transmission KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 2 of 1575

2007 > 2.7L V6 GASOLINE >

IDENTIFICATION NUMBER DESCRIPTION

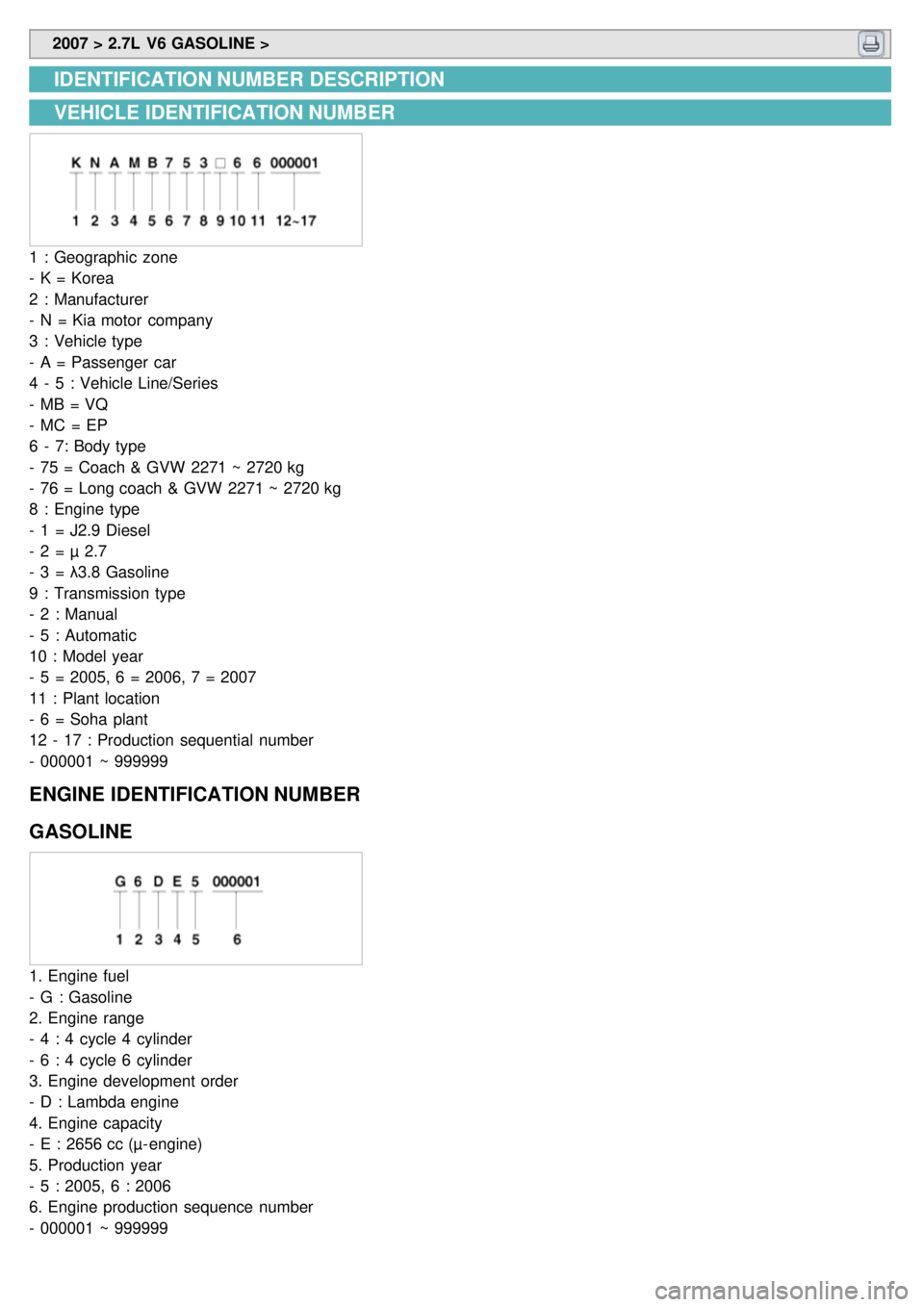

VEHICLE IDENTIFICATION NUMBER

1 : Geographic zone

- K = Korea

2 : Manufacturer

- N = Kia motor company

3 : Vehicle type

- A = Passenger car

4 - 5 : Vehicle Line/Series

- MB = VQ

- MC = EP

6 - 7: Body type

- 75 = Coach & GVW 2271 ~ 2720 kg

- 76 = Long coach & GVW 2271 ~ 2720 kg

8 : Engine type

- 1 = J2.9 Diesel

- 2 = µ 2.7

- 3 = λ3.8 Gasoline

9 : Transmission type

- 2 : Manual

- 5 : Automatic

10 : Model year

- 5 = 2005, 6 = 2006, 7 = 2007

11 : Plant location

- 6 = Soha plant

12 - 17 : Production sequential number

- 000001 ~ 999999

ENGINE IDENTIFICATION NUMBER

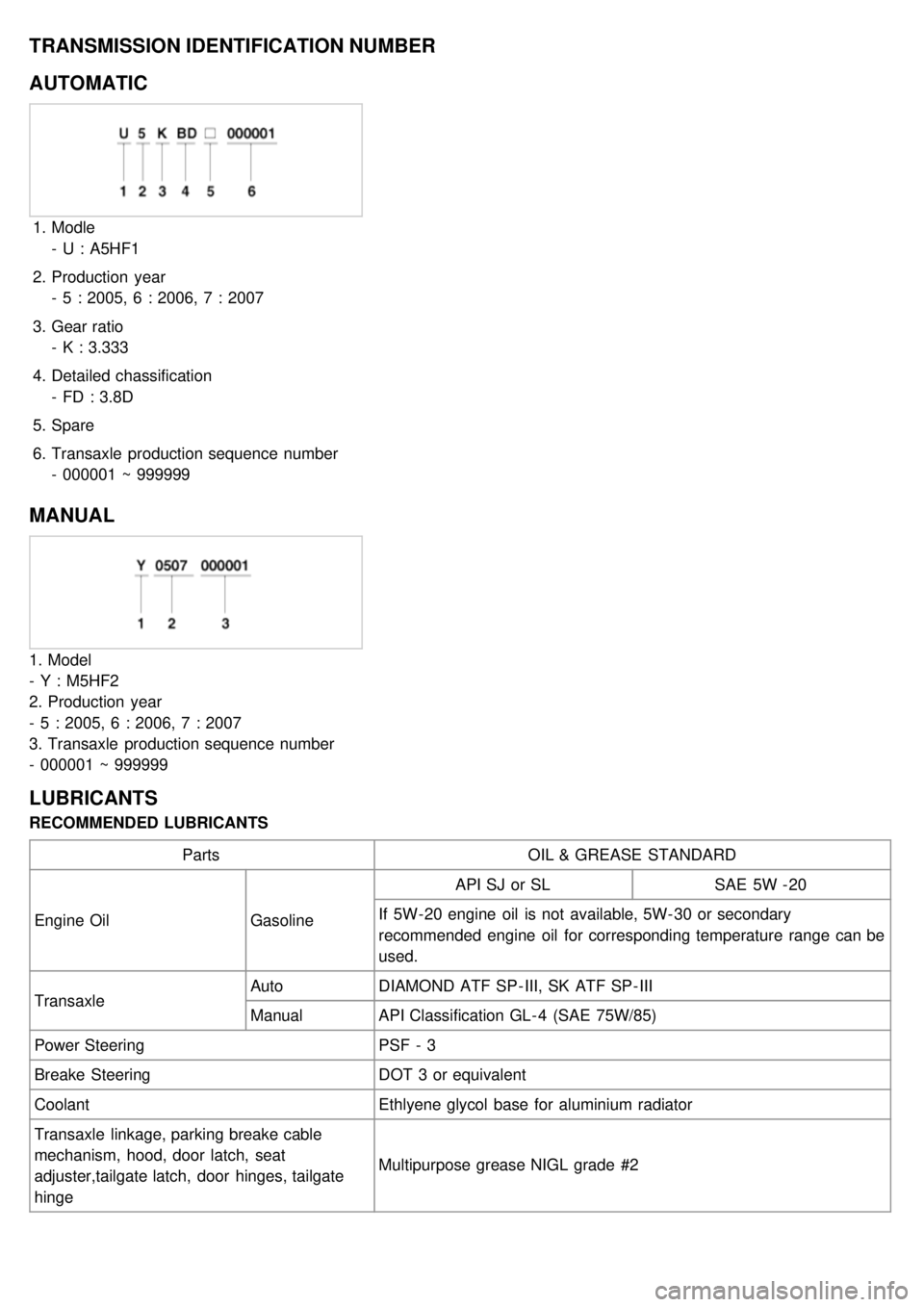

GASOLINE

1. Engine fuel

- G : Gasoline

2. Engine range

- 4 : 4 cycle 4 cylinder

- 6 : 4 cycle 6 cylinder

3. Engine development order

- D : Lambda engine

4. Engine capacity

- E : 2656 cc (µ- engine)

5. Production year

- 5 : 2005, 6 : 2006

6. Engine production sequence number

- 000001 ~ 999999

Page 3 of 1575

TRANSMISSION IDENTIFICATION NUMBER

AUTOMATIC

1.Modle

- U : A5HF1

2. Production year

- 5 : 2005, 6 : 2006, 7 : 2007

3. Gear ratio

- K : 3.333

4. Detailed chassification

- FD : 3.8D

5. Spare

6. Transaxle production sequence number

- 000001 ~ 999999

MANUAL

1. Model

- Y : M5HF2

2. Production year

- 5 : 2005, 6 : 2006, 7 : 2007

3. Transaxle production sequence number

- 000001 ~ 999999

LUBRICANTS

RECOMMENDED LUBRICANTS

Parts OIL & GREASE STANDARD

Engine Oil GasolineAPI SJ or SL

SAE 5W - 20

If 5W- 20 engine oil is not available, 5W- 30 or secondary

recommended engine oil for corresponding temperature range can be

used.

