Radio KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 224 of 1575

during testing. An example would be if a problem appears only when the vehicle is cold but has not appeared when

warm. In this case, the technician should thoroughly make out a "CUSTOMER PROBLEM ANALYSIS SHEET" and

recreate (simulate) the environment and condition which occurred when the vehicle was having the issue.1. Clear Diagnostic Trouble Code (DTC).

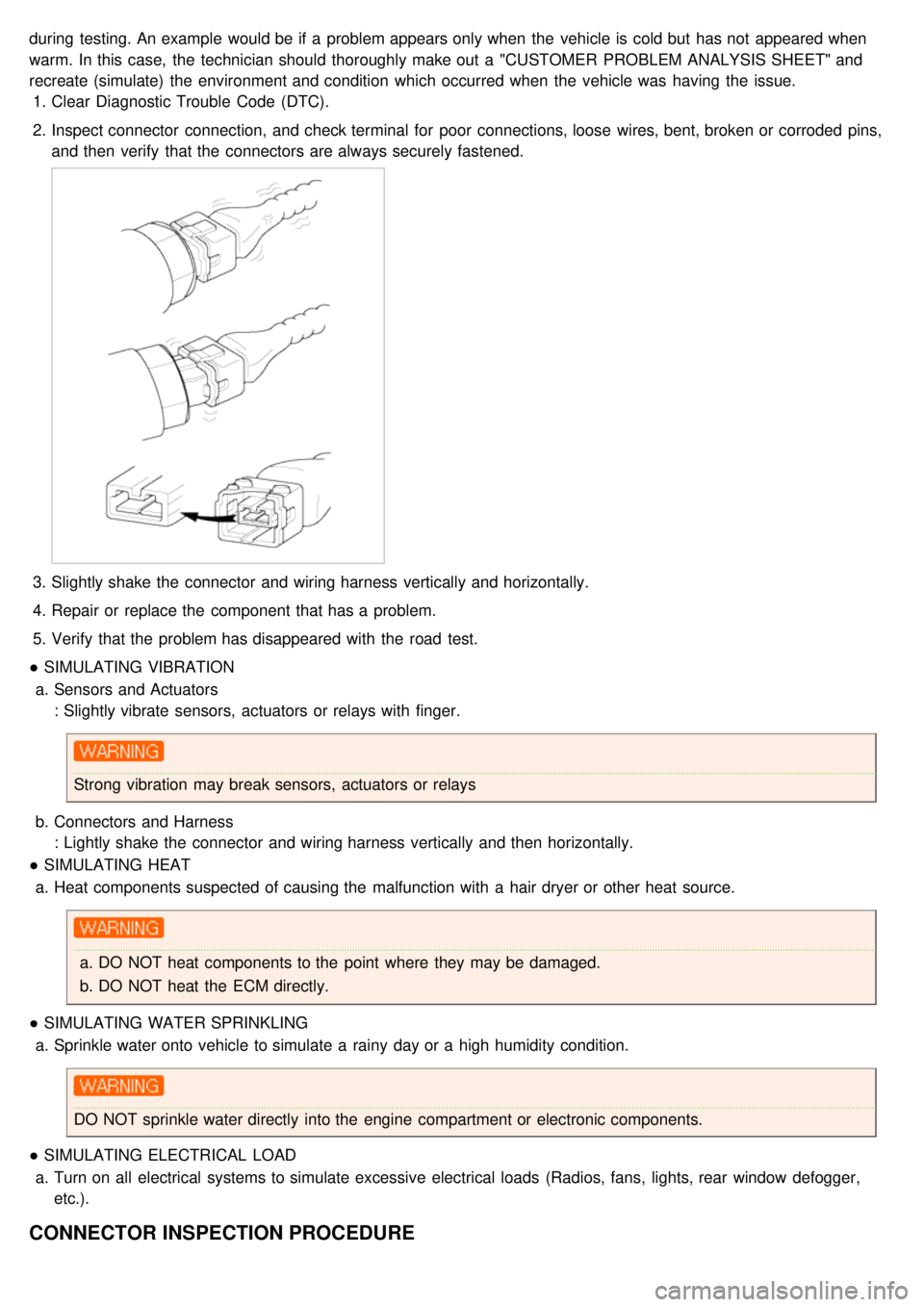

2. Inspect connector connection, and check terminal for poor connections, loose wires, bent, broken or corroded pins,

and then verify that the connectors are always securely fastened.

