wheel KIA CEED 2013 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2013, Model line: CEED, Model: KIA CEED 2013Pages: 1168, PDF Size: 48.01 MB

Page 1016 of 1168

611

What to do in an emergency

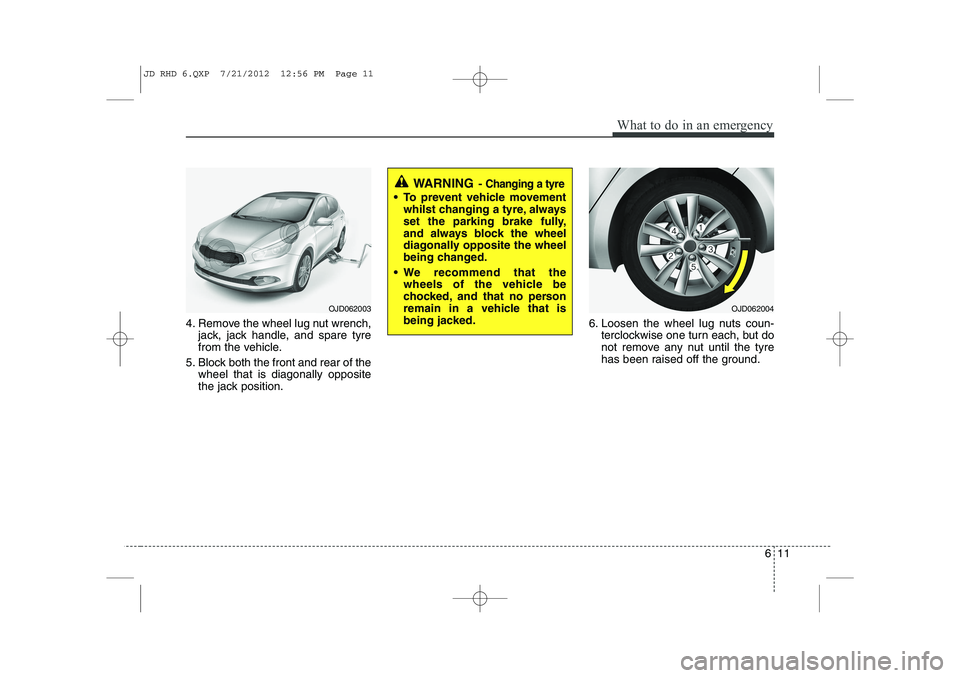

4. Remove the wheel lug nut wrench,jack, jack handle, and spare tyre

from the vehicle.

5. Block both the front and rear of the wheel that is diagonally opposite

the jack position. 6. Loosen the wheel lug nuts coun-

terclockwise one turn each, but do

not remove any nut until the tyre

has been raised off the ground.

WARNING - Changing a tyre

To prevent vehicle movement

whilst changing a tyre, always

set the parking brake fully,

and always block the wheel

diagonally opposite the wheel

being changed.

We recommend that the wheels of the vehicle be

chocked, and that no person

remain in a vehicle that is

being jacked.

