service KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 654 of 1575

2007 > 2.7L V6 GASOLINE >

REFRIGERANT SYSTEM SERVICE BASICS

REFRIGERANT RECOVERY

Use only service equipment that is U.L - listed and is certified to meet the requirements of SAE J2210 to remove HFC-

134a(R- 134a) from the air conditioning system.

a. Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

b. Be careful when connecting service equipment.

c. Do not breathe refrigerant or vapor.

If accidental system discharge occurs, ventilate work area before resuming service.

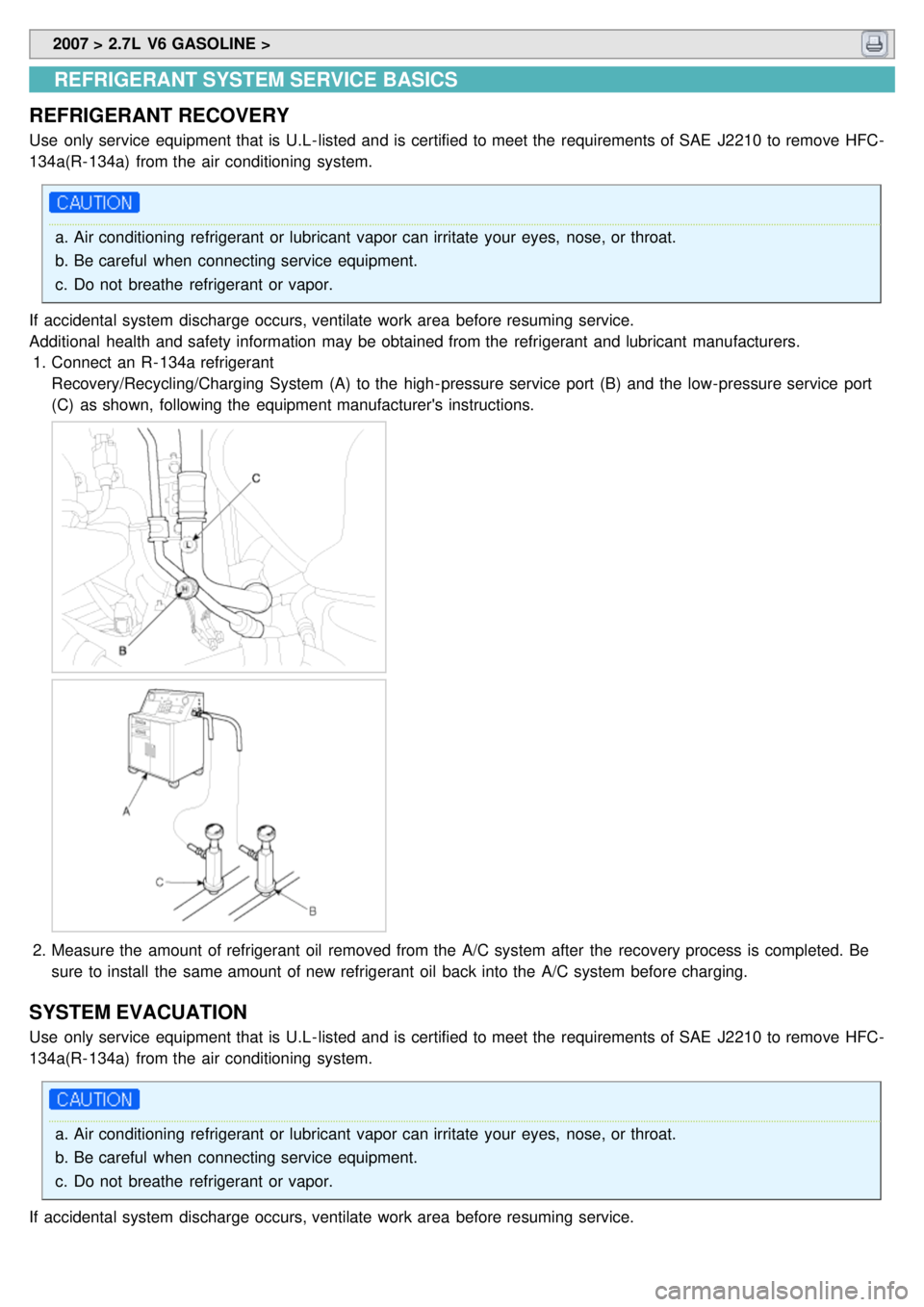

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers. 1. Connect an R- 134a refrigerant

