check engine KIA Cerato 2016 2.G Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2016, Model line: Cerato, Model: KIA Cerato 2016 2.GPages: 501, PDF Size: 14.8 MB

Page 383 of 501

What to do in an emergency

66

Jump starting procedure

1.Make sure the booster battery is12-volt and that its negative termi-

nal is grounded.

2.If the booster battery is in another vehicle, do not allow the vehicles to

touch.

3.Turn off all unnecessary electrical loads.

4.Connect the jumper cables in the exact sequence shown in the illus-

tration. First connect one end of a

jumper cable to the positive termi-

nal of the discharged battery (1),

then connect the other end to the

positive terminal on the booster

battery (2).

Proceed to connect one end of the

other jumper cable to the negative

terminal of the booster battery (3),

then the other end to a solid, sta-

tionary, metallic point (for example,

the engine lifting bracket) away

from the battery (4). Do not con-

nect it to or near any part that

moves when the engine is cranked. Do not allow the jumper cables to

contact anything except the correct

battery terminals or the correct

ground. Do not lean over the bat-

tery when making connections.

5.Start the engine of the vehicle with the booster battery and let it run at

2,000 rpm, then start the engine of

the vehicle with the discharged

battery.

If the cause of your battery discharg-ing is not apparent, you should haveyour vehicle checked by an author-ized Kia dealer.

Push-starting

Your manual transaxle-equipped

vehicle should not be push-started

because it might damage the emis-

sion control system.

Vehicles equipped with automatic

transaxle cannot be push-started.

Follow the directions in this section

for jump-starting.

WARNING- Battery

cables

Do not connect the jumper cable

from the negative terminal of the

booster battery to the negative

terminal of the discharged bat-

tery. This can cause the dis-

charged battery to overheat and

crack, releasing battery acid.

WARNING- Tow starting vehicle

Never tow a vehicle to start it

because the sudden surge for-

ward when the engine starts

could cause a collision with the

tow vehicle.

Page 384 of 501

67

What to do in an emergency

IF THE ENGINE OVERHEATS

If your temperature gauge indicates

overheating, you will experience a

loss of power, or hear loud pinging or

knocking, the engine is probably too

hot. If this happens, you should:

1.Pull off the road and stop as soonas it is safe to do so.

2.Place the shift lever in P (automat- ic transaxle) or neutral (manual

transaxle) and set the parking

brake. If the air conditioning is on,

turn it off.

3.If engine coolant is running out under the vehicle or steam is com-

ing out from underneath the hood,

stop the engine. Do not open the

hood until the coolant has stopped

running or the steaming has

stopped. If there is no visible loss

of engine coolant and no steam,

leave the engine running and

check to be sure the engine cool-

ing fan is operating. If the fan is not

running, turn the engine off. 4.Check to see if the water pump

drive belt is missing. If it is not

missing, check to see that it is

tight. If the drive belt seems to be

satisfactory, check for coolant leak-

ing from the radiator, hoses or

under the vehicle. (If the air condi-

tioning had been in use, it is nor-

mal for cold water to be draining

from it when you stop).

5.If the water pump drive belt is bro- ken or engine coolant leaks, stop

the engine immediately and call

the nearest authorized Kia dealer

for assistance. 6.If you cannot find the cause of the

overheating, wait until the engine

temperature has returned to nor-

mal. Then, if coolant has been lost,

carefully add coolant to the reser-

voir to bring the fluid level in the

reservoir up to the halfway mark.

7.Proceed with caution, keeping alert for further signs of overheat-

ing. If overheating happens again,

call an authorized Kia dealer for

assistance.

Serious loss of coolant indicates

there is a leak in the cooling system

and this should be checked as soon

as possible by an authorized Kia

dealer.

WARNING- Under the hood

While the engine is running,

keep hair, hands and clothing

away from moving parts such

as the fan and drive belts.

WARNING- Radiator cap

Do not remove the radiator cap

when the engine is hot. This can

allow coolant to be blown out of

the opening and cause serious

burns.

