuit descrip-

tions and diagrams. Refer to the owner's manual for

more information on the features and use of these

systems.

POWER LOCK SWITCH

The power locks are controlled by a two-way switch

mounted on the trim panel of each front door. The

switch controls battery feed to the lock and unlock

relays. The door lock switches can not be repaired. If

faulty, the entire switch must be replaced.

POWER LOCK/UNLOCK RELAYS

The power lock and unlock relays are located in the

relay center. The relay center is located on the lower

instrument panel reinforcement behind the lower in-

strument panel and just right of the steering column.

The relays respond to inputs from the power lock

switches and the keyless entry module by sending

the correct battery and ground feeds to the lock mo-

tors. The lock and unlock relays can not be repaired.

If faulty, they must be replaced.

POWER LOCK MOTOR

The locks are actuated by a reversible motor

mounted within each door. The motor direction iscontrolled by the battery and ground feeds from the

power lock/unlock relays. The motor can not be re-

paired. If faulty, the entire motor must be replaced.

KEYLESS ENTRY TRANSMITTER

The keyless entry transmitter is equipped with two

buttons labeled Lock and Unlock. It is also designed

to serve as a key fob and is equipped with a key ring.

Each transmitter has a different vehicle access code,

which must be programmed into the memory of the

keyless entry module in the vehicle in order to oper-

ate the locks. The operating range of the infrared

transmitter signal is up to 4.75 meters (15 feet) from

the receiver.

The transmitter operates on two CR1616 3-volt (or

equivalent) batteries. Typical battery life is from one

to two years.

KEYLESS ENTRY MODULE

The keyless entry module is mounted in a housing

on the headliner near the windshield between the

sunvisors, or inside and towards the rear of the over-

head console (if equipped). This module contains the

keyless entry receiver and program logic for the key-

less entry system.

The keyless entry module has a memory function

to retain the vehicle access code of at least one, and

up to four transmitters. The module receives input

from the remote keyless entry transmitter. In re-

sponse to that input, it is programmed to control out-

puts to the lock and unlock relays. The module can

not be repaired and, if faulty, must be replaced.

JPOWER LOCKS 8P - 1

Page 785 of 2158

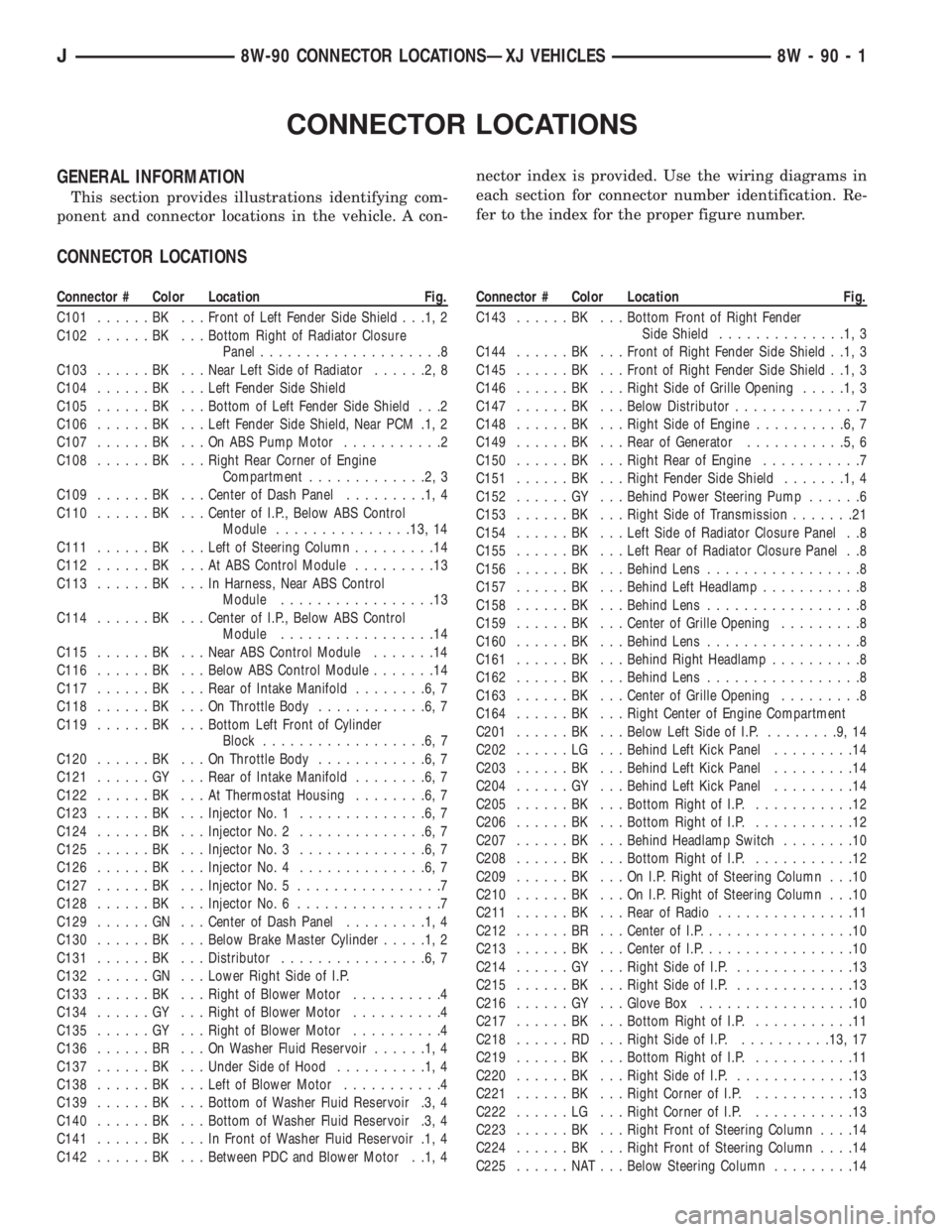

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # Color Location Fig.

C101......BK ...Front of Left Fender Side Shield . . .1, 2

C102......BK ...Bottom Right of Radiator Closure

Panel....................8

C103......BK ...Near Left Side of Radiator......2,8

C104......BK ...Left Fender Side Shield

C105......BK ...Bottom of Left Fender Side Shield . . .2

C106......BK ...Left Fender Side Shield, Near PCM .1, 2

C107......BK ...OnABSPump Motor...........2

C108......BK ...Right Rear Corner of Engine

Compartment.............2,3

C109......BK ...Center of Dash Panel.........1,4

C110......BK ...Center of I.P., Below ABS Control

Module...............13, 14

C111......BK ...Left of Steering Column.........14

C112......BK ...AtABSControl Module.........13

C113......BK ...InHarness, Near ABS Control

Module.................13

C114......BK ...Center of I.P., Below ABS Control

Module.................14

C115......BK ...Near ABS Control Module.......14

C116......BK ...Below ABS Control Module.......14

C117......BK ...Rear of Intake Manifold........6,7

C118......BK ...OnThrottle Body............6,7

C119......BK ...Bottom Left Front of Cylinder

Block..................6,7

C120......BK ...OnThrottle Body............6,7

C121......GY ...Rear of Intake Manifold........6,7

C122......BK ...AtThermostat Housing........6,7

C123......BK ...Injector No. 1..............6,7

C124......BK ...Injector No. 2..............6,7

C125......BK ...Injector No. 3..............6,7

C126......BK ...Injector No. 4..............6,7

C127......BK ...Injector No. 5................7

C128......BK ...Injector No. 6................7

C129......GN ...Center of Dash Panel.........1,4

C130......BK ...Below Brake Master Cylinder.....1,2

C131......BK ...Distributor................6,7

C132......GN ...Lower Right Side of I.P.