3.Slightly shake the connector and wiring harness vertically and horizontally.

4. Repair or replace the component that has a problem.

5. Verify that the problem has disappeared with the road test.

● SIMULATING VIBRATION

a. Sensors and Actuators

: Slightly vibrate sensors, actuators or relays with finger.

Strong vibration may break sensors, actuators or relays

b. Connectors and Harness

: Lightly shake the connector and wiring harness vertically and then horizontally.

● SIMULATING HEAT

a. Heat components suspected of causing the malfunction with a hair dryer or other heat source.

a.DO NOT heat components to the point where they may be damaged.

b. DO NOT heat the ECM directly.

● SIMULATING WATER SPRINKLING

a. Sprinkle water onto vehicle to simulate a rainy day or a high humidity condition.

DO NOT sprinkle water directly into the engine compartment or electronic components.

● SIMULATING ELECTRICAL LOAD

a. Turn on all electrical systems to simulate excessive electrical loads (Radios, fans, lights, rear window defogger,

etc.).

CONNECTOR INSPECTION PROCEDURE

Page 239 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

1.Engine is hard to start or does not start at all.

2. Unstable idle.

3. Poor driveability

If any of the above conditions are noted, first perform a routine diagnosis that includes basic engine checks (ignition

system malfunction, incorrect engine adjustment, etc.). Then, inspect the Gasoline Engine Control system components

with the HI- SCAN (Pro).

a. Before removing or installing any part, read the diagnostic trouble codes and then disconnect the battery

negative ( - ) terminal.

b. Before disconnecting the cable from battery terminal, turn the ignition switch to OFF. Removal or connection

of the battery cable during engine operation or while the ignition switch is ON could cause damage to the

ECM.

c. The control harnesses between the ECM and heated oxygen sensor are shielded with the shielded ground

wires to the body in order to prevent the influence of ignition noises and radio interference. When the shielded

wire is faulty, the control harness must be replaced.

d. When checking the generator for the charging state, do not disconnect the battery '+' terminal to prevent the

ECM from damage due to the voltage.

e. When charging the battery with the external charger, disconnect the vehicle side battery terminals to prevent

damage to the ECM.

Malfunction Indicator Lamp (MIL)

Faults with the following items will illuminate the MIL.

a. Catalyst

b. Fuel system

c. Mass Air Flow Sensor (MAFS)

d. Intake Air Temperature Sensor (IATS)

e. Engine Coolant Temperature Sensor (ECTS)

f. Throttle Position Sensor (TPS)

g. Upstream Oxygen Sensor

h. Upstream Oxygen Sensor Heater

i. Downstream Oxygen Sensor

j. Downstream Oxygen Sensor Heater

k. Injector

l. Misfire

m. Crankshaft Position Sensor (CKPS)

n. Camshaft Position Sensor (CMPS)

o. Evaporative Emission Control System

p. Vehicle Speed Sensor (VSS)

q. Idle Speed Control Actuator (ISCA)

r. Power Supply

s. ECM/ PCM

t. MT/AT Encoding

u. Acceleration Sensor

v. MIL- on Request Signal

w. Power Stage

Refer to "INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES (DTC)" for more information.

Page 1075 of 1575

9.Installation is the reverse of removal.

CRASH PAD REPLACEMENT

a.When prying with a flat- tipped screwdriver, wrap itwith protective tape, and apply protective tapearound the

related parts, to prevent damage.

b. Put on gloves to protect your hands.

1. Remove the following items.

a. Front seat.

b. Cluster facia panel, cluster.

c. Audio assembly.

d. Glove box.

e. Side cover, center under cover.

f. Front pillar trim.

2. Remove the photo sensor (C), speaker connector (B).

3. Disconnect the passenger`s air bag connector (A).

Loosen the bolt and nut, then remove the crash pad (D).

4. Installation is the reverse of removal.

a.Make sure the crash pad fits onto the guide pins correctly.

b. Before tightening the bolts, make sure the crash pad wire harnesses are not pinched.

c. Make sure the connectors are plugged in properly, and the antenna lead is connected properly.

d. Enter the anti- theft code for the radio, then enter.

