lock KIA Amanti 2004 1.G Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2004, Model line: Amanti, Model: KIA Amanti 2004 1.GPages: 296, PDF Size: 29.34 MB

Page 224 of 296

611

In case of an emergency

1

2

3

4

5

6

7

8

9

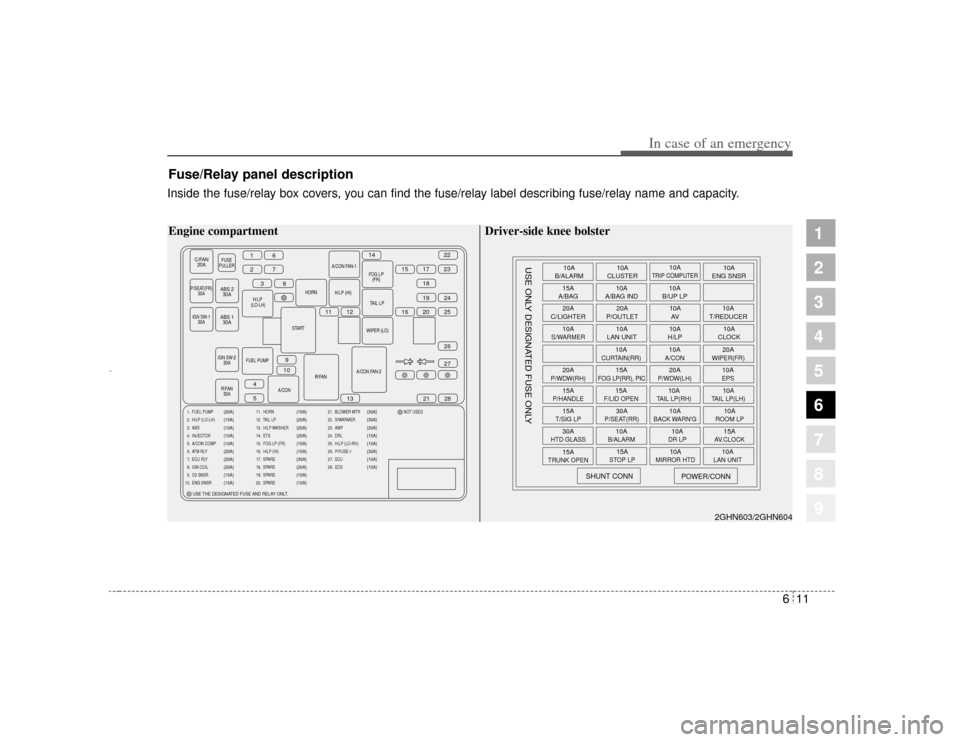

Fuse/Relay panel descriptionInside the fuse/relay box covers, you can find the fuse/relay label describing fuse/relay name and capacity.

C/FAN20A

FUSE

PULLER

P/SEAT(FR) 30A

H/

LP (LO-LH) HORN

START

IGN SW-2 30A

R/FAN 30A R/FAN

A/CON FAN-2WIPER (LO)

TAIL

LP

H/LP (HI)

A/CON FAN-1

FOG

LP(FR)

FUEL PUMP A/CON

16

2738

11 12 16 20

15

14

17

1822

23

19 25 24

27

21

13

9

10

4

5 28

26

IGN SW-1

30A

ABS 230A

ABS 1 30A

1. FUEL PUMP

2. H/LP (LO-LH)

3. ABS

4. INJECTOR

5. A/CON COMP

6. ATM RLY

7. ECU RLY

8. IGN COIL

9. O2 SNSR

10. ENG SNSR

(20A)

(15A)

(10A)

(10A)

(10A)

(20A)

(20A)

(20A)

(15A)

(15A)

11. HORN

12. TAIL LP

13. H/LP WASHER

14. ETS

15. FOG LP (FR)

16. H/LP (HI)

17. SPARE

18. SPARE

19. SPARE

20. SPARE

(15A)

(20A)

(20A)

(20A)

(15A)

(15A)

(30A)

(20A)

(15A)

(10A)

21. BLOWER MTR

22. S/WARMER

23. AMP

24. DRL

25. H/LP (LO-RH)

26. P/FUSE-1

27. ECU

28. ECS NOT USED

(30A)

(30A)

(20A)

(15A)

(15A)

(30A)

(10A)

(15A)

USE THE DESIGNATED FUSE AND RELAY ONLT.

