battery KIA CEED 2015 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2015, Model line: CEED, Model: KIA CEED 2015Pages: 1210, PDF Size: 35.92 MB

Page 1034 of 1210

What to do in an emergency

4

6

IF THE ENGINE WILL NOT START

If engine doesn't turn over or

turns over slowly

1. If your vehicle has an automatic transaxle, be sure the shift lever is in N

(Neutral) or P (Park) and the emer-

gency brake is set.

2. Check the battery connections to be sure they are clean and tight.

3. Turn on the interior light. If the light dims or goes out when you operate the

starter, the battery is discharged.

4. Check the starter connections to be sure they are securely tightened.

5. Do not push or pull the vehicle to start it. See instructions for "Jump starting". If engine turns over normally but

does not start

1. Check fuel level.

2. With the ignition switch in the LOCK/

OFF position, check all connectors at

ignition, coil and spark plugs.

Reconnect any that may be discon-

nected or loose.

3. Check the fuel line in the engine com- partment.

4. If the engine still does not start, we recommend that you call an autho-

rised Kia dealer.

WARNING

If the engine does not start, do not

push or pull the vehicle to start it.This could result in a collision or

cause other damage. In addition,

push or pull starting may cause the

catalytic converter (if equipped) to

be overloaded and create a fire haz-

ard.

JD RHD 6.QXP 2/17/2015 11:15 AM Page 4

Page 1035 of 1210

65

What to do in an emergency

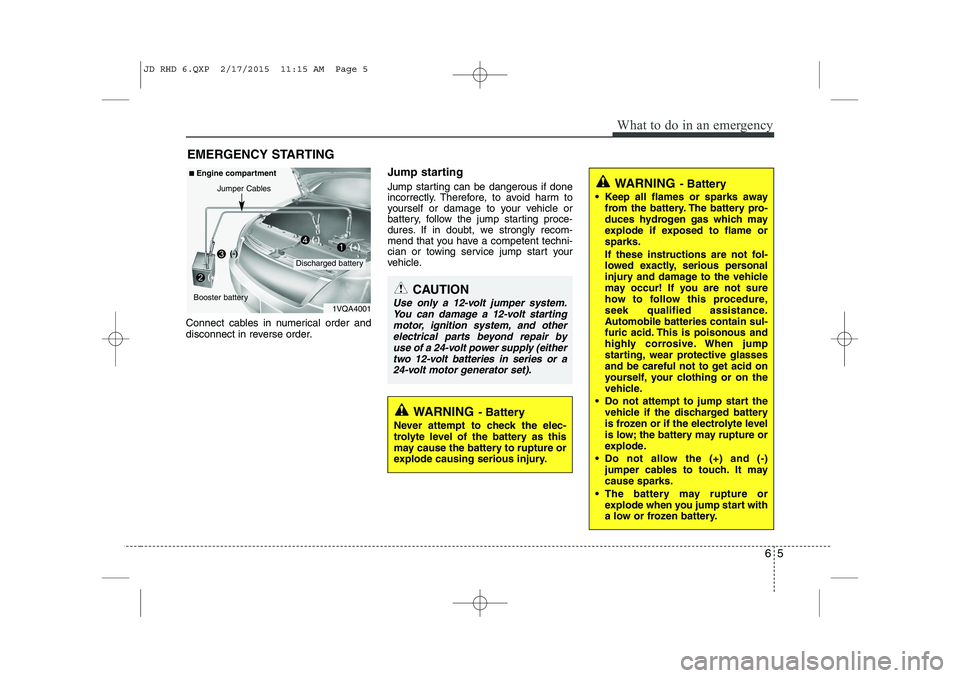

EMERGENCY STARTING

Connect cables in numerical order and

disconnect in reverse order. Jump starting

Jump starting can be dangerous if done

incorrectly. Therefore, to avoid harm to

yourself or damage to your vehicle or

battery, follow the jump starting proce-

dures. If in doubt, we strongly recom-

mend that you have a competent techni-

cian or towing service jump start your

vehicle.

CAUTION

Use only a 12-volt jumper system.

You can damage a 12-volt starting motor, ignition system, and otherelectrical parts beyond repair by

use of a 24-volt power supply (eithertwo 12-volt batteries in series or a 24-volt motor generator set).

WARNING - Battery

• Keep all flames or sparks away from the battery. The battery pro-

duces hydrogen gas which may

explode if exposed to flame orsparks.