Recovery/Recycling/Charging System (A) to the high- pressure service port (B) and the low- pressure service port

(C) as shown, following the equipment manufacturer's instructions.

2.Measure the amount of refrigerant oil removed from the A/C system after the recovery process is completed. Be

sure to install the same amount of new refrigerant oil back into the A/C system before charging.

SYSTEM EVACUATION

Use only service equipment that is U.L - listed and is certified to meet the requirements of SAE J2210 to remove HFC-

134a(R- 134a) from the air conditioning system.

a.Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

b. Be careful when connecting service equipment.

c. Do not breathe refrigerant or vapor.

If accidental system discharge occurs, ventilate work area before resuming service.

Page 655 of 1575

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.1. When an A/C System has been opened to the atmosphere, such as during installation or repair, it must be

evacuated using an R- 134a refrigerant Recovery/Recycling/Charging System. (If the system has been open for

several days, the receiver/dryer should be replaced, and the system should be evacuated for several hours.)

2. Connect an R- 134a refrigerant Recovery/Recycling/Charging System (A) to the high- pressure service port (B) and

the low- pressure service port (C) as shown, following the equipment manufacturer's instructions.

3.If the low- pressure does not reach more than 93.3 kPa (700 mmHg, 27.6 in.Hg) in 10 minutes, there is probably a

leak in the system. Partially charge the system, and check for leaks (see Leak Test.).

4. Remove the low pressure valve from the low- pressure service port.

SYSTEM CHARGING

Use only service equipment that is U.L - listed and is certified to meet the requirements of SAE J2210 to remove HFC-

134a(R- 134a) from the air conditioning system.

a.Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

b. Be careful when connecting service equipment.

c. Do not breathe refrigerant or vapor.

If accidental system discharge occurs, ventilate work area before resuming service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers. 1. Connect an R- 134a refrigerant Recovery/Recycling/Charging System (A) to the high- pressure service port (B) as

shown, following the equipment manufacturer's instructions.

2.Add the same amount of new refrigerant oil to system that was removed during recovery. Use only specified

refrigerant oil. Charge the system with 28.21 ± 0.88 oz. (800 ± 25g) of R- 134a refrigerant. Do not overcharge the

system the compressor will be damaged.

REFRIGERANT LEAK TEST

Always conduct a leak test with an electronic leak detector whenever leakage or refrigerant is suspected and when

conducting service operations which are accompanied by disassembly or loosening or connection fittings.