Engine compartment

10A

B/ALARM

15A

A/BAG

20A

C/LIGHTER

10AS/WARMER20AP/WDW(RH)15AP/HANDLE15AT/SIG LP30AHTD GLASS15A

TRUNK OPEN

SHUNT CONN

USE ONLY DESIGNATED FUSE ONLY

POWER/CONN

15ASTOP LP

10A

MIRROR HTD

10ALAN UNIT

10AB/ALARM

10ADR LP

15AAV.CLOCK

30AP/SEAT(RR)

10A

BACK WARN'G

10AROOM LP

15AF/LID OPEN

10ATAIL LP(RH)

10ATAIL LP(LH)

15A

FOG LP(RR), PIC

20AP/WDW(LH)

10AEPS

10A

CURTAIN(RR)

10AA/CON

20AWIPER(FR)

10A

LAN UNIT 10A

H/LP 10A

CLOCK

20A

P/OUTLET 10A

T/REDUCER

10A

AV

10A

A/BAG IND 10A

B/UP LP

10A

CLUSTER 10A

ENG SNSR

10A

TRIP COMPUTER

2GHN603/2GHN604

Driver-side knee bolster

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 11

Page 225 of 296

In case of an emergency12

6

1

2

3

4

5

6

7

8

9

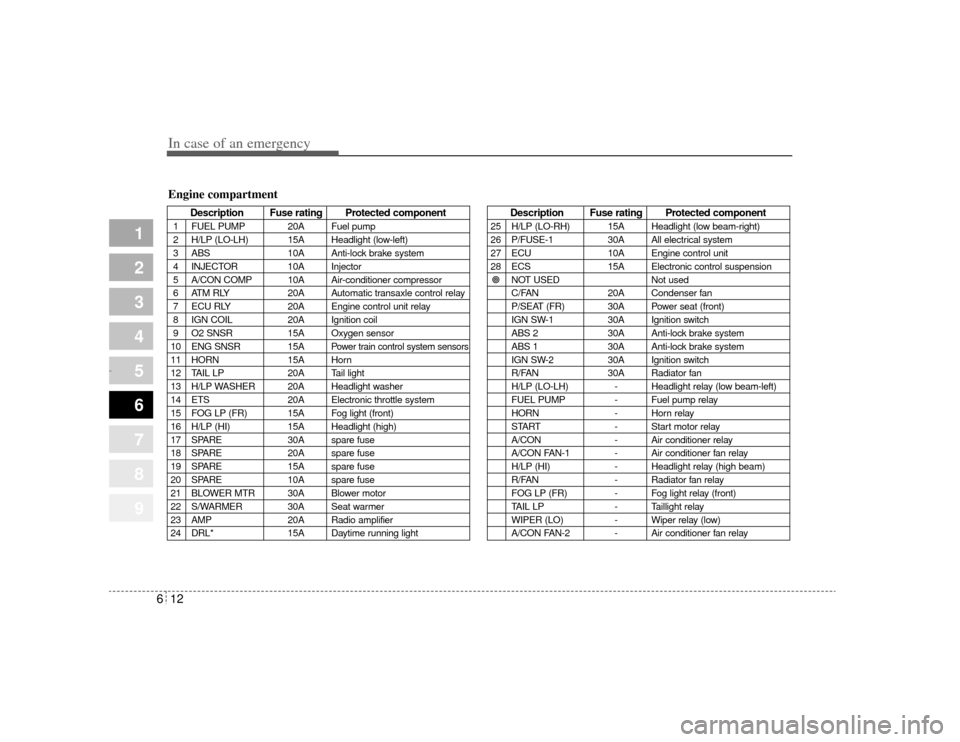

Description Fuse rating Protected component

1 FUEL PUMP 20A Fuel pump

2 H/LP (LO-LH) 15A Headlight (low-left)

3 ABS 10A Anti-lock brake system

4 INJECTOR 10A Injector

5 A/CON COMP 10A Air-conditioner compressor

6 ATM RLY 20A Automatic transaxle control relay

7 ECU RLY 20A Engine control unit relay

8 IGN COIL 20A Ignition coil

9 O2 SNSR 15A Oxygen sensor

10 ENG SNSR 15A

Power train control system sensors

