wheel KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 452 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

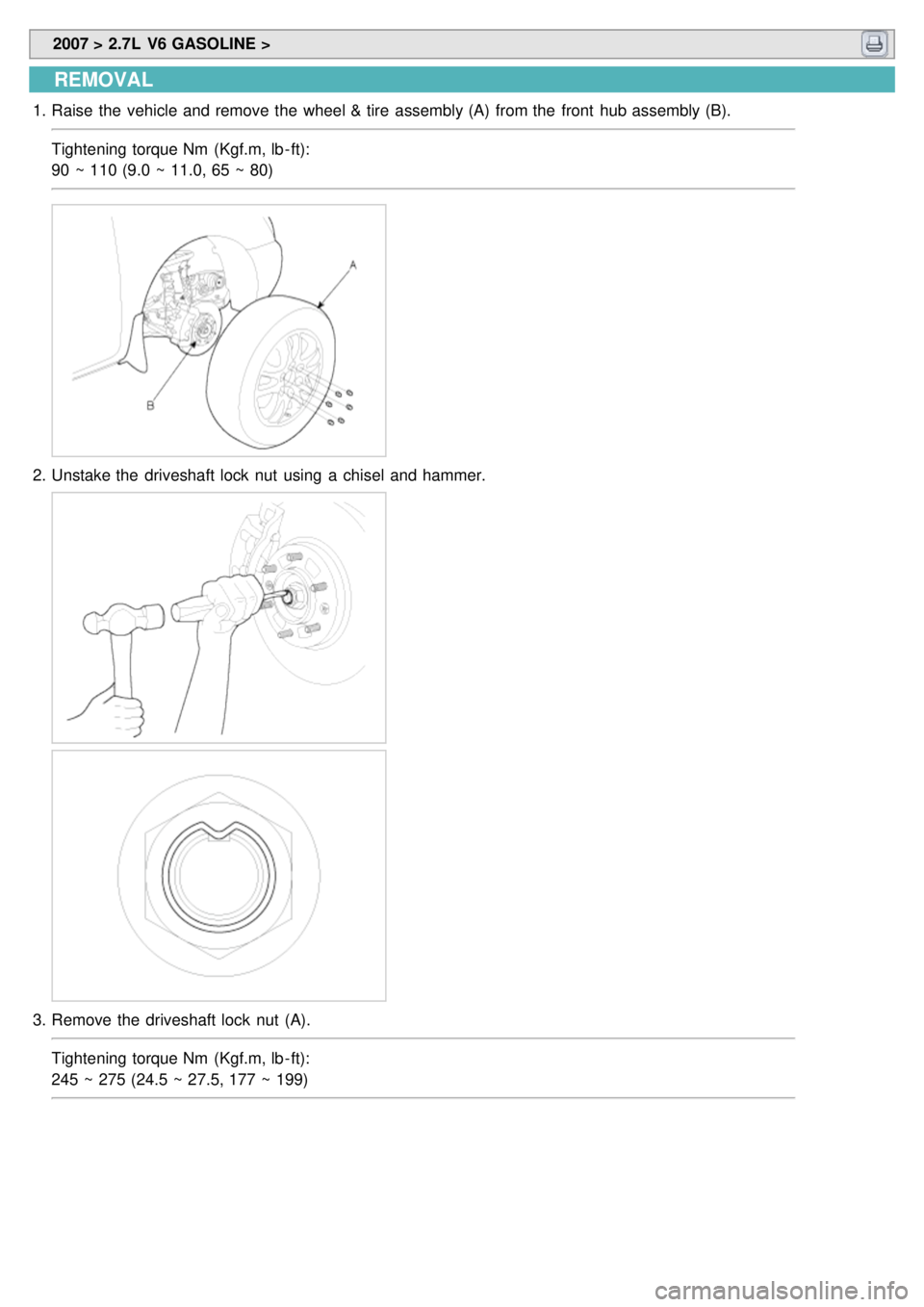

1.Raise the vehicle and remove the wheel & tire assembly (A) from the front hub assembly (B).

Tightening torque Nm (Kgf.m, lb - ft):

90 ~ 110 (9.0 ~ 11.0, 65 ~ 80)

2.Unstake the driveshaft lock nut using a chisel and hammer.

3.Remove the driveshaft lock nut (A).

