ESP KIA CARNIVAL 2007 Service Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1229 of 1575

switch, the status of the ABS EBD warning, the status of the brake fluid sensor and the speed of the vehicle.

The IPM sends the park brake indicator control on the CAN network.

The indicator is lighted if the vacuum switch or ABS EBD warning are on or brake fluid sensor is low or park brake

switch is on.

If the speed of the vehicle is over 10 km/h and ignition switch is on the status RUN the park brake indicator control is

blinking at 50% duty in 0.6 second if Parking Brake switch Input is active. In this case Vacuum switch, ABS EBD

warning and Brake Fluid sensor are ignored.

The park brake indicator is blinking on the same time that the chime is ringing. If a CAN signal among Vacuum switch,

EBD warning or Brake Fluid Sens switch is INVALID, out of range or not received this CAN signal is considered to be

OFF.

If VehicleSpeed CAN signal is INVALID or not received, it is considered to be 0 kph.

Charging Voltage Control

The IPM receives on analog input the voltage of generator and sends a warning.

When the voltage of generator L pass strictly above 10V, the state of the CAN variable.

Turn Indicators Status

The status of the turn indicators are sent on the CAN network when the CAN network is available.

High Beam Status

The status of the high beam is sent on the CAN network when the CAN network is available.

Front Fog Lamp Status

The status of the front fog lamp (lightning and state of the bulbs) is sent on the CAN network when the CAN network

is available.

Doors Open Warning

The RAM receives on digital input the status of the driver door open switch and sends it on the CAN network.

The RAM receives on digital input the status of the passenger door open switch and sends it on the CAN network.

The RAM receives on digital input the status of the left sliding door open switch and sends it on the CAN network.

The RAM receives on digital input the status of the right sliding door open switch and sends it on the CAN network.

When vehicle speed is under 10 kph, with ignition key not inserted and any door OPEN, DoorsOpenWngCtrl stays ON

for 20 min and then is turned OFF.

Tailgate Open Switch Status

When vehicle speed is under 10 kph, ignition key is inserted and Tailgate open switch is OPEN, Tailgate Open

warning stays ON forever (IPM can enter sleep mode).

When vehicle speed is under 10 kph, with ignition key not inserted and lgate open switch is OPEN, Tailgate Open

warning stays ON for 20 min and then is turned OFF.

Chime Control

1.The chime warns the driver that a problem is occurred.

These warning are:

a. Seat belt

b. Parking on

c. Over speed

d. Key reminder

e. Light Warning

f. Doors Open

g. Tailgate open warning

2. Chime sound priority:

a. 1st : Seatbelt warning

b. 2nd : Overspeed warning

c. 3rd : Door open warning

d. 4th : T/Gate open warning

e. 5th : Key operated warning

f. 6th : Parking Brake warning

Page 1259 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

An optimal seat position set by a driver can be memorized in P/seat unit by memory SW and position SW, which

enables restoration of seat position set by the driver despite seat adjustments.

Furthermore, data is transmitted between P/seat and IPM, DDM, ADM, RAM, FAM, CLUSTER through CAN BUS.

Seat position presets cannot be recalled while driving. An emergency stop function is provided; additional functions are

described below.

1. It conducts manual operation of seat by CAN BUS data transmitted by DDM as well as that of adjustable pedal by

CAN BUS data transmitted by IPM received when operating SW manually.

2. Manual SW behavior when communication stops (back- up behavior)

a. Slide front/rear

b. Recline front/rear

c. Position control of slide motor is possible by manual SW even in case of congestion in CPU or removal of a

fuse for P/seat unit B.

3. 2 memory locations are provided for storing seat, outside mirror, and adjustable pedal presets.

4. The driver seat can be set to slide rearward when the ignition key is removed, and forward when the key is

inserted.

5. 2 additional presets for seat, mirror, and adjustable pedal position can be stored with the RKE transmitter.