Page 728 of 1575

2007 > 2.7L V6 GASOLINE >

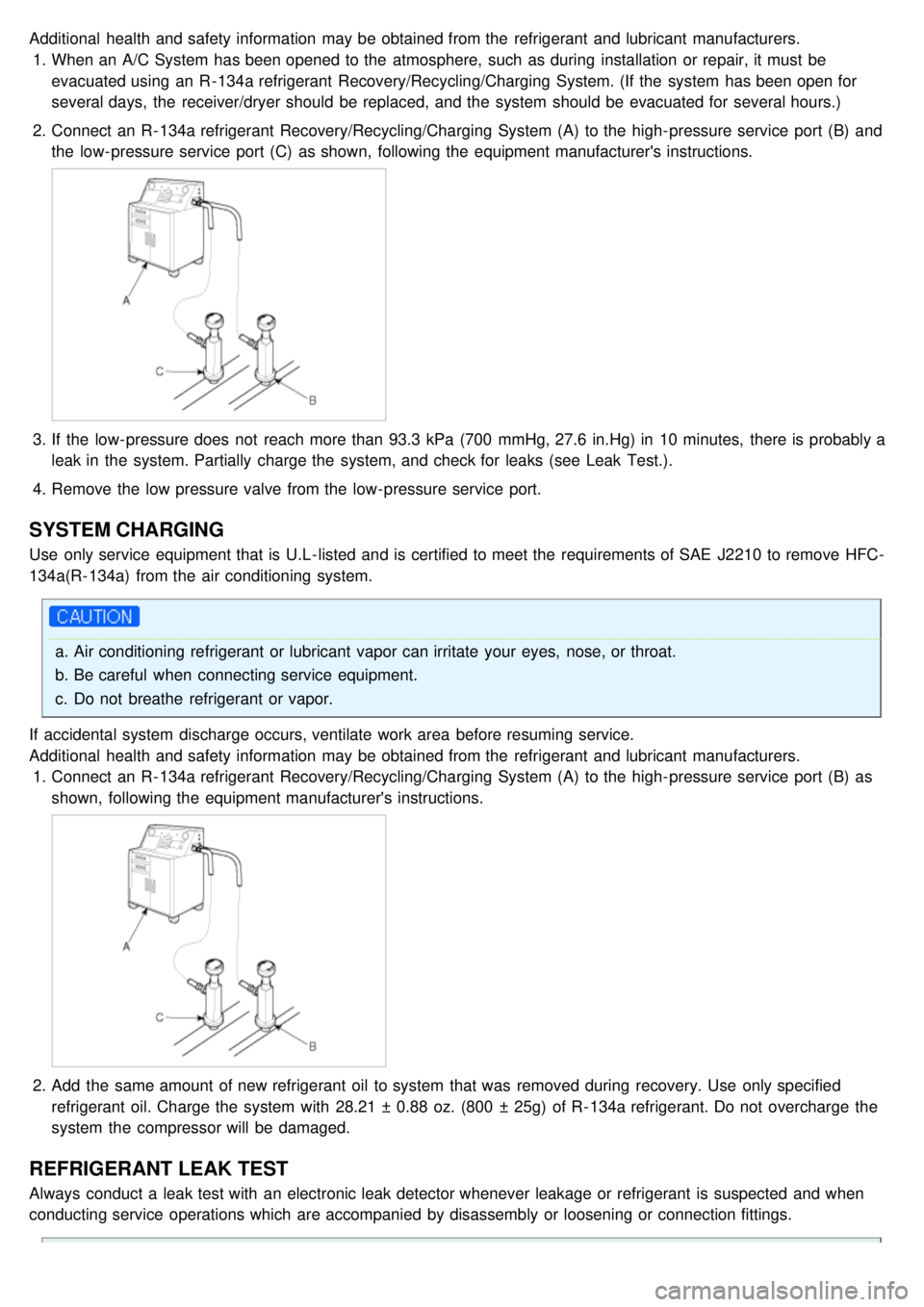

DESCRIPTION

The fuel fired heater has been applied to the diesel engine (CRDi) to increase heating capability by using diesel only in

cold weather

a.Follow the procedures specified in this bulletin during service or it may cause personal injury.

b. Be sure to turn the fuel fired heater off when refueling at station.

c. The fuel fired heater must be mounted at designated position, never in the passenger compartment.

d. The fuel fired heater must be kept below 120°C or a permanent failure on the components may occur.

e. Operational principle : The following 3 conditions should be met at the same time for automatic operation of

the fuel fired heater.

a. Engine runs.

b. Ambient temperature is lower than 2°C (Winter)

c. Coolant temperature is lower than 68°C

f. Cleaning process

a. A cleaning process of the fuel fired heater will be performed automatically when the heater is not operated

due to increase of coolant temperature and ignition off.

b. During cleaning process, supplied fuel in the heater will be burnt completely and any smoke will be expelled.