11 HORN 15A Horn

12 TAIL LP 20A Tail light

13 H/LP WASHER 20A Headlight washer

14 ETS 20A Electronic throttle system

15 FOG LP (FR) 15A Fog light (front)

16 H/LP (HI) 15A Headlight (high)

17 SPARE 30A spare fuse

18 SPARE 20A spare fuse

19 SPARE 15A spare fuse

20 SPARE 10A spare fuse

21 BLOWER MTR 30A Blower motor

22 S/WARMER 30A Seat warmer

23 AMP 20A Radio amplifier

24 DRL* 15A Daytime running light

Description Fuse rating Protected component

25 H/LP (LO-RH) 15A Headlight (low beam-right)

26 P/FUSE-1 30A All electrical system

27 ECU 10A Engine control unit

28 ECS 15A Electronic control suspension

! NOT USED Not used

C/FAN 20A Condenser fan

P/SEAT (FR) 30A Power seat (front)

IGN SW-1 30A Ignition switch

ABS 2 30A Anti-lock brake system

ABS 1 30A Anti-lock brake system

IGN SW-2 30A Ignition switch

R/FAN 30A Radiator fan

H/LP (LO-LH) - Headlight relay (low beam-left)

FUEL PUMP - Fuel pump relay

HORN - Horn relay

START - Start motor relay

A/CON - Air conditioner relay

A/CON FAN-1 - Air conditioner fan relay

H/LP (HI) - Headlight relay (high beam)

R/FAN - Radiator fan relay

FOG LP (FR) - Fog light relay (front)

TAIL LP - Taillight relay

WIPER (LO) - Wiper relay (low)

