KIA CERATO 2005 Owners Manual

Manufacturer: KIA, Model Year: 2005, Model line: CERATO, Model: KIA CERATO 2005Pages: 318, PDF Size: 58.49 MB

Page 271 of 318

727

Maintenance

1 23456789

DRIVE BELTSDrive belts should be checked peri-

odically for proper tension and

adjusted if necessary. At the same

time, belts should be examined for

cracks, wear, fraying or other evi-

dence of deterioration and replaced

if necessary.

Belt routing should also be checked

to be sure there is no interference

between the belts and other parts of

the engine. After a belt is replaced,

the new belt should be adjusted

again after two or three weeks to

eliminate slack resulting from initial

stretching after use. Checking the compressor drive belt When the air conditioning is being

used regularly, the compressor drive

belt tension should be checked atleast once a month.

To check the drive belt tension, turn

the engine off, press down on the

belt halfway between the engine

crankshaft and compressor pulleys.

Pressing with your finger, you should

not be able to deflect this belt any-

more than 8.5 mm (0.33 in). If you

have the instruments to check it, with

a force of 98 N (22 lb.), the deflection

should be 8.0 mm (0.315 in). If the

belt is too loose, have it adjusted by

an authorized Kia Dealer.

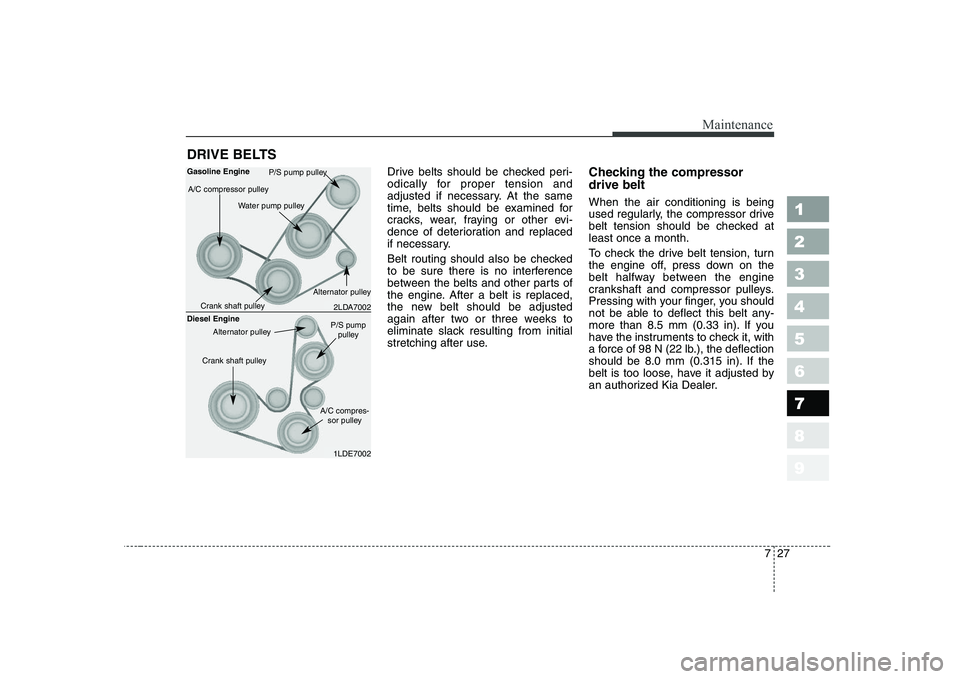

2LDA7002

A/C compressor pulley

P/S pump pulley

Water pump pulley

Crank shaft pulley Alternator pulley

Gasoline Engine

1LDE7002

Diesel Engine

Crank shaft pulley

Alternator pulleyP/S pumppulley

A/C compres- sor pulley

Page 272 of 318

Maintenance

28

7

1 23456789

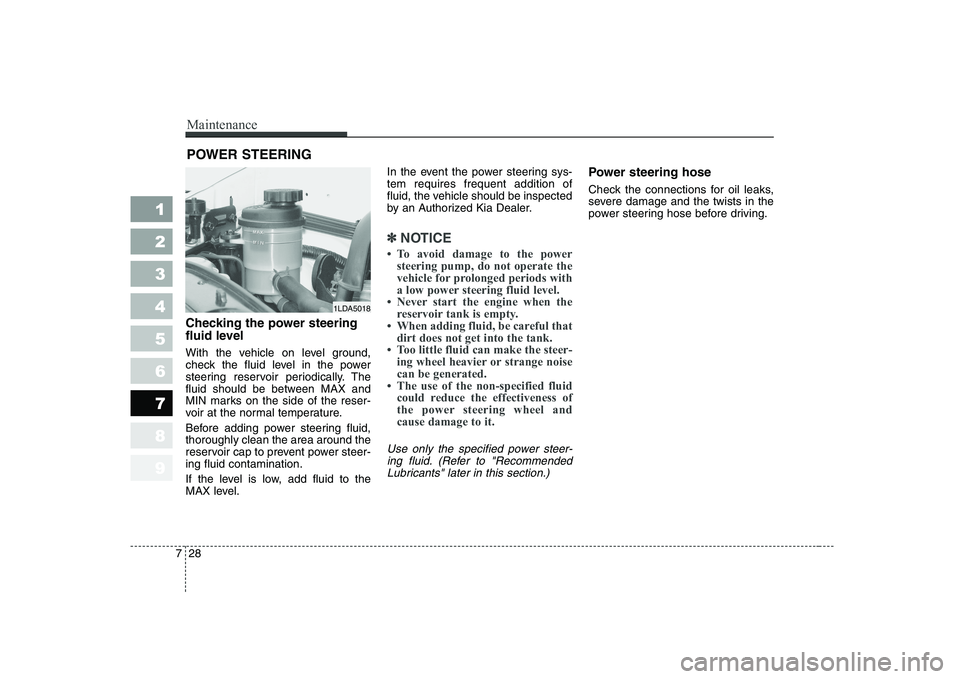

POWER STEERING

Checking the power steering

fluid level

With the vehicle on level ground,

check the fluid level in the power

steering reservoir periodically. The

fluid should be between MAX and

MIN marks on the side of the reser-

voir at the normal temperature.

Before adding power steering fluid, thoroughly clean the area around the

reservoir cap to prevent power steer-ing fluid contamination.

If the level is low, add fluid to the

MAX level. In the event the power steering sys-tem requires frequent addition of

fluid, the vehicle should be inspected

by an Authorized Kia Dealer.

✽✽

NOTICE

Page 273 of 318

729

Maintenance

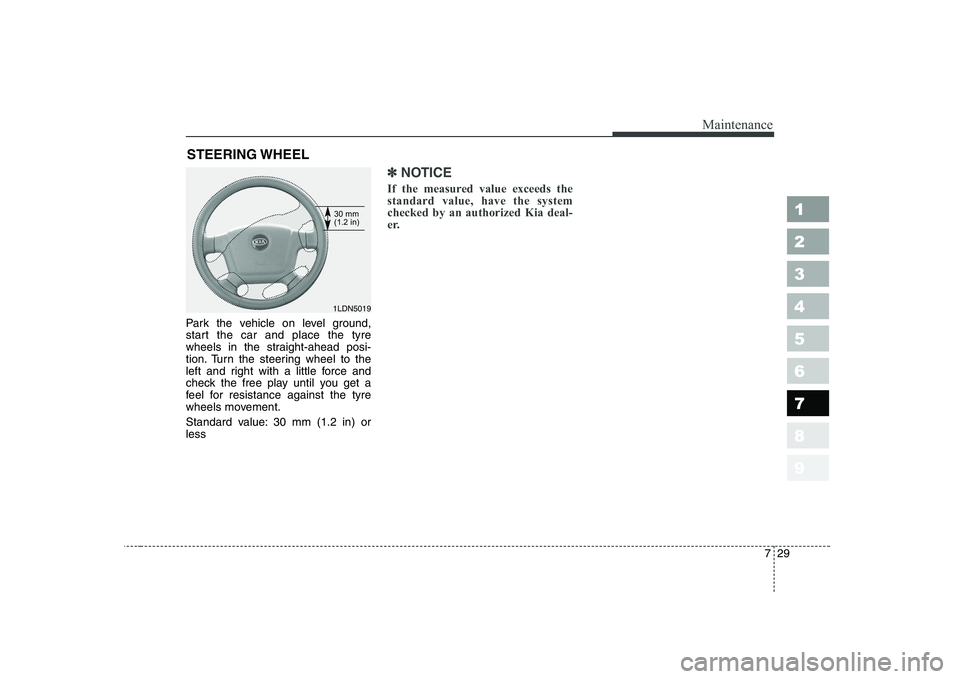

STEERING WHEEL

Park the vehicle on level ground,

start the car and place the tyre

wheels in the straight-ahead posi-

tion. Turn the steering wheel to the

left and right with a little force and

check the free play until you get a

feel for resistance against the tyre

wheels movement.