It is a necessary process for next operation and durability of the heater and takes about 3 minutes.

g. Others

The following symptoms should be explained to customers or technicians as a normal occurrence.

a. A white smoke may come out from the fuel fired heater exhaust pipe installed at the front side of the right

front tire during operation of the heater.

This is not an exhaust fumes.

When moisture in the fuel and air is discharged from the heater and is met cold ambient air, it is condensed

and looks like a white smoke however, when an excessive black smoke is discharged, the fuel fired heater

should be inspected.

b. A "buk- buk" noise from the heater is a noise to form flame for combustion. This is a normal operation.

c. When the heater is operated at full load, a "Wooing" noise is occurred.

d. When shutting off the engine during heater operation, a "Wing" noise is occurred to perform the cleaning

process.

OVERVIEW

1.This fuel fired heater supplies additional heat to the interior compartment with a low fuel consumption to

compensate the heat provided by engine alone.

2. The fuel fired heater has been adopted to warm up the interior compartment in a short time.

Page 791 of 1575

2007 > 2.7L V6 GASOLINE >

Precautions

General Precautions

Please read the following precautions carefully before performing the airbag system service. Observe the instructions

described in this manual, or the airbags could accidentally deploy and cause damage or injuries. a. Except when performing electrical inspections, always turn the ignition switch OFF and disconnect the negative

cable from the battery, and wait at least three minutes before beginning work.

The contents in the memory are not erased even if the ignition switch is turned OFF or the battery cables are

disconnected from the battery.

b. Use the replacement parts which are manufactured to the same standards as the original parts and quality.

Do not install used SRS parts from another vehicle.

Use only new parts when making SRS repairs.

c. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being dropped or improperly handled, such as dents, cracks or

deformation.

d.Before removing any of the SRS parts (including the disconnection of the connectors), always disconnect the SRS

connector.

Airbag Handling and Storage

Do not disassemble the airbags; it has no serviceable parts. Once an airbag has been deployed, it cannot be repaired

or reused.

For temporary storage of the air bag during service, please observe the following precautions.

a. Store the removed airbag with the pad surface up.

b. Keep free from any oil, grease, detergent, or water to prevent damage to the airbag assembly.

Page 793 of 1575

b.Be sure to install the harness wires so that they are not pinched, or interfere with other parts.

c.Make sure all SRS ground locations are clean, and grounds are securely fastened for optimum metal- to- metal

contact. Poor grounding can cause intermittent problems that are difficult to diagnose.