OPERATION

MANUAL OPERATION

Manual operation of the driver seat and adjustable pedals is possible provided the transaxle is in 'P' range and the

vehicle speed is 0 MPH. Operation of the manual controls overrides any automatic operation commanded via CAN.

MEMORY OPERATION

1. Pressing the 'M' button on the control panel will place the system into memory storage mode and will result in a

single pulse from the output buzzer.

2. If one of the memory location buttons is pressed and held within 5 seconds of pressing the 'M' button, the output

buzzer will pulse twice to indicate successful storage of seat, mirror, and adjustable pedal positions.

3. The ignition switch must be in the RUN or START position, the vehicle speed must be 0 MPH, and the transaxle

must be in 'P' range to store memory presets.

4. Pressing the 'M' button while recalling a stored preset will halt the preset recall operation.

5. Memory will be cleared if battery is removed.

MEMORY REPLAY OPERATION

1.Pressing one of the memory location buttons will result in the driver seat, outside mirrors, and adjustable pedals

being positioned based on the stored preset data.

2. The ignition switch must be in the RUN position, the transaxle must be in 'P' range, the vehicle speed must be 0

MPH, and the manual functions must not be in operation to recall stored presets.

3. Others

a. Play operation not recorded in the position switch will not be conducted and there will be no buzzer output.

b. If other data is received during preset recall operation, the most recent preset recall signal will take

precedence.

c. If engine is started during preset recall operation, halt preset recall operation, and resume it toward target

position 100ms after Ignition switch is returned to "RUN". However, if the START state lasts over 5 sec., it will

not resume even after returning to RUN.

d. If preset recall order is received during engine start, preset recall operation is inhibited.

e. If input from manual switch for seat and adjust pedal occurs during preset recall operation of seat and adjust

pedal, halt all their preset recall operations.

f. If an error occurs during manual operation of seat and adjust pedal, delete Memory.