If these instructions are not fol-

lowed exactly, serious personal

injury and damage to the vehicle

may occur! If you are not sure

how to follow this procedure,

seek qualified assistance.

Automobile batteries contain sul-

furic acid. This is poisonous and

highly corrosive. When jump

starting, wear protective glasses

and be careful not to get acid on

yourself, your clothing or on the

vehicle.

Do not attempt to jump start the vehicle if the discharged battery

is frozen or if the electrolyte level

is low; the battery may rupture or

explode.

Do not allow the (+) and (-) jumper cables to touch. It maycause sparks.

The battery may rupture or explode when you jump start with

a low or frozen battery.

WARNING - Battery

Never attempt to check the elec-

trolyte level of the battery as this

may cause the battery to rupture or

explode causing serious injury.

1VQA4001

Discharged battery

Jumper Cables

■

Engine compartment

Booster battery(-)

(+)

(+)(-)

JD RHD 6.QXP 2/17/2015 11:15 AM Page 5

Page 1036 of 1210

What to do in an emergency

6

6

Jump starting procedure ✽✽

NOTICE

If the battery is discharged, the engine

can be started using a battery of anoth-

er vehicle and two jumper cables. Only

use jumper cables with fully insulated

clamp handles.

To prevent personal injury or damage to

both vehicles, adhere strictly to the fol-

lowing procedure.

1. Make sure the booster battery is 12- volt and that its negative terminal is

grounded.

2. If the booster battery is in another vehicle, do not allow the vehicles totouch.

3. Turn off all unnecessary electrical loads. 4. Connect the jumper cables in the exact

sequence shown in the illustration.First connect one end of a jumper

cable to the positive terminal of the

discharged battery (1), then connect

the other end to the positive terminal

on the booster battery (2). Proceed toconnect one end of the other jumper

cable to the negative terminal of the

booster battery (3), then the other end

to a solid, stationary, metallic point (for

example, the engine lifting bracket)

away from the battery (4). Do not con-

nect it to or near any part that moves

when the engine is cranked. Make

sure that there is no contact between

the bodywork of the two vehicles; oth-

erwise, there is the danger of short cir-

cuits.

Do not allow the jumper cables to con-

tact anything except the correct battery

terminals or the correct ground. Do not

lean over the battery when making

connections.

CAUTION - Battery cables

Do not connect the jumper cable from

the negative terminal of the booster battery to the negative terminal of thedischarged battery. This can cause

the discharged battery to overheatand crack, releasing battery acid.

CAUTION -AGM battery (if equipped)

Absorbent Glass Matt (AGM) bat-

teries are maintenance-free andwe recommend that the AGM bat-

teries be serviced by an autho-rised Kia dealer. For chargingyour AGM battery, use only fully

automatic battery chargers thatare specially developed for AGMbatteries.

When replacing the AGM battery, we recommend that you use parts

for replacement from an autho-rised Kia dealer.

Do not open or remove the cap on top of the battery. This may cause

leaks of internal electrolyte thatcould result in severe injury.

If the AGM battery is reconnected or replaced, ISG function will notoperate immediately.

If you want to use the ISG func-tion, the battery sensor needs to be calibrated for approximately 4hours with the ignition off.

JD RHD 6.QXP 2/17/2015 11:15 AM Page 6

Page 1037 of 1210

67

What to do in an emergency

5. Start the engine of the vehicle with thebooster battery and let it run at 2,000

rpm, then start the engine of the vehi-

cle with the discharged battery. If the

first starting attempt is not successful,

wait a few minutes before making

another attempt in order to allow the

discharged battery to recharge.

If the cause of your battery discharging is

not apparent, we recommend that the system be checked by an authorised Kia

dealer.

Push-starting

Your manual transaxle-equipped vehicle

should not be push-started because itmight damage the emission control sys-

tem. Vehicles equipped with automatic

transaxle cannot be push-started. Follow

the directions in this section for jump-

starting.

WARNING

Never tow a vehicle to start it

because the sudden surge forward

when the engine starts could cause

a collision with the tow vehicle.

JD RHD 6.QXP 2/17/2015 11:15 AM Page 7

Page 1053 of 1210

623

What to do in an emergency

Notes on the safe use of the

TyreMobilityKit

Park your car at the side of theroad so that you can work with the

TyreMobilityKit away from moving

traffic. Place your warning triangle

in a prominent place to make pass-

ing vehicles aware of your location.