Page 388 of 501

611

What to do in an emergency

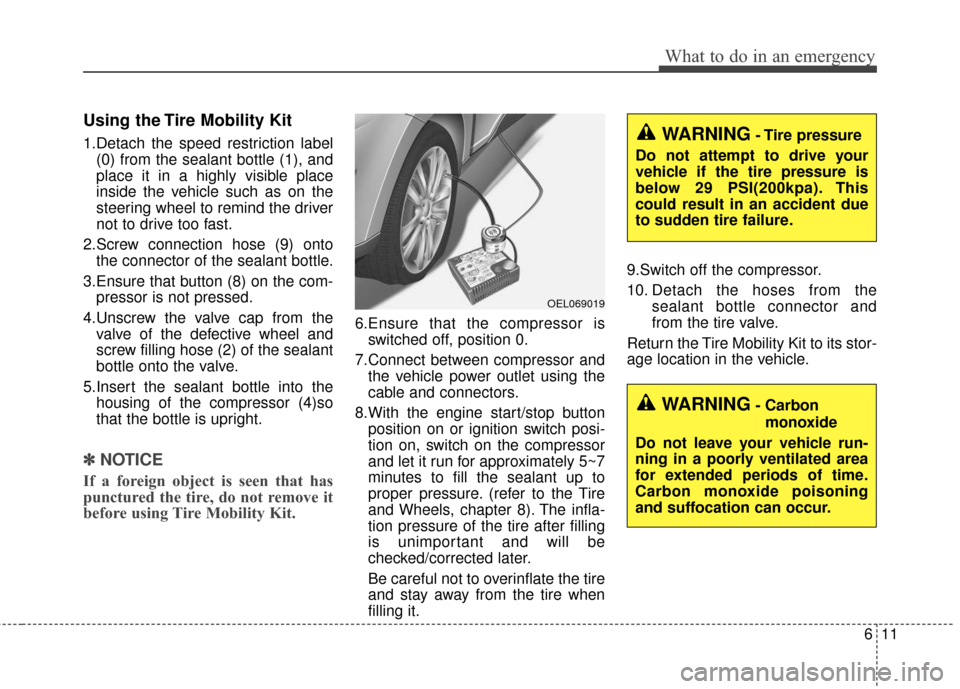

Using the Tire Mobility Kit

1.Detach the speed restriction label(0) from the sealant bottle (1), and

place it in a highly visible place

inside the vehicle such as on the

steering wheel to remind the driver

not to drive too fast.

2.Screw connection hose (9) onto the connector of the sealant bottle.

3.Ensure that button (8) on the com- pressor is not pressed.

4.Unscrew the valve cap from the valve of the defective wheel and

screw filling hose (2) of the sealant

bottle onto the valve.

5.Insert the sealant bottle into the housing of the compressor (4)so

that the bottle is upright.

✽ ✽ NOTICE

If a foreign object is seen that has

punctured the tire, do not remove it

before using Tire Mobility Kit.

6.Ensure that the compressor is

switched off, position 0.

7.Connect between compressor and the vehicle power outlet using the

cable and connectors.

8.With the engine start/stop button position on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tire

and Wheels, chapter 8). The infla-

tion pressure of the tire after filling

is unimportant and will be

checked/corrected later.

Be careful not to overinflate the tire

and stay away from the tire when

filling it. 9.Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tire valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

OEL069019

WARNING- Tire pressure

Do not attempt to drive your

vehicle if the tire pressure is

below 29 PSI(200kpa). This

could result in an accident due

to sudden tire failure.

WARNING- Carbon monoxide

Do not leave your vehicle run-

ning in a poorly ventilated area

for extended periods of time.

Carbon monoxide poisoning

and suffocation can occur.