[LHD]

Page 1078 of 1575

d.Enter the anti- theft code for the radio, then enter the customer`s radio station presets.

Page 1159 of 1575

2007 > 2.7L V6 GASOLINE >

CUSTOMER COMPLAINT ANALYSIS CHECK SHEET

TROUBLESHOOTING

There are six areas where a problem can occur: wiring harness, the radio, the cassette tape deck, the CD player, and

speaker. Troubleshooting enables you to confine the problem to a particular area.

Page 1170 of 1575

2007 > 2.7L V6 GASOLINE >

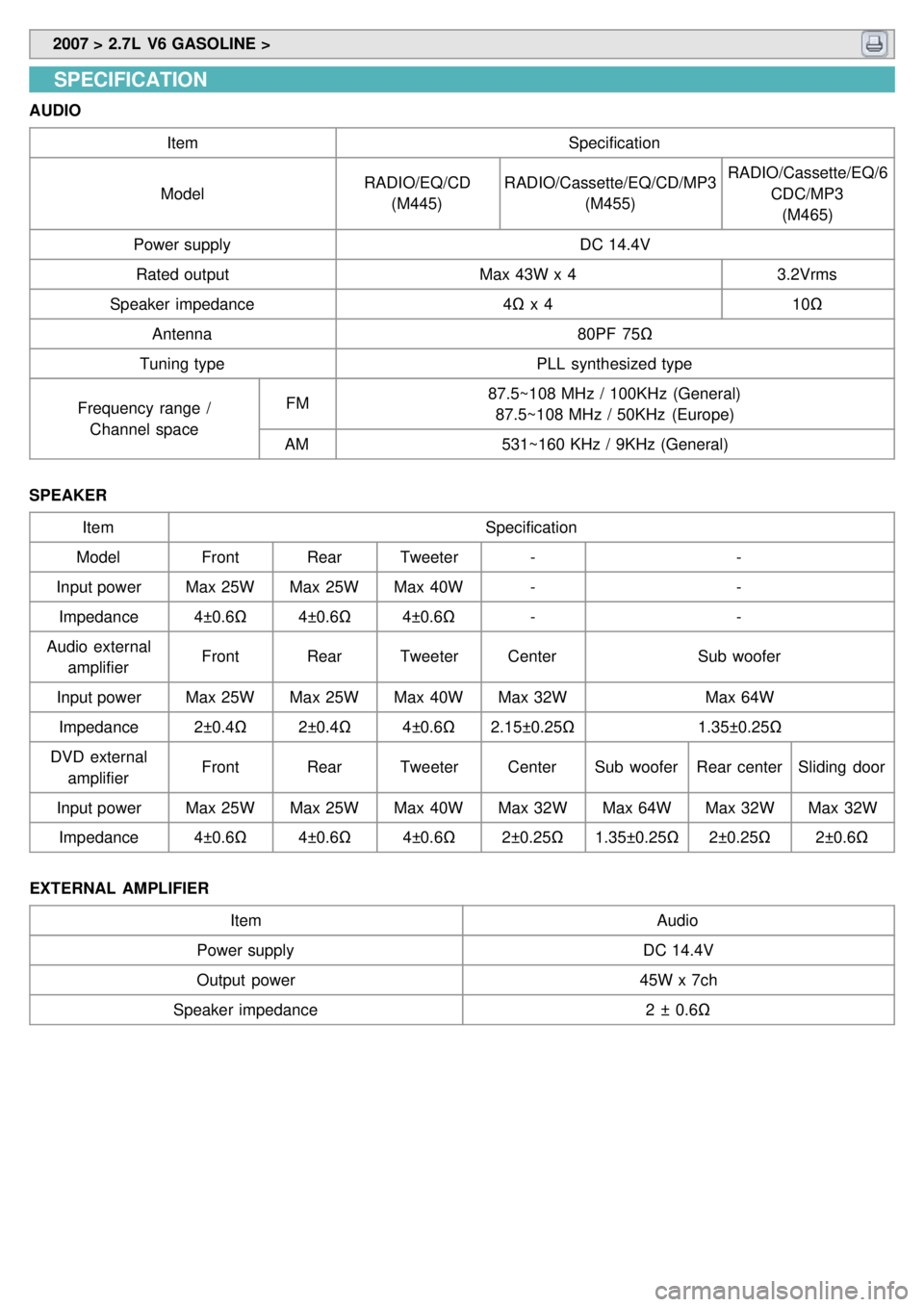

SPECIFICATION

AUDIO

Item Specification

Model RADIO/EQ/CD

(M445) RADIO/Cassette/EQ/CD/MP3

(M455) RADIO/Cassette/EQ/6

CDC/MP3(M465)