Transaxle Auto

DIAMOND ATF SP - III, SK ATF SP - III

Manual API Classification GL - 4 (SAE 75W/85)

Power Steering PSF - 3

Breake Steering DOT 3 or equivalent

Coolant Ethlyene glycol base for aluminium radiator

Transaxle linkage, parking breake cable

mechanism, hood, door latch, seat

adjuster,tailgate latch, door hinges, tailgate

hinge Multipurpose grease NIGL grade #2

Page 329 of 1575

LUBRICANT

ItemSpecified lubricant Quantity

Transmission oil Diamond ATF SP - III8.5ℓ(9.0 Us qt, 7.5Imp.qt)

SEALANT Item Specified Sealant

Rear cover

Torque converter housing

Valve body cover Three Bond - TB 1281B or LOCTITE - FMD - 546

Transmission case side cover Three Bond - TB 1389 or LOCTITE - 518

Side cover Three Bond - TB 1389 or LOCTITE - 518/587

Page 337 of 1575

2007 > 2.7L V6 GASOLINE >

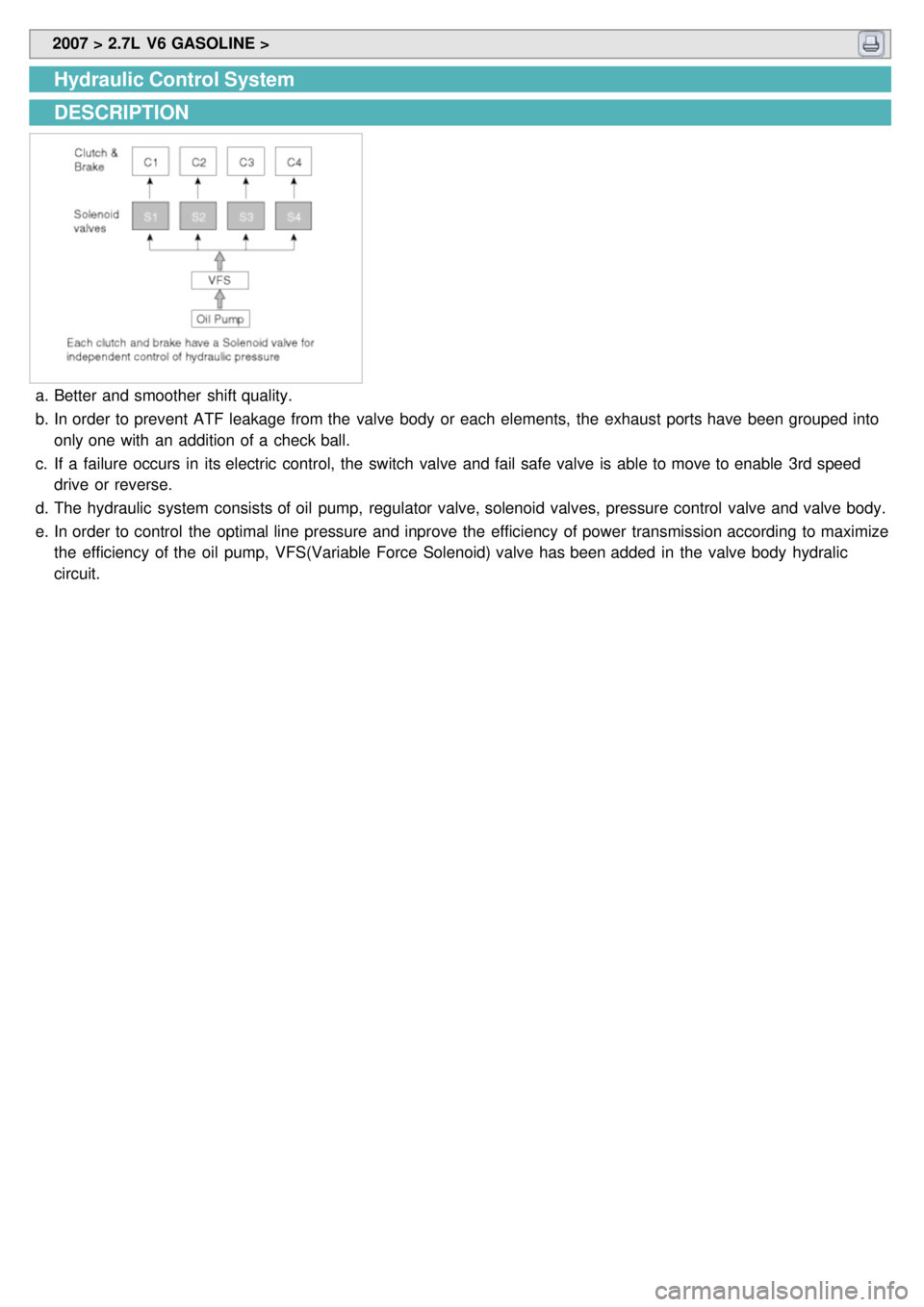

Hydraulic Control System

DESCRIPTION

a.Better and smoother shift quality.

b. In order to prevent ATF leakage from the valve body or each elements, the exhaust ports have been grouped into

only one with an addition of a check ball.

c. If a failure occurs in its electric control, the switch valve and fail safe valve is able to move to enable 3rd speed

drive or reverse.

d. The hydraulic system consists of oil pump, regulator valve, solenoid valves, pressure control valve and valve body.

e. In order to control the optimal line pressure and inprove the efficiency of power transmission according to maximize

the efficiency of the oil pump, VFS(Variable Force Solenoid) valve has been added in the valve body hydralic