Tightening torque Nm (Kgf.m, lb - ft):

245 ~ 275 (24.5 ~ 27.5, 177 ~ 199)

Page 462 of 1575

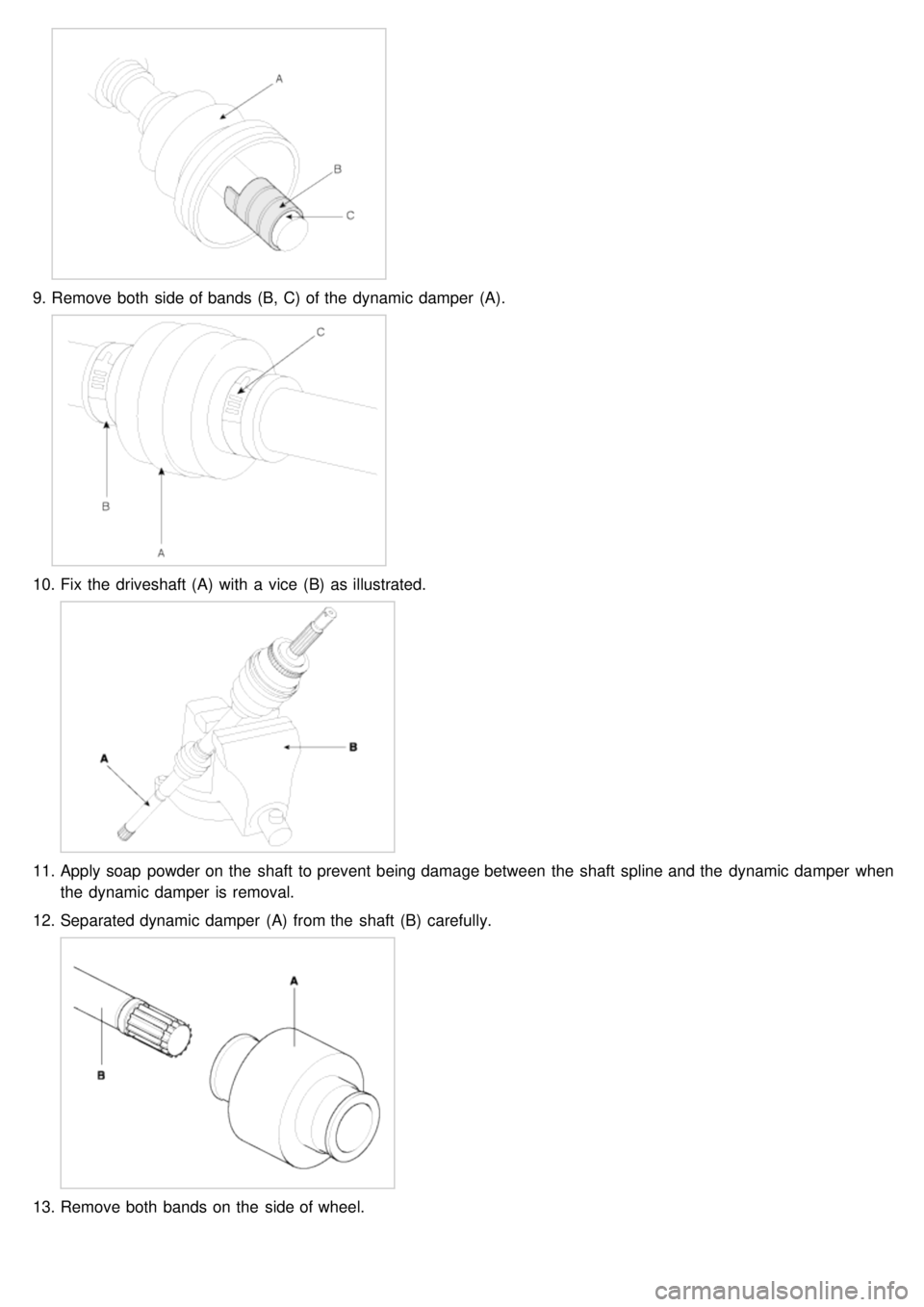

9.Remove both side of bands (B, C) of the dynamic damper (A).

10. Fix the driveshaft (A) with a vice (B) as illustrated.

11.Apply soap powder on the shaft to prevent being damage between the shaft spline and the dynamic damper when

the dynamic damper is removal.