A/CON FAN-2 - Air conditioner fan relay

Engine compartment

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 12

Page 226 of 296

613

In case of an emergency

1

2

3

4

5

6

7

8

9

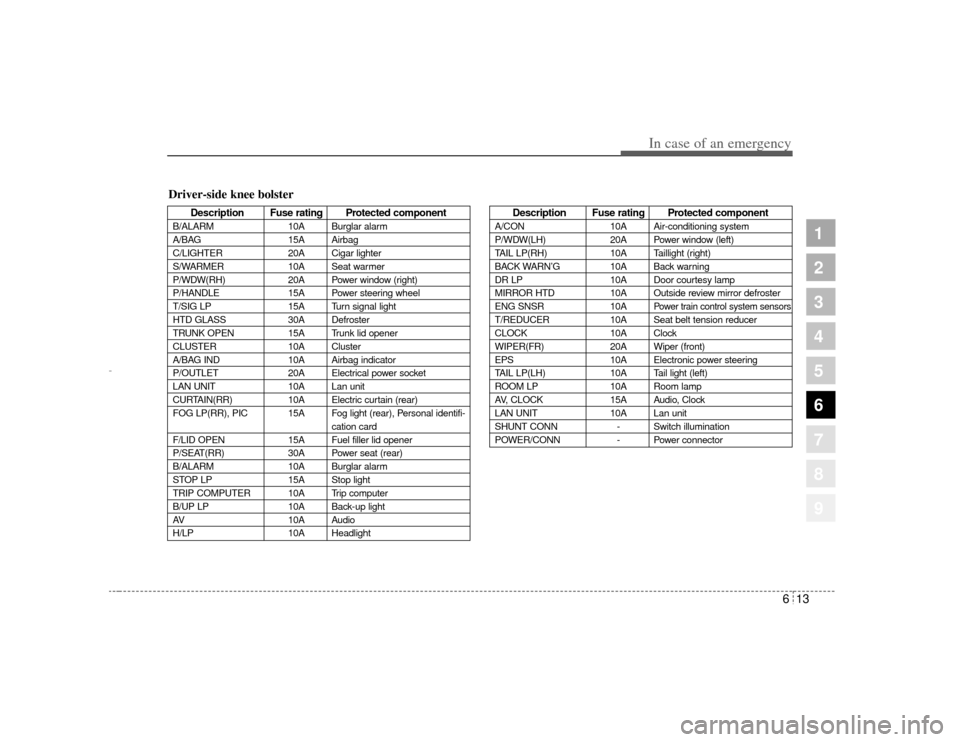

Driver-side knee bolster

Description Fuse rating Protected component

B/ALARM10A Burglar alarm

A/BAG 15A Airbag

C/LIGHTER 20A Cigar lighter

S/WARMER 10A Seat warmer

P/WDW(RH) 20A Power window (right)

P/HANDLE 15A Power steering wheel

T/SIG LP 15A Turn signal light

HTD GLASS 30A Defroster

TRUNK OPEN 15A Trunk lid opener

CLUSTER 10A Cluster

A/BAG IND 10A Airbag indicator

P/OUTLET 20A Electrical power socket

LAN UNIT 10A Lan unit

CURTAIN(RR) 10A Electric curtain (rear)

FOG LP(RR), PIC 15A Fog light (rear), Personal identifi- cation card

F/LID OPEN 15A Fuel filler lid opener

P/SEAT(RR) 30A Power seat (rear)

B/ALARM 10A Burglar alarm

STOP LP 15A Stop light

TRIP COMPUTER 10A Trip computer

B/UP LP 10A Back-up light

AV 10A Audio

H/LP 10A Headlight

Description Fuse rating Protected component

A/CON10A Air-conditioning system

P/WDW(LH) 20A Power window (left)

TAIL LP(RH) 10A Taillight (right)

BACK WARN’ G10A Back warning

DR LP 10A Door courtesy lamp

MIRROR HTD 10A Outside review mirror defroster

ENG SNSR 10A

Power train control system sensors

T/REDUCER10A Seat belt tension reducer

CLOCK 10A Clock

WIPER(FR) 20A Wiper (front)

EPS 10A Electronic power steering

TAIL LP(LH) 10A Tail light (left)

