KIA Borrego 2009 1.G Owner's Manual

Manufacturer: KIA, Model Year: 2009, Model line: Borrego, Model: KIA Borrego 2009 1.GPages: 425, PDF Size: 8.46 MB

Page 401 of 425

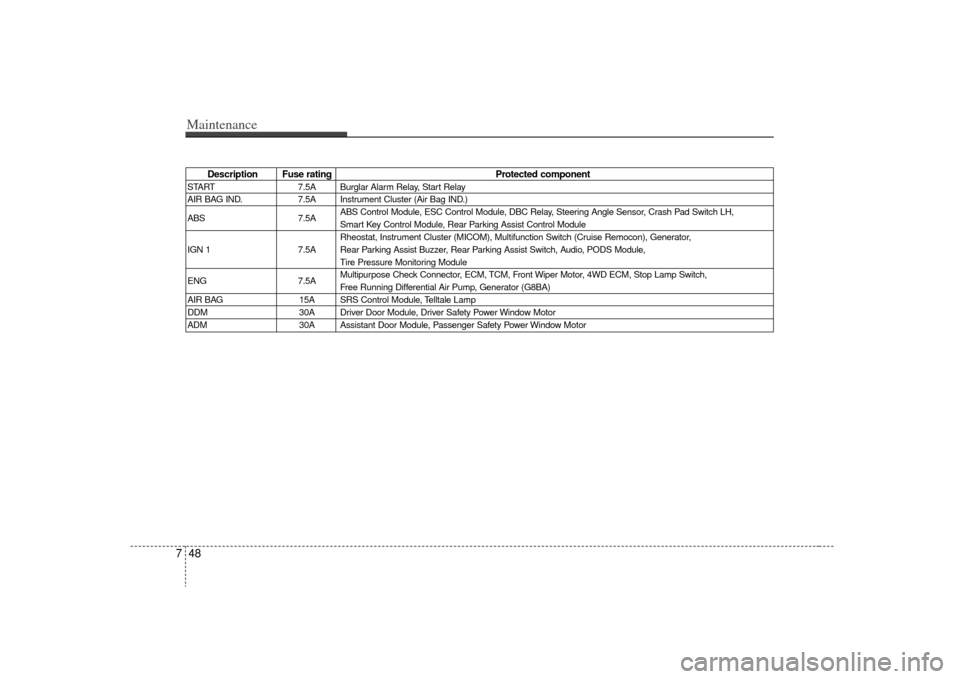

Maintenance48

7

Description Fuse rating Protected component

START7.5A Burglar Alarm Relay, Start Relay

AIR BAG IND. 7.5A Instrument Cluster (Air Bag IND.)

ABS 7.5AABS Control Module, ESC Control Module, DBC Relay, Steering Angle Sensor, Crash Pad Switch LH,

Smart Key Control Module, Rear Parking Assist Control Module

Rheostat, Instrument Cluster (MICOM), Multifunction Switch (Cruise Remocon), Generator,

IGN 1 7.5A Rear Parking Assist Buzzer, Rear Parking Assist Switch, Audio, PODS Module,

Tire Pressure Monitoring Module

ENG 7.5AMultipurpose Check Connector, ECM, TCM, Front Wiper Motor, 4WD ECM, Stop Lamp Switch,

Free Running Differential Air Pump, Generator (G8BA)