12. Separated dynamic damper (A) from the shaft (B) carefully.

13.Remove both bands on the side of wheel.

Page 463 of 1575

14.Pull out the joint(BJ) boot on the side of wheel into the transaxle direction.

Be careful not to damage the boot.

REASSEMBLY

1.Wrap tape around the drive shaft splines (UTJ side) to prevent damage to the boots.

2. Apply grease to the joint(BJ) boot on the side of wheel and install the boots.

3. Install the bands to both boots.

4.Using clamp, secure the boot bands.

Clearance (A) : 2.0 mm (0.079 in.) or less

5.To install the dynamic damper, keep the BJ shaft in a straight line and secure the dynamic damper with the

dynamic damper bands.

6. Install the UTJ boot bands and UTJ boot.

7. Using the alignment marks (D) made during disassembly as a guide, install the spider assembly (A) and snap ring

(B) on the driveshaft splines (C).

Page 469 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Raise the vehicle and remove the wheel & tire assembly (A) from the front hub assembly (B).

Tightening torque Nm (Kgf.m, lb - ft):

90 ~ 110 (9.0 ~ 11.0, 65 ~ 80)

2.Remove the wheel speed sensor & wire (A) by loosening the bolts.

3.Disconnect the brake hose (A) from the strut assembly.

4.Unstake the driveshaft lock nut using a chisel and hammer.

