wheel KIA CARNIVAL 2007 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 292 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Crankshaft Position Sensor (CKPS) detects the crankshaft position and is one of the most important sensors of the

engine control system. If there is no CKPS signal input, fuel is not supplied and the main relay does not operate. That

is, vehicle can't run without CKPS signal. This sensor is installed on transaxle housing and generates alternating

current by magnetic flux field which is made by the sensor and the target wheel when engine runs. The target wheel

consists of 58 slots and 2 missing slots on 360 CA (Crank Angle).

WAVEFORM

CIRCUIT DIAGRAM

Page 295 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Camshaft Position Sensor (CMPS) is a hall sensor and detects the camshaft position by using a hall element. It is

related with Crankshaft Position Sensor (CKPS) and detects the piston position of each cylinder which the CKPS can't

detect. The two CMPS are installed on engine head cover of bank 1 and 2 and uses a target wheel installed on the

camshaft. This sensor has a hall - effect IC which output voltage changes when magnetic field is made on the IC with

current flow.

Page 367 of 1575

6c.

Driving at constant

speed of 30 km/h in 2nd

gear

d. Driving at 50 km/h in 3rd

gear with accelerator

fully closed

e. Driving at constant

speed of 50 km/h in 4th

gear (1) 100%, (2) 0%, (3)

100%

Second solenoid valve

(2) 100%, (3) 100%,

(4) 0% Overdrive solenoid valve

(1) 0km/h

(4) 50km/h Vehicle speed sensor

(4) 1,800 ~ 2,100rpm Input shaft speed sensor

(4) 1,800 ~ 2,100rpm Output shaft speed sensor

7 Selector lever position

: D (Carry out on a

flat and straight road)

a.

Accelerate to 4th gear at

a throttle position sensor

output of 1.5V

(accelerator opening

angle of 30 %).

b. Gently decelerate to a

standstill.

c. Accelerate to 4th gear at

a throttle position sensor

output of 2.5 V

(accelerator opening

angle of 50%).

d. While driving at 60 km/h

in 4th gear, shift down

to 3rd gear.

e. While driving at 40 km/h

in 3rd gear, shift down

to 2nd gear.

f. While driving at 20 km/h

in 2nd gear, shift down

to 1st gear. For (1), (2) and (3),

the reading should be

the same as the

specified output shaft

torque, and no

abnormal shocks

should occur.

For (4), (5) and (6),

downshifting should

occur immediately

after the shifting

operation is made.

Malfunction when shifting

Displaced shift points

Does not shift

Does not shift from 1 to 2 or

2 to 1

Does not shift from 2 to 3 or

3 to 2

Does not shift from 3 to 4 or

4 to 3

8 Selector lever position

: N (Carry out on a

flat and straight road)

Move selector lever to R

range drive at constant

speed of 10km/h The ratio between

input and output shaft

speed sensor data

should be the same

as the gear ratio

when reversing.Does not shift

TORQUE CONVERTER STALL TEST

This test measures the maximum engine speed when the selector lever is in the D or R position. The torque converter

stalls to test the operation of the torque converter, starter motor, one- way clutch operation, the holding performance of

the clutches, and brakes in the transaxle.

Do not let anybody stand in front of or behind the vehicle while this test is being carried out

1. Check the automatic transmission fluid level and temperature, and the engine coolant temperature.

a. Fluid level : At the HOT mark on the oil level gauge

b. Fluid temperature : 80~100°C (176~212°F)

c. Engine coolant temperature : 80~100°C(176~212°F)

2. Prevent all the wheels from moving during the test.

3. Pull the parking brake lever up, with the brake pedal fully depressed.

4. Start the engine.

Page 368 of 1575

5.Move the selector lever to the "D" position, fully depress the accelerator pedal and take a reading of the maximum

engine speed at this time.

Stall speed : 2,100~2,900rpm

a.The throttle should not be left fully open for any more than five seconds.

b. If carrying out the stall test two or more times, move the selector lever to the "N" position and run the

engine at 1,000 r/min to let the automatic transaxle fluid cool down before carrying out subsequent tests.