Standard value: 30 mm (1.2 in) or less

✽✽ NOTICE

If the measured value exceeds the standard value, have the systemchecked by an authorized Kia deal-

er.

1 23456789

1LDN5019

30 mm (1.2 in)

Page 274 of 318

Maintenance

30

7

1 23456789

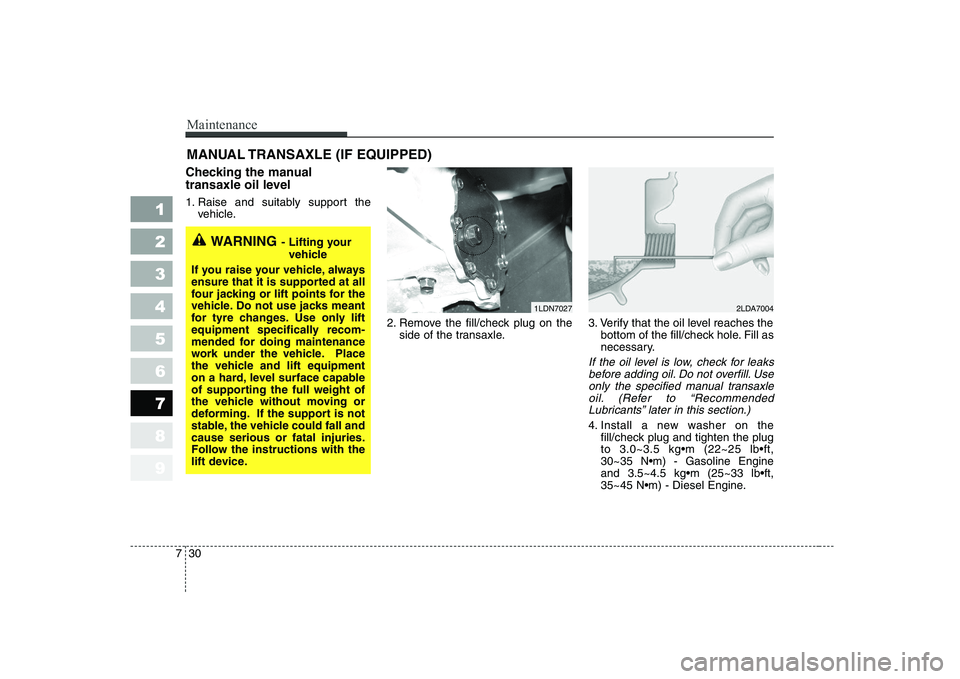

MANUAL TRANSAXLE (IF EQUIPPED)

Checking the manual

transaxle oil level

1. Raise and suitably support the vehicle.

2. Remove the fill/check plug on theside of the transaxle. 3. Verify that the oil level reaches the

bottom of the fill/check hole. Fill as

necessary.

If the oil level is low, check for leaks

before adding oil. Do not overfill. Useonly the specified manual transaxleoil. (Refer to “Recommended Lubricants” later in this section.)

4. Install a new washer on the fill/check plug and tighten the plug

1LDN7027

WARNING - Lifting your

vehicle

If you raise your vehicle, always

ensure that it is supported at all

four jacking or lift points for the

vehicle. Do not use jacks meant

for tyre changes. Use only lift

equipment specifically recom-

mended for doing maintenance

work under the vehicle. Place

the vehicle and lift equipment

on a hard, level surface capable

of supporting the full weight of

the vehicle without moving or

deforming. If the support is not

stable, the vehicle could fall andcause serious or fatal injuries.

Follow the instructions with the

lift device.