circuit.

Page 348 of 1575

2007 > 2.7L V6 GASOLINE >

Description

The automatic transmission is a combination of 3 - element 2 - phase 1 - stage torque converter and double shaft

electrocally - controlled unit which provides 4 speeds forward and 1 reverse. To improve the efficiency of power

transmission, the line pressure control was changed applying “Variable Force Solenoid (VFS) valve” on this model.

However, adopting VFS on this model, the line pressure is variably changed according to TPS and the vehicle speed,

this will enable more improved efficiency of power transmission and fuel consumption.

Characteristics

Some of the characteristics include:

▶Different power transfer

▶Different component layout

▶New shift logic(HIVEC) to improve shift feeling

▶Position of Valve Body

▶Variable shift pattern

▶Communication protocol and method

▶Step gate type shift lever.

Item Details

Weight Reduction 1. Aluminum oil pump

a. 2.3kg Approx

2. Pressed parts a. Retainer and hub of brakes and clutches

b. Carrier of planetary gear set

Better shift quality 1. Independent control of clutches and brakes enabled better control of

hydraulic pressure and skiped shifts (4 to 2, 3 to 1)

2. During N to D or N to R shift, feedback control adopted.

3. When starting from Creep condition, reduction of shock.(Creep condition is

controlled with 1st gear)

4. Solenoid valve frequency is increased for more accurate control. 35Hz to

61.3Hz except DCCSV that is 35Hz and VFS that is 600Hz.