AIR BAG 15A SRS Control Module, Telltale Lamp

DDM 30A Driver Door Module, Driver Safety Power Window Motor

ADM 30A Assistant Door Module, Passenger Safety Power Window Motor

Page 402 of 425

749

Maintenance

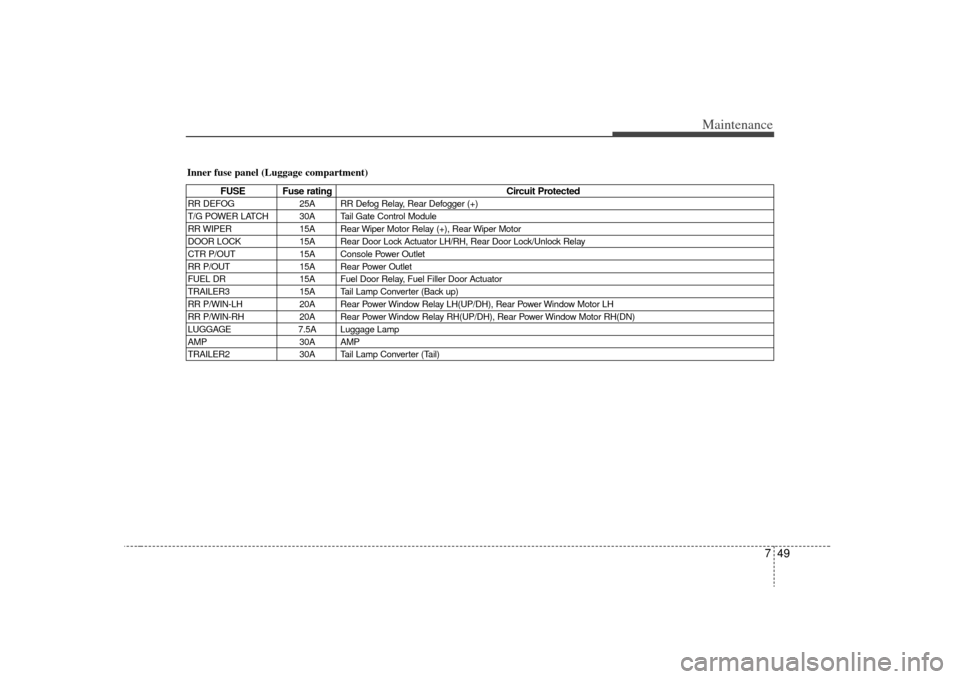

Inner fuse panel (Luggage compartment)

FUSE Fuse ratingCircuit Protected

RR DEFOG25A RR Defog Relay, Rear Defogger (+)

T/G POWER LATCH 30A Tail Gate Control Module

RR WIPER 15A Rear Wiper Motor Relay (+), Rear Wiper Motor

DOOR LOCK 15A Rear Door Lock Actuator LH/RH, Rear Door Lock/Unlock Relay

CTR P/OUT 15A Console Power Outlet

RR P/OUT 15A Rear Power Outlet

FUEL DR 15A Fuel Door Relay, Fuel Filler Door Actuator

TRAILER3 15A Tail Lamp Converter (Back up)

RR P/WIN-LH 20A Rear Power Window Relay LH(UP/DH), Rear Power Window Motor LH

RR P/WIN-RH 20A Rear Power Window Relay RH(UP/DH), Rear Power Window Motor RH(DN)

LUGGAGE 7.5A Luggage Lamp

AMP 30A AMP

TRAILER2 30A Tail Lamp Converter (Tail)

Page 403 of 425

Maintenance50

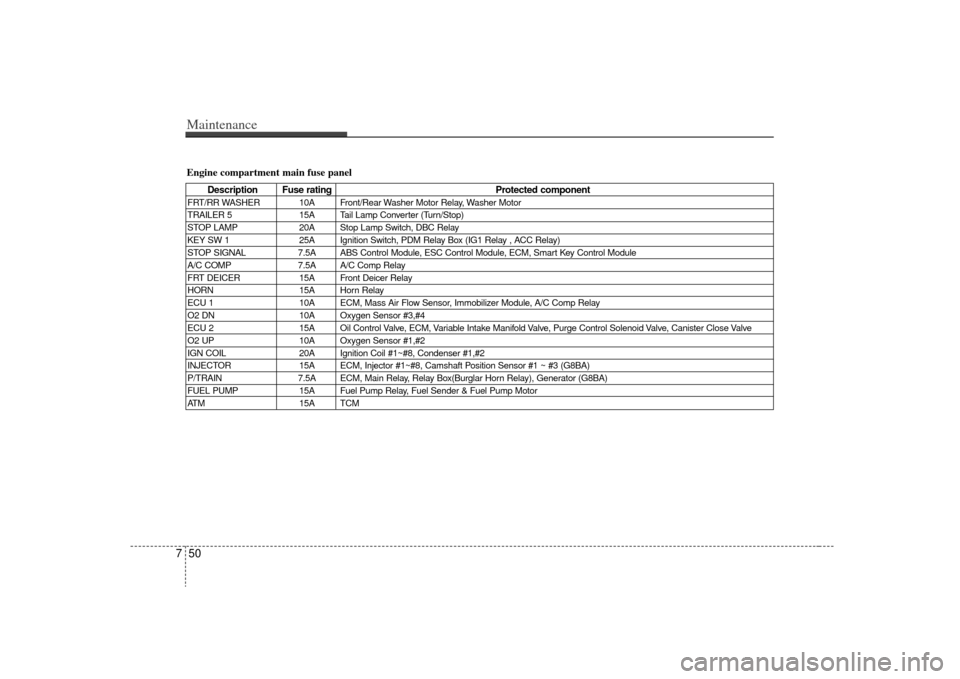

7Engine compartment main fuse panel

Description Fuse rating Protected component

FRT/RR WASHER 10A Front/Rear Washer Motor Relay, Washer Motor

TRAILER 5 15A Tail Lamp Converter (Turn/Stop)

