set clock KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 13 of 1575

1.Remove the engine cover.

2. Remove air cleaner assembly.

3. Remove the surge tank.

4. Remove the cylinder head cover.

(1) Disconnect the ignition coil connector and remove the ignition coil.

(2) Remove the cylinder head cover.

5.Set the piston of the No.1 cylinder to TDC(Top Dead Center) position.

(1) Turn the crankshaft pulley clockwise and align its groove with the timing mark "T" of the timing chain cover.

(2) Check that the timing marks of the camshaft sprocket are in straight line on that of the cylinder head cover

surface as shwn in the illustration. It makes the piston of the No.1 cylinder position at TDC.

If not, turn the crankshaft one revolution clockwise.

6. Inspect the intake and the exhaust valve clearance.

(1) With the piston of the No.1 cylinder positioning at TDC, the valves which can be measured its clearance are as

shown below.

Measurement method.

a. Using a thickness gauge, measure the clearance between the tappet and the base circle of camshaft.

b. Record the out - of- specification valve clearance measurements. They will be used later to determine the

required adjusting tappet for replacement.

Page 14 of 1575

![KIA CARNIVAL 2007 Workshop Manual Specification

Limit (Engine coolant temperature : 20°C [68°F])

Intake : 0.10 ~ 0.30mm (0.0039 ~ 0.0118in.)

Exhaust : 0.20 ~ 0.40mm (0.0079 ~ 0.0157in.)

(2) Turn the crankshaft pulley one revo KIA CARNIVAL 2007 Workshop Manual Specification

Limit (Engine coolant temperature : 20°C [68°F])

Intake : 0.10 ~ 0.30mm (0.0039 ~ 0.0118in.)

Exhaust : 0.20 ~ 0.40mm (0.0079 ~ 0.0157in.)

(2) Turn the crankshaft pulley one revo](/img/2/57045/w960_57045-13.png)

Specification

Limit (Engine coolant temperature : 20°C [68°F])

Intake : 0.10 ~ 0.30mm (0.0039 ~ 0.0118in.)

Exhaust : 0.20 ~ 0.40mm (0.0079 ~ 0.0157in.)

(2) Turn the crankshaft pulley one revolution (360°) clockwise and align the groove with the timing mark "T" of the

timing chain cover.

(3) With the piston of the No.4 cylinder positioning at TDC, the valves which can be measured its clearance are as

shown below.

7.Adjust the intake and the exhaust valve clearances.

(1) Set the piston of the No.1 cylinder to the TDC/position.

(2) Remove the timing belt.

(3) Remove the camshaft bearing caps(A, B).

(4)Remove the camshaft assembly.

(5) Remove MLA(Mechanical Lash Adjuster)s.

(6) Measure the thickness of the removed tappet using a micrometer.

(7)Calculate the thickness of a new tappet so that the valve clearance comes within the specified value.