Page 1260 of 1575

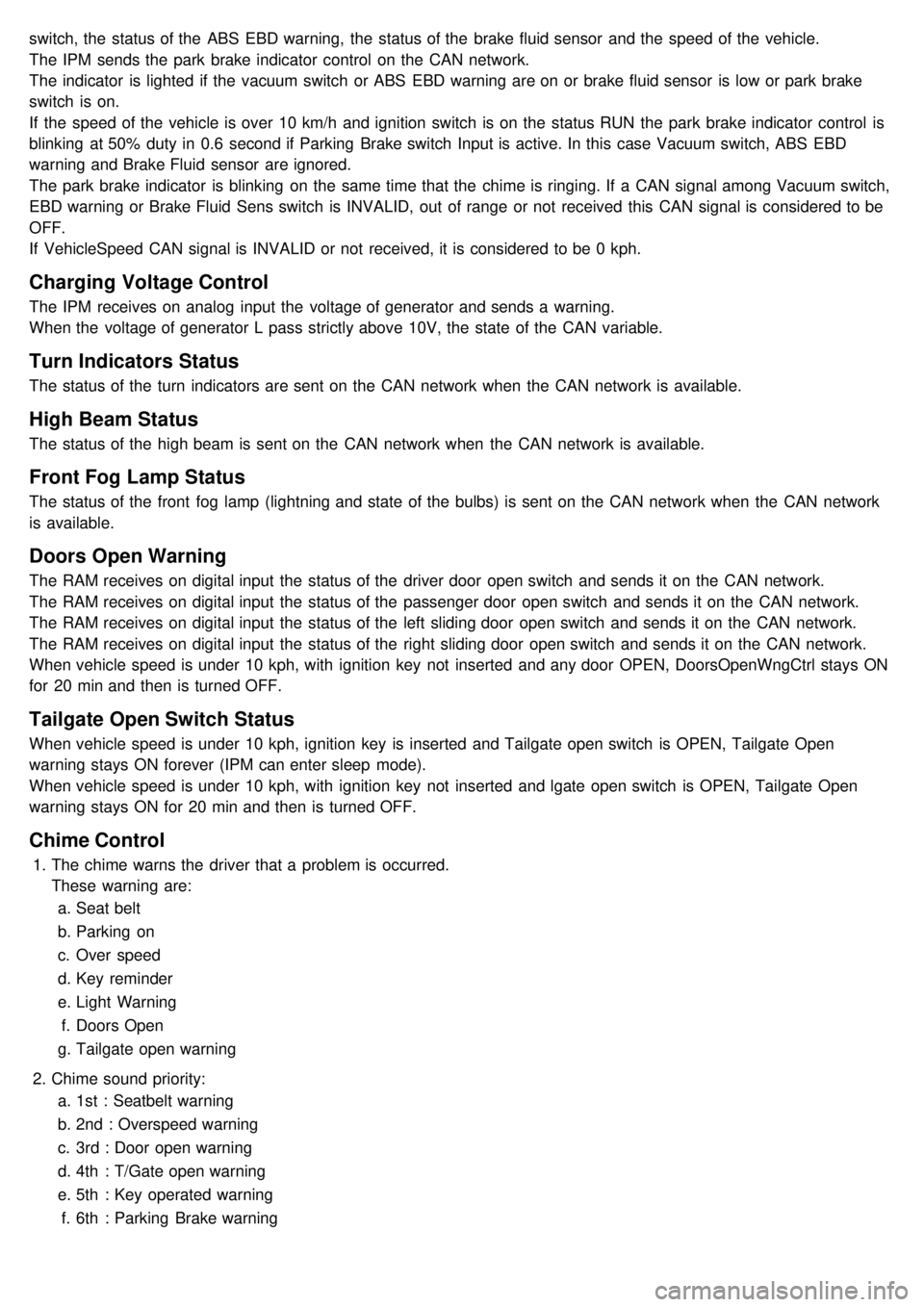

4.Operation control

a. Prioritization of operations

Motor starting is delayed for 100ms respectively in case of auto control to prevent rush current from overlap

when motors are running, and it follows the following order.

Slide > recline > front height > rear height > adjust pedal

b. Memory preset recall is conducted in the following order, and delay time for each motor is as follows.

T1 : Manimum 0.1 sec.

Continuous cooperation TIMER value for each motor

Slide: 15 sec., recline: 30 sec., front height: 5 sec., rear height: 8 sec., adjust pedal: 10 sec.

c. Control when turning to the opposite direction

When motor has to be run in a reverse direction during Easy access function or preset recall operation, stop the

operation immediately, wait for 100ms and then try operation to the reverse direction.

d. If the difference between position and the current one is below specified value, motor will not run even though

preset recall data is received.

Slide, recline, front height, rear height : 6PULSE

Adjust pedal: 3LSB(about 0.06V)

e. Operation will stop upon reaching Motor's target point when conducting Easy access function or preset recall

operation.

EASY ACCESS FUNCTION OPERATION (SLIDE MOTOR ONLY)

1.Easy access function operation is allowed only when auto switch is on, and the operation will be halted if auto

switch changes from on to off.

2. If a key is removed and CAN BUS data transmitted from IPM changes from "on" to "off", the seat slide will move

50mm backward based on the IGN off point. If a key off position is farther back than 50mm against the IGN off

point, get - off gearing will not be conducted. If slide rear limit becomes off in the middle of backward operation,

retreat control will be halted.

3. The following conditions will be identified and processed by IMS, and if any one of the following conditions is met,

Easy access function operation will be prevented or halted.

a. When "P" position switch is not on.

b. When Vehicle Speed in CAN BUS data transmitted from cluster is "3km/h" or faster.

c. When seat and pedal is under manual switch operation.

d. When auto switch is off.

4. When control is halted in the middle of backward operation, the remaining operation will not be completed, and

when returning, it will return just as much as it retreated.

5. It will move to IGN off point in case of Get- on gearing by key in despite manual switch input during or after

backward operation.