Page 474 of 1575

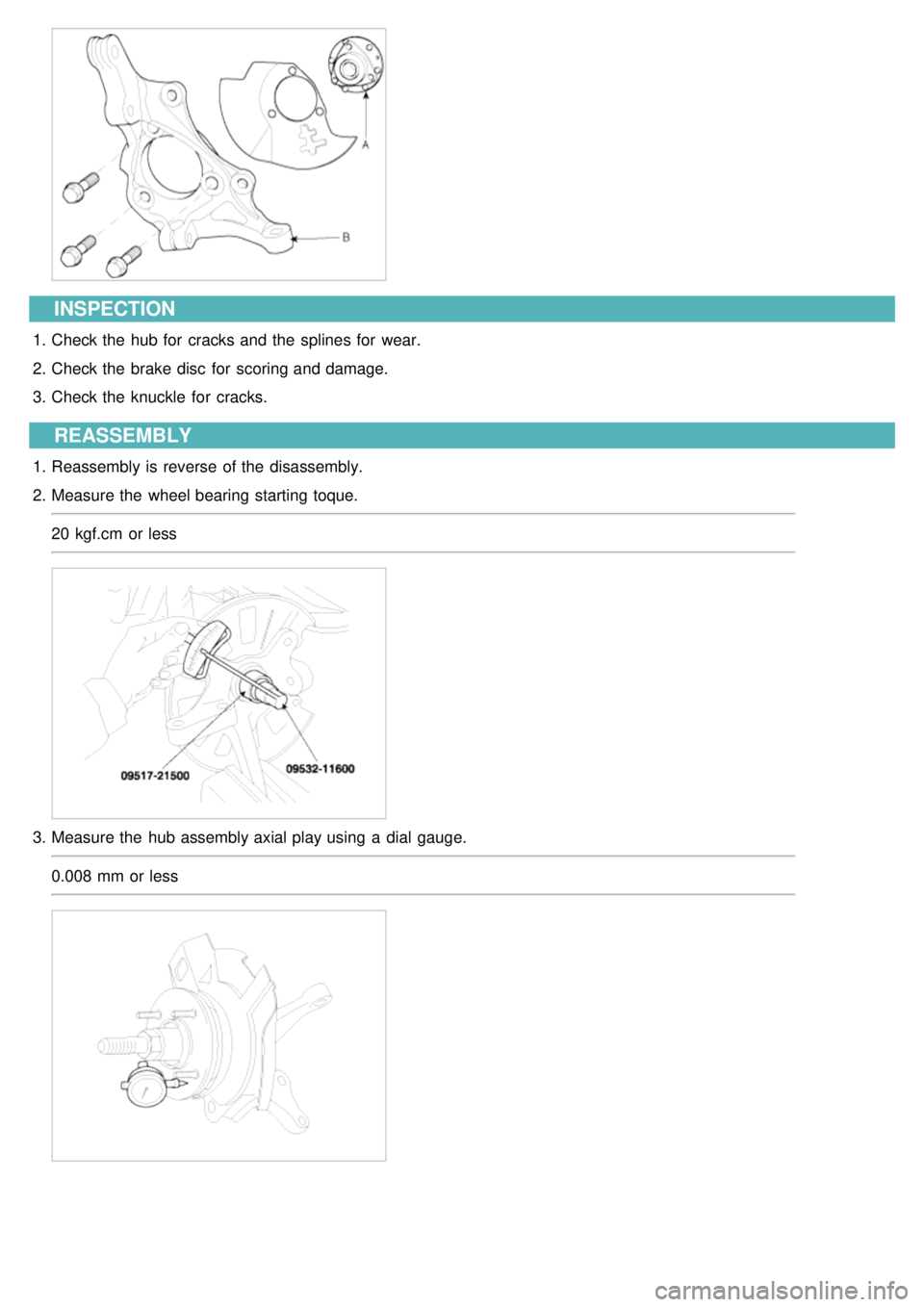

INSPECTION

1.Check the hub for cracks and the splines for wear.

2. Check the brake disc for scoring and damage.

3. Check the knuckle for cracks.

REASSEMBLY

1.Reassembly is reverse of the disassembly.

2. Measure the wheel bearing starting toque.

20 kgf.cm or less

3.Measure the hub assembly axial play using a dial gauge.

0.008 mm or less

Page 477 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Release the parking brake.

2. Remove the wheel & tire assembly.

Tightening torque Nm (kgf.m, lb - ft):

90 ~ 110 (9.0 ~ 11.0, 65 ~ 80)

3.Support lower part of the lower arm (A) using a jack and remove the bolt & nut (B).

Tightening torque Nm (kgf.m, lb - ft):

160 ~ 180 (16.0 ~ 18.0, 116 ~ 130)

4.Remove the coil spring (A) and upper pad.

5.Remove the wheel speed sensor (A).

Page 488 of 1575

accelerating around a cornerSee DS group - driveshaft.

Front suspension noise - A squeak,

creak, or rattle noise - occurs mostly

over bumps or rough roads Steering components

Loose or bent front struts or shock

absorbers

Damaged spring or spring mounts

Damaged or worn arm bushings

Worn or damaged stabilizer bar

bushing or linksGo to detailed test A.

Groaning or grinding - noise from the

front strut, occurs when driving on

bumpy roads or turning the vehicle Uneven seating surface between the

insulator and panel by the burrs

around the strut insulator mounting

bolts and the insulator boltes

mounting holesRepair or install a new parts as

necessary.

Rear suspension noise - a squeak,

creak or rattle noise - occurs mostly

over bumps or rough roads Loose or bent rear shock absorbers

Damaged spring or spring mounts

Damaged or worn control arm

bushingsGo to detailed test B.

Shudder - occurs during acceleration

from a slow speed or stop Rear axle assembly mis - positioned

Damaged or worn front suspension

componentsCheck the axle mounts and rear

suspension for damage or wear.

Repair as necessary.

Check for a loose stabilizer bar,

damaged or loose strut/strut bushings

or loose or worn ball joints. Inspect

the steering linkage for wear or

damage. Repair or Install new

components as necessary.

Shimmy - most noticeable on

coast/deceleration - also hard steering

condition Excessive positive caster

Check the caster alignment angle.

Correct as necessary.

Tire noise - hum/moan at constant

speeds Abnormal wear patterns

Spin the tire and Check for tire wear.

Install a new tire as necessary.

Inspect for damaged/worn suspension

components. Perform wheel

alignment.

Tire noise - noise tone lowers as the

vehicle speed is lowered Out- of- balance tire

Balance the tire and road test. Install

a new tire as necessary.

Tire noise - ticking noise, change with

speed Nail puncture or stone in tire tread

Inspect the tire. Repair or replace as

necessary.

Wheel and tire - vibration and noise

concern is directly related to vehicle

speed and is not affected by

acceleration, coasting or decelerating Damaged or worn tire

Go to detailed test C.

Tire wobble or shudder - occurs at

lower speeds Damaged wheel bearings

Spin the tire and check for abnormal

wheel bearing play or roughness.

Adjust or Install new wheel bearings

as necessary.

See DS group - front/rear axle.

Damaged wheel Inspect the wheel for damage. Install

a new wheel as necessary.