STOP LAMP 20A Stop Lamp Switch, DBC Relay

KEY SW 1 25A Ignition Switch, PDM Relay Box (IG1 Relay , ACC Relay)

STOP SIGNAL 7.5A ABS Control Module, ESC Control Module, ECM, Smart Key Control Module

A/C COMP 7.5A A/C Comp Relay

FRT DEICER 15A Front Deicer Relay

HORN 15A Horn Relay

ECU 1 10A ECM, Mass Air Flow Sensor, Immobilizer Module, A/C Comp Relay

O2 DN 10A Oxygen Sensor #3,#4

ECU 2 15A Oil Control Valve, ECM, Variable Intake Manifold Valve, Purge Control Solenoid Valve, Canister Close Valve

O2 UP 10A Oxygen Sensor #1,#2

IGN COIL 20A Ignition Coil #1~#8, Condenser #1,#2

INJECTOR 15A ECM, Injector #1~#8, Camshaft Position Sensor #1 ~ #3 (G8BA)

P/TRAIN 7.5A ECM, Main Relay, Relay Box(Burglar Horn Relay), Generator (G8BA)

FUEL PUMP 15A Fuel Pump Relay, Fuel Sender & Fuel Pump Motor

ATM 15A TCM

Page 404 of 425

751

Maintenance

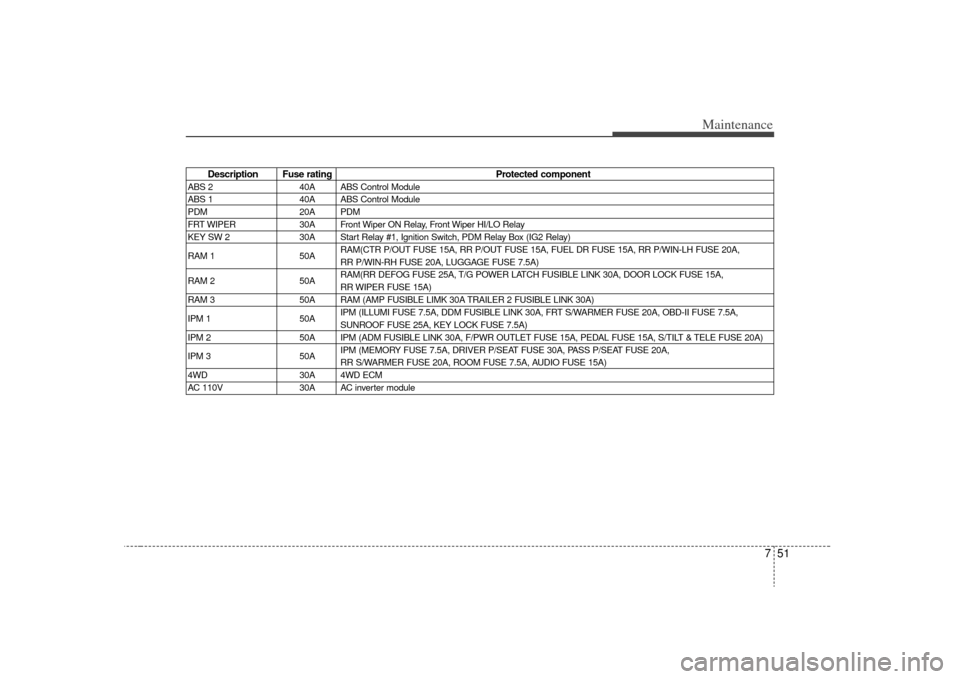

Description Fuse ratingProtected component

ABS 240A ABS Control Module

ABS 1 40A ABS Control Module

PDM 20A PDM

FRT WIPER 30A Front Wiper ON Relay, Front Wiper HI/LO Relay

KEY SW 2 30A Start Relay #1, Ignition Switch, PDM Relay Box (IG2 Relay)

RAM 1 50ARAM(CTR P/OUT FUSE 15A, RR P/OUT FUSE 15A, FUEL DR FUSE 15A, RR P/WIN-L\

H FUSE 20A,

RR P/WIN-RH FUSE 20A, LUGGAGE FUSE 7.5A)

RAM 2 50ARAM(RR DEFOG FUSE 25A, T/G POWER LATCH FUSIBLE LINK 30A, DOOR LOCK FUSE 15A,

RR WIPER FUSE 15A)