ROOM LP 10A Room lamp

AV, CLOCK 15A Audio, Clock

LAN UNIT 10A Lan unit

SHUNT CONN - Switch illumination

POWER/CONN - Power connector

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 13

Page 227 of 296

In case of an emergency14

6

1

2

3

4

5

6

7

8

9

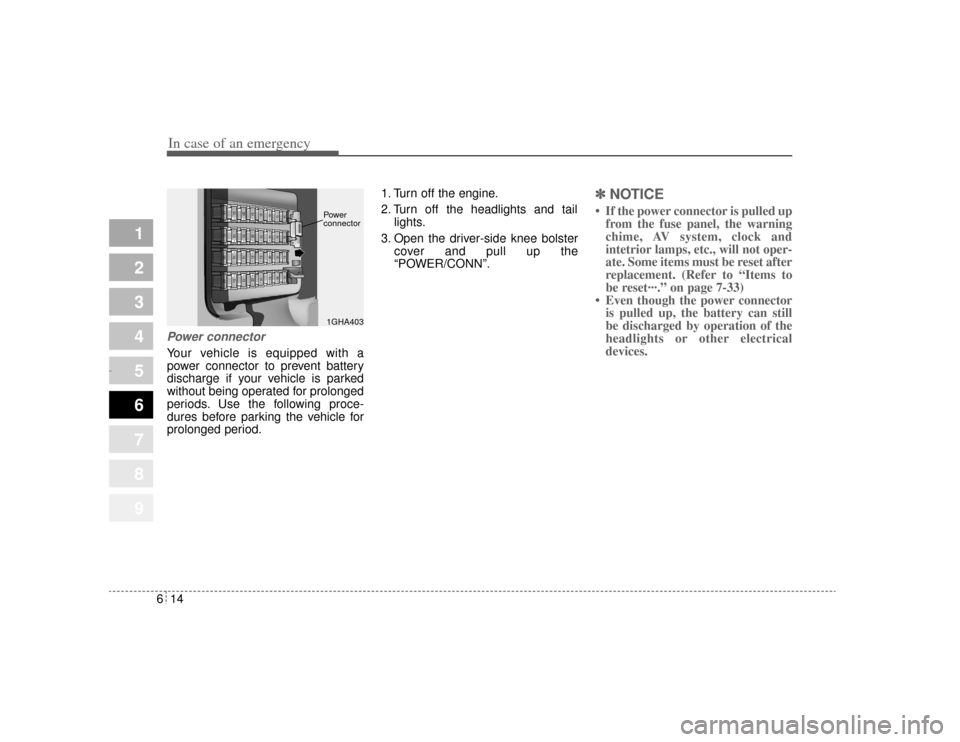

Power connectorYour vehicle is equipped with a

power connector to prevent battery

discharge if your vehicle is parked

without being operated for prolonged

periods. Use the following proce-

dures before parking the vehicle for

prolonged period. 1. Turn off the engine.

2. Turn off the headlights and tail

lights.

3. Open the driver-side knee bolster cover and pull up the

“POWER/CONN”.

✽ ✽NOTICE• If the power connector is pulled up

from the fuse panel, the warning

chime, AV system, clock and

intetrior lamps, etc., will not oper-

ate. Some items must be reset after

replacement. (Refer to “Items to

be reset···.” on page 7-33)

• Even though the power connector is pulled up, the battery can still

be discharged by operation of the

headlights or other electrical

devices.

1GHA403

Power

connector

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 14

Page 232 of 296

619

In case of an emergency

1

2

3

4

5

6

7

8

9

When your vehicle is being

towed by another vehicle

other than a tow truck (In case

of an emergency) Turn the ignition switch to ACC so

the steering wheel isn’t locked.

Place the transaxle shift lever in N

(Neutral).

Release the parking bake.

Vehicle equipped with automatic

transaxles should not exceed 45

km/h (28 mph) and should not be

towed more than 80 km (50 miles).

Press the brake pedal with more

force than normal since you will

have reduced brake performance.

More steering effort will be

required because the power steer-

ing system will be disabled.

If you are driving down a long hill,

the brakes may overheat and brake

performance will be reduced. Stop

often and let the brakes cool off.

✽ ✽

NOTICETo prevent internal damage to the

transaxle, never tow your vehicle

from the rear (backwards) with all

four tires in contact with the sur-

face.

Tips for towing a stuck vehicleThe following methods are effective

when your vehicle is stuck in mud,

sand or similar substances that pre-

vent the vehicle from being driven

out under its own power.

Remove the soil and sand, etc.

from the front and the back of the

tires.

Place a stone or wood under the

tires.

