bolt pattern KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 328 of 1575

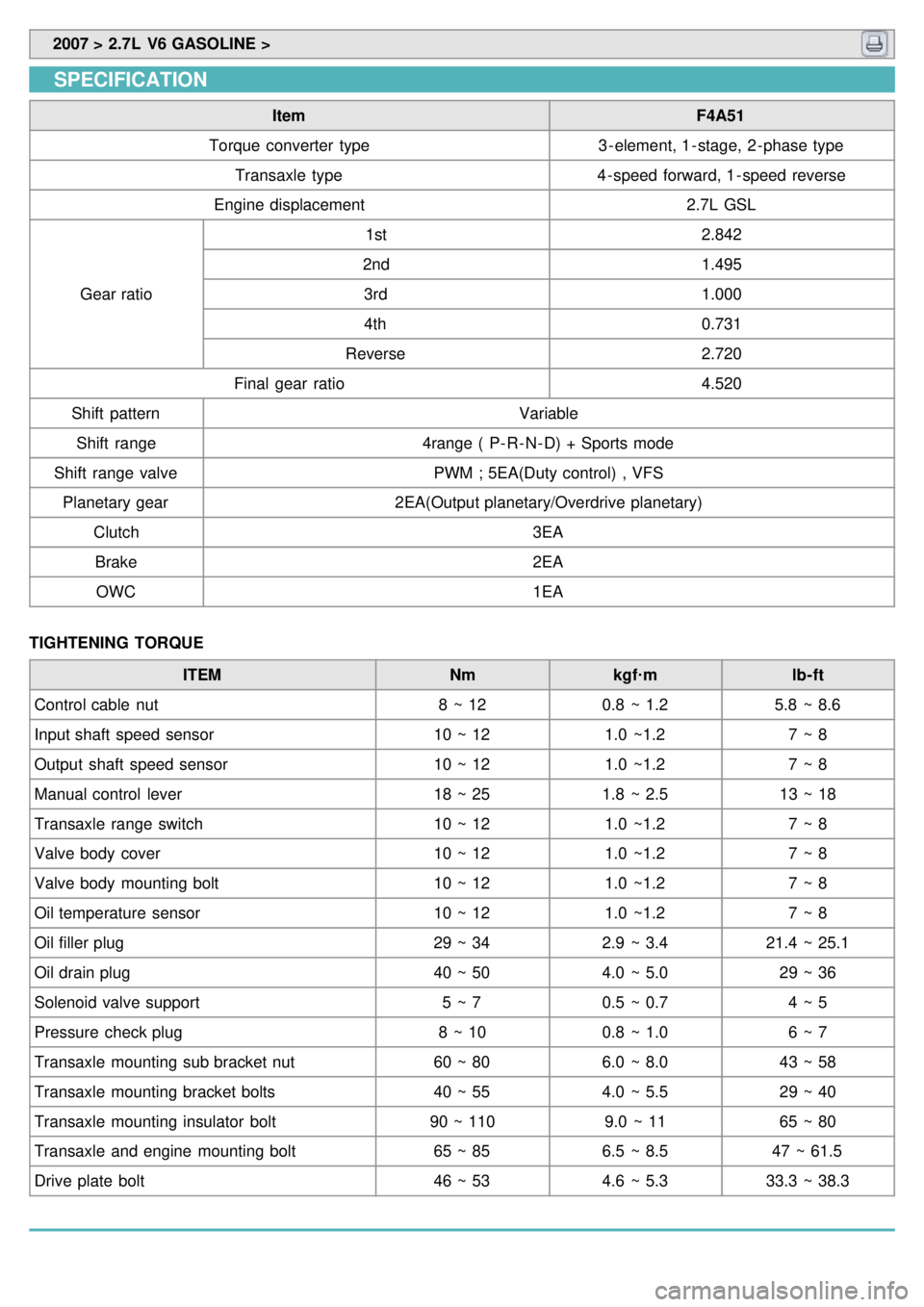

2007 > 2.7L V6 GASOLINE >

SPECIFICATION

Item F4A51

Torque converter type 3 - element, 1 - stage, 2 - phase type

Transaxle type 4 - speed forward, 1 - speed reverse

Engine displacement 2.7L GSL

Gear ratio 1st

2.842

2nd 1.495

3rd 1.000

4th 0.731

Reverse 2.720

Final gear ratio 4.520

Shift pattern Variable

Shift range 4range ( P- R- N- D) + Sports mode

Shift range valve PWM ; 5EA(Duty control) , VFS

Planetary gear 2EA(Output planetary/Overdrive planetary)