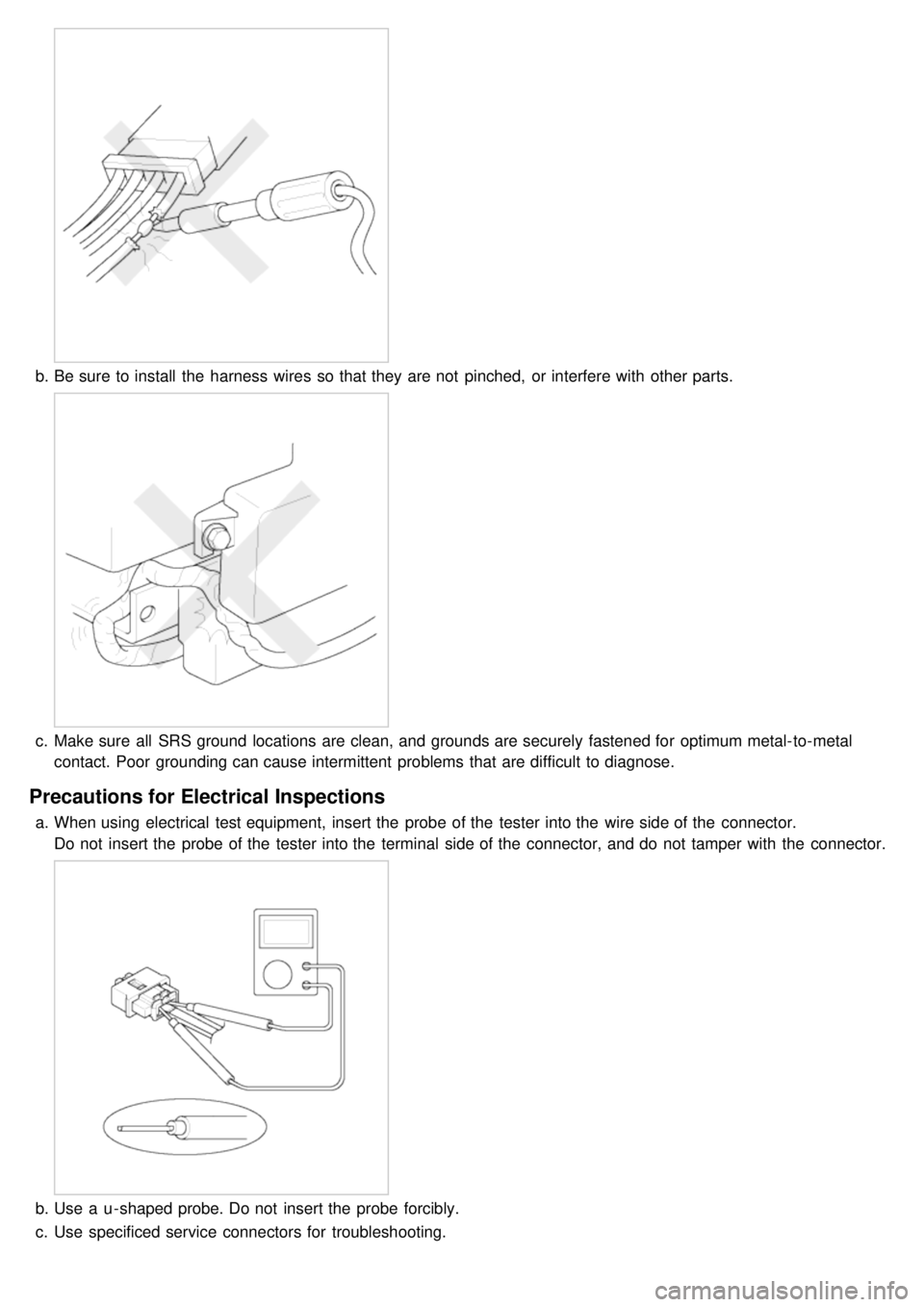

Precautions for Electrical Inspections

a.When using electrical test equipment, insert the probe of the tester into the wire side of the connector.

Do not insert the probe of the tester into the terminal side of the connector, and do not tamper with the connector.

b.Use a u - shaped probe. Do not insert the probe forcibly.

c. Use specificed service connectors for troubleshooting.