OJD062003OJD062004

JD RHD 6.QXP 7/21/2012 12:56 PM Page 11

Page 1017 of 1168

What to do in an emergency

12

6

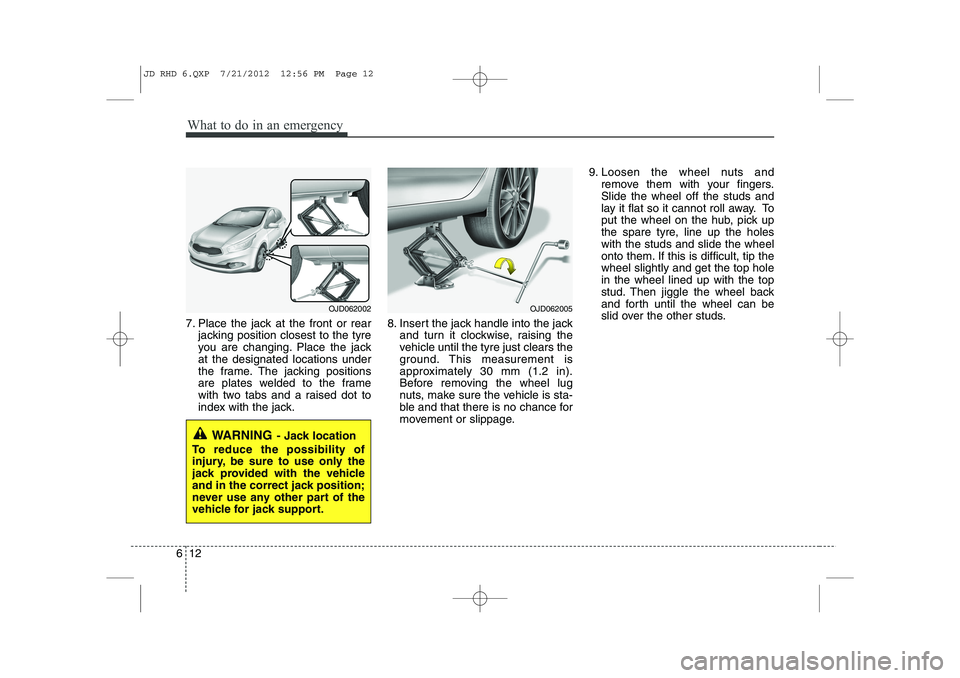

7. Place the jack at the front or rear

jacking position closest to the tyre

you are changing. Place the jackat the designated locations under

the frame. The jacking positions

are plates welded to the frame

with two tabs and a raised dot to

index with the jack. 8. Insert the jack handle into the jack

and turn it clockwise, raising the

vehicle until the tyre just clears the

ground. This measurement is

approximately 30 mm (1.2 in).

Before removing the wheel lug

nuts, make sure the vehicle is sta-

ble and that there is no chance for

movement or slippage. 9. Loosen the wheel nuts and

remove them with your fingers.Slide the wheel off the studs and

lay it flat so it cannot roll away. To

put the wheel on the hub, pick up

the spare tyre, line up the holeswith the studs and slide the wheel

onto them. If this is difficult, tip thewheel slightly and get the top holein the wheel lined up with the top

stud. Then jiggle the wheel back

and forth until the wheel can be

slid over the other studs.

WARNING - Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

OJD062002OJD062005

JD RHD 6.QXP 7/21/2012 12:56 PM Page 12

Page 1018 of 1168

613

What to do in an emergency

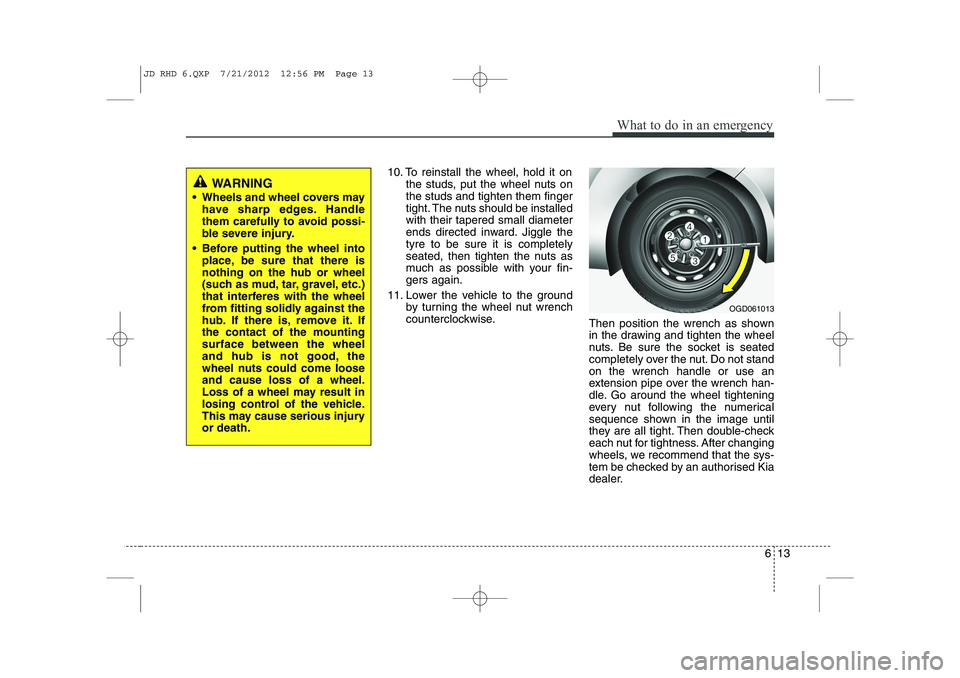

10. To reinstall the wheel, hold it onthe studs, put the wheel nuts on the studs and tighten them finger

tight. The nuts should be installedwith their tapered small diameter

ends directed inward. Jiggle thetyre to be sure it is completely

seated, then tighten the nuts as

much as possible with your fin-gers again.