6. After the key is removed, on the condition of SLEEP state, Easy access function operation will be conducted after

150ms if the key is inserted when auto switch is turned ON(OFF) from Off(ON).

Page 1262 of 1575

Error conditionBelow 6 pulses in 2 sec. Below 6 pulses in 1 sec.

Prerequisite FR/RR limit SW on Limit setting complete

a. Stop the related motor(seat / pedal) if an error is detected during playing or Easy access function operation.

b. Stop the corresponding motor if an error is detected during manual operation (excluding slide motor).

b. If seat sensor Vcc below 1V is detected by 1s

a. Stop all seat motors running if seat sensor Vcc error is detected during playing or Easy access function operation.

(no buzzer output)

c. Return if seat sensor Vcc is 4V or more.

DETECTING ERRORS FOR ADJUST PEDAL

1.If signal change is below 0.06V per sec though motor is running.

a. Stop the corresponding motor if error is detected during playing or Easy access function operation.

2. If adjust pedal sensor Vcc below 1V is detected by 1s

a. Stop pedal motor running if pedal sensor Vcc error is detected during playing or Easy access function operation.

(no buzzer output)

3. Return if adjust pedal sensor Vcc is 4V or more.

HANDLING ERRORS

1.If errors are discovered, regard them as harness disconnection or sensor failure, and conduct the following

measures.

a. Stop auto control (play or Easy access function operation) if it is under auto control and set off buzzer 10 times

(however, have motors other than the one with an error operate normally).

b. Set off alarm again in case of recurrence of error after restoration of a motor with an error.

c. Complete alarm 10 times though it comes back to normal during error alarm.

d. Stop alarm if receiving memory recall or play order, and set off buzzer in the corresponding function.

e. Manual operation control is allowed even for a motor with errors.

f. Set off buzzer if memory or play order is received even during error.

g. The timing to lift auto control suspension is when repair for the failing motor is completed, and the criteria for

the completion point are as follows:

a. Seat: if signal input is normal with over 6 pulses within a sec. from position sensor of a motor with an error

caused by manual switch.

b. Adjust pedal: if there is change in input of over 3 LSB within 1 sec. from sensor by manual switch.

Page 1327 of 1575

a.The door could suddenly close by itself and cause a serious injury especially when stopping on a down - hill

grade.

b. To prevent the battery from being discharged, do not leave the power sliding door and power tailgate at

open position for a long time.

a.Let the rear passengers get on or off the vehicle after the door is open fully. Sudden closing could cause a

serious injury.

b. To prevent power sliding door system, don't use excessive force to open/close the door during operation.