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 19

Page 233 of 296

In case of an emergency20

6

1

2

3

4

5

6

7

8

9

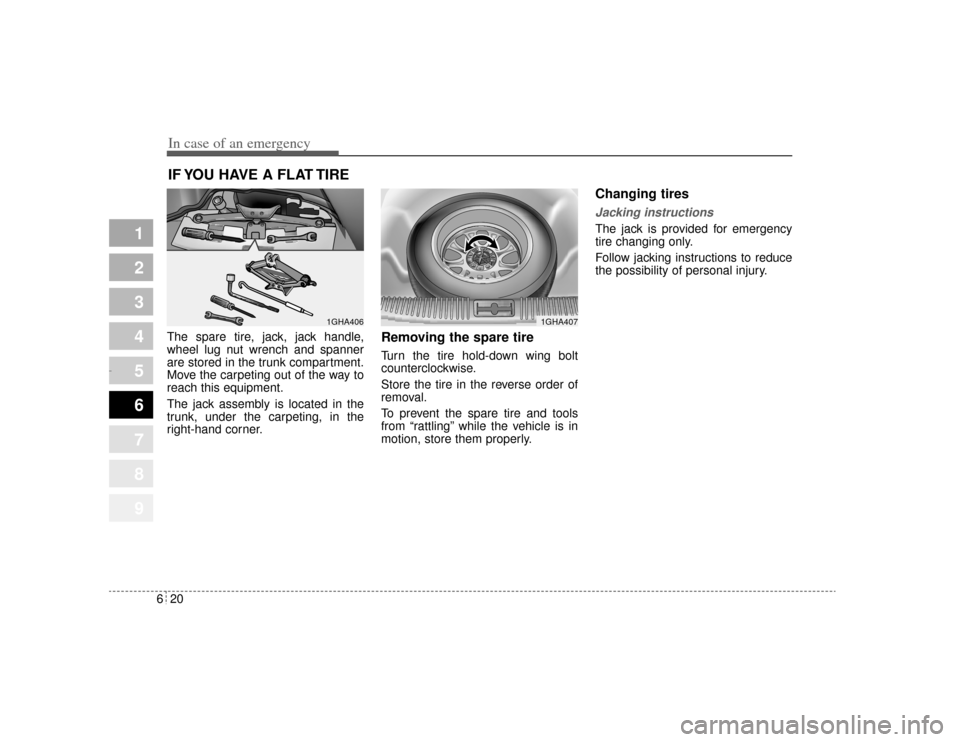

IF YOU HAVE A FLAT TIRE The spare tire, jack, jack handle,

wheel lug nut wrench and spanner

are stored in the trunk compartment.

Move the carpeting out of the way to

reach this equipment.

The jack assembly is located in the

trunk, under the carpeting, in the

right-hand corner.

Removing the spare tire Turn the tire hold-down wing bolt

counterclockwise.

Store the tire in the reverse order of

removal.

To prevent the spare tire and tools

from “rattling” while the vehicle is in

motion, store them properly.

Changing tires Jacking instructions The jack is provided for emergency

tire changing only.

Follow jacking instructions to reduce

the possibility of personal injury.

1GHA406

1GHA407

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 20

Page 235 of 296

In case of an emergency22

6

1

2

3

4

5

6

7

8

9

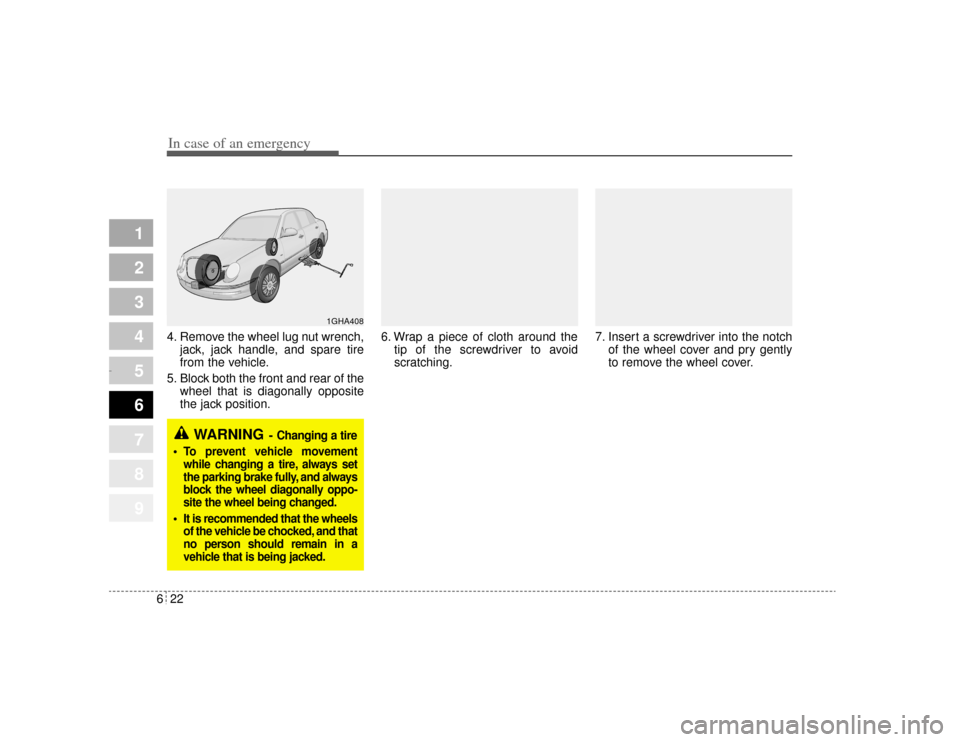

4. Remove the wheel lug nut wrench,

jack, jack handle, and spare tire

from the vehicle.