C133......BK ...Right of Blower Motor..........4

C134......GY ...Right of Blower Motor..........4

C135......GY ...Right of Blower Motor..........4

C136......BR ...OnWasher Fluid Reservoir......1,4

C137......BK ...Under Side of Hood..........1,4

C138......BK ...Left of Blower Motor...........4

C139......BK ...Bottom of Washer Fluid Reservoir .3, 4

C140......BK ...Bottom of Washer Fluid Reservoir .3, 4

C141......BK ...InFront of Washer Fluid Reservoir .1, 4

C142......BK ...Between PDC and Blower Motor . .1, 4Connector # Color Location Fig.

C143......BK ...Bottom Front of Right Fender

Side Shield..............1,3

C144......BK ...Front of Right Fender Side Shield . .1, 3

C145......BK ...Front of Right Fender Side Shield . .1, 3

C146......BK ...Right Side of Grille Opening.....1,3

C147......BK ...Below Distributor..............7

C148......BK ...Right Side of Engine..........6,7

C149......BK ...Rear of Generator...........5,6

C150......BK ...Right Rear of Engine...........7

C151......BK ...Right Fender Side Shield.......1,4

C152......GY ...Behind Power Steering Pump......6

C153......BK ...Right Side of Transmission.......21

C154......BK ...Left Side of Radiator Closure Panel . .8

C155......BK ...Left Rear of Radiator Closure Panel . .8

C156......BK ...Behind Lens.................8

C157......BK ...Behind Left Headlamp...........8

C158......BK ...Behind Lens.................8

C159......BK ...Center of Grille Opening.........8

C160......BK ...Behind Lens.................8

C161......BK ...Behind Right Headlamp..........8

C162......BK ...Behind Lens.................8

C163......BK ...Center of Grille Opening.........8

C164......BK ...Right Center of Engine Compartment

C201......BK ...Below Left Side of I.P.........9,14

C202......LG ...Behind Left Kick Panel.........14

C203......BK ...Behind Left Kick Panel.........14

C204......GY ...Behind Left Kick Panel.........14

C205......BK ...Bottom Right of I.P............12

C206......BK ...Bottom Right of I.P............12

C207......BK ...Behind Headlamp Switch........10

C208......BK ...Bottom Right of I.P............12

C209......BK ...OnI.P.Right of Steering Column . . .10

C210......BK ...OnI.P.Right of Steering Column . . .10

C211......BK ...Rear of Radio...............11

C212......BR ...Center of I.P.................10

C213......BK ...Center of I.P.................10

C214......GY ...Right Side of I.P..............13

C215......BK ...Right Side of I.P..............13

C216......GY ...Glove Box.................10

C217......BK ...Bottom Right of I.P............11

C218......RD ...Right Side of I.P...........13, 17

C219......BK ...Bottom Right of I.P............11

C220......BK ...Right Side of I.P..............13

C221......BK ...Right Corner of I.P............13

C222......LG ...Right Corner of I.P............13

C223......BK ...Right Front of Steering Column....14

C224......BK ...Right Front of Steering Column....14

C225......NAT...Below Steering Column.........14

J8W-90 CONNECTOR LOCATIONSÐXJ VEHICLES 8W - 90 - 1

Page 1067 of 2158

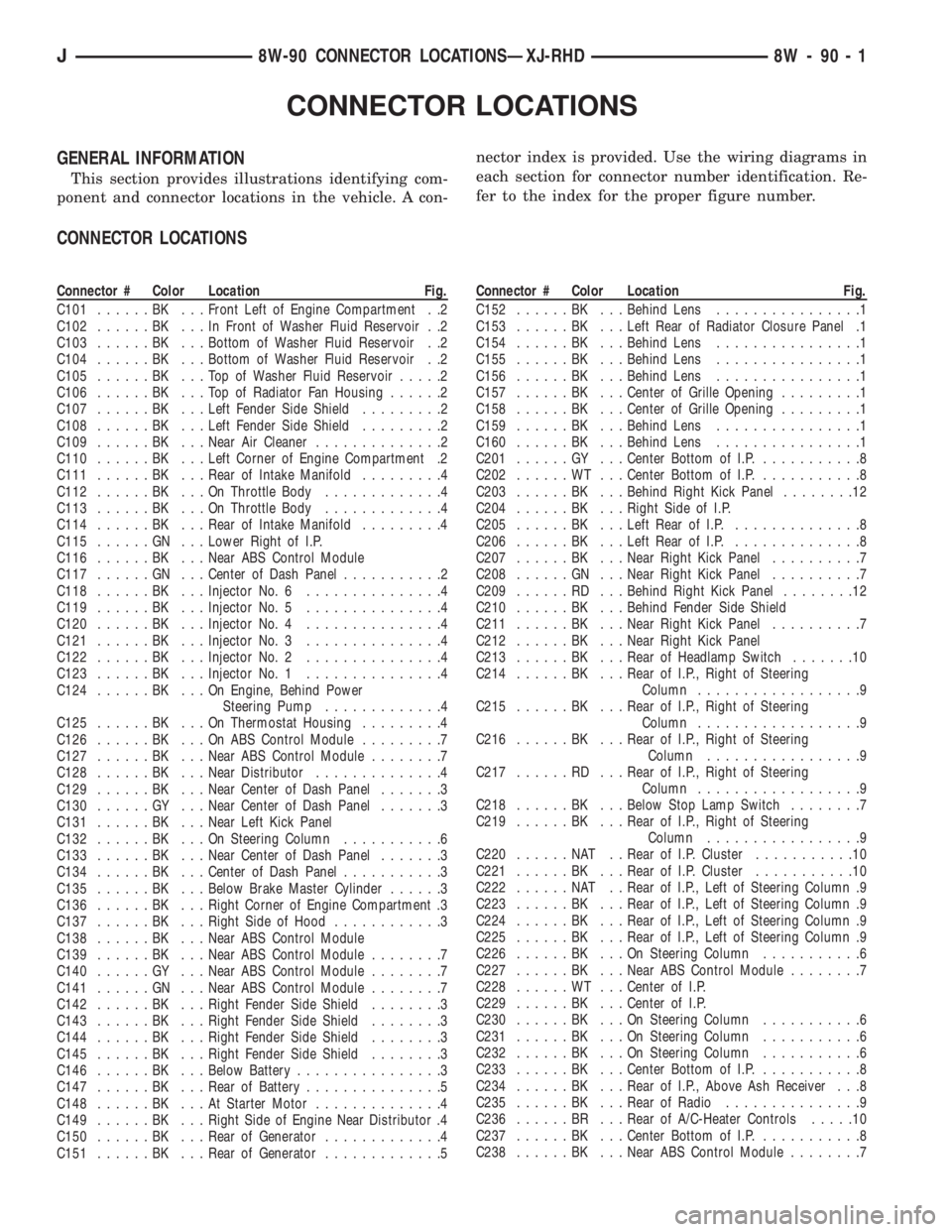

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # Color Location Fig.