RAM 3 50A RAM (AMP FUSIBLE LIMK 30A TRAILER 2 FUSIBLE LINK 30A)

IPM 1 50AIPM (ILLUMI FUSE 7.5A, DDM FUSIBLE LINK 30A, FRT S/WARMER FUSE 20A, OBD-II FUSE 7.5A,

SUNROOF FUSE 25A, KEY LOCK FUSE 7.5A)

IPM 2 50A IPM (ADM FUSIBLE LINK 30A, F/PWR OUTLET FUSE 15A, PEDAL FUSE 15A, S/TILT & TELE FUSE 20A)

IPM 3 50AIPM (MEMORY FUSE 7.5A, DRIVER P/SEAT FUSE 30A, PASS P/SEAT FUSE 20A,

RR S/WARMER FUSE 20A, ROOM FUSE 7.5A, AUDIO FUSE 15A)

4WD 30A 4WD ECM

AC 110V 30A AC inverter module

Page 405 of 425

Maintenance52

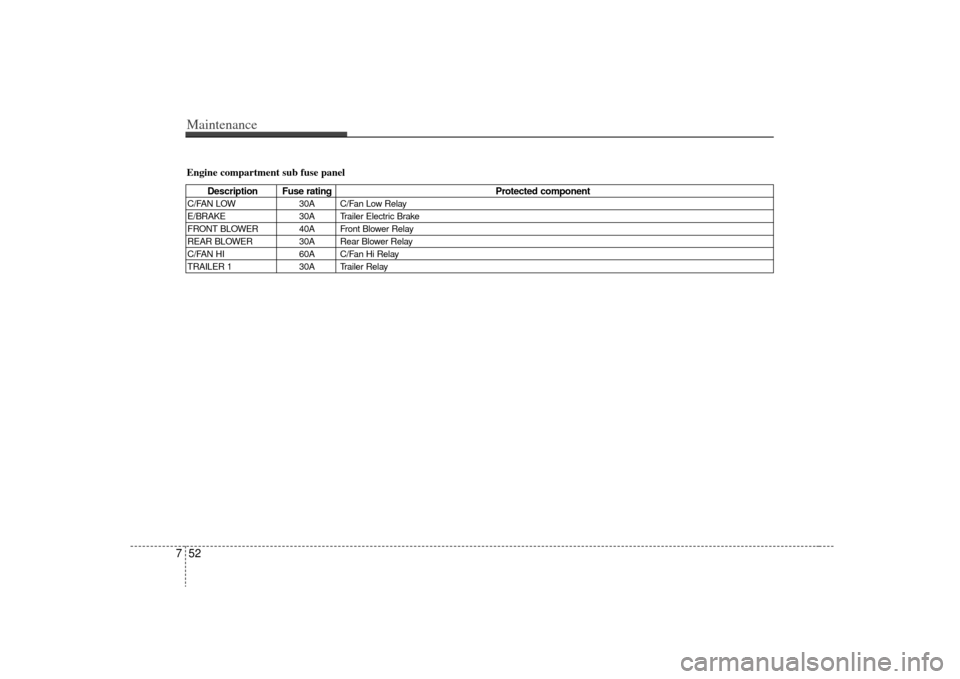

7Engine compartment sub fuse panel

Description Fuse rating Protected component

C/FAN LOW30A C/Fan Low Relay

E/BRAKE 30A Trailer Electric Brake

FRONT BLOWER 40A Front Blower Relay

REAR BLOWER 30A Rear Blower Relay

C/FAN HI 60A C/Fan Hi Relay

TRAILER 1 30A Trailer Relay

Page 406 of 425

753

Maintenance

APPEARANCE CAREExterior careG230101AUNExterior general caution It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning and

caution statements that appear on the

label.

G230102BUNFinish maintenanceWashing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are kept

clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

CAUTION

Do not use strong soap, chemicaldetergents or hot water, and do notwash the vehicle in direct sunlightor when the body of the vehicle is warm.

WARNING -

Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 407 of 425

Maintenance54

7

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.

G230103AUNFinish damage repair Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.✽ ✽

NOTICEIf your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced. G230104AUNBright-metal maintenance To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

CAUTION

Water washing in the engine com- partment including high pressurewater washing may cause the fail-ure of electrical circuits located in the engine compartment.

Never allow water or other liquids to come in contact with electri-cal/electronic components insidethe vehicle as this may damagethem.