Page 404 of 501

Maintenance

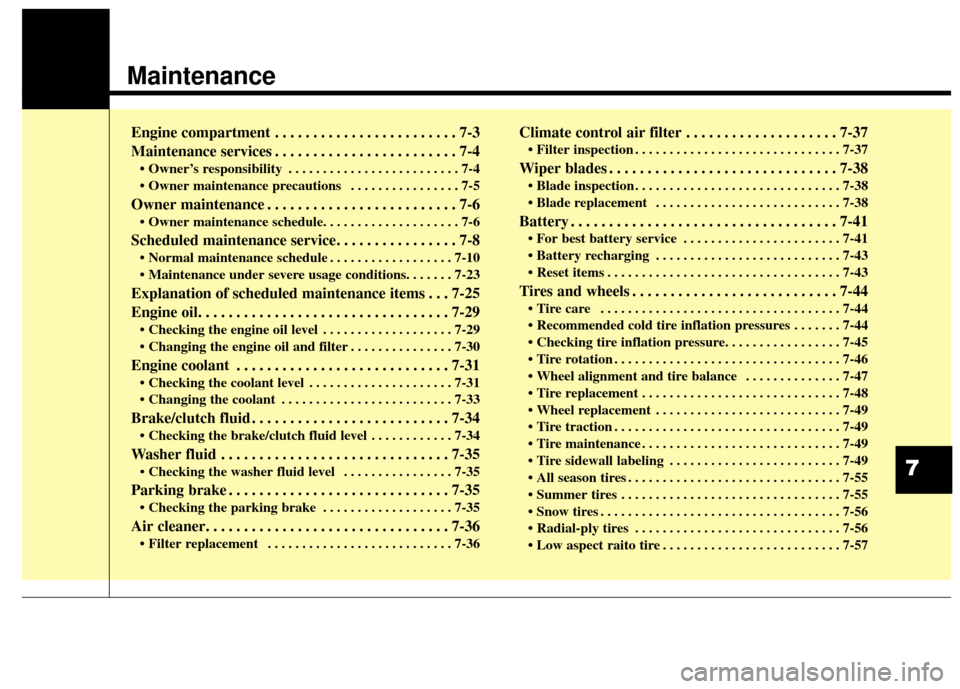

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-4

• Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

• Owner maintenance precautions . . . . . . . . . . . . . . . . 7-5

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

• Owner maintenance schedule. . . . . . . . . . . . . . . . . . . . 7-6

Scheduled maintenance service. . . . . . . . . . . . . . . . 7-8

• Normal maintenance schedule . . . . . . . . . . . . . . . . . . 7-10

• Maintenance under severe usage conditions. . . . . . . 7-23

Explanation of scheduled maintenance items . . . 7-25

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

• Checking the engine oil level . . . . . . . . . . . . . . . . . . . 7-29

• Changing the engine oil and filter . . . . . . . . . . . . . . . 7-30

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

• Checking the coolant level . . . . . . . . . . . . . . . . . . . . . 7-31

• Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

• Checking the brake/clutch fluid level . . . . . . . . . . . . 7-34

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

. . . . . . . . . . . . . . . . 7-35

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

• Checking the parking brake . . . . . . . . . . . . . . . . . . . 7-35

Air cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

• Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Climate control air filter . . . . . . . . . . . . . . . . . . . . 7-37

• Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

• Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

• Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

41

• For best battery service . . . . . . . . . . . . . . . . . . . . . . . 7-41

• Battery recharging . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

• Reset items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43\

Tires and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

• Tire care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

44

• Recommended cold tire inflation pressures . . . . . . . 7-44

• Checking tire inflation pressure. . . . . . . . . . . . . . . . . 7-45

• Tire rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

• Wheel alignment and tire balance . . . . . . . . . . . . . . 7-47

• Tire replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

• Wheel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

• Tire traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

• Tire maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

• Tire sidewall labeling . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

• All season tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

• Summer tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

• Snow tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

56

• Radial-ply tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

• Low aspect raito tire . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

7

Page 409 of 501

Maintenance

67

OWNER MAINTENANCE

The following lists are vehicle checks

and inspections that should be per-

formed by the owner or an author-

ized Kia dealer at the frequencies

indicated to help ensure safe,

dependable operation of your vehi-

cle.

Any adverse conditions should be

brought to the attention of your deal-

er as soon as possible.

These Owner Maintenance Checks

are generally not covered by war-

ranties and you may be charged for

labor, parts and lubricants used.Owner maintenance schedule

When you stop for fuel:

Check the engine oil level.

Check the coolant level in coolantreservoir.

Check the windshield washer fluid level.

Look for low or under-inflated tires.

While operating your vehicle:

Note any changes in the sound of the exhaust or any smell of

exhaust fumes in the vehicle.

Check for vibrations in the steering wheel. Notice any increased steer-

ing effort or looseness in the steer-

ing wheel, or change in its straight-

ahead position.

Notice if your vehicle constantly turns slightly or “pulls” to one side

when traveling on smooth, level

road.