To be sure your vehicle won't move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the TyreMobilityKit for sealing/inflation passenger car

tyres. Do not use on motorcycles,

bicycles or any other type of tyres.

Do not remove any foreign objects- such as nails or screws -that have

penetrated the tyre.

Before using the TyreMobilityKit, read the precautionary advice

printed on the sealant bottle!

Provided the car is outdoors, leave the engine running. Otherwise

operating the compressor may

eventually drain the car battery. Never leave the TyreMobilityKit

unattended whilst it is being used.

Do not leave the compressor run- ning for more than 10 min. at a time

or it may overheat.

Do not use the TyreMobilityKit if the ambient temperature is below -30°C(-22°F).

Do not use the sealing compound after its expiration date which can

be found on the label of the bottle.

Keep away from children. Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 10A ± 1A

(at DC 12V operation)

Suitable for use at temperatures: -30 ~ +70°C (-22 ~ +158°F)

Max. working pressure: 6 bar (87 psi)

Size

Compressor: 161 X 150 X 55.8 mm (6.3 X 5.9 X 2.2 in.)

Sealant bottle: 81 x ø 85 mm (3.2 x ø 3.3 in.)

Compressor weight: 735 g ± 25 g (1.62 lbs ± 0.06 lbs)

Sealant volume: 200 ml (12.2 cu. in.)

❈ Sealing compound and spare

parts can be obtained and

replaced at an authorised vehicle

or tyre dealer. Empty sealing com-

pound bottles may be disposed of

at home. Liquid residue from thesealing compound should be dis-

posed of by your vehicle or tyredealer or in accordance with local

waste disposal regulations.

JD RHD 6.QXP 2/17/2015 11:16 AM Page 23

Page 1064 of 1210

Maintenance

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-6 Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Owner maintenance precautions . . . . . . . . . . . . . . . . 7-6

Engine compartment precautions (Diesel engine). . . 7-7

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-9 Owner maintenance schedule . . . . . . . . . . . . . . . . . . . 7-9

Scheduled maintenance service . . . . . . . . . . . . . . . 7-11 For Europe, Except Russia . . . . . . . . . . . . . . . . . . . . . 7-12

Except Russia, for Russia . . . . . . . . . . . . . . . . . . . . . . 7-23

Explanation of scheduled maintenance items . . . . 7-35

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38 Checking the engine oil level . . . . . . . . . . . . . . . . . . . . 7-38

Changing the engine oil and filter . . . . . . . . . . . . . . . 7-39

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40 Checking the coolant level . . . . . . . . . . . . . . . . . . . . . . 7-40

Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43 Checking the brake/clutch fluid level. . . . . . . . . . . . . 7-43

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44 Checking the washer fluid level . . . . . . . . . . . . . . . . . 7-44

Parking brake - hand type . . . . . . . . . . . . . . . . . . . 7-44 Checking the parking brake . . . . . . . . . . . . . . . . . . . . 7-44

Fuel filter (for Diesel) . . . . . . . . . . . . . . . . . . . . . . . 7-45 Draining water from fuel filter . . . . . . . . . . . . . . . . . . 7-45 Extracting air from the fuel filter . . . . . . . . . . . . . . . . 7-45

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46 Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Climate control air filter . . . . . . . . . . . . . . . . . . . . . 7-48 Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50 Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53 For best battery service . . . . . . . . . . . . . . . . . . . . . . . . 7-53

Battery capacity label . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Battery recharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Reset items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Tyres and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56 Tyre care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Recommended cold tyre inflation pressures . . . . . . . 7-56

Checking tyre inflation pressure. . . . . . . . . . . . . . . . . 7-58

Tyre rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Wheel alignment and tyre balance . . . . . . . . . . . . . . . 7-60

Tyre replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

Wheel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Tyre traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Tyre maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Tyre sidewall labeling. . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Low aspect ratio tyre . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