6. Move the selector lever to the "R" position and carry out the same test again.

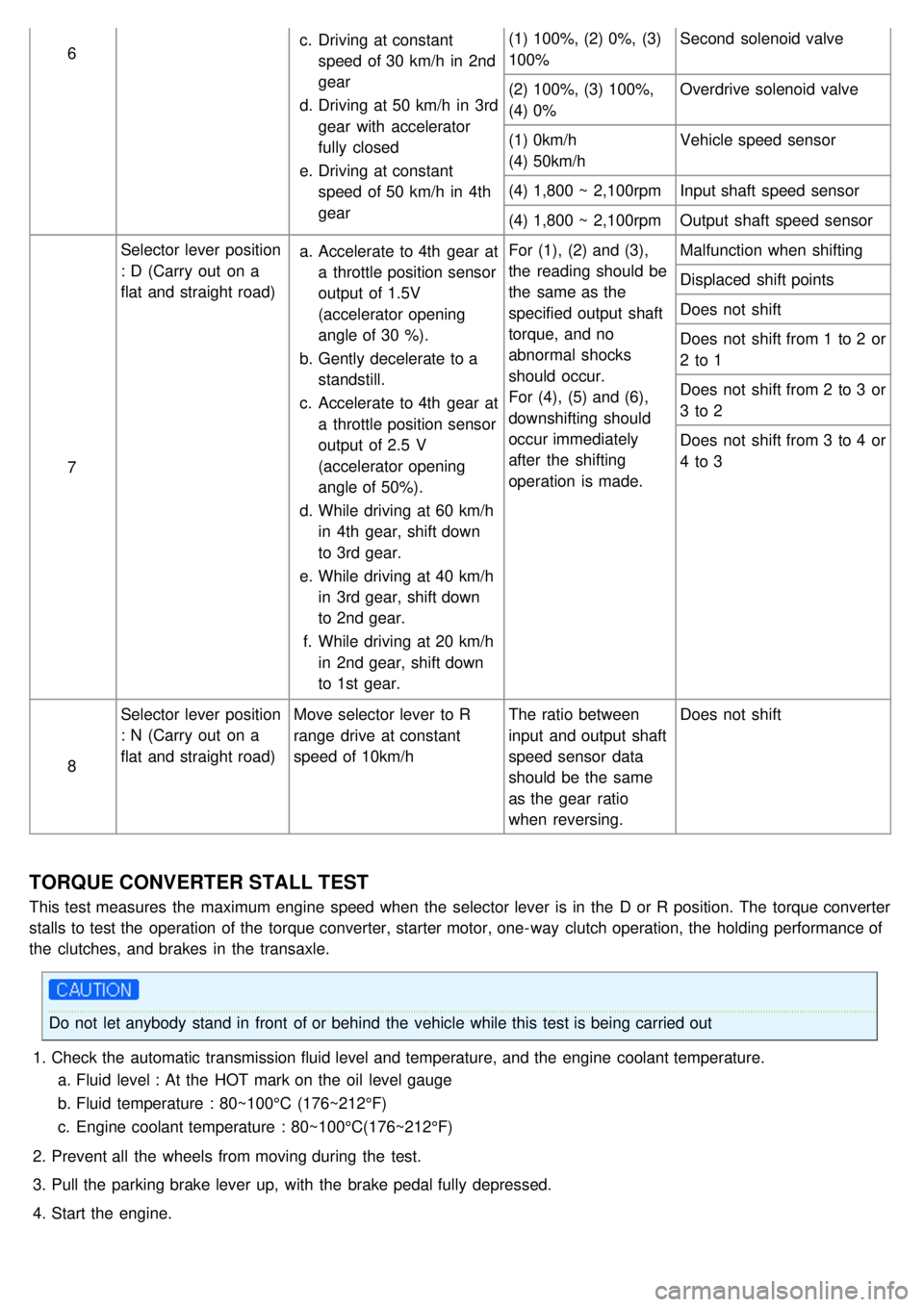

TORQUE CONVERTER STALL TEST CONCLUSION

1.Stall speed is too high in both "D" and "R" ranges

a. Low line pressure

b. Low & reverse brake(B) slippage

2. Stall speed is to high in "D" range only

a. Underdrive clutch(C) slippage

3. Stall speed is too high in "R" range only

a. Reverse clutch(A) slippage

4. Stall speed too low in both "D" and "R" ranges

a. Malfunction of torque converter(D)

b. Insufficient engine output

HYDRAULIC PRESSURE TEST

1.Warm up the engine until the automatic transaxle fluid temperature is 80- 100°C.