Damaged or worn suspension

components Inspect the suspension components

for wear or damage. Repair as

necessary.

Page 489 of 1575

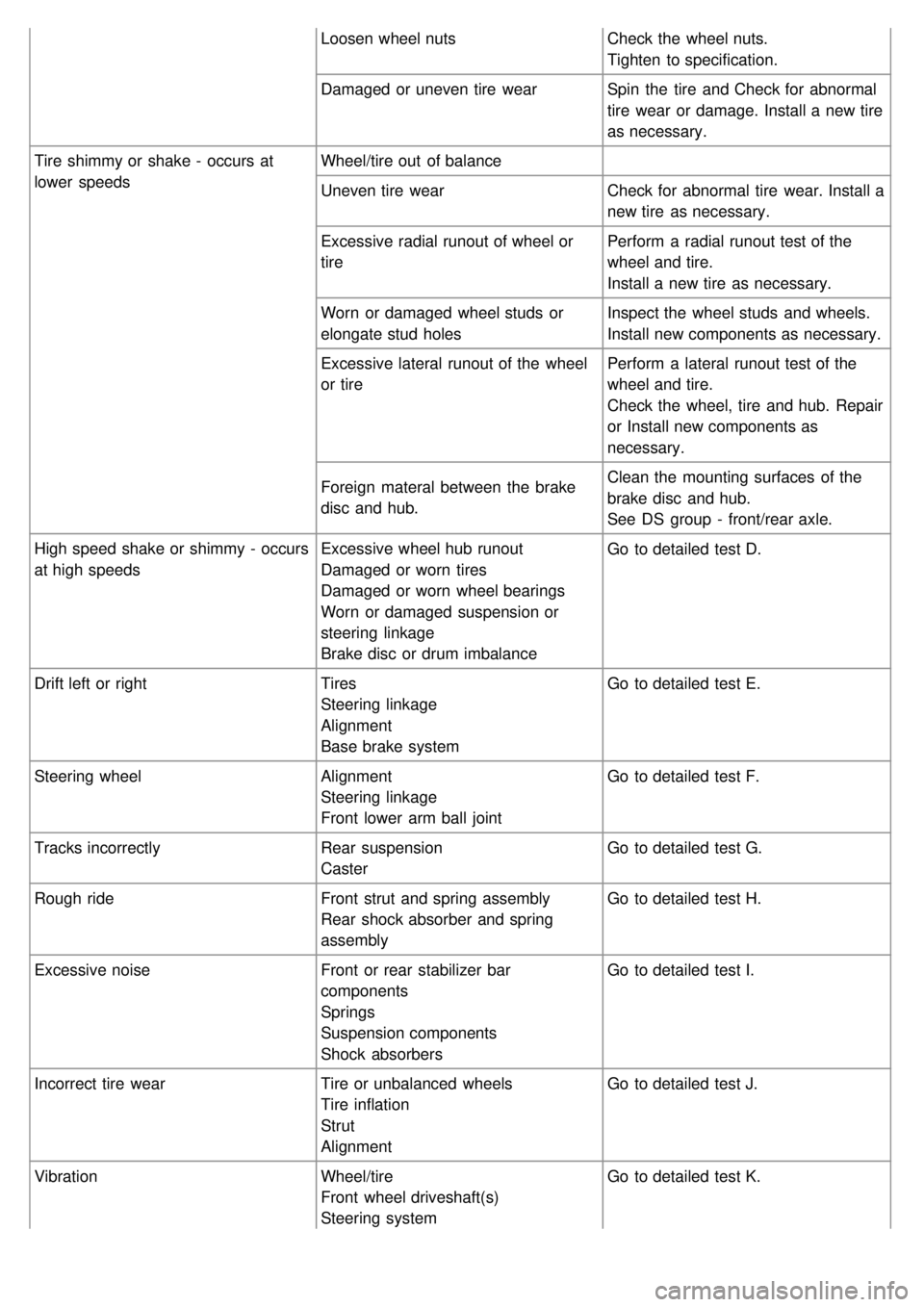

Loosen wheel nutsCheck the wheel nuts.

Tighten to specification.

Damaged or uneven tire wear Spin the tire and Check for abnormal

tire wear or damage. Install a new tire

as necessary.