Power supply DC 14.4V

Rated output Max 43W x 43.2Vrms

Speaker impedance 4Ω x 4 10Ω

Antenna 80PF 75Ω

Tuning type PLL synthesized type

Frequency range / Channel space FM

87.5~108 MHz / 100KHz (General)

87.5~108 MHz / 50KHz (Europe)

AM 531~160 KHz / 9KHz (General)

SPEAKER Item Specification

Model FrontRearTweeter - -

Input power Max 25WMax 25WMax 40W - -

Impedance 4±0.6Ω4±0.6Ω4±0.6Ω - -

Audio external amplifier Front

RearTweeter Center Sub woofer

Input power Max 25WMax 25WMax 40WMax 32W Max 64W

Impedance 2±0.4Ω2±0.4Ω4±0.6Ω2.15±0.25Ω 1.35±0.25Ω

DVD external amplifier Front

RearTweeter CenterSub woofer Rear centerSliding door

Input power Max 25WMax 25WMax 40WMax 32WMax 64WMax 32WMax 32W

Impedance 4±0.6Ω4±0.6Ω4±0.6Ω2±0.25Ω1.35±0.25Ω 2±0.25Ω2±0.6Ω

EXTERNAL AMPLIFIER Item Audio

Power supply DC 14.4V

Output power 45W x 7ch

Speaker impedance 2 ± 0.6Ω

Page 1182 of 1575

2007 > 2.7L V6 GASOLINE >

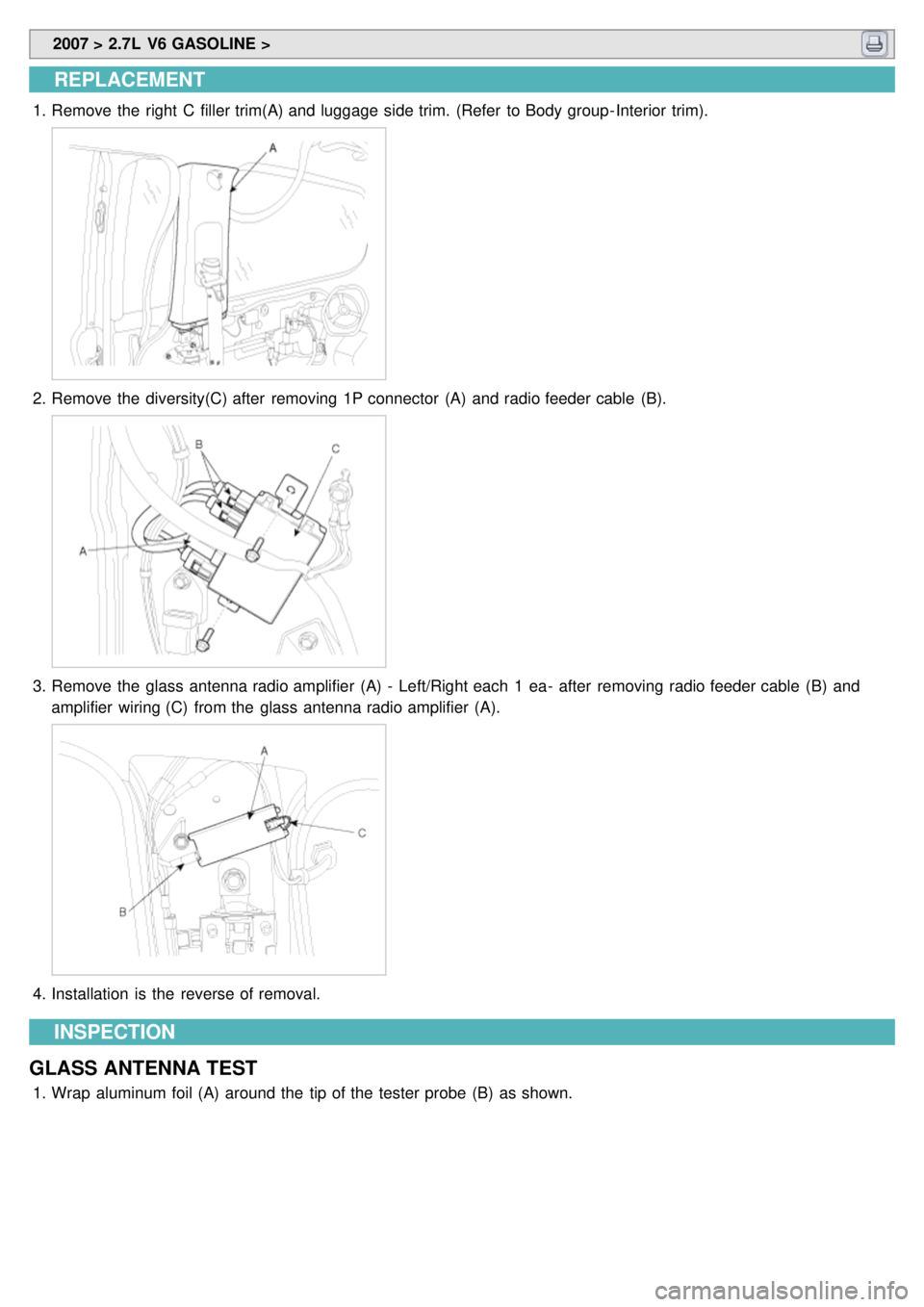

REPLACEMENT

1.Remove the right C filler trim(A) and luggage side trim. (Refer to Body group - Interior trim).

2.Remove the diversity(C) after removing 1P connector (A) and radio feeder cable (B).

3.Remove the glass antenna radio amplifier (A) - Left/Right each 1 ea- after removing radio feeder cable (B) and

amplifier wiring (C) from the glass antenna radio amplifier (A).

4.Installation is the reverse of removal.

INSPECTION

GLASS ANTENNA TEST

1. Wrap aluminum foil (A) around the tip of the tester probe (B) as shown.

Page 1184 of 1575

4.Check for continuity in the repaired wire.