2LDA7004

Page 275 of 318

731

Maintenance

1 23456789

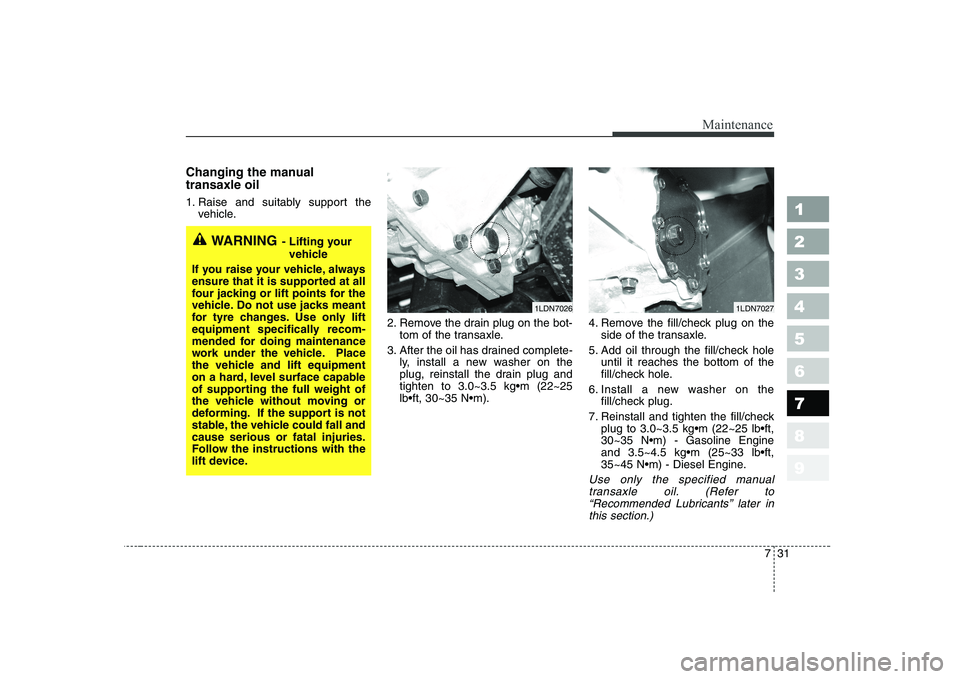

Changing the manual transaxle oil

1. Raise and suitably support thevehicle.

2. Remove the drain plug on the bot-tom of the transaxle.

3. After the oil has drained complete- ly, install a new washer on the

plug, reinstall the drain plug and 4. Remove the fill/check plug on the

side of the transaxle.

5. Add oil through the fill/check hole until it reaches the bottom of the

fill/check hole.

6. Install a new washer on the fill/check plug.

7. Reinstall and tighten the fill/check

Use only the specified manual

transaxle oil. (Refer to“Recommended Lubricants’’ later in this section.)

1LDN7026

WARNING - Lifting your

vehicle

If you raise your vehicle, always

ensure that it is supported at all

four jacking or lift points for the

vehicle. Do not use jacks meant

for tyre changes. Use only lift

equipment specifically recom-

mended for doing maintenance

work under the vehicle. Place

the vehicle and lift equipment

on a hard, level surface capable

of supporting the full weight of

the vehicle without moving or

deforming. If the support is not

stable, the vehicle could fall andcause serious or fatal injuries.

Follow the instructions with the

lift device.

1LDN7027

Page 276 of 318

Maintenance

32

7

1 23456789

AUTOMATIC TRANSAXLE (IF EQUIPPED)