C101......BK ...Front Left of Engine Compartment . .2

C102......BK ...InFront of Washer Fluid Reservoir . .2

C103......BK ...Bottom of Washer Fluid Reservoir . .2

C104......BK ...Bottom of Washer Fluid Reservoir . .2

C105......BK ...TopofWasher Fluid Reservoir.....2

C106......BK ...TopofRadiator Fan Housing......2

C107......BK ...Left Fender Side Shield.........2

C108......BK ...Left Fender Side Shield.........2

C109......BK ...Near Air Cleaner..............2

C110......BK ...Left Corner of Engine Compartment .2

C111......BK ...Rear of Intake Manifold.........4

C112......BK ...OnThrottle Body.............4

C113......BK ...OnThrottle Body.............4

C114......BK ...Rear of Intake Manifold.........4

C115......GN ...Lower Right of I.P.

C116......BK ...Near ABS Control Module

C117......GN ...Center of Dash Panel...........2

C118......BK ...Injector No. 6...............4

C119......BK ...Injector No. 5...............4

C120......BK ...Injector No. 4...............4

C121......BK ...Injector No. 3...............4

C122......BK ...Injector No. 2...............4

C123......BK ...Injector No. 1...............4

C124......BK ...OnEngine, Behind Power

Steering Pump.............4

C125......BK ...OnThermostat Housing.........4

C126......BK ...OnABSControl Module.........7

C127......BK ...Near ABS Control Module........7

C128......BK ...Near Distributor..............4

C129......BK ...Near Center of Dash Panel.......3

C130......GY ...Near Center of Dash Panel.......3

C131......BK ...Near Left Kick Panel

C132......BK ...OnSteering Column...........6

C133......BK ...Near Center of Dash Panel.......3

C134......BK ...Center of Dash Panel...........3

C135......BK ...Below Brake Master Cylinder......3

C136......BK ...Right Corner of Engine Compartment .3

C137......BK ...Right Side of Hood............3

C138......BK ...Near ABS Control Module

C139......BK ...Near ABS Control Module........7

C140......GY ...Near ABS Control Module........7

C141......GN ...Near ABS Control Module........7

C142......BK ...Right Fender Side Shield........3

C143......BK ...Right Fender Side Shield........3

C144......BK ...Right Fender Side Shield........3

C145......BK ...Right Fender Side Shield........3

C146......BK ...Below Battery................3

C147......BK ...Rear of Battery...............5

C148......BK ...AtStarter Motor..............4

C149......BK ...Right Side of Engine Near Distributor .4

C150......BK ...Rear of Generator.............4

C151......BK ...Rear of Generator.............5Connector # Color Location Fig.

C152......BK ...Behind Lens................1

C153......BK ...Left Rear of Radiator Closure Panel .1

C154......BK ...Behind Lens................1

C155......BK ...Behind Lens................1

C156......BK ...Behind Lens................1

C157......BK ...Center of Grille Opening.........1

C158......BK ...Center of Grille Opening.........1

C159......BK ...Behind Lens................1

C160......BK ...Behind Lens................1

C201......GY ...Center Bottom of I.P............8

C202......WT ...Center Bottom of I.P............8

C203......BK ...Behind Right Kick Panel........12

C204......BK ...Right Side of I.P.

C205......BK ...Left Rear of I.P...............8

C206......BK ...Left Rear of I.P...............8

C207......BK ...Near Right Kick Panel..........7

C208......GN ...Near Right Kick Panel..........7

C209......RD ...Behind Right Kick Panel........12

C210......BK ...Behind Fender Side Shield

C211......BK ...Near Right Kick Panel..........7

C212......BK ...Near Right Kick Panel

C213......BK ...Rear of Headlamp Switch.......10

C214......BK ...Rear of I.P., Right of Steering

Column..................9

C215......BK ...Rear of I.P., Right of Steering

Column..................9

C216......BK ...Rear of I.P., Right of Steering

Column.................9

C217......RD ...Rear of I.P., Right of Steering

Column..................9

C218......BK ...Below Stop Lamp Switch........7

C219......BK ...Rear of I.P., Right of Steering

Column.................9

C220......NAT ..Rear of I.P. Cluster...........10

C221......BK ...Rear of I.P. Cluster...........10

C222......NAT ..Rear of I.P., Left of Steering Column .9

C223......BK ...Rear of I.P., Left of Steering Column .9

C224......BK ...Rear of I.P., Left of Steering Column .9

C225......BK ...Rear of I.P., Left of Steering Column .9

C226......BK ...OnSteering Column...........6

C227......BK ...Near ABS Control Module........7

C228......WT ...Center of I.P.

C229......BK ...Center of I.P.