Tire shimmy or shake - occurs at

lower speeds Wheel/tire out of balance

Uneven tire wear

Check for abnormal tire wear. Install a

new tire as necessary.

Excessive radial runout of wheel or

tire Perform a radial runout test of the

wheel and tire.

Install a new tire as necessary.

Worn or damaged wheel studs or

elongate stud holes Inspect the wheel studs and wheels.

Install new components as necessary.

Excessive lateral runout of the wheel

or tire Perform a lateral runout test of the

wheel and tire.

Check the wheel, tire and hub. Repair

or Install new components as

necessary.

Foreign materal between the brake

disc and hub. Clean the mounting surfaces of the

brake disc and hub.

See DS group - front/rear axle.

High speed shake or shimmy - occurs

at high speeds Excessive wheel hub runout

Damaged or worn tires

Damaged or worn wheel bearings

Worn or damaged suspension or

steering linkage

Brake disc or drum imbalanceGo to detailed test D.

Drift left or right Tires

Steering linkage

Alignment

Base brake systemGo to detailed test E.

Steering wheel Alignment

Steering linkage

Front lower arm ball jointGo to detailed test F.

Tracks incorrectly Rear suspension

CasterGo to detailed test G.

Rough ride Front strut and spring assembly

Rear shock absorber and spring

assemblyGo to detailed test H.

Excessive noise Front or rear stabilizer bar

components

Springs

Suspension components

Shock absorbersGo to detailed test I.

Incorrect tire wear Tire or unbalanced wheels

Tire inflation

Strut

AlignmentGo to detailed test J.

Vibration Wheel/tire

Front wheel driveshaft(s)

Steering system

Strut and spring assemblyGo to detailed test K.

Page 490 of 1575

Strut and spring assembly

Spring and strut mounting

Front lower arm ball joint

Front lower arm mounting bolt

bushing

Stabilizer bar bushings

Wheel hubs and bearing

Rear suspension arms and bushings

Vehicle leans Tire/wheel

Vehicle load

Suspension components

Incorrect ride heightInflate tires to specification.

Redistribute the load as necessary.

Visually inspect the suspention

system.

Correct the ride height as necessary.

Poor steering returnability High knuckle rotating torque

AlignmentGo to detailed test E.