T : Thickness of removed tappet

A : Measured valve clearance

Page 28 of 1575

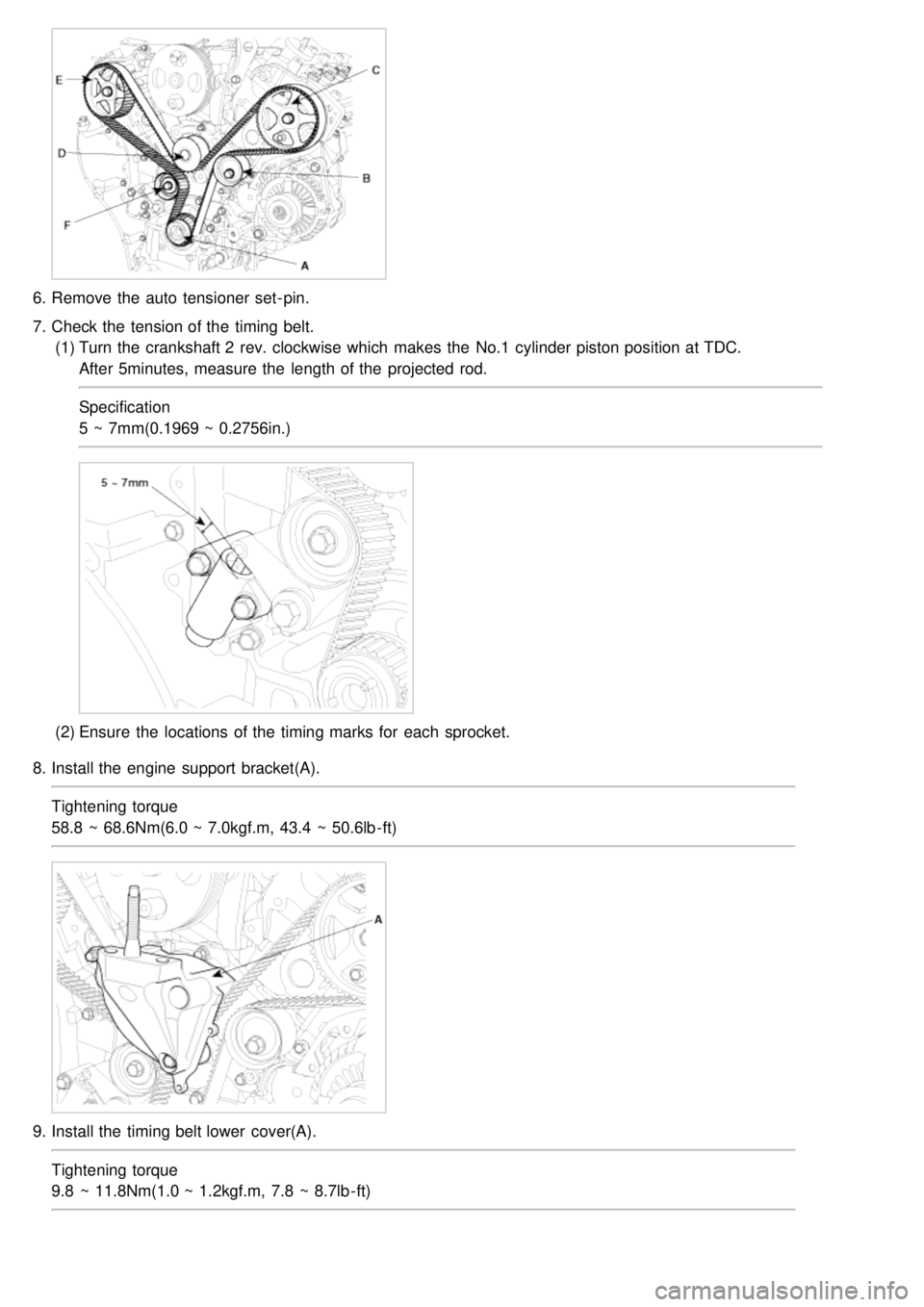

6.Remove the auto tensioner set- pin.

7. Check the tension of the timing belt.

(1) Turn the crankshaft 2 rev. clockwise which makes the No.1 cylinder piston position at TDC.

After 5minutes, measure the length of the projected rod.

Specification

5 ~ 7mm(0.1969 ~ 0.2756in.)

(2)Ensure the locations of the timing marks for each sprocket.

8. Install the engine support bracket(A).

Tightening torque

58.8 ~ 68.6Nm(6.0 ~ 7.0kgf.m, 43.4 ~ 50.6lb- ft)

9.Install the timing belt lower cover(A).

Tightening torque

9.8 ~ 11.8Nm(1.0 ~ 1.2kgf.m, 7.8 ~ 8.7lb - ft)

Page 44 of 1575

camshaft. Ensure that the pin will not be installed in the hole for oil feeding.

Tightening torque

66.7~78.5Nm(6.8~8.0kgf.m, 49.2~57.9lb - ft)

After tightening the CVVT bolts, rotate the CVVT assembly housing counterclockwise by hand to seat the lock

pin in the CVVT assembly in good position.

Fix the hexagonal part of the camshaft in a vice when tightening the CVVT bolts. Do not fix the CVVT housing

or sprocket in a vice.

4. Install the camshaft in the cylinder head assembly.

(1) Align the timing mark of the camshaft timinig chain.

LH camshaft chain timing mark

RH camshaft chain timing mark

Both timing marks should face upward in reassemby.

5. Install the timing chain tensioner.

(1) Insert the set pin by pressing the timing chain tensioner.

(2) Install the chain tensioner(A) in the cylinder head assembly.

Page 574 of 1575

ItemDescription

A Positive camber angle

B True vertical

When the wheel tilts out at the top, then the camber is positive (+).

When the wheel tilts in at the top, then the camber is negative(- ).

Standard value : 0° ± 30´

Difference between right and left angle is within 0° 30´

Camber is pre- set at the factory and doesn't need to be adjusted. If the camber is not within the standard value,

replace the bent or damaged parts.

[REAR]

Standard value : - 6´ ± 30´

Difference between right and left angle is within 0° 30´

Adjust the camber by turning the cambolt of the rear upper arm.

Left cambolt : Clockwise → camber(- )

Right cambolt : Clockwise →camber(+)

The variation of camber by a rotation of the cambolt :

About 0°8´35´´

CASTER

Caster is the tilting of the strut axis either forward or backward from vertical. A backward tilt is positive (+) and a

forward tilt is negative ( - ).

Caster is pre- set at the factory and doesn't need to be adjusted. If the caster is not within the standard value, replace

the bent or damaged parts.

Page 836 of 1575

2.Remove ignition key from the vehicle.

3. Connect the clock spring harness connetor and horn harness connector to the clock spring.

4. Set the clock spring on neutral position and after turning the front wheels to the straight- ahead position, install the

clock spring.

5. Install the steering wheel column cover and the steering wheel. (Refer to ST group)

6. Connect the Driver Airbag (DAB) module connector and horn connector, then install the Driver Airbag (DAB)

module on the steering wheel.

7. Secure the Driver Airbag (DAB) with the new mounting bolts.

Tightening Torque (DAB Mounting Bolt)

: 0.8 ~ 1.1 kgf.m (7.9 ~ 10.8 Nm, 5.8 ~ 8.0 lb.ft)

8.Connect the battery negative cable.

9. After installing the airbag, confirm proper system operation:

a. Turn the ignition switch ON; the SRS indicator light should be turned on for about six seconds and then go off.

b. Make sure horn button works.

INSPECTION

Driver Airbag (DAB)

If any improper parts are found during the following inspection, replace the airbag module with a new one.

Never attempt to measure the circuit resistance of the airbag module (squib) even if you are using the specified

tester. If the circuit resistance is measured with a tester, accidental airbag deployment will result in serious

personal injury.

1. Check pad cover for dents, cracks or deformities.

2. Check the airbag module for denting, cracking or deformation.

3. Check hooks and connectors for damage, terminals for deformities, and harness for binds.