C230......BK ...OnSteering Column...........6

C231......BK ...OnSteering Column...........6

C232......BK ...OnSteering Column...........6

C233......BK ...Center Bottom of I.P............8

C234......BK ...Rear of I.P., Above Ash Receiver . . .8

C235......BK ...Rear of Radio...............9

C236......BR ...Rear of A/C-Heater Controls.....10

C237......BK ...Center Bottom of I.P............8

C238......BK ...Near ABS Control Module........7

J8W-90 CONNECTOR LOCATIONSÐXJ-RHD 8W - 90 - 1

Page 1262 of 2158

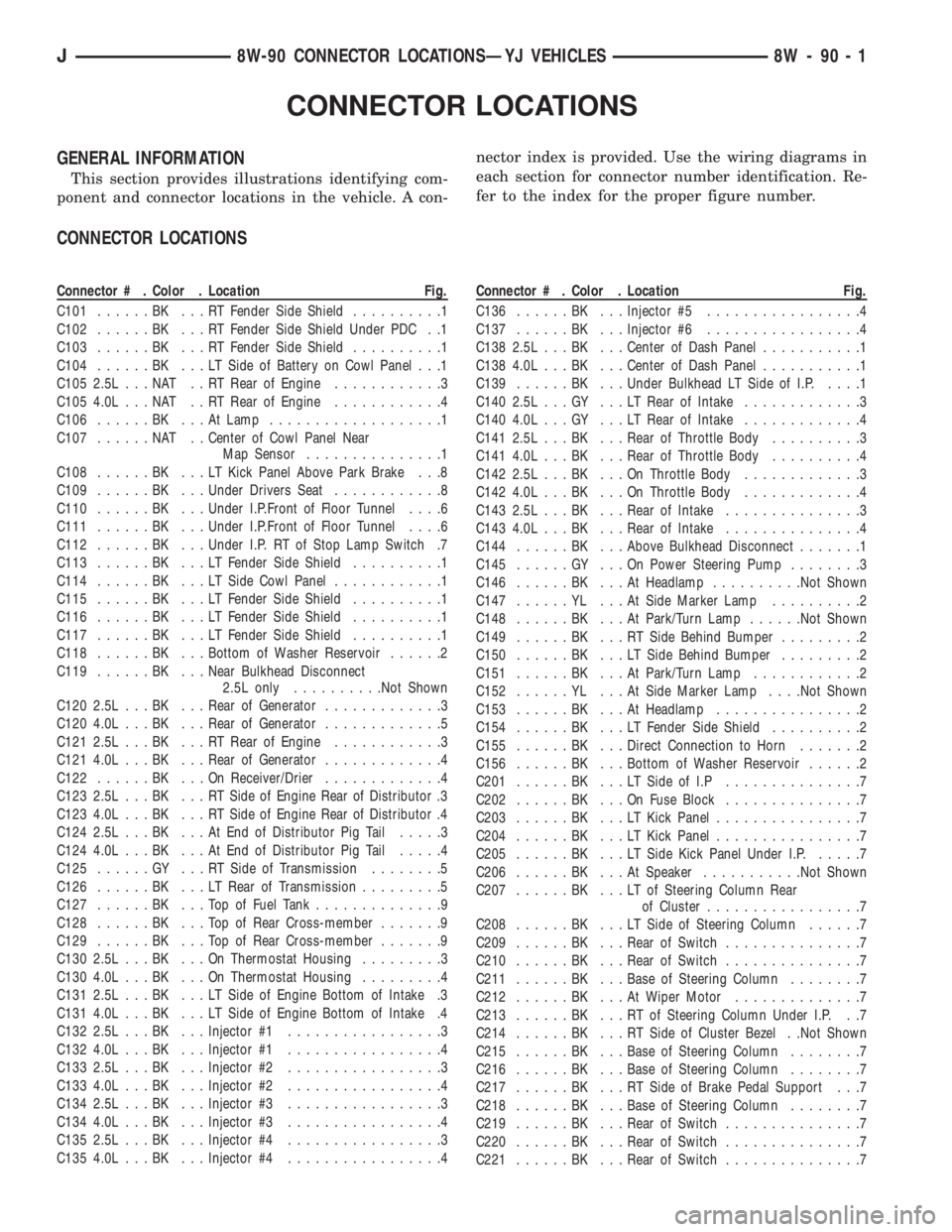

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # . Color . Location Fig.

C101......BK ...RTFender Side Shield..........1

C102......BK ...RTFender Side Shield Under PDC . .1

C103......BK ...RTFender Side Shield..........1

C104......BK ...LTSide of Battery on Cowl Panel . . .1

C105 2.5L . . . NAT . . RT Rear of Engine............3

C105 4.0L . . . NAT . . RT Rear of Engine............4

C106......BK ...AtLamp...................1

C107......NAT ..Center of Cowl Panel Near

Map Sensor...............1

C108......BK ...LTKick Panel Above Park Brake . . .8

C109......BK ...Under Drivers Seat............8

C110......BK ...Under I.P.Front of Floor Tunnel....6

C111......BK ...Under I.P.Front of Floor Tunnel....6

C112......BK ...Under I.P. RT of Stop Lamp Switch .7

C113......BK ...LTFender Side Shield..........1

C114......BK ...LTSide Cowl Panel............1

C115......BK ...LTFender Side Shield..........1

C116......BK ...LTFender Side Shield..........1

C117......BK ...LTFender Side Shield..........1

C118......BK ...Bottom of Washer Reservoir......2

C119......BK ...Near Bulkhead Disconnect

2.5L only..........Not Shown

C120 2.5L . . . BK . . . Rear of Generator.............3

C120 4.0L . . . BK . . . Rear of Generator.............5

C121 2.5L . . . BK . . . RT Rear of Engine............3

C121 4.0L . . . BK . . . Rear of Generator.............4

C122......BK ...OnReceiver/Drier.............4

C123 2.5L . . . BK . . . RT Side of Engine Rear of Distributor .3

C123 4.0L . . . BK . . . RT Side of Engine Rear of Distributor .4

C124 2.5L . . . BK . . . At End of Distributor Pig Tail.....3

C124 4.0L . . . BK . . . At End of Distributor Pig Tail.....4

C125......GY ...RTSide of Transmission........5

C126......BK ...LTRear of Transmission.........5

C127......BK ...TopofFuel Tank..............9

C128......BK ...TopofRear Cross-member.......9

C129......BK ...TopofRear Cross-member.......9

C130 2.5L . . . BK . . . On Thermostat Housing.........3

C130 4.0L . . . BK . . . On Thermostat Housing.........4

C131 2.5L . . . BK . . . LT Side of Engine Bottom of Intake .3

C131 4.0L . . . BK . . . LT Side of Engine Bottom of Intake .4

C132 2.5L . . . BK . . . Injector #1.................3

C132 4.0L . . . BK . . . Injector #1.................4

C133 2.5L . . . BK . . . Injector #2.................3

C133 4.0L . . . BK . . . Injector #2.................4

C134 2.5L . . . BK . . . Injector #3.................3

C134 4.0L . . . BK . . . Injector #3.................4

C135 2.5L . . . BK . . . Injector #4.................3

C135 4.0L . . . BK . . . Injector #4.................4Connector # . Color . Location Fig.