5. HIVEC adoption for better shift feeling.

6. Variable shift pattern.

Increase in Power train efficiency 1. Fully Variable Line Pressure

2. VFS(Variable Force Solenoid)

- Manual shifting possible

- Step gate type shift lever

Page 351 of 1575

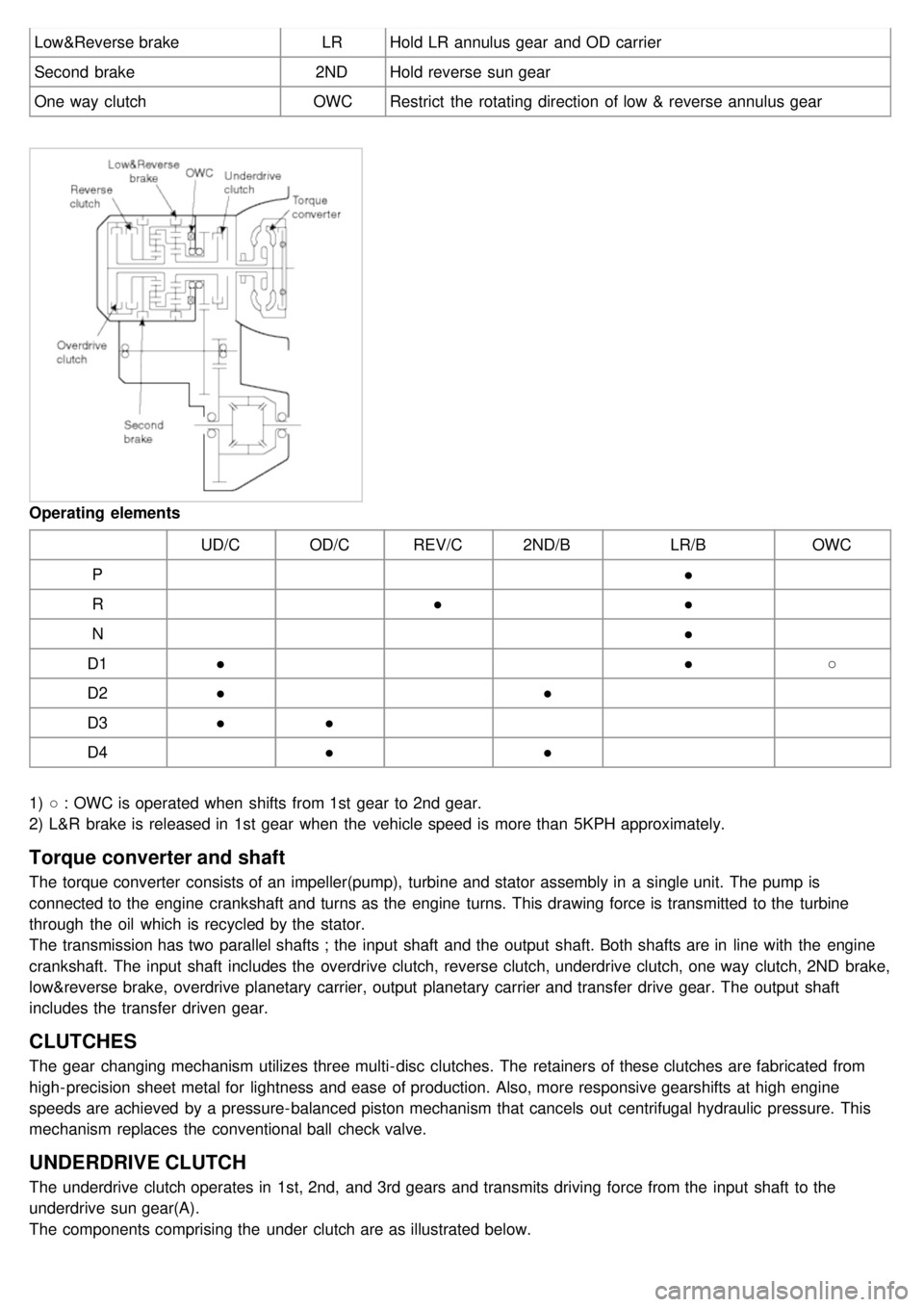

Low&Reverse brakeLRHold LR annulus gear and OD carrier

Second brake 2NDHold reverse sun gear

One way clutch OWCRestrict the rotating direction of low & reverse annulus gear

Operating elements

UD/COD/CREV/C 2ND/B LR/BOWC

P ●

R ●●

N ●

D1 ● ●○

D2 ● ●

D3 ●●

D4 ●●

1) ○ : OWC is operated when shifts from 1st gear to 2nd gear.

2) L&R brake is released in 1st gear when the vehicle speed is more than 5KPH approximately.

Torque converter and shaft

The torque converter consists of an impeller(pump), turbine and stator assembly in a single unit. The pump is

connected to the engine crankshaft and turns as the engine turns. This drawing force is transmitted to the turbine

through the oil which is recycled by the stator.

The transmission has two parallel shafts ; the input shaft and the output shaft. Both shafts are in line with the engine

crankshaft. The input shaft includes the overdrive clutch, reverse clutch, underdrive clutch, one way clutch, 2ND brake,

low&reverse brake, overdrive planetary carrier, output planetary carrier and transfer drive gear. The output shaft

includes the transfer driven gear.

CLUTCHES

The gear changing mechanism utilizes three multi- disc clutches. The retainers of these clutches are fabricated from

high- precision sheet metal for lightness and ease of production. Also, more responsive gearshifts at high engine

speeds are achieved by a pressure- balanced piston mechanism that cancels out centrifugal hydraulic pressure. This

mechanism replaces the conventional ball check valve.

UNDERDRIVE CLUTCH

The underdrive clutch operates in 1st, 2nd, and 3rd gears and transmits driving force from the input shaft to the

underdrive sun gear(A).

The components comprising the under clutch are as illustrated below.

Page 361 of 1575

Shocks when changing from N to D, N to R

and large time lag

If abnormal shocks or a time lag of 2 seconds

or more occur when the selector lever is

shifted from N to D range and from N to R

range while the engine is idling, the cause is

probably abnormal line pressure or a

malfunction of the oil pump or valve body.a.

Abnormal line pressure

b. Malfunction of the oil pump

c. Malfunction of the valve body

Malfunction when

shifting Shocks and running up

If shocks occur when driving due to up

shifting or down shifting and the transmission

speed becomes higher than the engine

speed, the cause is probably abnormal line

pressure or a malfunction of a solenoid valve,

oil pump, valve body or of a brake or clutch. a.