Page 796 of 1575

2007 > 2.7L V6 GASOLINE >

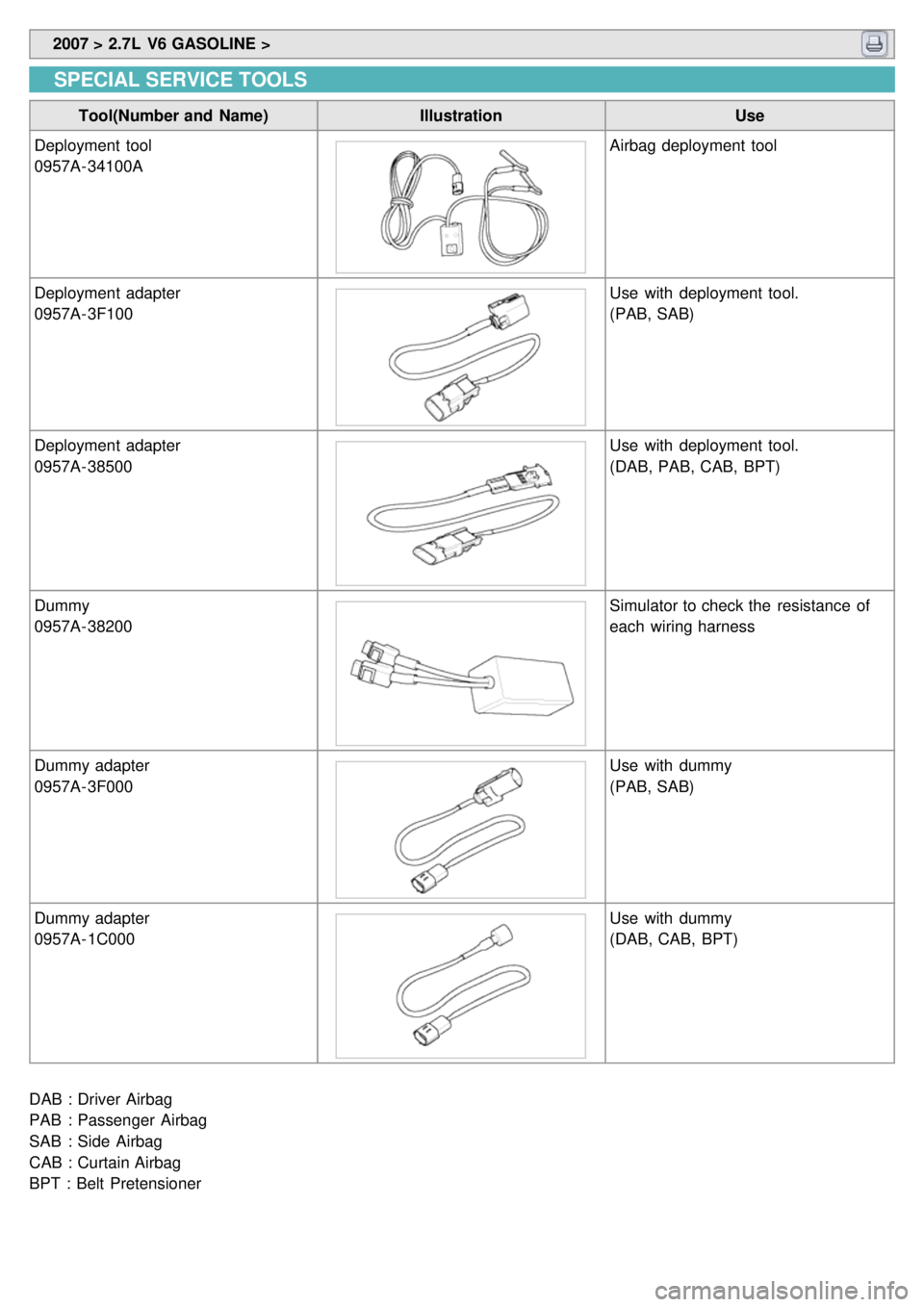

SPECIAL SERVICE TOOLS

Tool(Number and Name) IllustrationUse

Deployment tool

0957A- 34100A

Airbag deployment tool

Deployment adapter

0957A- 3F100

Use with deployment tool.

(PAB, SAB)

Deployment adapter

0957A- 38500

Use with deployment tool.

(DAB, PAB, CAB, BPT)

Dummy

0957A- 38200

Simulator to check the resistance of

each wiring harness

Dummy adapter

0957A- 3F000

Use with dummy

(PAB, SAB)

Dummy adapter

0957A- 1C000

Use with dummy

(DAB, CAB, BPT)

DAB : Driver Airbag

PAB : Passenger Airbag

SAB : Side Airbag

CAB : Curtain Airbag

BPT : Belt Pretensioner

Page 831 of 1575

DEPLOYING THE AIRBAG OUT OF THE VEHICLE

If an intact airbag has been removed from a scrapped vehicle, or has been found defective or damage during transit,

storage or service, it should be deployed as follows :1. Position the airbag face up, outdoors on flat ground at least thirty feet (10meters) from any obstacles or people.

DISPOSAL OF DAMAGED AIRBAG

1.If installed in a vehicle, follow the removal procedure of driver's airbag front passenger's and side airbag.