C136......BK ...Injector #5.................4

C137......BK ...Injector #6.................4

C138 2.5L . . . BK . . . Center of Dash Panel...........1

C138 4.0L . . . BK . . . Center of Dash Panel...........1

C139......BK ...Under Bulkhead LT Side of I.P.....1

C140 2.5L . . . GY . . . LT Rear of Intake.............3

C140 4.0L . . . GY . . . LT Rear of Intake.............4

C141 2.5L . . . BK . . . Rear of Throttle Body..........3

C141 4.0L . . . BK . . . Rear of Throttle Body..........4

C142 2.5L . . . BK . . . On Throttle Body.............3

C142 4.0L . . . BK . . . On Throttle Body.............4

C143 2.5L . . . BK . . . Rear of Intake...............3

C143 4.0L . . . BK . . . Rear of Intake...............4

C144......BK ...Above Bulkhead Disconnect.......1

C145......GY ...OnPower Steering Pump........3

C146......BK ...AtHeadlamp..........Not Shown

C147......YL ...AtSide Marker Lamp..........2

C148......BK ...AtPark/Turn Lamp......Not Shown

C149......BK ...RTSide Behind Bumper.........2

C150......BK ...LTSide Behind Bumper.........2

C151......BK ...AtPark/Turn Lamp............2

C152......YL ...AtSide Marker Lamp. . . .Not Shown

C153......BK ...AtHeadlamp................2

C154......BK ...LTFender Side Shield..........2

C155......BK ...Direct Connection to Horn.......2

C156......BK ...Bottom of Washer Reservoir......2

C201......BK ...LTSide of I.P...............7

C202......BK ...OnFuse Block...............7

C203......BK ...LTKick Panel................7

C204......BK ...LTKick Panel................7

C205......BK ...LTSide Kick Panel Under I.P......7

C206......BK ...AtSpeaker...........Not Shown

C207......BK ...LTofSteering Column Rear

of Cluster.................7

C208......BK ...LTSide of Steering Column......7

C209......BK ...Rear of Switch...............7

C210......BK ...Rear of Switch...............7

C211......BK ...Base of Steering Column........7

C212......BK ...AtWiper Motor..............7

C213......BK ...RTofSteering Column Under I.P. . .7

C214......BK ...RTSide of Cluster Bezel . .Not Shown

C215......BK ...Base of Steering Column........7

C216......BK ...Base of Steering Column........7

C217......BK ...RTSide of Brake Pedal Support . . .7

C218......BK ...Base of Steering Column........7

C219......BK ...Rear of Switch...............7

C220......BK ...Rear of Switch...............7

C221......BK ...Rear of Switch...............7

J8W-90 CONNECTOR LOCATIONSÐYJ VEHICLES 8W - 90 - 1

Page 2129 of 2158

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-2

CLUSTER ILLUMINATION LAMPS . . 8E-16,8E-26,

8E-34,8E-4

CLUSTER, INSTRUMENT; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

CLUSTER, INSTRUMENT; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

CLUSTER, INSTRUMENT; INSTRUMENT

CLUSTER (YJ).....................8W-40-1

CLUSTER (LHD), HIGH-LINE GAUGE.......8E-9

CLUSTER (LHD), TELL-TALE............8E-10

CLUSTER, LOW-LINE GAUGE............8E-8

CLUSTER, MAIN.....................8E-30

CLUSTERS, INSTRUMENT..........8E-24,8E-1

CLUTCH, A/C COMPRESSOR............24-15

CLUTCH AND BRAKE PACK

REQUIREMENTS, AW-4...............21-341

CLUTCH AND BRAKE PEDAL BUSHINGS . . . 0-22

CLUTCH ASSEMBLY, COMPRESSOR......24-20

CLUTCH COMPONENT LUBRICATION......6-10

CLUTCH COMPONENTS..................6-1

CLUTCH, COMPRESSOR...............24-16

CLUTCH CONTAMINATION...............6-3

CLUTCH COVER AND DISC

INSTALLATION........................6-10

CLUTCH COVER AND DISC REMOVAL.....6-10

CLUTCH COVER AND DISC RUNOUT.......6-3

CLUTCH DIAGNOSIS.....................6-3

CLUTCH DISC AND PLATE THICKNESS,

AW-4 .............................21-338

CLUTCH FLUID LEVEL..................6-14

CLUTCH HOUSING MISALIGNMENT........6-4

CLUTCH HOUSING REPLACEMENT........6-13

CLUTCH HYDRAULIC LINKAGE

INSTALLATION........................6-14

CLUTCH HYDRAULIC LINKAGE REMOVAL . . 6-13

CLUTCH INSPECTION, TORQUE

CONVERTER STATOR................21-199

CLUTCH LINKAGE FLUID.................6-1

CLUTCH MASTER CYLINDER............0-22

CLUTCH MISALIGNMENT................6-3

CLUTCH OPERATION....................6-2

CLUTCH OVERHAUL, DIRECT..........21-228

CLUTCH OVERHAUL, OVERDRIVE

PLANETARY GEAR...................21-218

CLUTCH OVERHAUL, SUN GEAR AND

NO. 1 ONE-WAY....................21-238

CLUTCH PEDAL INSTALLATION..........6-15

CLUTCH PEDAL REMOVAL..............6-15

CLUTCH RELAY, A/C COMPRESSOR . 24-15,24-16

CLUTCH RELAY, AIR CONDITIONING

(A/C)..............................14-58

CLUTCH RELAY TEST, TORQUE

CONVERTER........................14-48

CLUTCH RELAY, TORQUE CONVERTER....14-65

CLUTCH RELAYÐPCM OUTPUT, AIR

CONDITIONING (A/C)..................14-26

CLUTCH RELAYÐPCM OUTPUT, TORQUE

CONVERTER........................14-29

CLUTCH SAFETY PRECAUTIONS..........6-10

CLUTCH SERVICE

.....................6-10

CLUTCH SWITCH, FIN SENSING

CYCLING

......................24-15,24-31

CLUTCH (TCC) SOLENOID AND RELAY,

TORQUE CONVERTER; FUEL/IGNITION

(XJ)

.............................8W-30-4

CLUTCH (TCC) SOLENOID AND RELAY,

TORQUE CONVERTER; TRANSMISSION

CONTROLS (YJ)

...................8W-31-1

CLUTCH (TCC) SOLENOID AND

RELAYÐ2.5L ENGINE ONLY, TORQUE

CONVERTER; TRANSMISSION

CONTROLS (XJ)

...................8W-31-1

CLUTCHÐLOW-REVERSE DRUMÐREAR

SUPPORT OVERHAUL, OVERRUNNING

. . . 21-125

CODE DECODING, VEHICLE

...........Intro.-5

CODE DESIGNATIONS, VEHICLE

........Intro.-1

CODE (DTC), DIAGNOSTIC TROUBLE

.....14-54

CODE, GENERATOR DIAGNOSTIC

TROUBLE

...........................8A-22

CODE IDENTIFICATION, WIRE; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)