5. Block both the front and rear of the wheel that is diagonally opposite

the jack position. 6. Wrap a piece of cloth around the

tip of the screwdriver to avoid

scratching. 7. Insert a screwdriver into the notch

of the wheel cover and pry gently

to remove the wheel cover.

WARNING

- Changing a tire

To prevent vehicle movement

while changing a tire, always set

the parking brake fully, and always

block the wheel diagonally oppo-

site the wheel being changed.It is recommended that the wheels

of the vehicle be chocked, and that

no person should remain in a

vehicle that is being jacked.

1GHA408

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 22

Page 236 of 296

623

In case of an emergency

1

2

3

4

5

6

7

8

9

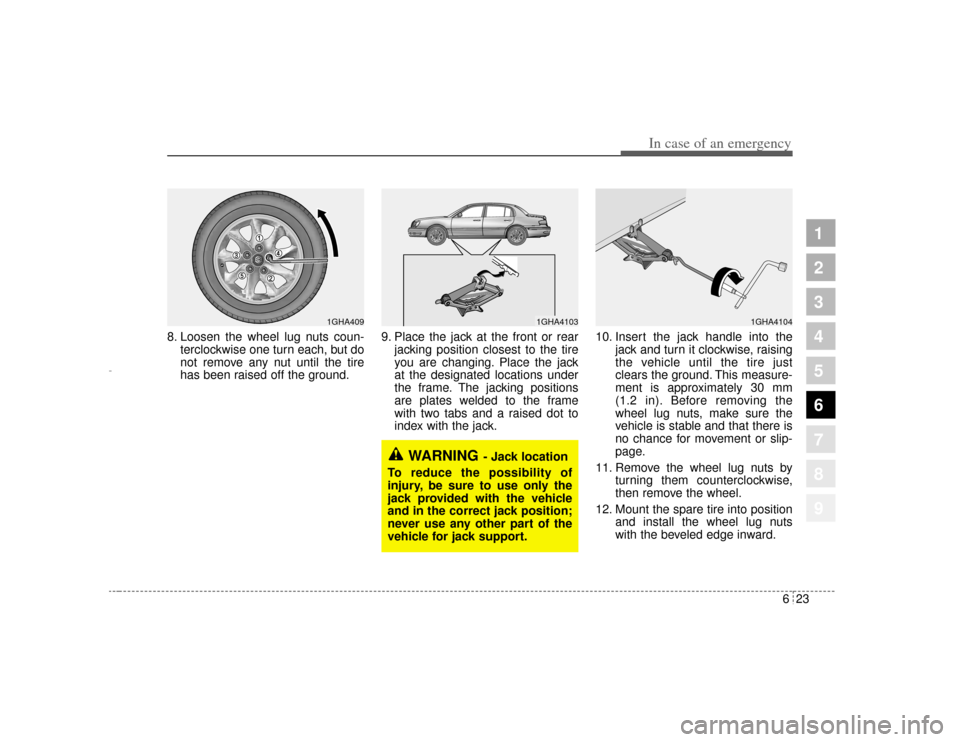

8. Loosen the wheel lug nuts coun-terclockwise one turn each, but do

not remove any nut until the tire

has been raised off the ground. 9. Place the jack at the front or rear

jacking position closest to the tire

you are changing. Place the jack

at the designated locations under

the frame. The jacking positions

are plates welded to the frame

with two tabs and a raised dot to

index with the jack. 10. Insert the jack handle into the

jack and turn it clockwise, raising

the vehicle until the tire just

clears the ground. This measure-

ment is approximately 30 mm

(1.2 in). Before removing the

wheel lug nuts, make sure the

vehicle is stable and that there is

no chance for movement or slip-

page.

11. Remove the wheel lug nuts by turning them counterclockwise,

then remove the wheel.

12. Mount the spare tire into position and install the wheel lug nuts

with the beveled edge inward.