CAUTION

Wiping dust or dirt off the body with a dry cloth will scratch thefinish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining highly alkaline or caustic agents on chrome-platedor anodized aluminum parts. This may result in damage to the pro-tective coating and cause discol-oration or paint deterioration.

OJB037800

Page 408 of 425

755

Maintenance

G230105ASAUnderbody maintenanceCorrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of the doors, rocker panels,

and frame members have drain holes

that should not be allowed to clog with

dirt; trapped water in these areas can

cause rusting.

G230106AHMAluminum wheel maintenance The aluminum wheels are coated with a

clear protective finish.

Do not use any abrasive cleaner, pol-ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Use only mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any cleaners containing acid or acid detergents. It may damage

and corrode the aluminum wheels

coated with a clear protective finish.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 409 of 425

Maintenance56

7G230107AHMCorrosion protectionProtecting your vehicle from corrosion

By using the most advanced design and

construction practices to combat corro-

sion, we produce vehicles of the highest

quality. However, this is only part of the

job. To achieve the long-term corrosion

resistance your vehicle can deliver, the

owner's cooperation and assistance is

also required.

Common causes of corrosion

The most common causes of corrosion

on your vehicle are:

allowed to accumulate underneath the

vehicle.

Removal of paint or protective coatings by stones, gravel, abrasion or minor

scrapes and dents which leave unpro-

tected metal exposed to corrosion. High-corrosion areas

If you live in an area where your vehicle

is regularly exposed to corrosive materi-

als, corrosion protection is particularly

important. Some of the common causes

of accelerated corrosion are road salts,

dust control chemicals, ocean air and

industrial pollution.

Moisture breeds corrosion

Moisture creates the conditions in which

corrosion is most likely to occur. For

example, corrosion is accelerated by

high humidity, particularly when tempera-

tures are just above freezing. In such

conditions, the corrosive material is kept

in contact with the vehicle’s surface by

moisture that evaporate slowly.

Mud is particularly corrosive because it

dries slowly and holds moisture in con-

tact with the vehicle. Although the mud

appears to be dry, it can still retain the

moisture and promote corrosion.

High temperatures can also accelerate

corrosion of parts that are not properly

ventilated so the moisture can be dis-

persed. For all these reasons, it is par-

ticularly important to keep your vehicle

clean and free of mud or accumulations

of other materials. This applies not only

to the visible surfaces but particularly to

the underside of the vehicle.

Page 410 of 425

757

Maintenance

To help prevent corrosion

You can help prevent corrosion from get-

ting started by observing the following:

Keep your vehicle clean

The best way to prevent corrosion is to

keep your vehicle clean and free of cor-

rosive materials. Attention to the under-

side of the vehicle is particularly impor-

tant.

If you live in a high-corrosion area —where road salts are used, near the

ocean, areas with industrial pollution,

acid rain, etc.—, you should take extra

care to prevent corrosion. In winter,

hose off the underside of your vehicle

at least once a month and be sure to

clean the underside thoroughly when

winter is over. When cleaning underneath the vehicle,

give particular attention to the compo-

nents under the fenders and other

areas that are hidden from view. Do a

thorough job; just dampening the accu-

mulated mud rather than washing it

away will accelerate corrosion rather

than prevent it. Water under high pres-

sure and steam are particularly effec-

tive in removing accumulated mud and

corrosive materials.

rocker panels and frame members, be

sure that drain holes are kept open so

that moisture can escape and not be

trapped inside to accelerate corrosion.

Keep your garage dry

Don't park your vehicle in a damp, poorly

ventilated garage. This creates a favor-

able environment for corrosion. This is

particularly true if you wash your vehicle

in the garage or drive it into the garage

when it is still wet or covered with snow,

ice or mud. Even a heated garage can

contribute to corrosion unless it is well

ventilated so moisture is dispersed. Keep paint and trim in good condition

Scratches or chips in the finish should be

covered with "touch-up" paint as soon as

possible to reduce the possibility of cor-

rosion. If bare metal is showing through,

the attention of a qualified body and paint

shop is recommended.

Bird droppings : Bird droppings are high-

ly corrosive and may damage painted

surfaces in just a few hours. Always

remove bird droppings as soon as possi-

ble.

Don't neglect the interior

Moisture can collect under the floor mats

and carpeting and cause corrosion.

Check under the mats periodically to be

sure the carpeting is dry. Use particular

care if you carry fertilizers, cleaning

materials or chemicals in the vehicle.

These should be carried only in proper

containers and any spills or leaks should

be cleaned up, flushed with clean water

and thoroughly dried.