...............................8W-1

CODE PLATE, VEHICLE

...............Intro.-4

CODE, SPEED CONTROL DIAGNOSTIC

TROUBLE

...........................8H-5CODES AND DIMENSIONS,

DESIGNATIONS, LABELS/PLATES.......Intro.-1

COIL, EVAPORATOR..................24-30

COIL, IGNITION; FUEL SYSTEM.........14-62

COIL, IGNITION; FUEL/IGNITION (XJ) . . . 8W-30-2

COIL, IGNITION; FUEL/IGNITION (YJ) . . . 8W-30-2

COIL, IGNITION; IGNITION SYSTEMS....8D-22,

8D-4,8D-9

COIL, IGNITION; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

COIL RESISTANCE, IGNITION............8D-9

COIL SPRING........................2-14

COILÐPCM OUTPUT, IGNITION.........14-28

COLD CRANKING SPECIFICATIONS, 2.5L

STARTING SYSTEM...................8A-23

COLD CRANKING SPECIFICATIONS, 4.0L

STARTING SYSTEM...................8A-23

COLUMN ASSEMBLY REPLACEMENT.....19-52

COLUMN COMPONENT SERVICE........19-54

COLUMN GENERAL SERVICEÐXJ,

STEERING..........................19-47

COLUMN, NON-TILT STEERING..........19-60

COLUMN REPLACEMENT..............19-58

COLUMN, TILT STEERING..............19-66

COLUMNÐXJ, STEERING..............19-78

COLUMNÐYJ, STEERING.........19-58,19-78

COMBINATION BUZZER; INTERIOR

LIGHTING (YJ)....................8W-44-1

COMBINATION FLASHER; TURN SIGNALS

(XJ).............................8W-52-1

COMBINATION VALVE..................5-34

COMBINATION VALVE INSTALLATION

(WITH ABS), MASTER CYLINDER.........5-20

COMBINATION VALVE REMOVAL (WITH

ABS), MASTER CYLINDER..............5-17

COMBINATION VALVE REPLACEMENT

(NON-ABS)..........................5-16

COMBUSTION PRESSURE LEAKAGE

TEST, CYLINDER.......................9-6

COMBUSTION PRESSURE LEAKAGE

TEST DIAGNOSIS, CYLINDER.............9-7

COMFORT SWITCH, TRANSMISSION;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

COMPASS...........................8C-1

COMPASS/DISPLAY SELF-DIAGNOSTIC

TEST...............................8C-2

COMPASS/THERMOMETER DIAGNOSIS....8C-4

COMPENSATION, CALIPER OPERATION

AND WEAR..........................5-45

COMPONENTSÐYJ, EVAPORATIVE

HOUSING............................24-6

COMPONENTSÐYJ, INSTRUMENT

PANEL............................23-152

COMPONENTSÐYJ VEHICLES, BODY....23-102

COMPRESSION PRESSURE TEST,

CYLINDER............................9-5

COMPRESSOR.......................24-19

COMPRESSOR, A/C; AIR CONDITIONING/

HEATER (YJ)......................8W-42-2

COMPRESSOR, AIR-CONDITIONER........0-21

COMPRESSOR CLUTCH...............24-16

COMPRESSOR CLUTCH, A/C............24-15

COMPRESSOR CLUTCH ASSEMBLY......24-20

COMPRESSOR CLUTCH RELAY, A/C . 24-15,24-16

COMPRESSOR SERVICE...............24-19

CONDENSER, A/C

....................24-34

CONDENSER FILTER DRIERÐ2.5L

ENGINES

...........................24-27

CONDENSERÐ4.0L ENGINES

...........24-28

CONDITION, CHECKING FLUID LEVEL

....21-182

CONDITIONING (A/C) CLUTCH RELAY,

AIR

...............................14-58

CONDITIONING (A/C) CLUTCH

RELAYÐPCM OUTPUT, AIR

............14-26

CONDITIONING (A/C) CONTROLSÐPCM

INPUT, AIR

.........................14-21

CONDITIONING, AIR

..................24-37

CONDITIONING CONTROLSÐXJ

VEHICLES, AIR

......................24-15

CONDITIONING CONTROLSÐYJ

VEHICLES, AIR

......................24-16

CONDITIONING, HEATER AND AIR; AIR

CONDITIONING/HEATER (YJ)

.........8W-42-2

CONDITIONING OPERATION, AIR; AIR

CONDITIONING/HEATER (XJ)

.........8W-42-2

CONDITIONING OPERATION, AIR; AIR

CONDITIONING/HEATER (XJ-RHD)