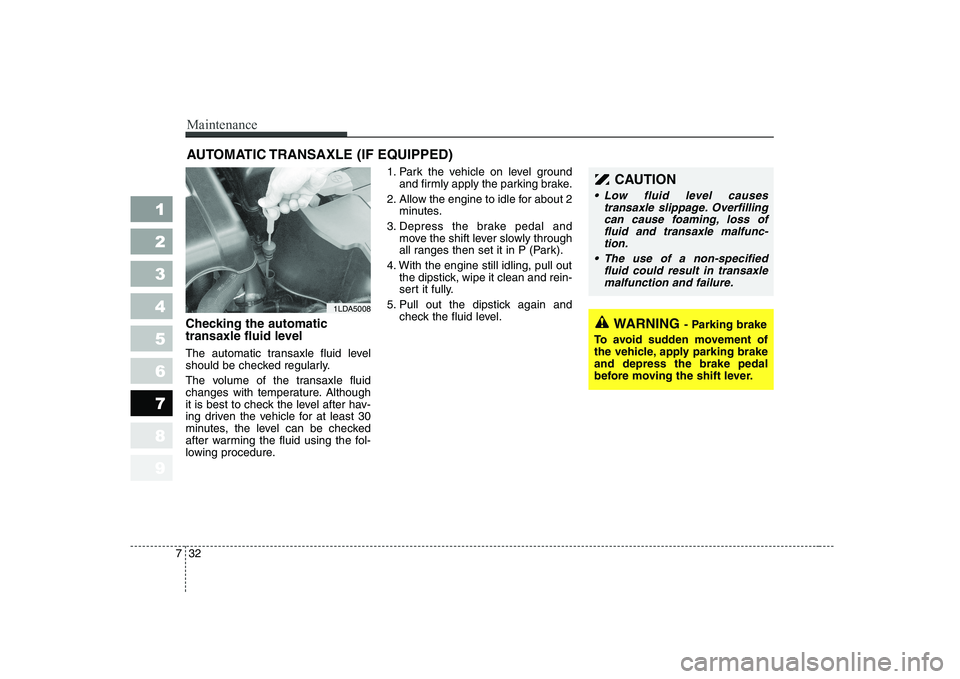

Checking the automatic

transaxle fluid level

The automatic transaxle fluid level

should be checked regularly.

The volume of the transaxle fluid

changes with temperature. Although

it is best to check the level after hav-

ing driven the vehicle for at least 30

minutes, the level can be checked

after warming the fluid using the fol-

lowing procedure. 1. Park the vehicle on level ground

and firmly apply the parking brake.

2. Allow the engine to idle for about 2 minutes.

3. Depress the brake pedal and move the shift lever slowly through

all ranges then set it in P (Park).

4. With the engine still idling, pull out the dipstick, wipe it clean and rein-

sert it fully.

5. Pull out the dipstick again and check the fluid level.

1LDA5008

CAUTION

Low fluid level causes

transaxle slippage. Overfillingcan cause foaming, loss offluid and transaxle malfunc- tion.

The use of a non-specified fluid could result in transaxlemalfunction and failure.

WARNING - Parking brake

To avoid sudden movement of

the vehicle, apply parking brakeand depress the brake pedal

before moving the shift lever.

Page 277 of 318

733

Maintenance

1 23456789

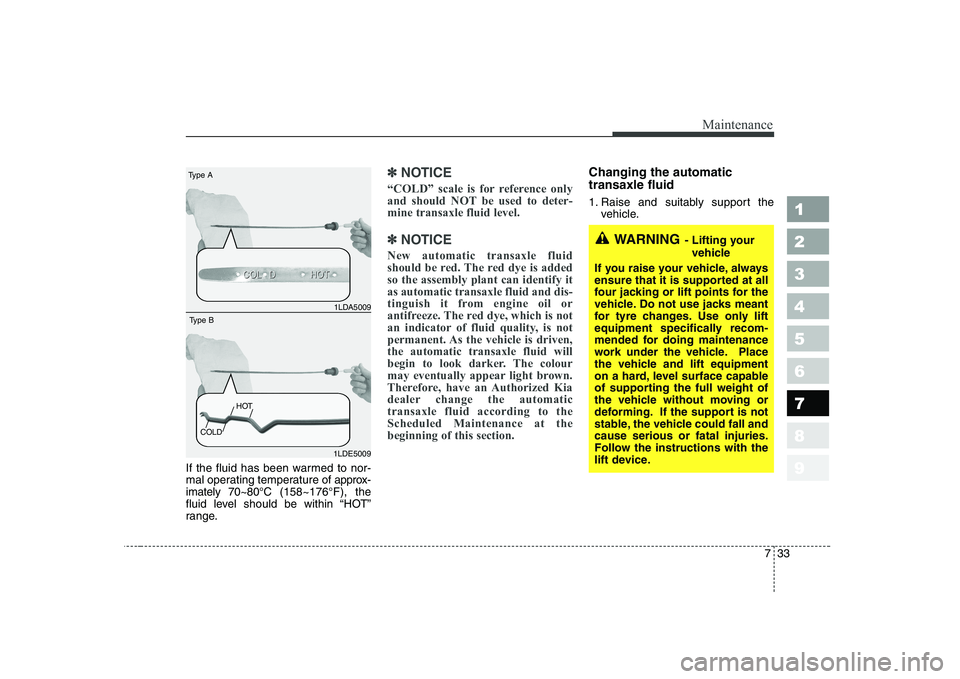

If the fluid has been warmed to nor-

mal operating temperature of approx-

imately 70~80°C (158~176°F), the

fluid level should be within “HOT”

range.

✽✽ NOTICE

“COLD” scale is for reference only

and should NOT be used to deter-mine transaxle fluid level.