Abnormal line pressure

b. Malfunction of each solenoid valve

c. Malfunction of the oil pump

d. Malfunction of the valve body

e. Malfunction of each brake or each clutch

Displaced shifting

points All points

If all shift points are displaced while driving,

the cause is probably a malfunction of the

output shaft speed sensor, TPS or of a

solenoid valve. a.

Malfunction of the output shaft speed

sensor

b. Malfunction of the throttle position sensor

c. Malfunction of each solenoid valve

d. Abnormal line pressure

e. Malfunction of the valve body

f. Malfunction of the TCM(PCM)

Some points

If some of the shift points are displaced while

driving, the cause is probably a malfunction of

the valve body, or it is related to control and

is not an abnormality. a.

Malfunction of the valve body

Does not shift No diagnosis codes

If shifting does not occur while driving and no

diagnosis codes are output, the cause is

probably a malfunction of the transaxle range

switch, or TCM(PCM) a.

Malfunction of the transaxle range

b. Malfunction of the TCM(PCM)

Malfunction while

driving Poor acceleration

If acceleration is poor even if down shifting

occurs while driving, the cause is probably a

malfunction of the engine system or of a

brake or clutch. a.

Malfunction of the engine system

b. Malfunction of the brake or clutch

Malfunction while

driving Vibration

If vibration occurs when driving at constant

speed or when accelerating and deceleration

in top range, the cause is probably abnormal

damper clutch pressure or a malfunction of

the engine system, damper clutch control

solenoid valve, torque converter or valve

body. a.

Abnormal damper clutch pressure

b. Malfunction of the engine system

c. Malfunction of the damper clutch control

solenoid valve

d. Malfunction of the torque converter

e. Malfunction of the valve body

Transaxle range switch system

The cause is probably a malfunction of the inhibitor switch circuit,

ignition switch circuit or a defective TCM(PCM). a.

Malfunction of the transaxle range switch

b. Malfunction of the ignition switch

c. Malfunction of connector

d. Malfunction of the TCM(PCM)

Idle position switch system

The cause is probably a defective idle position switch circuit, or a

defective TCM(PCM). a.

Malfunction of the triple pressure switch

b. Malfunction of connector

c. Malfunction of the TCM(PCM)

Page 362 of 1575

Triple pressure switch system

The cause is probably a defective dual pressure switch circuit or a

defective TCM(PCM).a.

Malfunction of the triple pressure switch

b. Malfunction of connector

c. Malfunction of A/C system

d. Malfunction of the TCM(PCM)

Vehicle speed sensor system

The cause is probably a defective vehicle speed sensor circuit or a

defective TCM(PCM). a.

Malfunction of the vehicle speed sensor

b. Malfunction of connector

c. Malfunction of the TCM(PCM)

DTC TROUBLESHOOTING INDEX

No. Code ItemMILRemark

1 P0707 TRANSAXLE RANGE SWITCH CIRCUIT LOW INPUT ON

2 P0708 TRANSAXLE RANGE SWITCH CIRCUIT HIGH INPUT ON

3 P0711 TRANSAXLE FLUID TEMPERATURE SENSOR RATIONALITY ON

4 P0712 TRANSAXLE FLUID TEMPERATURE SENSOR CIRCUIT LOW INPUT ON

5 P0713 TRANSAXLE FLUID TEMPERATURE SENSOR CIRCUIT HIGH INPUT ON

6 P0717 A/T INPUT SPEED SENSOR CIRCUIT - OPEN or SHORT(GND) ON

7 P0722 AT OUTPUT SPEED SENSOR CIRCUIT - OPEN or SHORT(GND) ON

8 P0731 GEAR 1 INCORRECT RATIO ON

9 P0732 GEAR 2 INCORRECT RATIO ON

10 P0733 GEAR 3 INCORRECT RATIO ON

11 P0734 GEAR 4 INCORRECT RATIO ON

12 P0741 TORQUE CONVERTER CLUTCH STUCK OFF ON

13 P0742 TORQUE CONVERTER CLUTCH STUCK ON ON

14 P0743 TORQUE CONVERTER CLUTCH CONTROL SOLENOID VALVE - OPEN or

SHORT(GND) ON

15 P0748 VFS SOLENOID OFF

16 P0750 LOW and REVERSE SOLENOID VALVE CIRCUIT - OPEN or SHORT(GND) ON

17 P0755 UNDER DRIVE SOLENOID VALVE CIRCUIT - OPEN or SHORT(GND) ON

18 P0760 SECOND SOLENOID VALVE CIRCUIT - OPEN or SHORT(GND) ON

19 P0765 OVERDRIVE SOLENOID VALVE CIRCUIT - OPEN or SHORT(GND) ON

20 P0885 A/T CONTROL RELAY - OPEN or SHORT(GND) ON

21 P0890 TCM power Relay sense circuit low ON

22 P0891 TCM power Relay sense circuit High ON

Failsafe

Activation and deactivation of error failsafe is coordinated Error failsafe Management.