.....8W-42-2CONDITIONING PERFORMANCE TESTS,

AIR ...............................24-12

CONDITIONING SCHEMATICÐXJ, AIR.....24-5

CONDITIONING TEST PROCEDURES,

HEATING AND AIR....................24-15

CONDITIONS, NORMAL OPERATING........5-3

CONNECTING ROD BEARING FITTING

CHART..........................9-41,9-83

CONNECTING RODS, PISTONS.......9-39,9-81

CONNECTIONS, INTERMITTENT AND

POOR; WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-4

CONNECTIONS, RADIO ILLUMINATION

RELAY..............................8F-4

CONNECTIONS, STARTER RELAY........8A-15

CONNECTOR, ABS DIAGNOSTIC.......5-35,5-3

CONNECTOR AND TERMINAL

REPLACEMENT; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-7

CONNECTOR, DATA LINK; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

CONNECTOR, DATA LINK; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

CONNECTOR, DATA LINK; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

CONNECTOR, DATA LINK; FUEL/IGNITION

(XJ).............................8W-30-5

CONNECTOR, DATA LINK; FUEL/IGNITION

(YJ).............................8W-30-5

CONNECTOR, DATA LINK;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

CONNECTOR, DATA LINK; FUEL/IGNITION

(XJ-RHD)..........................8W-30-4

CONNECTOR LOCATIONS; CONNECTOR

LOCATIONS (XJ)...................8W-90-1

CONNECTOR LOCATIONS; CONNECTOR

LOCATIONS (XJ-RHD)...............8W-90-1

CONNECTOR LOCATIONS; CONNECTOR

LOCATIONS (YJ)...................8W-90-1

CONNECTOR LOCATIONS; CONNECTOR

PIN OUTS (XJ)....................8W-80-1

CONNECTOR LOCATIONS; CONNECTOR

PIN OUTS (XJ-RHD)................8W-80-1

CONNECTOR LOCATIONS; CONNECTOR

PIN OUTS (YJ)....................8W-80-1

CONNECTOR LOCATIONS; WIRING

DIAGRAMS (XJ)......................8W-1

CONNECTOR LOCATIONS; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

CONNECTOR LOCATIONS; WIRING

DIAGRAMS (YJ)......................8W-1

CONNECTOR, POWERTRAIN CONTROL

MODULE (PCM) 60-WAY...............14-40

CONNECTOR REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-6

CONNECTORÐPCM INPUT, DATA LINK . . . 14-22

CONNECTORÐPCM OUTPUT, DATA LINK . . 14-27

CONNECTORS; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-2

CONNECTORS (RHD), CLUSTER.........8E-11

CONNECTORS, TERMINAL/CONNECTOR

REPAIRÐMOLEX; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-6

CONSOLE, OVERHEAD; OVERHEAD

CONSOLE (XJ)....................8W-49-1

CONSOLE, OVERHEAD; OVERHEAD

CONSOLE (XJ-RHD)................8W-49-1

CONSOLE REMOVE/INSTALL, OVERHEAD . . . 8C-6

CONSOLE SHIFT, DISASSEMBLYÐ

COLUMN OR........................19-60

CONSOLEÐXJ, FULL FLOOR...........23-95

CONSOLEÐXJ, MINI-FLOOR............23-94

CONSOLEÐXJ, OVERHEAD; BODY

COMPONENTSÐXJ VEHICLES..........23-93

CONSOLEÐXJ, OVERHEAD; LAMPS......8L-17

CONSOLESÐYJ, FLOOR..............23-155

CONTACT PATTERN ANALYSIS,

BACKLASH; FRONT SUSPENSION AND

AXLE...............................2-45

CONTACT PATTERN ANALYSIS,

BACKLASH; REAR SUSPENSION AND

AXLES

..............................3-27

CONTACT/CLOCKSPRING, HORN

.........8G-4

CONTAMINATED BRAKELINING

............5-7

CONTAMINATION, BRAKE FLUID

.......5-10,5-7

CONTAMINATION, CLUTCH

...............6-3

JINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2136 of 2158

GENERAL INFORMATION; POWER LOCKS . . 8P-1

GENERAL INFORMATION; POWER

MIRRORS...........................8T-1

GENERAL INFORMATION; POWER SEATS . . 8R-1

GENERAL INFORMATION; POWER

WINDOWS...........................8S-1

GENERAL INFORMATION; PROPELLER

SHAFTS.............................16-1

GENERAL INFORMATION; REAR

SUSPENSION AND AXLES........3-13,3-1,3-9

GENERAL INFORMATION; REAR

WINDOW DEFOGGER..................8N-1

GENERAL INFORMATION; RESTRAINT

SYSTEMS...........................8M-1

GENERAL INFORMATION; SPLICE

INFORMATION (XJ).................8W-70-1

GENERAL INFORMATION; SPLICE

INFORMATION (XJ-RHD)............8W-70-1

GENERAL INFORMATION; SPLICE

INFORMATION (YJ).................8W-70-1

GENERAL INFORMATION; SPLICE

LOCATIONS (XJ)...................8W-95-1

GENERAL INFORMATION; SPLICE

LOCATIONS (XJ-RHD)...............8W-95-1

GENERAL INFORMATION; SPLICE

LOCATIONS (YJ)...................8W-95-1

GENERAL INFORMATION; STEERING . 19-48,19-1

GENERAL INFORMATION;

TRANSMISSION AND TRANSFER CASE . . 21-165,

21-283,21-307,21-33,21-67,21-70,21-1

GENERAL INFORMATION; TURN SIGNAL

AND HAZARD WARNING SYSTEMS.......8J-1

GENERAL INFORMATION; VEHICLE

SPEED CONTROL SYSTEM..............8H-1

GENERAL INFORMATION; WHEELS AND

TIRES..........................22-1,22-6

GENERAL INFORMATION - XJ............8K-1

GENERAL INFORMATION - YJ...........8K-10

GENERAL SERVICE INFORMATION; BODY

COMPONENTSÐXJ VEHICLES.........23-102

GENERAL SERVICE INFORMATION;