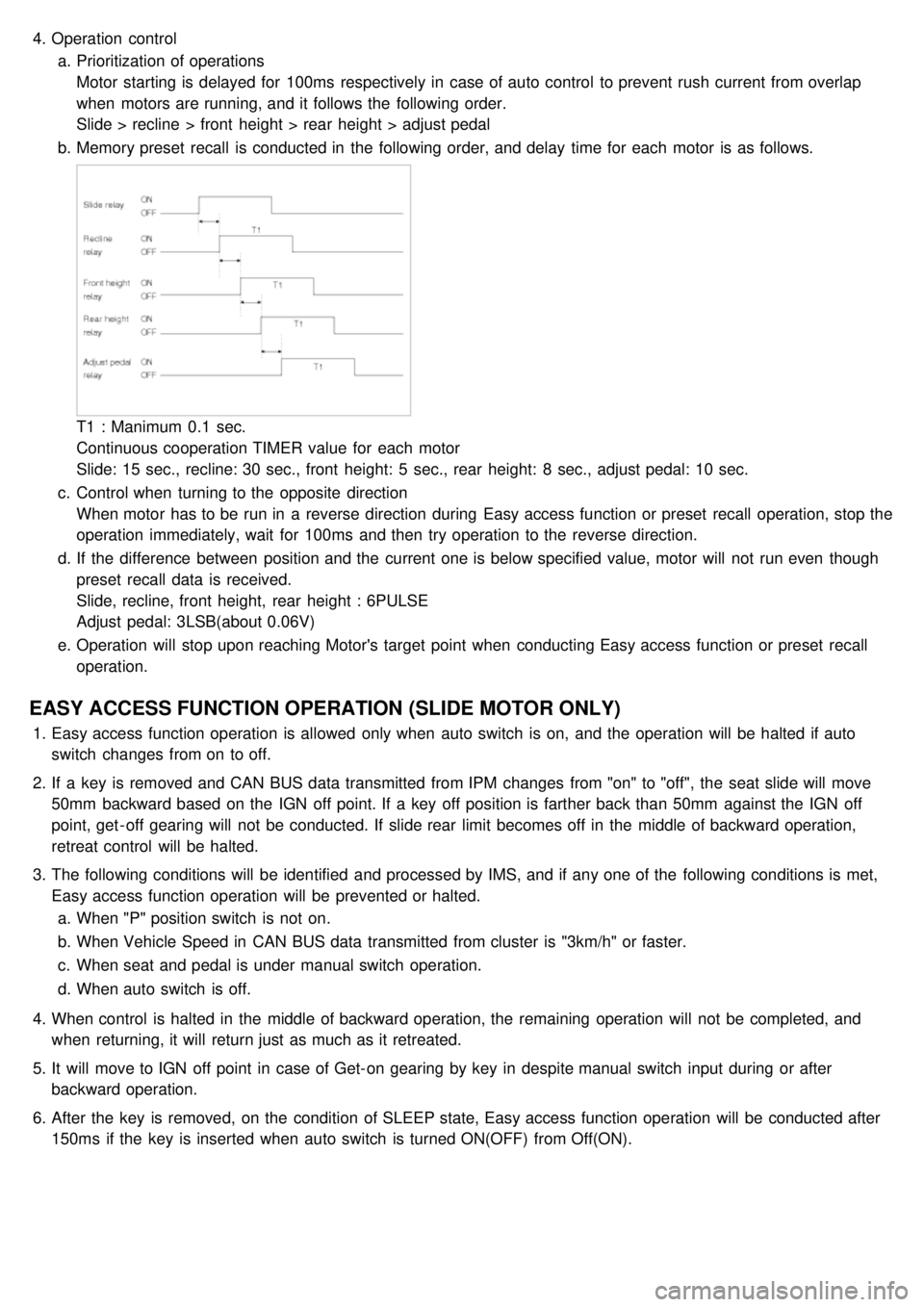

CHILD SAFETY LOCKS

To prevent children from opening the power sliding doors from the inside, the child safety locks (A) should be used

whenever children are in the vehicle.

Be careful, when the child safety lock is used in an accident, that the passengers are not held in vehicle.

POWER OPERATION

The PSD system shall not open the Sliding Door when the vehicle is moving.

The PSD system shall operate through the full range of Sliding Door travel.

The PSD system shall learn the position of each travel extreme: full open and full closed.

Page 1331 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

Check the following items prior to performing Power Sliding Door System service.

1. Manual movement

Make sure the sliding door moves manually. Place the ON/OFF switch on the overhead console in the OFF

position. Move the door manually and check for proper door fit and latch effort. Check for interference with other

body parts such as latch striker, trim, and weather seals.

2. Battery voltage

Make sure the battery is fully charged. The PSD system is an electronic device and requires a minimum battery

voltage to operate. The PSDM(Power sliding door module) monitors the battery voltage present at the PSDM input

battery input and will not permit operation if the battery voltage is out of range.

3. Fuses

Two fuses protect the battery supply to the PSDM(Power sliding door module), one for Power, and one for logic.

Check that the fuses are intact

4. Repeat Operations

Make sure the customer has not been operating the PSD repeatedly while the vehicle is turned off. The battery will

be discharged and the PSDM(Power sliding door module) will not permit operation.