2. Lift up the vehicle so that the wheels are free to turn.

3. Connect the special tool (oil pressure gauge) to each pressure discharge port.

4. Measure the hydraulic pressure at each port under the conditions given in the standard hydraulic pressure table,

and check that the measured values are within the standard value ranges.

5. If a value is outside the standard range, correct the problem while referring to the hydraulic pressure test diagnosis

table.

Page 383 of 1575

13.Remove the starter motor by disconnecting the connector. (see EE group)

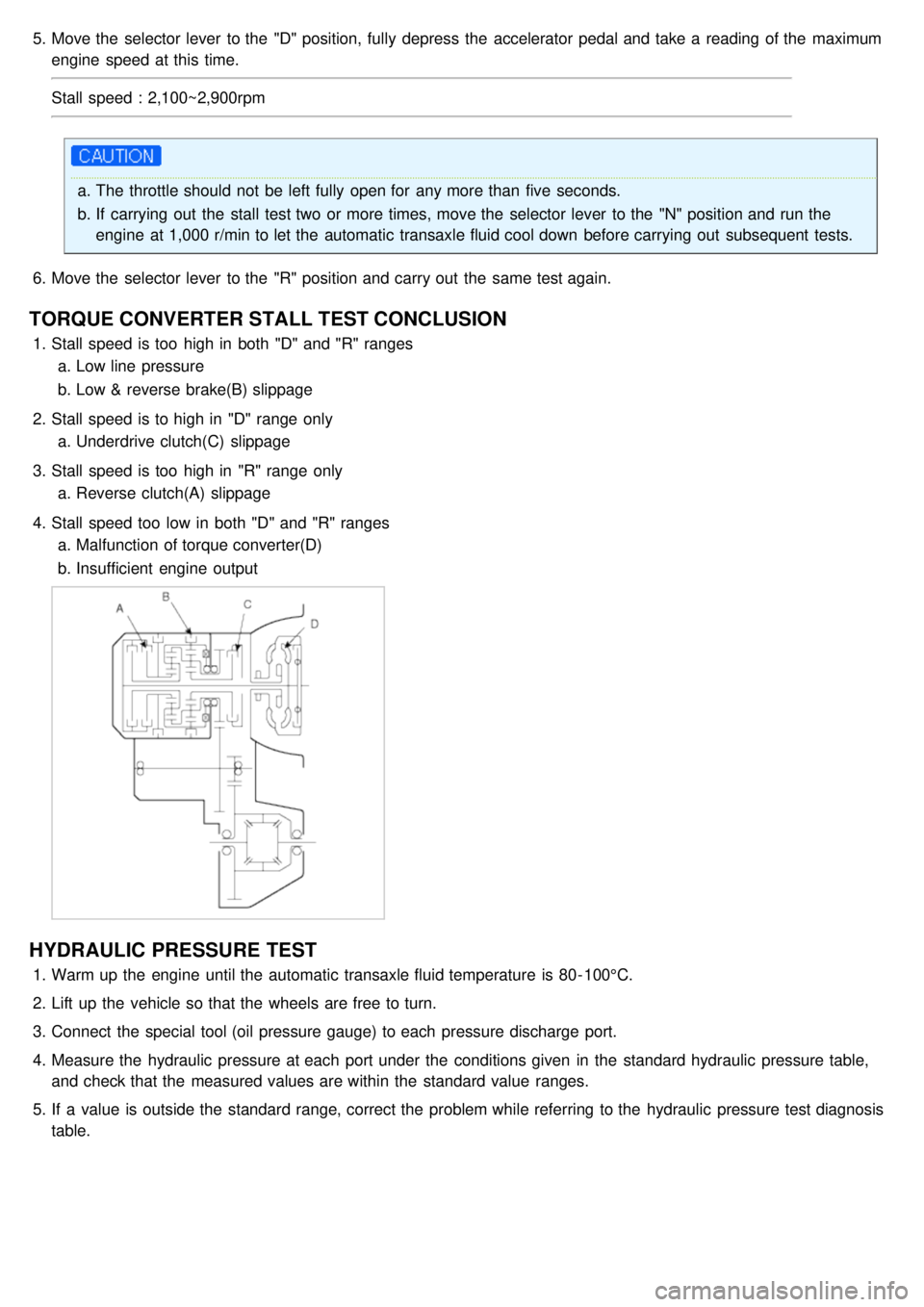

14. Using the SST(09200- 38001), hold the engine and transaxle assembly safely.

15.Remove the transaxle insulator mounting (B) bolts (A).

16.Remove the front wheels. (see SS group)

17. Lift up the vehicle.

18. Remove the power steering column joint bolt and the VRS connector (A). (see ST group)

Page 386 of 1575

8.Install the under cover (A).

9.Install the steering column joint bolt and the VRS connector (A). (see ST group)

10. Connect the return tube(A) with a clamp. (see ST group)

11.Install the front wheels and tires.

12. Tighten the transaxle insulator mounting (B) bolt (A).

TORQUE:

90~110 Nm(9~11 kgf.m, 65.1~79.5 lb - ft)