BRAKES.........................5-15,5-60

GENERAL SERVICEÐXJ, STEERING

COLUMN...........................19-47

GENERAL SPECIFICATIONS, 30RH/32RH . 21-335

GENERAL SPECIFICATIONS, AW-4......21-337

GENERATOR.........................8B-6

GENERATOR DIAGNOSTIC TROUBLE

CODE..............................8A-22

GENERATOR FIELDÐPCM OUTPUT......14-27

GENERATOR LAMPÐPCM OUTPUT......14-27

GENERATOR RATINGS................8A-23

GENERATOR REMOVE/INSTALLÐLEFT-

HAND DRIVE.........................8B-6

GENERATOR REMOVE/INSTALLÐRIGHT-

HAND DRIVE.........................8B-7

GENERATOR SPECIFICATIONS...........8B-8

GENERATOR SPLASH SHIELD...........13-13

GLASS AND DOOR OPENING

WEATHERSTRIP SEALSÐXJ, DOOR

WINDOW...........................23-55

GLASS CHANNEL REPLACEMENTÐYJ,

DOOR FRAME......................23-142

GLASS GRID, REAR WINDOW.......8N-1,8N-2

GLASS GRID REPAIRS, REAR WINDOW . . . 8N-3

GLASS REGULATOR HANDLEÐYJ,

FULL-METAL DOOR WINDOW..........23-136

GLASS REGULATORÐXJ, FRONT DOOR

WINDOW...........................23-42

GLASS REGULATORÐXJ, REAR DOOR

WINDOW...........................23-44

GLASS REGULATORÐYJ, FULL-METAL

DOOR WINDOW....................23-138

GLASS REPLACEMENTÐXJ,

WINDSHIELD........................23-69

GLASS, STATIONARY.................23-144

GLASS, STATIONARY WINDOW..........23-66

GLASS WATER LEAK DETECTION AND

REPAIRÐXJ, STATIONARY.............23-76

GLASS WATER LEAK DETECTION AND

REPAIRÐYJ, STATIONARY............23-150

GLASS WEATHERSTRIP SEAL

REPLACEMENTÐYJ, LIFTGATE

.........23-125

GLASSÐXJ, FRONT DOOR WINDOW

.....23-43

GLASSÐXJ, LIFTGATE WINDOW

........23-74

GLASSÐXJ, REAR DOOR STATIONARY

WINDOW

...........................23-46

GLASSÐXJ, REAR DOOR WINDOW

......23-45GLASSÐXJ, REAR QUARTER VENT

WINDOW...........................23-73

GLASSÐYJ, FULL-METAL DOOR VENT

WINDOW..........................23-137

GLASSÐYJ, FULL-METAL DOOR

WINDOW..........................23-139

GLASSÐYJ, HARD TOP LIFTGATE......23-124

GLASSÐYJ, HARD TOP QUARTER

WINDOW..........................23-149

GLASSÐYJ, WINDSHIELD............23-146

GLASS/REAR QUARTER PLASTIC

INSERTÐXJ, REAR QUARTER

WINDOW...........................23-73

GLOVE BOX LAMP; INTERIOR LIGHTING

(XJ).............................8W-44-1

GLOVE BOX LAMP; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-1

GLOVE BOXÐYJ....................23-152

(GOP)ÐXJ, GRILLE AND GRILLE

OPENING PANEL......................23-3

GOVERNOR AND PARK GEAR OVERHAUL . 21-127

GOVERNOR AND PARK GEAR SERVICE . . 21-105

GRAB, REAR BRAKE....................5-7

GRID, REAR WINDOW GLASS.......8N-1,8N-2

GRID REPAIRS, REAR WINDOW GLASS . . . 8N-3

GRILLE AND GRILLE OPENING PANEL

(GOP)ÐXJ...........................23-3

GRILLE AND SCREENÐXJ, COWL.......23-12

GRILLE AND SCREENÐYJ, COWL......23-109

GRILLE APPLIQUEÐYJ, RADIATOR.....23-104

GRILLE OPENING PANEL (GOP)ÐXJ,

GRILLE.............................23-3

GRILLEÐXJ, AIR EXHAUST............23-25

GROUND CLEARANCE AND RAMP

ANGLE..............................0-11

GROUND, CLUSTER; INSTRUMENT

CLUSTER (XJ).....................8W-40-3

GROUND, CLUSTER; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-2

GROUND, POWER....................14-24

GROUND, POWER (DEVICE); FUEL/

IGNITION (XJ).....................8W-30-5

GROUND, POWER (DEVICE); FUEL/

IGNITION (YJ).....................8W-30-5

GROUND, POWER (DEVICE); FUEL/

IGNITION (XJ-RHD)................8W-30-5

GROUP, HOW TO USE THIS; WIRING

DIAGRAMS (XJ)......................8W-1

GROUP, HOW TO USE THIS; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

GROUP, HOW TO USE THIS; WIRING

DIAGRAMS (YJ)......................8W-1

GUARD/EDGE PROTECTOR STRIPÐXJ,

DOOR EDGE........................23-54

GUARDÐXJ, BRUSH...................23-3

GUIDES AND CHARTS, DIAGNOSIS......21-77

HALF METAL DOOR MIRROR

(EXTERNAL)ÐYJ....................23-121

HALF-METAL DOOR LATCH STRIKERÐ

YJ ...............................23-135

HALF-METAL SOFT TOP DOORÐYJ.....23-134

HAND DRIVE, AUTOMATIC BELT

TENSIONERÐXJ MODELS WITH

RIGHT..............................7-42

HAND DRIVE, BELT SERVICEÐEXCEPT

RIGHT..............................7-40

HAND DRIVE, BELT SERVICEÐXJ

MODELS WITH RIGHT..................7-42

HAND DRIVE (RHD), BELT TENSIONÐ

EXCEPT RIGHT.......................7-38

HAND DRIVE (RHD), BELT TENSIONÐ

RIGHT..............................7-38

HAND DRIVE (RHD) MODELS, BELT

TENSIONÐEXCEPT RIGHT..............7-45

HAND DRIVE VEHICLES, RIGHT..........23-1

HANDLE COVERÐXJ, PARKING BRAKE . . . 23-94

HANDLEÐXJ, ASSIST.................23-89

HANDLEÐXJ, DOOR EXTERNAL.........23-48

HANDLEÐYJ, FULL-METAL DOOR

ASSIST

...........................23-136

HANDLEÐYJ, FULL-METAL DOOR LATCH

EXTERNAL RELEASE

.................23-140

HANDLEÐYJ, FULL-METAL DOOR LATCH

INSIDE RELEASE AND LOCK

...........23-137

HANDLEÐYJ, FULL-METAL DOOR

WINDOW GLASS REGULATOR

.........23-136

HANDLEÐYJ, TAILGATE LATCH AND

RELEASE

..........................23-122HANDLING, AIRBAG MODULE...........8M-2

HARD PEDAL OR HIGH PEDAL EFFORT.....5-6

HARD TOP LIFTGATE GLASSÐYJ.......23-124

HARD TOP QUARTER WINDOW

GLASSÐYJ........................23-149

HARD TOP REPAIRÐYJ..............23-127

HARD TOP ROOF VENTÐYJ...........23-127

HARD TOPÐYJ.....................23-126

HARDTOP DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES..........8L-31

HAS A MISS, INJECTOR DIAGNOSISÐ

VEHICLE RUNS ROUGH AND/OR........14-52

HAZARD FLASHERS; TURN SIGNALS

(XJ).............................8W-52-1

HAZARD FLASHERS; TURN SIGNALS

(XJ-RHD).........................8W-52-1

HAZARD FLASHERS; TURN SIGNALS

(YJ).............................8W-52-1

HAZARD WARNING SYSTEM.............8J-1

HAZARD WARNING SYSTEM - YJ.........8J-4

HCU DIAGNOSIS, ANTILOCK ECU..........5-3

HCU INSTALLATION (XJ)................5-43

HCU INSTALLATION (YJ)................5-44

HCU OPERATION......................5-36

HCU REMOVAL (XJ)...................5-41

HCU REMOVAL (YJ)...................5-44

HEAD COVER, ENGINE CYLINDER....9-22,9-64

HEAD, ENGINE CYLINDER...........9-25,9-67

HEAD GASKET FAILURE DIAGNOSIS,

ENGINE CYLINDER.....................9-5

HEAD NOT REMOVED, VALVE

COMPONENT REPLACEÐCYLINDER . . . 9-23,9-65

HEADLAMP ALIGNMENT

PREPARATIONÐXJ....................8L-6

HEADLAMP ALIGNMENT

PREPARATIONÐYJ...................8L-22

HEADLAMP ALIGNMENTÐXJ............8L-6

HEADLAMP ALIGNMENTÐYJ...........8L-22

HEADLAMP BULB REPLACEMENTÐXJ.....8L-7

HEADLAMP BULB REPLACEMENTÐYJ....8L-23

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ.....................8L-14

HEADLAMP DELAY MODULE; FRONT

LIGHTING (XJ)....................8W-50-2

HEADLAMP DELAY MODULE; FRONT

LIGHTING (XJ-RHD)................8W-50-1

HEADLAMP DELAY MODULE

REPLACEMENTÐXJ..................8L-14

HEADLAMP DELAY MODULEÐXJ,

SENTINEL..........................8L-14

HEADLAMP DIAGNOSIS...........8L-20,8L-2

HEADLAMP DIMMER SWITCH

REPLACEMENTÐYJ..................8L-26

HEADLAMP OR PANEL DIMMER SWITCH

REMOVE/INSTALL....................8E-42

HEADLAMP RELAY; FRONT LIGHTING

(XJ-RHD).........................8W-50-1

HEADLAMP SWITCH REMOVE/INSTALL . . . 8E-19

HEADLAMP SWITCH (XJ ONLY)......8U-1,8U-3

HEADLAMP SWITCHÐXJ..............8L-10

HEADLAMP SWITCHÐYJ..............8L-26

HEADLAMP/FOG LAMP ADJUSTMENT

USING ALIGNMENT SCREENÐXJ.........8L-7

HEADLAMP/FOG LAMP ADJUSTMENT

USING ALIGNMENT SCREENÐYJ........8L-23

HEADLAMPS; FRONT LIGHTING (XJ) . . . 8W-50-1

HEADLAMPS; FRONT LIGHTING

(XJ-RHD).........................8W-50-1

HEADLAMPS; FRONT LIGHTING (YJ) . . . 8W-50-1

HEADLAMPS; LUBRICATION AND

MAINTENANCE.......................0-33

HEADLINERÐXJ.....................23-92

HEAT SHIELDS......................14-13

HEAT SHIELDS, EXHAUST...............11-1

HEATED OXYGEN SENSOR; FUEL/

IGNITION (XJ).....................8W-30-3

HEATED OXYGEN SENSOR; FUEL/

IGNITION (YJ).....................8W-30-3

HEATED OXYGEN SENSOR; FUEL/

IGNITION (XJ-RHD)

................8W-30-3

HEATED REAR WINDOW; HEATED REAR

WINDOW (XJ)

.....................8W-48-1

HEATED REAR WINDOW; HEATED REAR

WINDOW (XJ-RHD)

.................8W-48-1

HEATED REAR WINDOW; HEATED REAR

WINDOW (YJ)

.....................8W-48-1

HEATER; AIR CONDITIONING/HEATER

(YJ)

.............................8W-42-1

12 INDEXJ

Description Group-Page Description Group-Page Description Group-Page