7

JD RHD 7.QXP 4/14/2015 6:29 PM Page 1

Page 1066 of 1210

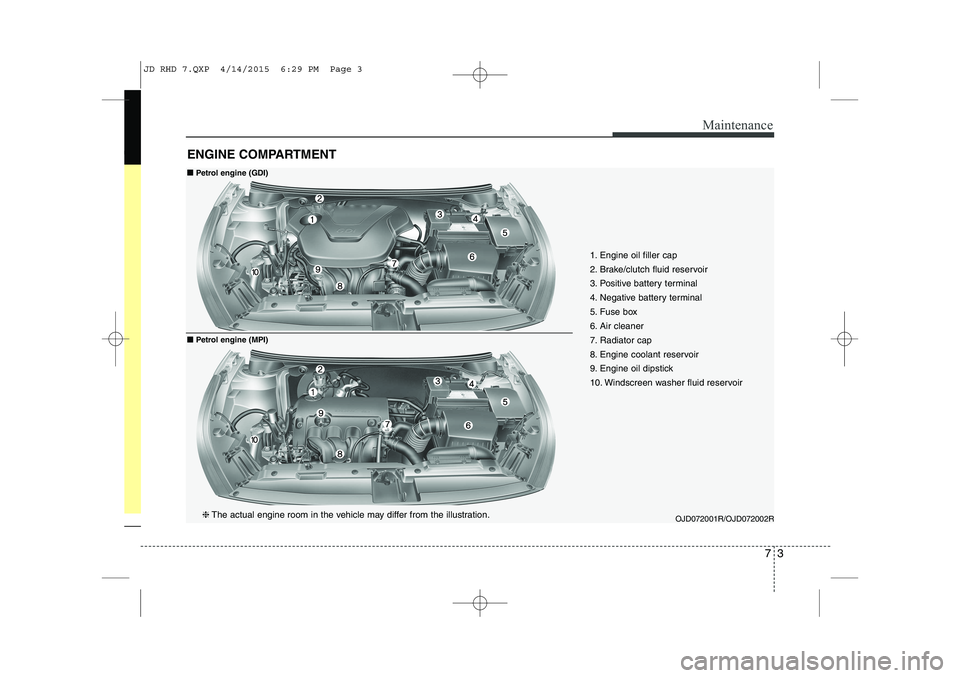

73

Maintenance

ENGINE COMPARTMENT

OJD072001R/OJD072002R

❈

The actual engine room in the vehicle may differ from the illustration. 1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

■■

Petrol engine (GDI)

■■Petrol engine (MPI)

JD RHD 7.QXP 4/14/2015 6:29 PM Page 3

Page 1067 of 1210

Maintenance

4

7

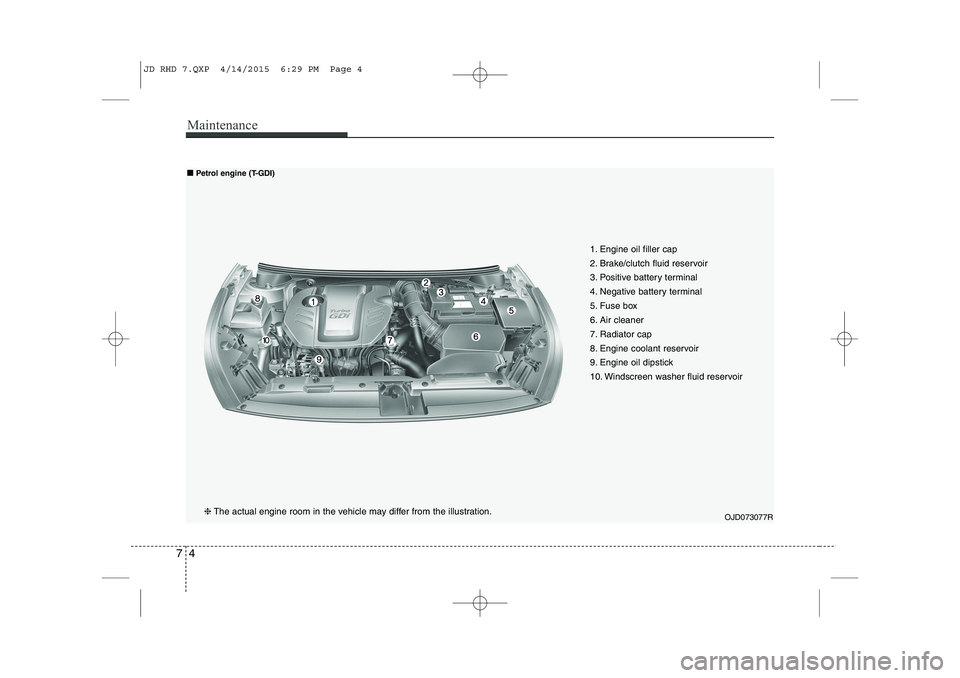

1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

OJD073077R❈ The actual engine room in the vehicle may differ from the illustration.