Page 429 of 1575

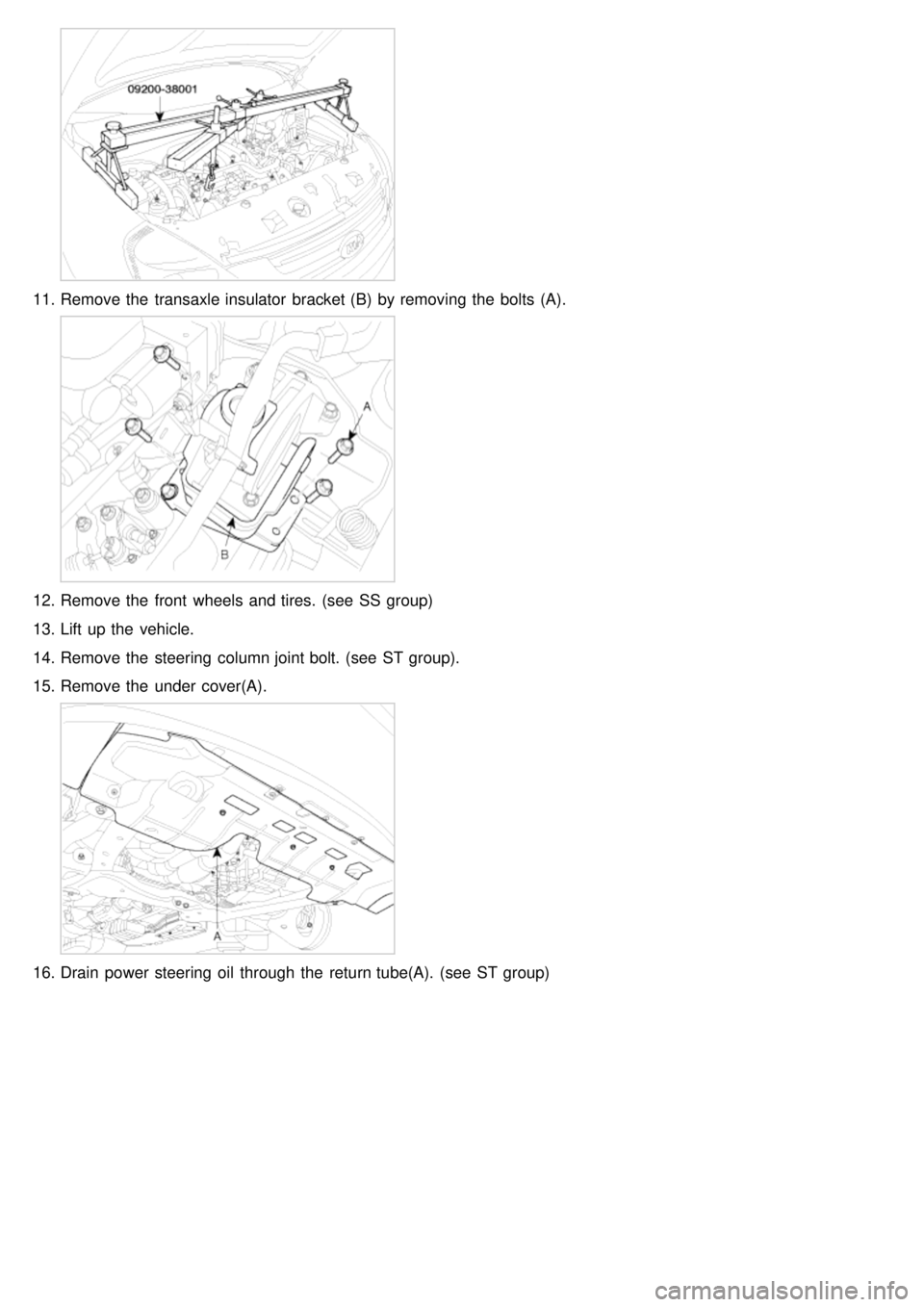

11.Remove the transaxle insulator bracket (B) by removing the bolts (A).

12.Remove the front wheels and tires. (see SS group)

13. Lift up the vehicle.

14. Remove the steering column joint bolt. (see ST group).

15. Remove the under cover(A).

16.Drain power steering oil through the return tube(A). (see ST group)

Page 438 of 1575

19.Install the under cover(A).

20.Install the steering column joint bolt.(See ST group).

21. Install the front wheels and tires. (see SS group)

22. Install the transaxle insulator and mounting bracket (B) by tightening the bolts (A).

TORQUE:

60~80 Nm (6~8 kgf.m, 43.6~58.2 lb - ft)

23.remove the SST (09200- 38001) holding the engine and transaxle assembly.

TORQUE:

65~85 Nm (6.5~8.5kgf.m, 47.0~61.5 lb - ft)

Page 444 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIAL TOOLS

Tool(Number and name) IllustrationUse

Tie rod end puller

09568 - 4A000

Separation of a lower arm and a tie

rod end ball joint

Front hub remover and installer

09517 - 21500

Removal of a front hub from a

knuckle.

(use with 09517 - 21600)

Main shaft bearing puller

09432 - 11000

Removla of a tone wheel from a

driveshaft

09495 - 3K000

Band installer

Installation of ear type boot band

09495 - 39100

Band installer

Installation of hook type boot band

Page 445 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

Symptom Possible cause Remedy

Vehicle pulls to one side Scoring of driveshaft ball joint

Wear, rattle or scoring of wheel bearing

Defective front suspension and steering Replace