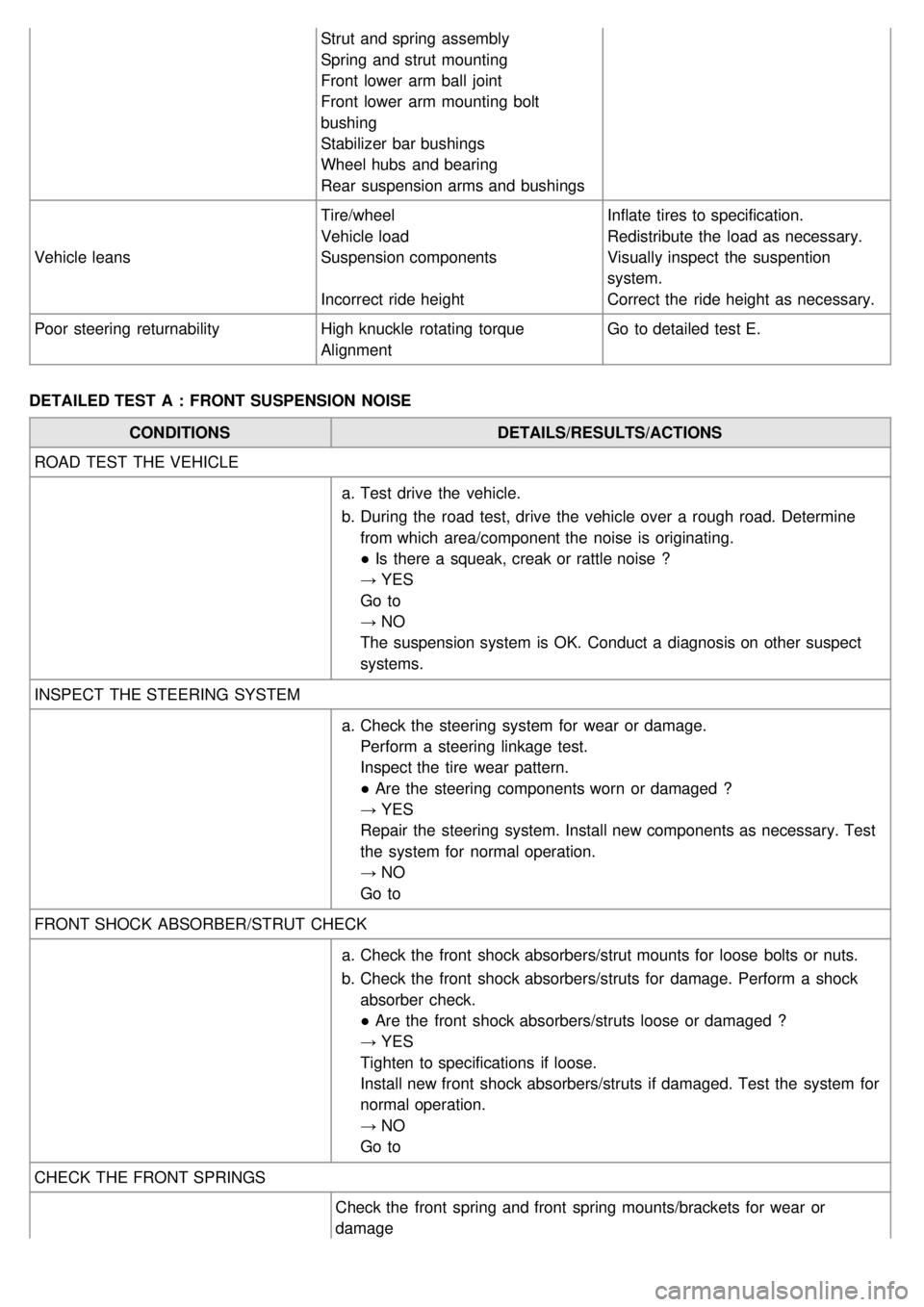

DETAILED TEST A : FRONT SUSPENSION NOISE CONDITIONS DETAILS/RESULTS/ACTIONS

ROAD TEST THE VEHICLE

a.Test drive the vehicle.

b. During the road test, drive the vehicle over a rough road. Determine

from which area/component the noise is originating.

● Is there a squeak, creak or rattle noise ?

→ YES

Go to

→ NO

The suspension system is OK. Conduct a diagnosis on other suspect

systems.

INSPECT THE STEERING SYSTEM a.Check the steering system for wear or damage.

Perform a steering linkage test.

Inspect the tire wear pattern.

● Are the steering components worn or damaged ?

→ YES

Repair the steering system. Install new components as necessary. Test

the system for normal operation.

→ NO

Go to

FRONT SHOCK ABSORBER/STRUT CHECK a.Check the front shock absorbers/strut mounts for loose bolts or nuts.

b. Check the front shock absorbers/struts for damage. Perform a shock

absorber check.

● Are the front shock absorbers/struts loose or damaged ?

→ YES

Tighten to specifications if loose.

Install new front shock absorbers/struts if damaged. Test the system for

normal operation.

→ NO

Go to

CHECK THE FRONT SPRINGS Check the front spring and front spring mounts/brackets for wear or

damage

Page 492 of 1575

operation.

→ NO

Go toB4.