5. Vehicle on Steep Grade

Make sure the customer has not been operating the PSD system when the vehicle is parked on a steep grade

(greater than 30%). The system will operate but the force of gravity and normal flex of the vehicle body may affect

proper operation.

6. Obstacle Detection

The obstacle detection force is not adjustable. Factors that may affect the force are vehicle grade, battery voltage,

or dirt in sliding door tracks.

7. Outside handle response time

When the vehicle has been parked and OFF, there may be a delay before power operation starts after the outside

handle is pulled. This is normal because the PSDM(Power sliding door module) must wake up and check for proper

conditions before starting a power open operation.

8. The sliding doors are not identical. Open and close times and obstacle detection efforts may vary when comparing

the two doors. This is normal and is caused by vehicle build conditions such as door fit and rolling resistance.

9. Scan tool Diagnostic tool

Connect Scan tool to the K- line and check status of system.

POWER SLIDING DOOR SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

Sliding Door opens

unexpectedly Accidental activation or failure of

open/close command switch

Check for shorted or defective switch

Failure of latch assembly Check wiring connections

Check for diagnostic trouble codes

Failure of Power Sliding Door or Body

Control module Disconnect then reconnect battery or fuse to

reset module and function sliding door. If no

function exists check for loose wire

connections. See Body Diagnostic Manual for

detailed procedures

Sliding Door will not power

open or close Not in Park or false indication

Check switch status with SCAN tool

Battery voltage at PSDM is too low

<9.5V to start operation and

<8.0V to continue operation Check for proper voltage at the PSDM.

Charge battery

Blown fuse Check for blown fuse

BCM or sliding door control module

Page 1431 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the front bumper cover. (Refer to Body group - Front bumper)

3. Remove the washer hose, the washer motor connector (A) and washer level sensor connector (C).

4. Remove the washer reservoir after removing 2 bolts and 1 step bolt.

5.Installation is the reverse of removal.

INSPECTION

1.With the washer motor connected to the reservoir tank, fill the reservoir tank with water.

2. Connect positive (+) battery cables to terminal 2 and negative ( - ) battery cables to terminal 1 respectively.

3. Check that the motor operates normally and the washer motor runs and water sprays from the front nozzles. If they

are abnormal, replace the washer motor.

Page 1441 of 1575

5.Installation is the reverse of removal.

INSTALLATION

1.Install the rear wiper arm and blade to the specified position.

※ Specified position : The first defogger line from bottom of the rear window.

2. Set the rear washer nozzle on the specified spray position.

INSPECTION

1.Remove the 3P connector from the rear wiper motor.

2. Connect battery positive (+) and negative ( - ) cables to terminals 2 and 1 respectively.

3. Check that the motor operates normally. Replace the motor if it operates abnormally.

Page 1445 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.With the washer motor connected to the reservoir tank, fill the reservoir tank with water.

2. Remove the front bumper. (Refer to the Body group - Front bumper)

3. Connect positive (+) and negative ( - ) battery cables to terminals 3 and 1 respectively to see that the washer motor

runs and water is pumped.

4. Check that the motor operates normally.

Replace the motor if it operates abnormally.

Page 1470 of 1575

2.The vehicle should be placed on a flat floor.

3. Check the suspension spring.

4. Draw vertical lines (Vertical lines passing through respective head lamp centers) and a horizontal line (Horizontal

line passing through center of head lamps) on the screen.

5. With the head lamp and battery in normal condition, aim the head lamps so the brightest portion falls on the

horizontal and vertical lines.

Make vertical and horizontal adjustments to the lower beam using the adjusting wheel.

FRONT FOG LAMP AIMING

The front fog lamps should be aimed as the same manner used to adjust the head lamps.

With the front fog lamps and battery normal condition, aim the front fog lamps by turning the adjusting gear (A).

HEAD LAMP AND FOG LAMP AIMING POINT