Clutch 3EA

Brake 2EA

OWC 1EA

TIGHTENING TORQUE ITEM Nmkgf·m lb- ft

Control cable nut 8 ~ 120.8 ~ 1.2 5.8 ~ 8.6

Input shaft speed sensor 10 ~ 121.0 ~1.2 7 ~ 8

Output shaft speed sensor 10 ~ 121.0 ~1.2 7 ~ 8

Manual control lever 18 ~ 251.8 ~ 2.5 13 ~ 18

Transaxle range switch 10 ~ 121.0 ~1.2 7 ~ 8

Valve body cover 10 ~ 121.0 ~1.2 7 ~ 8

Valve body mounting bolt 10 ~ 121.0 ~1.2 7 ~ 8

Oil temperature sensor 10 ~ 121.0 ~1.2 7 ~ 8

Oil filler plug 29 ~ 342.9 ~ 3.421.4 ~ 25.1

Oil drain plug 40 ~ 504.0 ~ 5.0 29 ~ 36

Solenoid valve support 5 ~ 70.5 ~ 0.7 4 ~ 5

Pressure check plug 8 ~ 100.8 ~ 1.0 6 ~ 7

Transaxle mounting sub bracket nut 60 ~ 806.0 ~ 8.0 43 ~ 58

Transaxle mounting bracket bolts 40 ~ 554.0 ~ 5.5 29 ~ 40

Transaxle mounting insulator bolt 90 ~ 1109.0 ~ 1165 ~ 80

Transaxle and engine mounting bolt 65 ~ 856.5 ~ 8.5 47 ~ 61.5

Drive plate bolt 46 ~ 534.6 ~ 5.333.3 ~ 38.3

Page 488 of 1575

accelerating around a cornerSee DS group - driveshaft.

Front suspension noise - A squeak,

creak, or rattle noise - occurs mostly

over bumps or rough roads Steering components

Loose or bent front struts or shock

absorbers

Damaged spring or spring mounts

Damaged or worn arm bushings

Worn or damaged stabilizer bar

bushing or linksGo to detailed test A.

Groaning or grinding - noise from the

front strut, occurs when driving on

bumpy roads or turning the vehicle Uneven seating surface between the

insulator and panel by the burrs

around the strut insulator mounting

bolts and the insulator boltes

mounting holesRepair or install a new parts as

necessary.

Rear suspension noise - a squeak,

creak or rattle noise - occurs mostly

over bumps or rough roads Loose or bent rear shock absorbers

Damaged spring or spring mounts

Damaged or worn control arm

bushingsGo to detailed test B.

Shudder - occurs during acceleration

from a slow speed or stop Rear axle assembly mis - positioned

Damaged or worn front suspension

componentsCheck the axle mounts and rear

suspension for damage or wear.

Repair as necessary.

Check for a loose stabilizer bar,

damaged or loose strut/strut bushings

or loose or worn ball joints. Inspect

the steering linkage for wear or

damage. Repair or Install new

components as necessary.

Shimmy - most noticeable on

coast/deceleration - also hard steering

condition Excessive positive caster

Check the caster alignment angle.

Correct as necessary.

Tire noise - hum/moan at constant

speeds Abnormal wear patterns

Spin the tire and Check for tire wear.

Install a new tire as necessary.

Inspect for damaged/worn suspension

components. Perform wheel

alignment.

Tire noise - noise tone lowers as the

vehicle speed is lowered Out- of- balance tire

Balance the tire and road test. Install

a new tire as necessary.

Tire noise - ticking noise, change with

speed Nail puncture or stone in tire tread

Inspect the tire. Repair or replace as

necessary.