5. Apply a second coat of paint in the same way. Let it dry three hours before removing the tape.

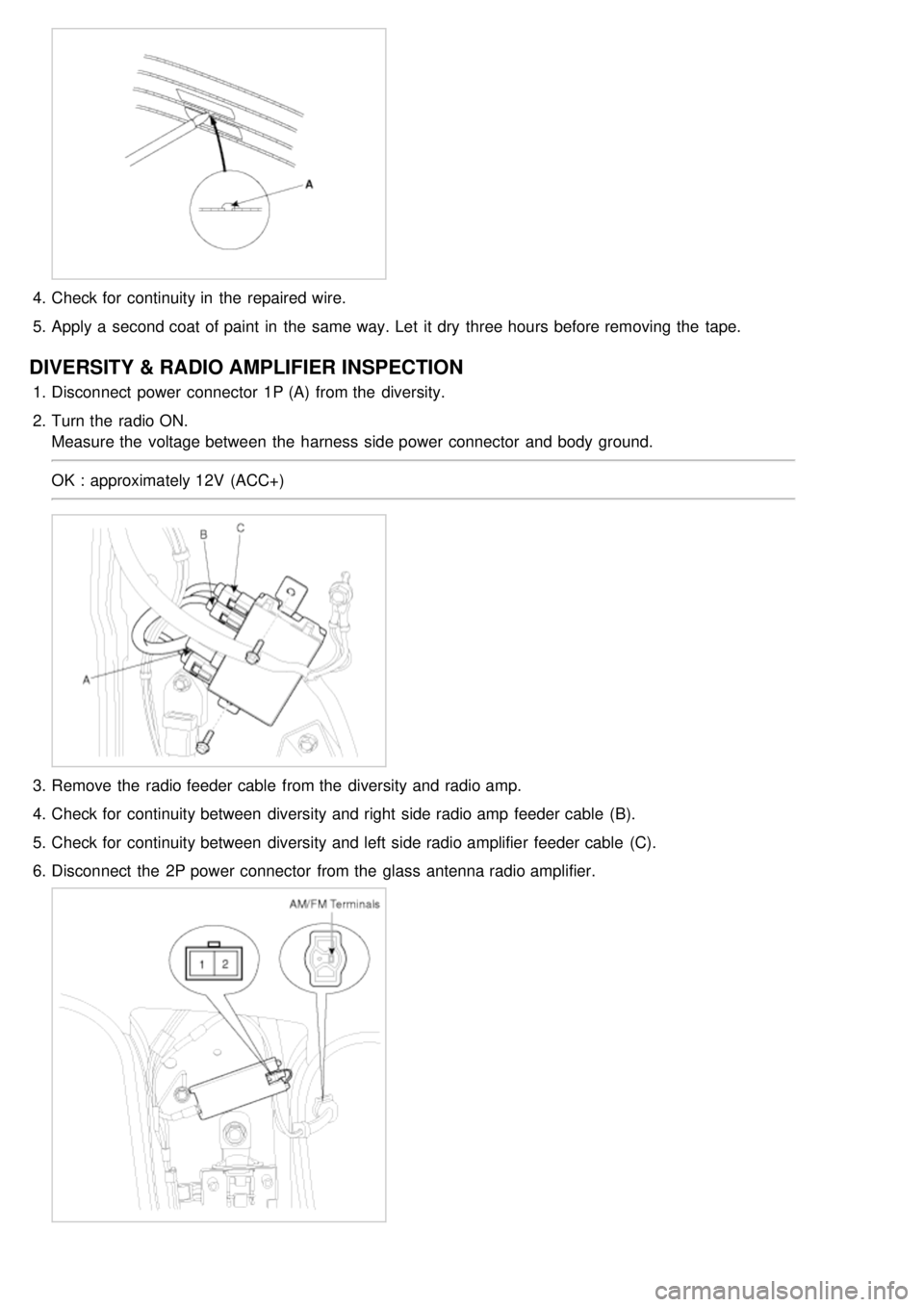

DIVERSITY & RADIO AMPLIFIER INSPECTION

1.Disconnect power connector 1P (A) from the diversity.

2. Turn the radio ON.

Measure the voltage between the harness side power connector and body ground.

OK : approximately 12V (ACC+)

3.Remove the radio feeder cable from the diversity and radio amp.

4. Check for continuity between diversity and right side radio amp feeder cable (B).

5. Check for continuity between diversity and left side radio amplifier feeder cable (C).

6. Disconnect the 2P power connector from the glass antenna radio amplifier.

Page 1185 of 1575

7.Check for continuity between terminals of harness side connector and antenna grid terminals (AM, FM).

8. Check the grid lines for continuity.

9. When a poor radio reception is not repaired through the above inspection methods, replace the amp.

If the radio reception is still poor, check the radio cable for short and radio head unit for failure.