When stopping, listen and check for unusual sounds, pulling to one

side, increased brake pedal travel

or “hard-to-push” brake pedal.

If any slipping or changes in the operation of your transaxle occurs,

check the transaxle fluid level.

Check the automatic transaxle P (Park) function.

Check the parking brake.

Check for fluid leaks under your vehicle (water dripping from the air

conditioning system during or after

use is normal).

WARNING - Hot coolant

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot

coolant and steam may blow

out under pressure.

Page 410 of 501

77

Maintenance

At least monthly:

Check the coolant level in theengine coolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flash-

ers.

Check the inflation pressures of all tires including the spare.

At least twice a year

(i.e., every Spring and Fall) :

Check the radiator, heater and air conditioning hoses for leaks or

damage.

Check the windshield washer spray and wiper operation. Clean

the wiper blades with clean cloth

dampened with washer fluid.

Check the headlight alignment.

Check the muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tires and loose wheel lug nuts.

At least once a year :

Clean the body and door drainholes.

Lubricate the door hinges and check the hood hinges.

Lubricate the door and hood locks and latches.

Lubricate the door rubber weather- strips.

Check the air conditioning system.

Check the power steering fluid level.

Inspect and lubricate automatic transaxle linkage and controls.

Clean the battery and terminals.

Check the brake/clutch fluid level.

Page 425 of 501

Maintenance

22

7

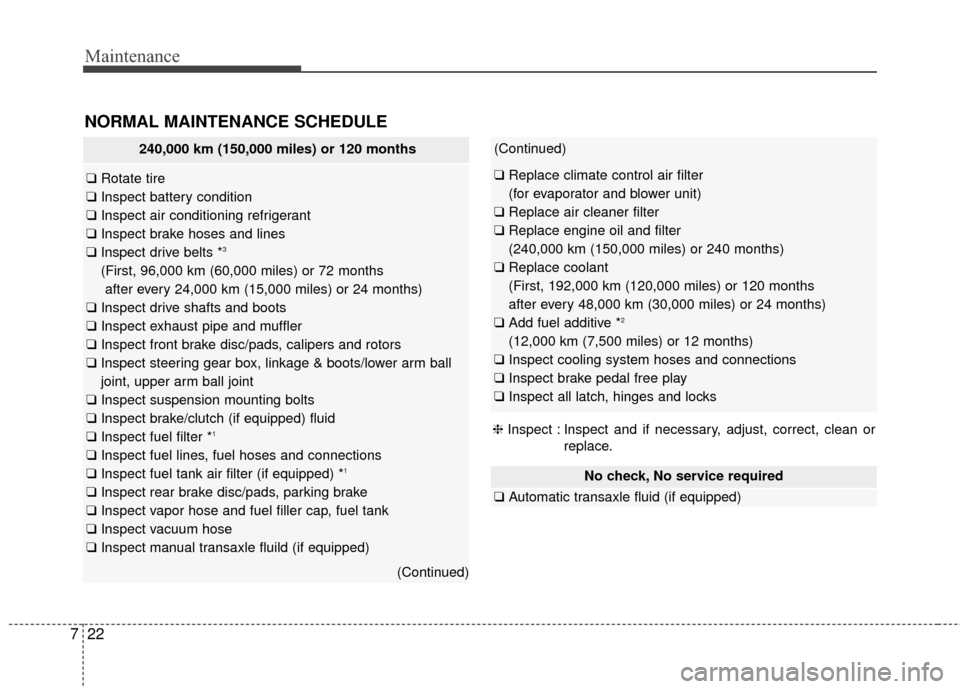

No check, No service required

❑ Automatic transaxle fluid (if equipped)

240,000 km (150,000 miles) or 120 months

❑Rotate tire

❑ Inspect battery condition

❑ Inspect air conditioning refrigerant

❑ Inspect brake hoses and lines

❑ Inspect drive belts *

3

(First, 96,000 km (60,000 miles) or 72 months

after every 24,000 km (15,000 miles) or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust pipe and muffler