✽

✽ NOTICE

New automatic transaxle fluid

should be red. The red dye is addedso the assembly plant can identify itas automatic transaxle fluid and dis-

tinguish it from engine oil or

antifreeze. The red dye, which is not

an indicator of fluid quality, is not

permanent. As the vehicle is driven,the automatic transaxle fluid will

begin to look darker. The colour

may eventually appear light brown.

Therefore, have an Authorized Kia

dealer change the automatictransaxle fluid according to theScheduled Maintenance at thebeginning of this section.

Changing the automatic transaxle fluid

1. Raise and suitably support the vehicle.

1LDA5009

Type A

1LDE5009

Type B

COLD HOT

WARNING

- Lifting your

vehicle

If you raise your vehicle, always

ensure that it is supported at all

four jacking or lift points for the

vehicle. Do not use jacks meant

for tyre changes. Use only lift

equipment specifically recom-

mended for doing maintenance

work under the vehicle. Place

the vehicle and lift equipment

on a hard, level surface capable

of supporting the full weight of

the vehicle without moving or

deforming. If the support is not

stable, the vehicle could fall andcause serious or fatal injuries.

Follow the instructions with the

lift device.

Page 278 of 318

Maintenance

34

7

1 23456789

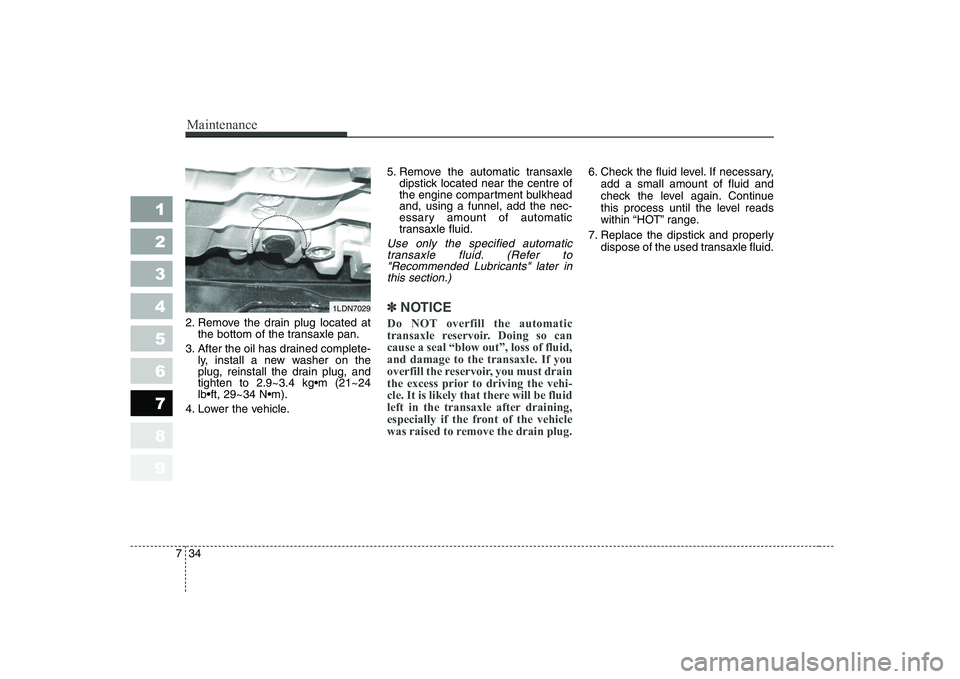

2. Remove the drain plug located at

the bottom of the transaxle pan.

3. After the oil has drained complete- ly, install a new washer on the

plug, reinstall the drain plug, and

4. Lower the vehicle. 5. Remove the automatic transaxle

dipstick located near the centre of

the engine compartment bulkheadand, using a funnel, add the nec-

essary amount of automatic

transaxle fluid.

Use only the specified automatic

transaxle fluid. (Refer to"Recommended Lubricants" later in this section.)

✽✽ NOTICE

Do NOT overfill the automatic

transaxle reservoir. Doing so cancause a seal “blow out”, loss of fluid,and damage to the transaxle. If you

overfill the reservoir, you must drain

the excess prior to driving the vehi-

cle. It is likely that there will be fluid

left in the transaxle after draining,

especially if the front of the vehicle

was raised to remove the drain plug.

6. Check the fluid level. If necessary, add a small amount of fluid and

check the level again. Continue

this process until the level reads

within “HOT” range.