2. In all cases, make a short circuit by twisting together the two airbag inflator wires.

3. Package the airbag in exactly the same packing that the new replacement part come in.

Page 865 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIFICATIONS

Item Specification

Master cylinder

· Type

· I.D. mm(in)

· Piston stroke mm(in)

· Fluid level warning sensor Tandem type

26.99/(1.063)

30(1.18)

Provided

Brake booster

· Type

· Boosting ratio 8 + 9 in Tandem

9.0 : 1

Front brake(Disc)

· Type

· Disc O.D.

· Disc thickness

· Pad thickness

· Cylinder type

· Cylinder I.D. Floating type with ventilated disc

298 mm (11.73 in)

28 mm (1.10 in)

10.5 mm (0.41 in)

Double piston

Ø48 mm (Ø1.89 in)

Rear brake(Disc)

· Type

· Disc O.D.

· Disc thickness

· Pad thickness

· Cylinder type

· Cylinder I.D Floating type with solid disc

302 mm (11.89 in)

12 mm (0.47 in)

10 mm (0.39 in)

Single piston

Ø42.9 mm (Ø1.69 in)

Parking brake

· Type

· Actuation

· Drum DIH(Drum in hat)

Foot brake

Ø190 mm (Ø7.48 in)

O.D=Outer Diameter

I.D=Inner Diameter

ABS : Anti- lock Brake System

ESP : Electronic Stability Program

SERVICE STANDARD

Items Standard value

Brake pedal height 192.4 mm(7.57 in)

Brake pedal full stroke 122 mm (4.8 in)

Adjust Brake pedal full stroke 60 mm (2.36 in)

Brake pedal free play 3 ~ 8 mm(0.11 ~ 0.31 in)

Stop lamp switch outer case to pedal stopper clearance 1.0 ~ 1.5 mm (0.04 ~ 0.06 in)

Booster push rod to master cylinder piston clearance 0.6 ~ 1.7(0.02 ~ 0.07 in)(at 500 mmHg)

Parking brake pedal stroke when pedal assembly is depressed with

294N (30kgf, 66lb force) 145 mm (5.71 in) above

Front disc brake pad thickness 10.5 mm (0.41 in)

Front disc thickness 28 mm (1.10 in)

Rear disc brake pad thickness 10 mm (0.39 in)

Rear disc brake disc thickness 12 mm (0.47 in)

Rear parking brake liner thickness 4 mm (0.16 in)

Page 872 of 1575

BRAKE SWITCH CLEARANCE

Screw in the brake switch until its plunger is fully depressed (threded end (A) touching the pad (B) on the pedal arm)

then brake off the switch 3/4 turn to make 0.5 ~ 1.0 mm(0.0197 ~ 0.0394 in.) of clearance between the brake switch

connector. Make sure that the brake lights go off when the pedal is released.

PEDAL FREE PLAY

1.With the engine off, inspect the pedal free play (A) on the pedal pad (B) by pushing the pedal by hand.

Free play: 3 ~ 8 mm (0.12 ~ 0.31 in.)

2.If the pedal free play is out of specification, adjust the brake switch (C). If the pedal free play is insufficient, it may

result in brake drag.