❑ Inspect front brake disc/pads, calipers and rotors

❑ Inspect steering gear box, linkage & boots/lower arm ball

joint, upper arm ball joint

❑ Inspect suspension mounting bolts

❑ Inspect brake/clutch (if equipped) fluid

❑ Inspect fuel filter *

1

❑Inspect fuel lines, fuel hoses and connections

❑ Inspect fuel tank air filter (if equipped) *1

❑Inspect rear brake disc/pads, parking brake

❑ Inspect vapor hose and fuel filler cap, fuel tank

❑ Inspect vacuum hose

❑ Inspect manual transaxle fluild (if equipped)

(Continued)

(Continued)

❑Replace climate control air filter

(for evaporator and blower unit)

❑ Replace air cleaner filter

❑ Replace engine oil and filter

(240,000 km (150,000 miles) or 240 months)

❑ Replace coolant

(First, 192,000 km (120,000 miles) or 120 months

after every 48,000 km (30,000 miles) or 24 months)

❑ Add fuel additive *

2

(12,000 km (7,500 miles) or 12 months)

❑ Inspect cooling system hoses and connections

❑ Inspect brake pedal free play

❑ Inspect all latch, hinges and locks

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

NORMAL MAINTENANCE SCHEDULE

Page 428 of 501

725

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

Fuel filters should be installed by an

authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Page 431 of 501

Maintenance

28

7

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 432 of 501

729

Maintenance

ENGINE OIL

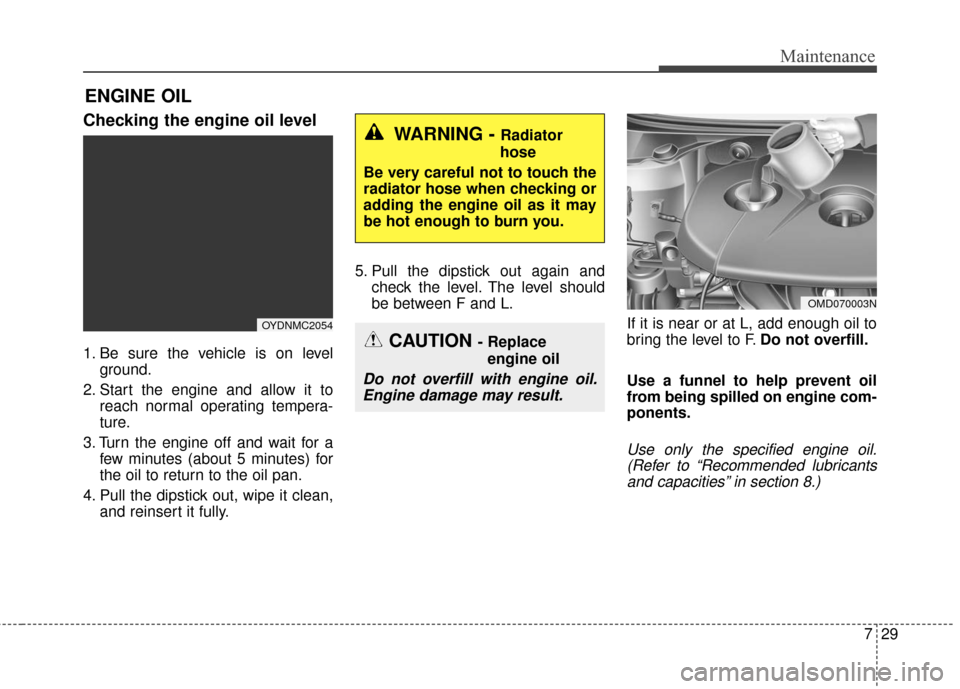

Checking the engine oil level

1. Be sure the vehicle is on levelground.

2. Start the engine and allow it to reach normal operating tempera-

ture.

3. Turn the engine off and wait for a few minutes (about 5 minutes) for

the oil to return to the oil pan.

4. Pull the dipstick out, wipe it clean, and reinsert it fully. 5. Pull the dipstick out again and

check the level. The level should

be between F and L.

If it is near or at L, add enough oil to

bring the level to F.Do not overfill.

Use a funnel to help prevent oil

from being spilled on engine com-

ponents.

Use only the specified engine oil. (Refer to “Recommended lubricantsand capacities” in section 8.)

WARNING - Radiator

hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may

be hot enough to burn you.

CAUTION - Replace engine oil

Do not overfill with engine oil.Engine damage may result.

OMD070003N

OYDNMC2054