Replace

Adjust or replace

Vibration Wear, damage or bending of driveshaft

Driveshaft rattle and worn hub splines

Wear, rattle or scratching of wheel bearing Replace

Replace

Replace

Shimmy Improper wheel balance

Bent wheel

Defective front suspension and steering Adjust or replace

Replace

Adjust or replace

Excessive noise Wear, damage or bending of driveshaft

Driveshaft rattle and worn hub splines

Driveshaft rattle and worn side gear splines

Wear, rattle or galling of wheel bearing

Loose hub nut

Defective front suspension and steering Replace

Replace

Replace

Replace

Adjust or replace

Adjust or replace

Bent cage Cage damaged by improper handling or tool usage Replace bearing

Galling Metal smears on roller end due to overheating,

incorrect lubricant or overloading Replace bearing

Check seals, check for

proper lubrication

Cracked inner race Race cracked due to improper fit, cocking or poor bearing

seats Replace bearing

Etching Bearing surfaces appear gray or grayish black

in color accompanied by material etched

away usually at roller spacing Replace bearing

Check seals, check for

proper lubrication

Brinelling Surface indentations on race surface caused by rollers

being under impact loading or vibration while the bearing

is not rotating Replace bearing

Heat discoloration Heat discoloration is dark blue resulting

from overload or no lubricant (Yellow or brown color is

normal) Replace bearing

Check seals and other parts

Fatigue spalling Flaking of surface metal resulting from fatigue Replace bearing

Clean all related parts