Once Error failsafe is activated, it will be kept until ignition key OFF.

In every new TCM start, TCM start with No Error failsafe and No Error present.

0. Mechanical Limp Home Mode

a. Switch off A/T relay

1. Electrical Limp Home Mode a. Keep 2nd / 3rd gear

2. Prohibit Intelligent Shift a. Fuzzy SAT(Siements Adaptive Transmission) shift pattern (Medium Driver, Sporty Driver) will not be used

Page 365 of 1575

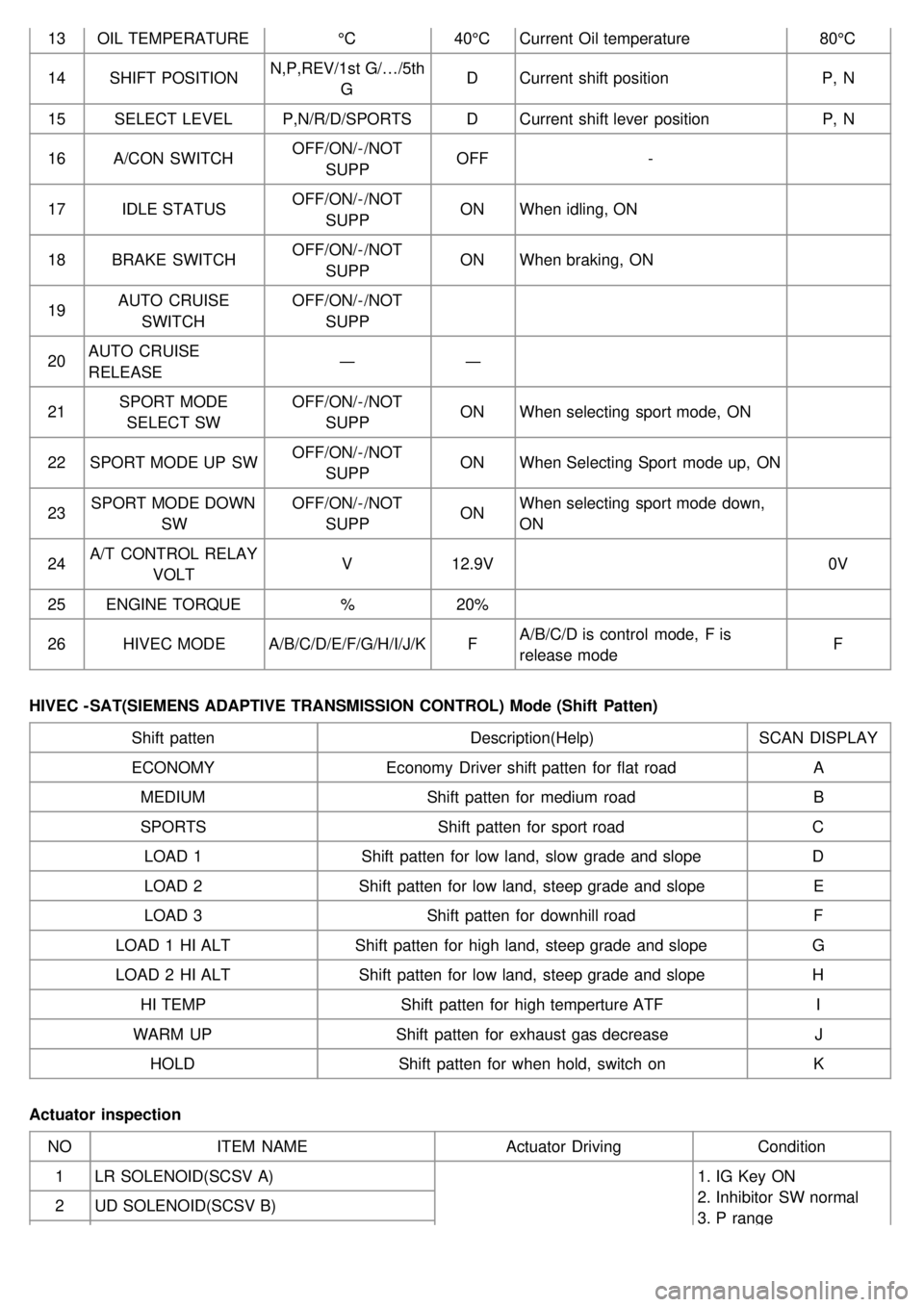

13OIL TEMPERATURE °C40°CCurrent Oil temperature 80°C

14 SHIFT POSITION N,P,REV/1st G/…/5th

G D

Current shift position P, N

15 SELECT LEVEL P,N/R/D/SPORTS DCurrent shift lever position P, N

16 A/CON SWITCH OFF/ON/- /NOT

SUPP OFF

-

17 IDLE STATUS OFF/ON/- /NOT

SUPP ON

When idling, ON

18 BRAKE SWITCH OFF/ON/- /NOT

SUPP ON

When braking, ON

19 AUTO CRUISE

SWITCH OFF/ON/- /NOT

SUPP

20 AUTO CRUISE

RELEASE ―

―

21 SPORT MODE

SELECT SW OFF/ON/- /NOT

SUPP ON

When selecting sport mode, ON

22 SPORT MODE UP SW OFF/ON/- /NOT

SUPP ON

When Selecting Sport mode up, ON

23 SPORT MODE DOWN

SW OFF/ON/- /NOT

SUPP ON

When selecting sport mode down,

ON

24 A/T CONTROL RELAY

VOLT V

12.9V 0V

25 ENGINE TORQUE %20%

26 HIVEC MODE A/B/C/D/E/F/G/H/I/J/K FA/B/C/D is control mode, F is

release mode F

HIVEC - SAT(SIEMENS ADAPTIVE TRANSMISSION CONTROL) Mode (Shift Patten) Shift patten Description(Help)SCAN DISPLAY

ECONOMY Economy Driver shift patten for flat road A

MEDIUM Shift patten for medium road B

SPORTS Shift patten for sport road C

LOAD 1 Shift patten for low land, slow grade and slope D

LOAD 2 Shift patten for low land, steep grade and slope E

LOAD 3 Shift patten for downhill road F

LOAD 1 HI ALT Shift patten for high land, steep grade and slope G

LOAD 2 HI ALT Shift patten for low land, steep grade and slope H

HI TEMP Shift patten for high temperture ATF I

WARM UP Shift patten for exhaust gas decrease J

HOLD Shift patten for when hold, switch on K

Actuator inspection NO ITEM NAME Actuator DrivingCondition

1 LR SOLENOID(SCSV A) 1. IG Key ON

2. Inhibitor SW normal

3. P range

2

UD SOLENOID(SCSV B)

Page 367 of 1575

6c.

Driving at constant

speed of 30 km/h in 2nd

gear

d. Driving at 50 km/h in 3rd

gear with accelerator

fully closed

e. Driving at constant

speed of 50 km/h in 4th