Wheel and tire - vibration and noise

concern is directly related to vehicle

speed and is not affected by

acceleration, coasting or decelerating Damaged or worn tire

Go to detailed test C.

Tire wobble or shudder - occurs at

lower speeds Damaged wheel bearings

Spin the tire and check for abnormal

wheel bearing play or roughness.

Adjust or Install new wheel bearings

as necessary.

See DS group - front/rear axle.

Damaged wheel Inspect the wheel for damage. Install

a new wheel as necessary.

Damaged or worn suspension

components Inspect the suspension components

for wear or damage. Repair as

necessary.

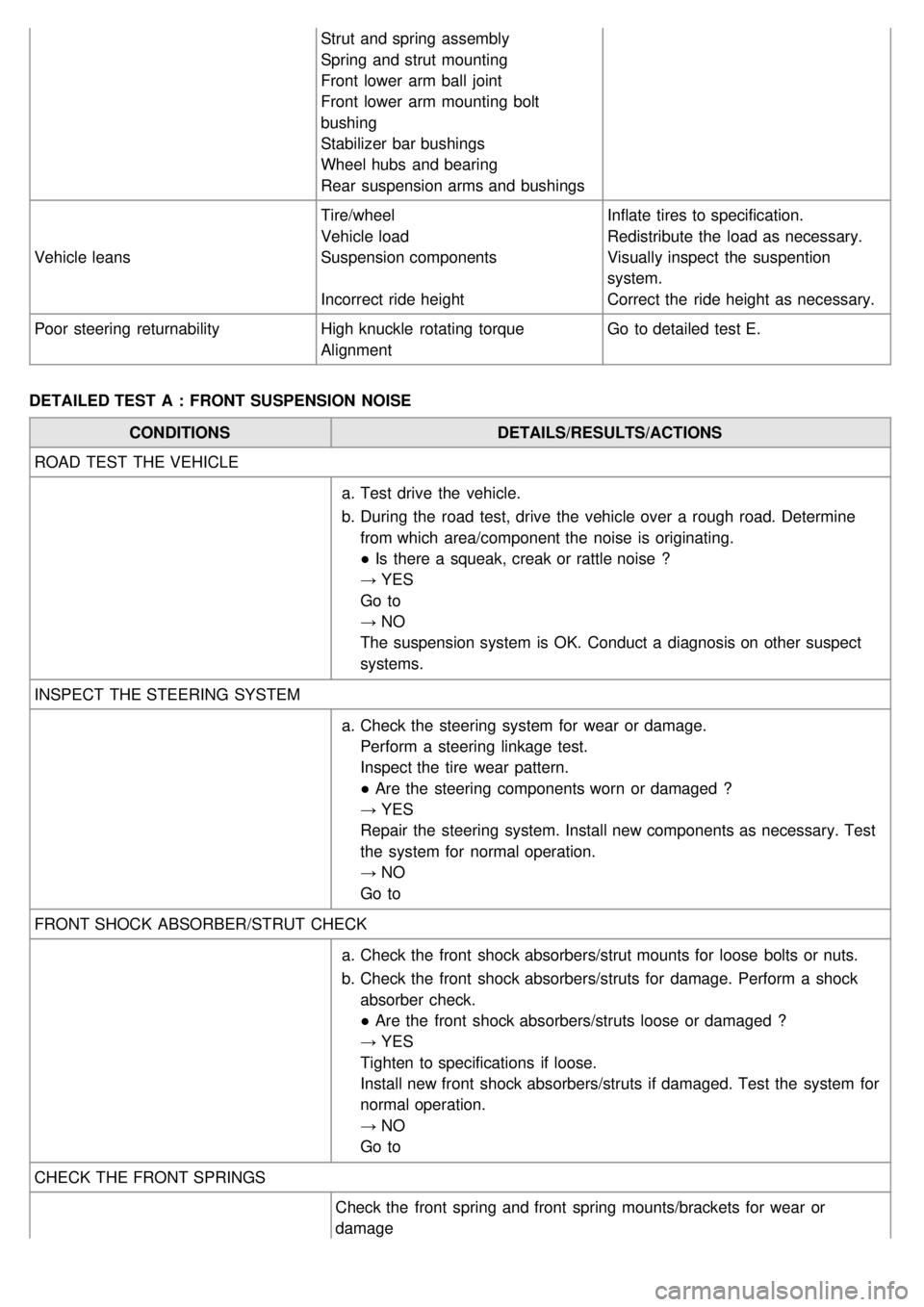

Page 490 of 1575

Strut and spring assembly

Spring and strut mounting

Front lower arm ball joint

Front lower arm mounting bolt

bushing

Stabilizer bar bushings

Wheel hubs and bearing

Rear suspension arms and bushings

Vehicle leans Tire/wheel

Vehicle load

Suspension components

Incorrect ride heightInflate tires to specification.

Redistribute the load as necessary.

Visually inspect the suspention

system.

Correct the ride height as necessary.

Poor steering returnability High knuckle rotating torque

AlignmentGo to detailed test E.

DETAILED TEST A : FRONT SUSPENSION NOISE CONDITIONS DETAILS/RESULTS/ACTIONS

ROAD TEST THE VEHICLE

a.Test drive the vehicle.

b. During the road test, drive the vehicle over a rough road. Determine

from which area/component the noise is originating.

● Is there a squeak, creak or rattle noise ?

→ YES

Go to

→ NO

The suspension system is OK. Conduct a diagnosis on other suspect

systems.

INSPECT THE STEERING SYSTEM a.Check the steering system for wear or damage.

Perform a steering linkage test.

Inspect the tire wear pattern.

● Are the steering components worn or damaged ?

→ YES

Repair the steering system. Install new components as necessary. Test

the system for normal operation.

→ NO

Go to

FRONT SHOCK ABSORBER/STRUT CHECK a.Check the front shock absorbers/strut mounts for loose bolts or nuts.