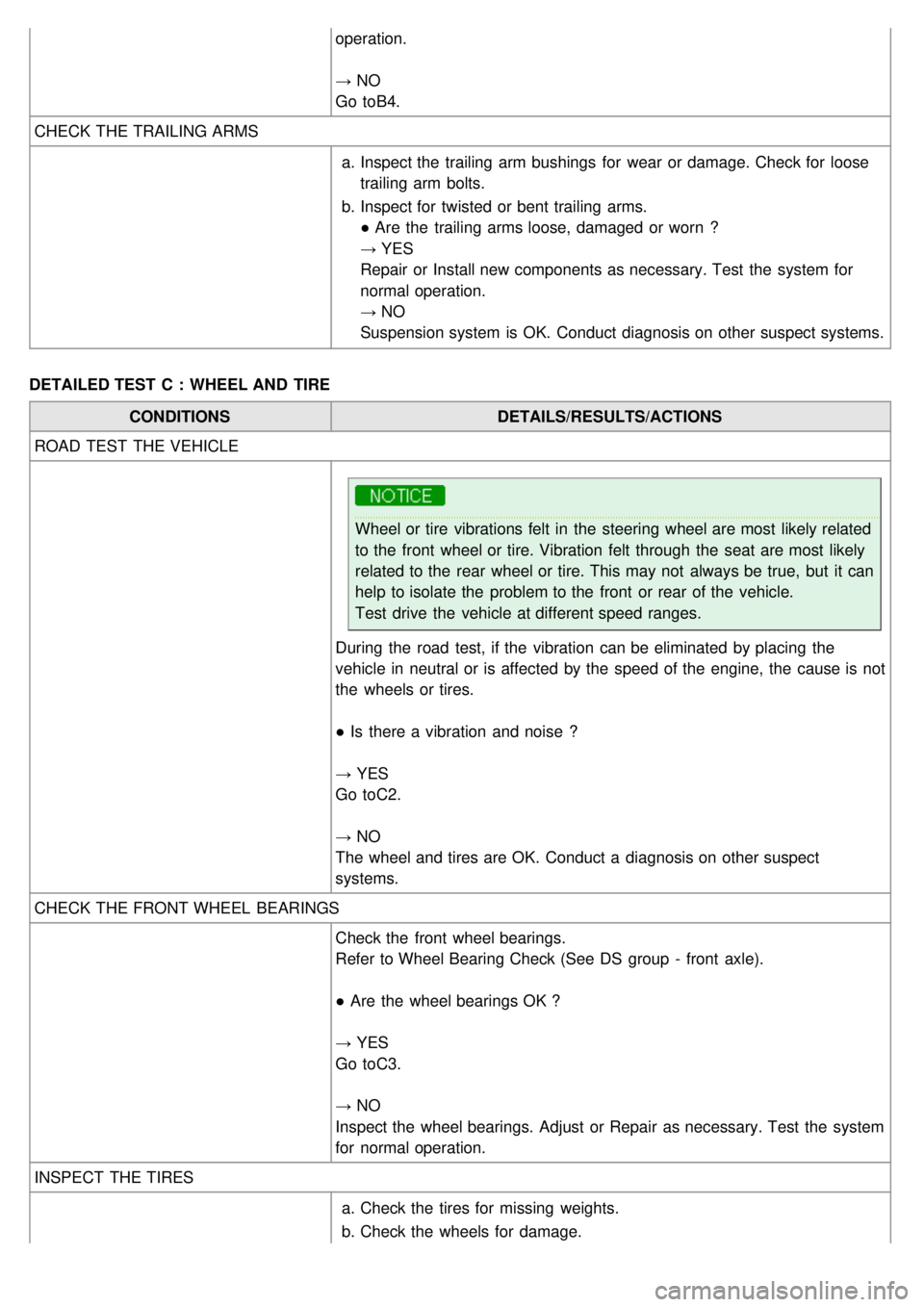

CHECK THE TRAILING ARMS

a.Inspect the trailing arm bushings for wear or damage. Check for loose

trailing arm bolts.

b. Inspect for twisted or bent trailing arms.

● Are the trailing arms loose, damaged or worn ?

→ YES

Repair or Install new components as necessary. Test the system for

normal operation.

→ NO

Suspension system is OK. Conduct diagnosis on other suspect systems.

DETAILED TEST C : WHEEL AND TIRE CONDITIONS DETAILS/RESULTS/ACTIONS

ROAD TEST THE VEHICLE

Wheel or tire vibrations felt in the steering wheel are most likely related

to the front wheel or tire. Vibration felt through the seat are most likely

related to the rear wheel or tire. This may not always be true, but it can

help to isolate the problem to the front or rear of the vehicle.

Test drive the vehicle at different speed ranges.

During the road test, if the vibration can be eliminated by placing the

vehicle in neutral or is affected by the speed of the engine, the cause is not

the wheels or tires.

● Is there a vibration and noise ?

→ YES

Go to C2.

→ NO

The wheel and tires are OK. Conduct a diagnosis on other suspect

systems.

CHECK THE FRONT WHEEL BEARINGS Check the front wheel bearings.

Refer to Wheel Bearing Check (See DS group - front axle).

● Are the wheel bearings OK ?

→ YES

Go to C3.

→ NO

Inspect the wheel bearings. Adjust or Repair as necessary. Test the system

for normal operation.

INSPECT THE TIRES

a.Check the tires for missing weights.

b. Check the wheels for damage.