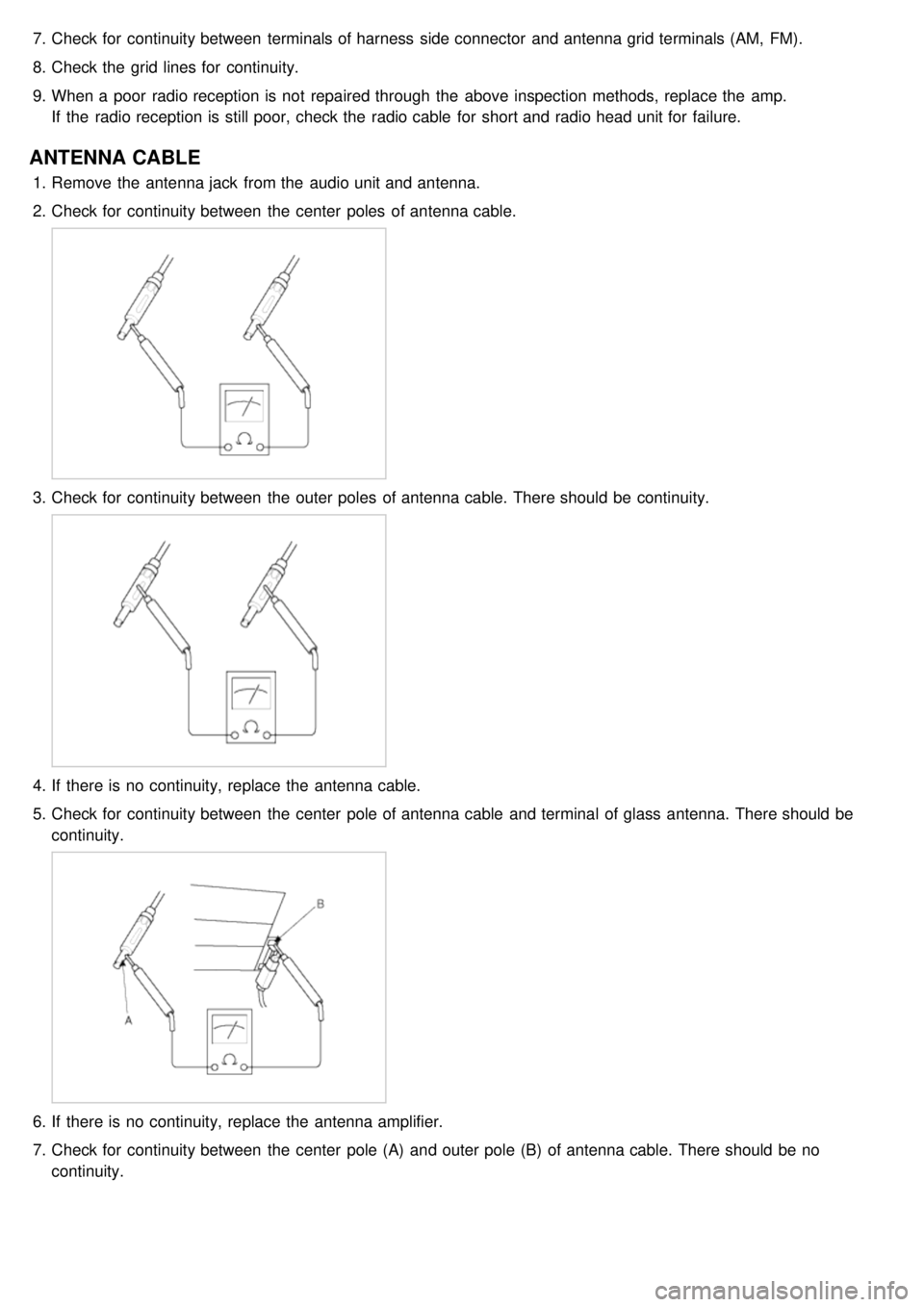

ANTENNA CABLE

1.Remove the antenna jack from the audio unit and antenna.

2. Check for continuity between the center poles of antenna cable.

3.Check for continuity between the outer poles of antenna cable. There should be continuity.

4.If there is no continuity, replace the antenna cable.

5. Check for continuity between the center pole of antenna cable and terminal of glass antenna. There should be

continuity.

6.If there is no continuity, replace the antenna amplifier.

7. Check for continuity between the center pole (A) and outer pole (B) of antenna cable. There should be no

continuity.

Page 1231 of 1575

1.The aim of this function is to receive the key fob signal and decode it. There are 8 different data included in the

radio frequency frame sent by the RKE to the IPM module:

a. Central door lock

b. Central door unlock

c. Panic function

d. Driver door window close (long press on RKE lock button)

e. Driver door window open (long press on RKE unlock button)

f. Left sliding door open/close

g. Right sliding door open/close

h. Power tailgate open/close

2. Each vehicle can have at most 2 associated key fobs. The key fob is physically separated from the key itself

(separate device).

3. Input/Output Definition and Characteristics

Central Lock/unlock

1.Central locking/unlocking logic is controlled by IPM. Locking/Unlocking inputs are located in ADM, DDM

(Lock/Unlock switch, door knobs, door key cylinder) and in IPM (RKE receiver).

2. Locking/Unlocking actuators are located in ADM for passenger door, DDM for driver door and RAM for sliding doors

and tailgate.

There are 5 ways of operating central lock/unlock:

a. With Key RKE

b. With Door Lock/Unlock switches located on ADM/DDM

c. With Door Lock Monitoring switches located on the passenger/driver door

d. With Door/Tailgate Key Cylinder Lock/Unlock switches located on the tailgate or passenger/driver door.

3. Functional Diagram