b. Check the front shock absorbers/struts for damage. Perform a shock

absorber check.

● Are the front shock absorbers/struts loose or damaged ?

→ YES

Tighten to specifications if loose.

Install new front shock absorbers/struts if damaged. Test the system for

normal operation.

→ NO

Go to

CHECK THE FRONT SPRINGS Check the front spring and front spring mounts/brackets for wear or

damage

Page 493 of 1575

c.Inspect the tire wear pattern.

● Do the tires have an abnormal wear pattern ?

→ YES

Correct the condition that caused the abnormal wear. Install new tire(s).

Test the system for normal operation.

→ NO

Go to

TIRE ROTATION DIAGNOSIS a.Spin the tires slowly and watch for signs of lateral runout.

b. Spin the tires slowly and watch for signs of radial runout.

● Are there signs of visual runout ?

→ YES

Go to

→ NO

Check the wheel and tire balance.

Correct as necessary. Test the system for normal operation.

RADIAL RUNOUT CHECK ON THE TIRE Measure the radial runout of the wheel and tire assembly. A typical

specification for total radial runout is 1.15mm (0.059 inch).

● Is the radial runout within specifications ?

→ YES

Go to C8.

→ NO

Go to C6.

RADIAL RUNOUT CHECK ON THE WHEEL Measure the radial runout of the wheel. A typical specification for total radial

runout is 1.14mm (0.045 inch.).

● Is the radial runout within specifications ?

→ YES

Install a new tire. Test the system for normal operation.

→ NO

Go to C7.

CHECK THE HUB/BRAKE DISC OR DRUM PILOT RUNOUT OR BOLT CIRCLE RUNOUT Measure the pilot or bolt circle runout. A typical specification for radial

runout is :

● pilot runout - less than 0.15mm (0.006 inch.)

● bolt circle runout - less than 0.38 mm (0.015 inch.)

● Is the radial runout within specification ?

→ YES

Install a new wheel. Test the system for normal operation.

→ NO

Repair or Install new components as necessary.

LATERAL RUNOUT CHECK ON THE TIRE Measure the lateral runout of the wheel and tire assembly. A typical

specification for total lateral runout is 2.5mm (0.098 inch).