WARNING

- Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

1GHA4104

1GHA4103

1GHA409

Opirus CAN 6-1.qxd 7/8/03 2:22 PM Page 23

Page 243 of 296

Maintenance67

1

2

3

4

5

6

7

8

9

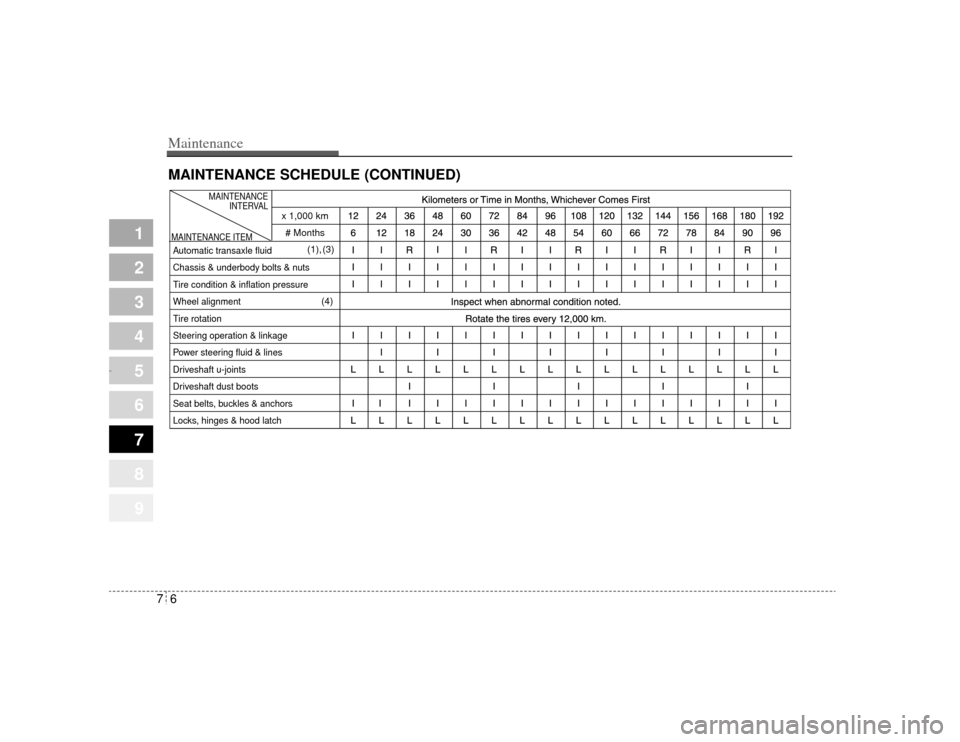

MAINTENANCE SCHEDULE (CONTINUED)

(4)

(1), (3)

Automatic transaxle fluid

Chassis & underbody bolts & nuts

Tire condition & inflation pressure

Wheel alignment

Tire rotation

Steering operation & linkage

Power steering fluid & lines

Driveshaft u-joints

Driveshaft dust boots

Seat belts, buckles & anchors

Locks, hinges & hood latch

x 1,000 km

# Months

MAINTENANCE ITEM MAINTENANCE

INTERVAL

Opirus CAN 7-1.qxd 7/8/03 2:25 PM Page 6

Page 246 of 296

79

Maintenance

1

2

3

4

5

6

7

8

9

At least monthly: Check coolant level in the coolantrecovery reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flash-

ers.

Check the inflation pressures of all tires including the spare.

At least twice a year

(i.e., every Spring and Fall) : Check radiator, heater and air con- ditioning hoses for leaks or da-

mage.

Check windshield washer spray and wiper operation. Clean wiper

blades with clean cloth dampened

with washer fluid.

Check headlight alignment.

Check muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tires and loose wheel lug nuts.

At least once a year : Clean body and door drain holes.

Lubricate door hinges and checks,and hood hinges.

Lubricate door and hood locks and latches.

Lubricate door rubber weather- strips.

Check the air conditioning system before the warm weather season.

Check the power steering fluid level.

Inspect and lubricate automatic transaxle linkage and controls.

Clean battery and terminals.

Check the brake fluid level.

Opirus CAN 7-1.qxd 7/8/03 2:25 PM Page 9