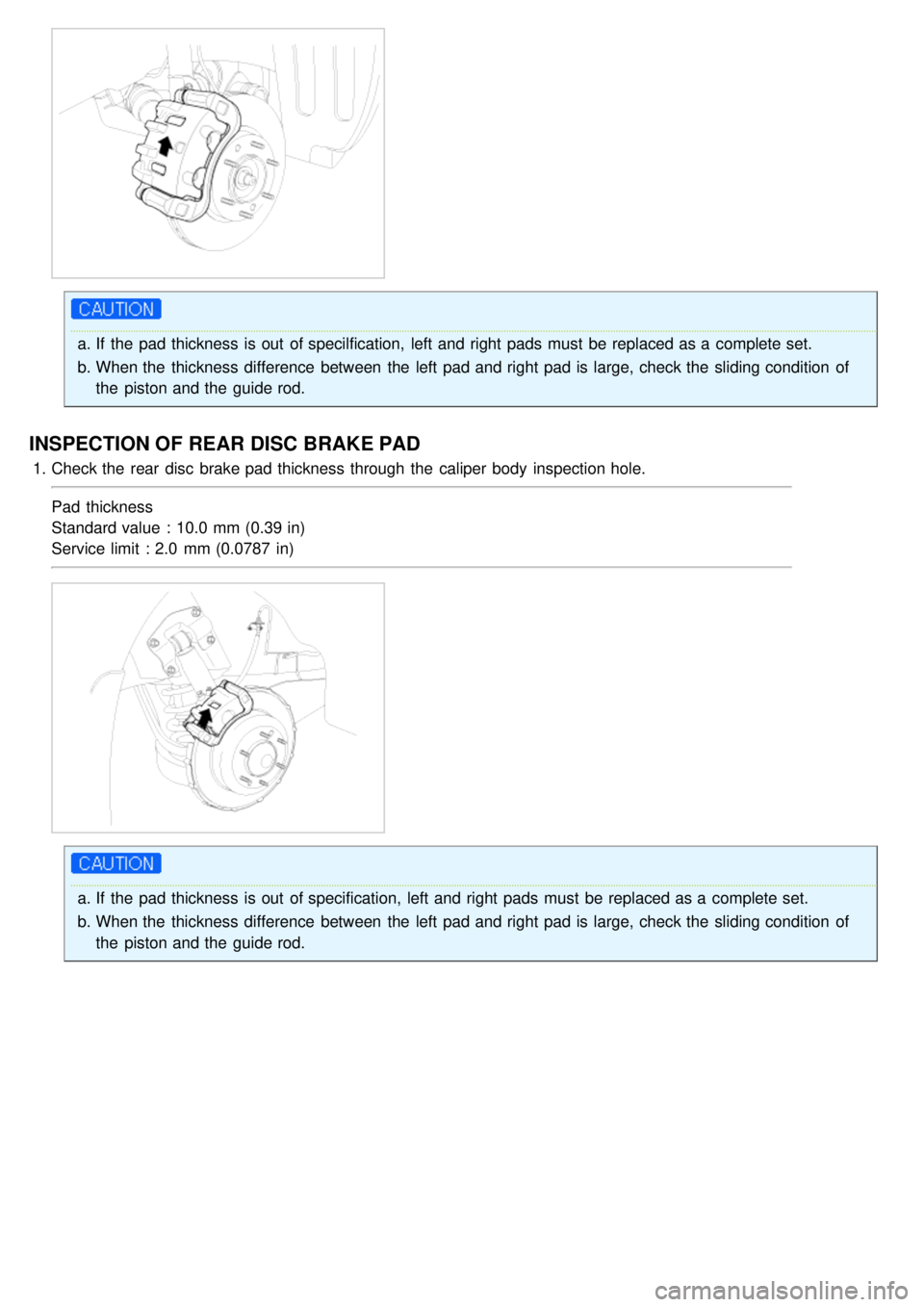

INSPECTION OF FRONT DISC BRAKE PAD

1.Check the brake pad thickness through the caliper body inspection hole.

Pad thickness

Standard value : 10.5 mm ( 0.41 in)

Service limit : 2 mm (0.0787 in)

Page 873 of 1575

a.If the pad thickness is out of specilfication, left and right pads must be replaced as a complete set.

b. When the thickness difference between the left pad and right pad is large, check the sliding condition of

the piston and the guide rod.

INSPECTION OF REAR DISC BRAKE PAD

1.Check the rear disc brake pad thickness through the caliper body inspection hole.

Pad thickness

Standard value : 10.0 mm (0.39 in)

Service limit : 2.0 mm (0.0787 in)

a.If the pad thickness is out of specification, left and right pads must be replaced as a complete set.

b. When the thickness difference between the left pad and right pad is large, check the sliding condition of

the piston and the guide rod.