11. Lower the vehicle to the ground by turning the wheel nut wrench

counterclockwise. Then position the wrench as shown

in the drawing and tighten the wheel

nuts. Be sure the socket is seated

completely over the nut. Do not standon the wrench handle or use an

extension pipe over the wrench han-

dle. Go around the wheel tightening

every nut following the numerical

sequence shown in the image until

they are all tight. Then double-check

each nut for tightness. After changing

wheels, we recommend that the sys-

tem be checked by an authorised Kia

dealer.

WARNING

Wheels and wheel covers may have sharp edges. Handle

them carefully to avoid possi-

ble severe injury.

Before putting the wheel into place, be sure that there isnothing on the hub or wheel

(such as mud, tar, gravel, etc.)

that interferes with the wheel

from fitting solidly against the

hub. If there is, remove it. Ifthe contact of the mountingsurface between the wheel

and hub is not good, the

wheel nuts could come looseand cause loss of a wheel.

Loss of a wheel may result in

losing control of the vehicle.

This may cause serious injuryor death.

OGD061013

JD RHD 6.QXP 7/21/2012 12:56 PM Page 13

Page 1019 of 1168

What to do in an emergency

14

6

Wheel nut tightening torque:

Steel wheel & aluminium alloy wheel:

9~11 kg.m (65~79 lb.ft)

If you have a tyre gauge, remove the

valve cap and check the air pressure.

If the pressure is lower than recom-

mended, drive slowly to the nearest

service station and inflate to the cor-

rect pressure. If it is too high, adjust

it until it is correct. Always reinstall

the valve cap after checking or

adjusting tyre pressure. If the cap is

not replaced, air may leak from the

tyre. If you lose a valve cap, buyanother and install it as soon as pos-

sible.

After you have changed wheels,

always secure the flat tyre in its place

and return the jack and tools to their

proper storage locations. To prevent the jack, jack handle,

wheel lug nut wrench and spare tyre

from rattling whilst the vehicle is in

motion, store them properly.CAUTION

Your vehicle has metric threads

on the wheel studs and nuts.Make certain during wheel removal that the same nuts thatwere removed are reinstalled -or, if replaced, that nuts with metric threads and the samechamfer configuration are used.Installation of a non-metric thread nut on a metric stud orvice-versa will not secure thewheel to the hub properly andwill damage the stud so that it must be replaced.

Note that most lug nuts do nothave metric threads. Be sure touse extreme care in checking for thread style before installingaftermarket lug nuts or wheels.If in doubt, we recommend thatyou consult an authorised Kia dealer.

WARNING - Wheel studs

If the studs are damaged, they

may lose their ability to retain

the wheel. This could lead to theloss of the wheel and a collisionresulting in serious injuries.

WARNING - Inadequate

spare tyre pressure

Check the inflation pressures as

soon as possible after installing

the spare tyre. Adjust it to the

specified pressure, if necessary.

Refer to “Tyres and wheels” insection 8.

JD RHD 6.QXP 7/21/2012 12:56 PM Page 14

Page 1021 of 1168

What to do in an emergency

16

6

Do not take this vehicle through an

automatic car wash whilst the com- pact spare tyre is installed.

Do not use tyre chains on the com- pact spare tyre. Because of the

smaller size, a tyre chain will not fit

properly. This could damage the

vehicle and result in loss of thechain.

The compact spare tyre should not be installed on the front axle if the

vehicle must be driven in snow or

on ice.

Do not use the compact spare tyre on any other vehicle because thistyre has been designed especially

for your vehicle.

The compact spare tyre’s tread life is shorter than a regular tyre.

Inspect your compact spare tyre

regularly and replace worn com-

pact spare tyres with the same sizeand design, mounted on the samewheel. The compact spare tyre should not

be used on any other wheels, nor

should standard tyres, snow tyres,

wheel covers or trim rings be used

with the compact spare wheel. Ifsuch use is attempted, damage tothese items or other car compo-

nents may occur.