■

■

Petrol engine (T-GDI)

JD RHD 7.QXP 4/14/2015 6:29 PM Page 4

Page 1068 of 1210

75

Maintenance

OJD072003R

❈

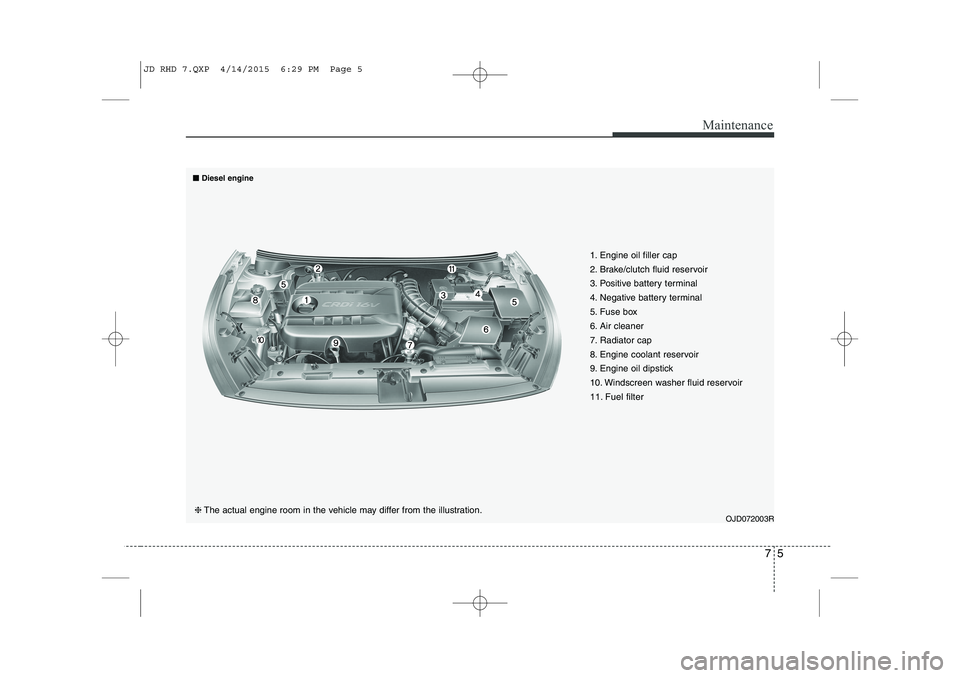

The actual engine room in the vehicle may differ from the illustration. 1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

11. Fuel filter

■■

Diesel engine

JD RHD 7.QXP 4/14/2015 6:29 PM Page 5

Page 1070 of 1210

77

Maintenance

Engine compartment precautions (Diesel engine)

• The injector operates at high voltage(maximum 200v). Therefore, the follow-

ing accidents may occur.

- Direct contact with the injector or

injector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause the arti-

ficial heart pacemaker to malfunction.

Follow the safety tips provided below, when you are checking the engine

room whilst the engine is running.

- Do not touch the injector, injector

wirings, and the engine computer

whilst the engine is running.

- Do not remove the injector connector whilst the engine is running.

- People using pacemakers must not go near the engine whilst the engine

is starting or running.

WARNING - Maintenance

work

Performing maintenance work on a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, we recommend that the

system be serviced by an autho-

rised Kia dealer.

Working under the bonnet with the engine running is dangerous.

It becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before gettingnear the engine or cooling fans.CAUTION

Do not put heavy objects or apply

excessive force on top of the

engine cover (if equipped) or fuel related parts.

When you inspect the fuel system (fuel lines and fuel injection

devices), we recommend that you contact an authorised Kia dealer.

Do not drive long time with the engine cover (if equipped)removed.

When checking the engine room, do not go near fire.

Fuel, washer fluid, etc. are flam-mable oils that may cause fire.

Before touching the battery, igni- tion cables and electrical wiring,

you should disconnect the battery"-" terminal. You may get an elec-tric shock from the electric current.

When you remove the interior trim cover with a flat bed (-) driver, be

careful not to damage the cover.

Be careful when you replace and clean bulbs to avoid burns orelectrical shock.

JD RHD 7.QXP 4/14/2015 6:29 PM Page 7