gear (1) 100%, (2) 0%, (3)

100%

Second solenoid valve

(2) 100%, (3) 100%,

(4) 0% Overdrive solenoid valve

(1) 0km/h

(4) 50km/h Vehicle speed sensor

(4) 1,800 ~ 2,100rpm Input shaft speed sensor

(4) 1,800 ~ 2,100rpm Output shaft speed sensor

7 Selector lever position

: D (Carry out on a

flat and straight road)

a.

Accelerate to 4th gear at

a throttle position sensor

output of 1.5V

(accelerator opening

angle of 30 %).

b. Gently decelerate to a

standstill.

c. Accelerate to 4th gear at

a throttle position sensor

output of 2.5 V

(accelerator opening

angle of 50%).

d. While driving at 60 km/h

in 4th gear, shift down

to 3rd gear.

e. While driving at 40 km/h

in 3rd gear, shift down

to 2nd gear.

f. While driving at 20 km/h

in 2nd gear, shift down

to 1st gear. For (1), (2) and (3),

the reading should be

the same as the

specified output shaft

torque, and no

abnormal shocks

should occur.

For (4), (5) and (6),

downshifting should

occur immediately

after the shifting

operation is made.

Malfunction when shifting

Displaced shift points

Does not shift

Does not shift from 1 to 2 or

2 to 1

Does not shift from 2 to 3 or

3 to 2

Does not shift from 3 to 4 or

4 to 3

8 Selector lever position

: N (Carry out on a

flat and straight road)

Move selector lever to R

range drive at constant

speed of 10km/h The ratio between

input and output shaft

speed sensor data

should be the same

as the gear ratio

when reversing.Does not shift

TORQUE CONVERTER STALL TEST

This test measures the maximum engine speed when the selector lever is in the D or R position. The torque converter

stalls to test the operation of the torque converter, starter motor, one- way clutch operation, the holding performance of

the clutches, and brakes in the transaxle.

Do not let anybody stand in front of or behind the vehicle while this test is being carried out

1. Check the automatic transmission fluid level and temperature, and the engine coolant temperature.

a. Fluid level : At the HOT mark on the oil level gauge

b. Fluid temperature : 80~100°C (176~212°F)

c. Engine coolant temperature : 80~100°C(176~212°F)

2. Prevent all the wheels from moving during the test.

3. Pull the parking brake lever up, with the brake pedal fully depressed.

4. Start the engine.