Do not use more than one compact spare tyre at a time.

Do not tow a trailer whilst the com- pact spare tyre is installed.

JD RHD 6.QXP 7/21/2012 12:56 PM Page 16

Page 1023 of 1168

What to do in an emergency

18

6

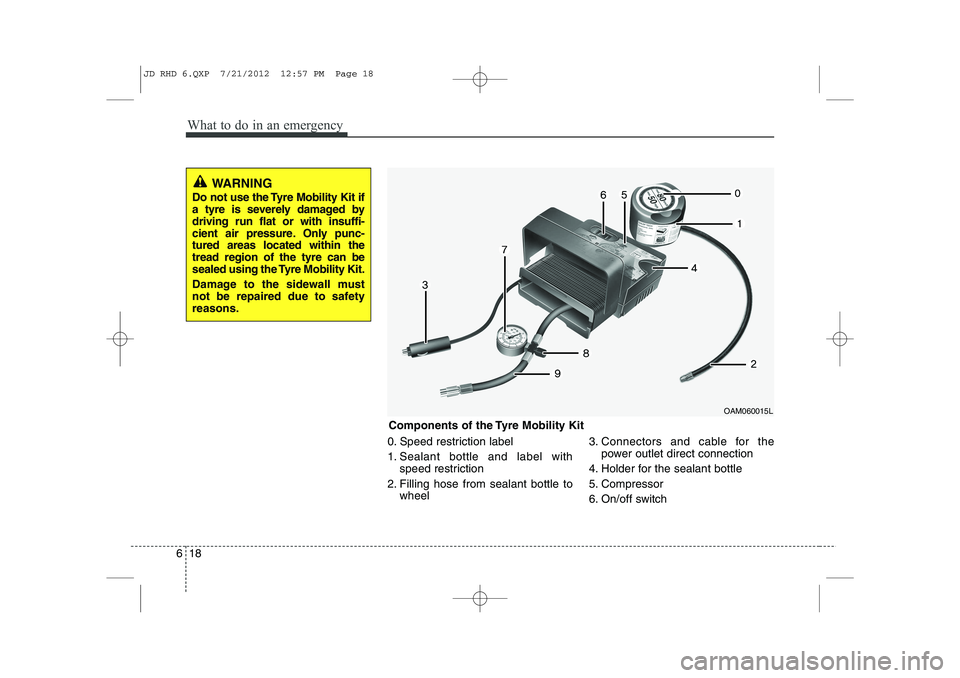

0. Speed restriction label

1. Sealant bottle and label with

speed restriction

2. Filling hose from sealant bottle to wheel 3. Connectors and cable for the

power outlet direct connection

4. Holder for the sealant bottle

5. Compressor

6. On/off switch

WARNING

Do not use the Tyre Mobility Kit if

a tyre is severely damaged bydriving run flat or with insuffi-

cient air pressure. Only punc-tured areas located within thetread region of the tyre can be

sealed using the Tyre Mobility Kit.

Damage to the sidewall must

not be repaired due to safetyreasons.