7. Replace the dipstick and properly dispose of the used transaxle fluid.

1LDN7029

Page 279 of 318

735

Maintenance

1 23456789

LUBRICANTS AND FLUIDS

Checking the washer fluid

level

The reservoir is translucent so that

you can check the level with a quickvisual inspection.

Check the fluid level in the washer

fluid reservoir and add fluid if neces-

sary. Plain water may be used if

washer fluid is not available.

However, use washer solvent with

antifreeze characteristics in cold cli-

mates to prevent freezing. Body lubrication

All moving points of the body, such

as door hinges, hood hinges, and

locks, should be lubricated each time

the engine oil is changed. Use a non-

freezing lubricant on locks during

cold weather.

Make sure the engine hood second-

ary latch keeps the hood from open-

ing when the primary latch isreleased.

1LDA5021

WARNING

Do not use radiator coolant or antifreeze in the washer fluid

reservoir.

Radiator coolant can severely obscure visibility when

sprayed on the windshield

and may cause loss of vehicle

control or damage to paint

and body trim.

Windshield washer fluid agents contain some amountsof alcohol and can be flamma-

ble under certain circum-

stances. Do not allow sparksor flame to contact the washerfluid or the washer fluid reser-

voir. Damage to the vehicle or

it's occupants could occur.

Windshield washer fluid is poisonous to humans and ani-

mals. Do not drink and avoidcontacting windshield washer

fluid. Serious injury or death

could occur.

Page 280 of 318

Maintenance

36

7

1 23456789

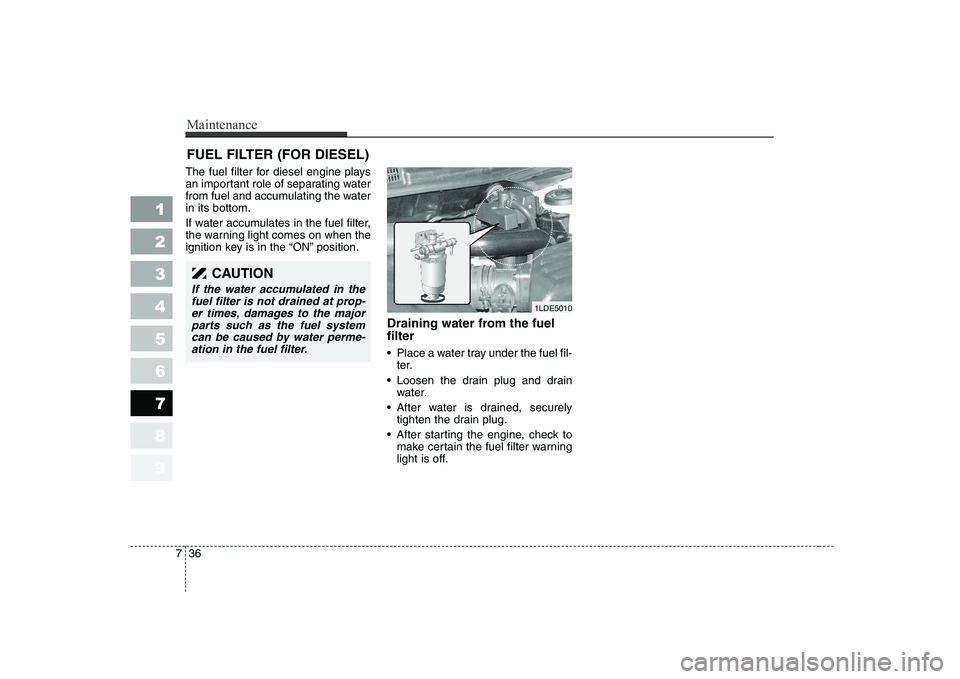

FUEL FILTER (FOR DIESEL)

The fuel filter for diesel engine plays

an important role of separating water

from fuel and accumulating the waterin its bottom.

If water accumulates in the fuel filter,

the warning light comes on when the

ignition key is in the “ON” position.

Draining water from the fuel filter

Place a water tray under the fuel fil-ter.

Loosen the drain plug and drain water.

After water is drained, securely tighten the drain plug.

After starting the engine, check to make certain the fuel filter warning

light is off.

1LDE5010

CAUTION

If the water accumulated in the

fuel filter is not drained at prop-er times, damages to the majorparts such as the fuel system can be caused by water perme-ation in the fuel filter.