Components of the Tyre Mobility Kit OAM060015L

JD RHD 6.QXP 7/21/2012 12:57 PM Page 18

Page 1024 of 1168

619

What to do in an emergency

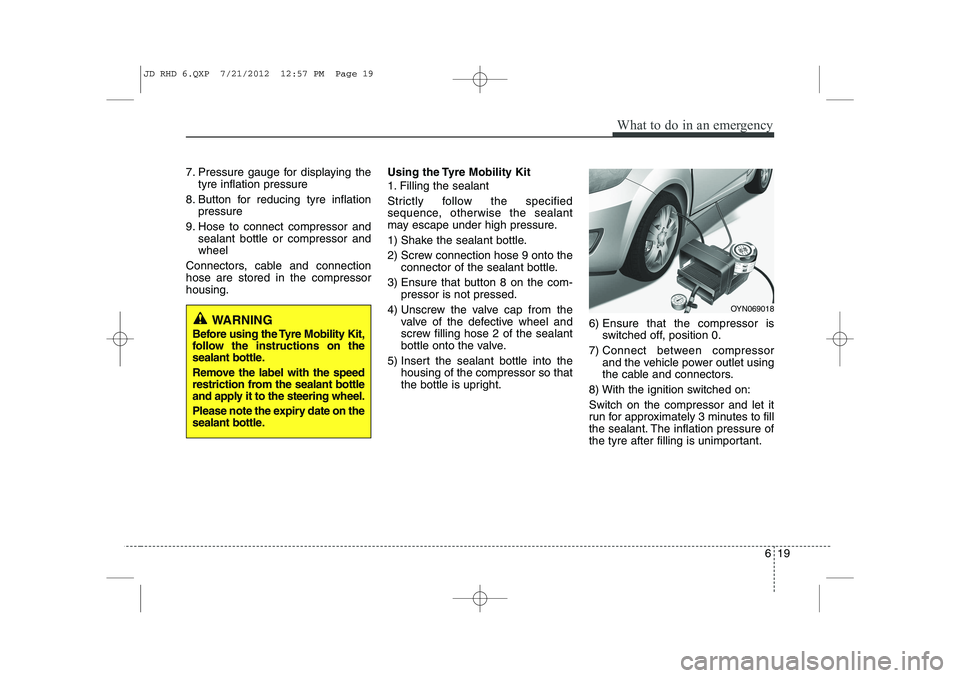

7. Pressure gauge for displaying thetyre inflation pressure

8. Button for reducing tyre inflation pressure

9. Hose to connect compressor and sealant bottle or compressor and wheel

Connectors, cable and connectionhose are stored in the compressorhousing. Using the Tyre Mobility Kit

1. Filling the sealant

Strictly follow the specified

sequence, otherwise the sealant

may escape under high pressure.

1) Shake the sealant bottle.

2) Screw connection hose 9 onto the

connector of the sealant bottle.

3) Ensure that button 8 on the com- pressor is not pressed.

4) Unscrew the valve cap from the valve of the defective wheel and

screw filling hose 2 of the sealant

bottle onto the valve.

5) Insert the sealant bottle into the housing of the compressor so that

the bottle is upright. 6) Ensure that the compressor is

switched off, position 0.

7) Connect between compressor and the vehicle power outlet using

the cable and connectors.

8) With the ignition switched on: Switch on the compressor and let it

run for approximately 3 minutes to fill

the sealant. The inflation pressure of

the tyre after filling is unimportant.

OYN069018

WARNING

Before using the Tyre Mobility Kit,

follow the instructions on the

sealant bottle.

Remove the label with the speed

restriction from the sealant bottle

and apply it to the steering wheel.

Please note the expiry date on the

sealant bottle.

JD RHD 6.QXP 7/21/2012 12:57 PM Page 19

Page 1027 of 1168

What to do in an emergency

22

6

Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A

Suitable for use at temperatures:

-30 ~ +70°C (-22 ~ +158°F)

Max. working pressure: 6 bar (87 psi)

Size (for 15´´, 16´´ wheel)

Compressor: 170 x 150 x 60 mm (6.7 x 5.9 x 2.4 in.)

Sealant bottle: 85 x 77 ø mm (3.3 x 3.0 ø in.)

Compressor weight: 0.8 kg (1.8 lbs)

Sealant volume: 200 ml (12.2 cu. in.)

Size (for 17´´ wheel)

Compressor: 168 x 150 x 68 mm (6.6 x 5.9 x 2.7 in.)

Sealant bottle: 104 x ø 85 mm (4.1 x ø 3.3 in.)

Compressor weight: 1.05 kg (2.31 lbs)

Sealant volume: 300 ml (18.3 cu. in.) ❈

Sealing compound and spare

parts can be obtained and

replaced at an authorised vehicle

or tyre dealer. Empty sealing com-

pound bottles may be disposed of

at home. Liquid residue from thesealing compound should be dis-

posed of by your vehicle or tyredealer or in accordance with local

waste disposal regulations.CAUTION - TPMS (if equipped )

When using Tyre Mobility Kit,

the tyre sealant can damage thetyre pressure sensor. After using the Tyre Mobility Kit, werecommend that the tyre pres-sure sensor be checked by an authorised Kia dealer.

JD RHD 6.QXP 7/21/2012 12:57 PM Page 22

Page 1029 of 1168

What to do in an emergency

24

6

TPMS malfunctions may occur for a

variety of reasons, including theinstallation of replacement or alter-

nate tyres or wheels on the vehicle

that prevent the TPMS from function-

ing properly. Always check theTPMS malfunction telltale afterreplacing one or more tyres or

wheels on your vehicle to ensure that

the replacement or alternate tyres

and wheels allow the TPMS to con-

tinue to function properly.

✽✽

NOTICE

If any of the below happens, we rec- ommend that the system be checked

by an authorised Kia dealer.

1.The low tyre pressure telltale/ TPMS malfunction indicator do

not illuminate for 3 seconds whenthe ignition switch is turned to theON position.

2. The TPMS malfunction indicator remains illuminated after blinking

for approximately 1 minute.

3. The Low tyre pressure position telltale remains illuminated.

Low tyre pressure tell- tale

Low tyre pressure posi- tion telltale

When the tyre pressure monitoring

system warning indicators are illumi-

nated, one or more of your tyres is

significantly under-inflated. The lowtyre pressure position telltale lightwill indicate which tyre is significant-

ly under-inflated by illuminating thecorresponding position light.

If either telltale illuminates, immedi-

ately reduce your speed, avoid hard

cornering and anticipate increased

stopping distances. You should stop

and check your tyres as soon as pos-

sible. Inflate the tyres to the proper

pressure as indicated on the vehi-

cle’s placard or tyre inflation pres-

sure label located on the driver’s side

centre pillar outer panel. If you can-

not reach a service station or if the

tyre cannot hold the newly added air,

replace the low pressure tyre with a

spare tyre. If you drive the vehicle for about 10

minutes at speeds above 25 km/h

after replaceing the low pressure tyre

with the spare tyre, one of the follow-ing will happen:

The TPMS malfunction indicator

may blink for approximately 1

minute and then remain continuous-

ly illuminated because the TPMSsensor is not mounted on the spare

wheel. (changed tyre equipped with

a sensor not in the vehicle)

The TPMS malfunction indicator will remain continuously illuminated

whilst driving because the TPMSsensor is not mounted on the spare

wheel. (changed tyre equipped with

a sensor in the vehicle)

JD RHD 6.QXP 7/26/2012 6:00 PM Page 24

Page 1031 of 1168

What to do in an emergency

26

6

Changing a tyre with TPMS

If you have a flat tyre, the low Tyre

Pressure and Position telltales will

come on. We recommend that the

system be checked by an authorised

Kia dealer. Each wheel is equipped with a tyre pressure sensor mounted inside the

tyre behind the valve stem. You must

use TPMS specific wheels. It is rec-

ommended that you have your tyres

serviced by an authorised Kia dealer. If you drive the vehicle for about 10

minutes at speeds above 25 km/h

after replaceing the low pressure tyre

with the spare tyre, one of the follow-ing will happen:

The TPMS malfunction indicator

may blink for approximately 1

minute and then remain continuous-

ly illuminated because the TPMSsensor is not mounted on the spare

wheel. (changed tyre equipped with

a sensor not in the vehicle)

The TPMS malfunction indicator will remain continuously illuminated

whilst driving because the TPMSsensor is not mounted on the spare

wheel. (changed tyre equipped with

a sensor in the vehicle)CAUTION

The TPMS malfunction indica-

tor may blink for approximate-ly 1 minute and then remaincontinuously illuminated if thevehicle is moving around elec- tric power supply cables orradios transmitter such as atpolice stations, government and public offices, broadcast-ing stations, military installa-tions, airports, or transmitting towers, etc. This can interferewith normal operation of theTyre Pressure Monitoring System (TPMS).

The TPMS malfunction indica- tor may blink for approximate-ly 1 minute and then remaincontinuously illuminated if snow chains are used or someseparate electronic devicessuch as notebook computer, mobile charger, remote starteror navigation etc., are used inthe vehicle. This can interfere with normal operation of theTyre Pressure MonitoringSystem (TPMS).

CAUTION

We recommend that you use thesealant approved by Kia.

The sealant on the tyre pressuresensor and wheel shall be elem-inated when you replace the tyre with a new one.

JD RHD 6.QXP 7/21/2012 12:57 PM Page 26