gas KIA FORTE 2018 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: FORTE, Model: KIA FORTE 2018Pages: 584, PDF Size: 15.14 MB

Page 491 of 584

729

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

Fuel filters should be installed by an

authorized Kia dealer.

Fuel filter (for gasoline)

Kia gasoline vehicle is equipped a

lifetime fuel filter that integrated with

the fuel tank. Regular maintenance

or replacement is not needed but

depends on fuel quality. If there are

some important safety matters like

fuel flow restriction, surging, loss of

power, hard starting problem etc, fuel

filter inspection or replace is needed.

The fuel filter be Inspected or

replaced by an authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Page 494 of 584

Maintenance

32

7

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Dual clutch transmission Fluid

Inspect the dual clutch transmission

fluid according to the maintenance

schedule.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age. When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 506 of 584

Maintenance

44

7

WIPER BLADES

Blade inspection

Commercial hot waxes applied by

automatic car washes have been

known to make the windshield diffi-

cult to clean. Contamination of either the wind-

shield or the wiper blades with for-

eign matter can reduce the effective-

ness of the windshield wipers.

Common sources of contamination

are insects, tree sap, and hot wax

treatments used by some commer-

cial car washes. If the blades are not

wiping properly, clean both the win-

dow and the blades with a good

cleaner or mild detergent, and rinse

thoroughly with clean water.

Blade replacement

When the wipers no longer clean

adequately, the blades may be worn

or cracked, and require replacement.

To prevent damage to the wiper arms

or other components, do not attempt

to move the wipers manually.

The use of a non-specified wiper

blade could result in wiper malfunc-

tion and failure.

1JBA5122CAUTION - Wiper blades

To prevent damage to the wiper

blades, do not use gasoline,kerosene, paint thinner, or othersolvents on or near them.

Page 509 of 584

747

Maintenance

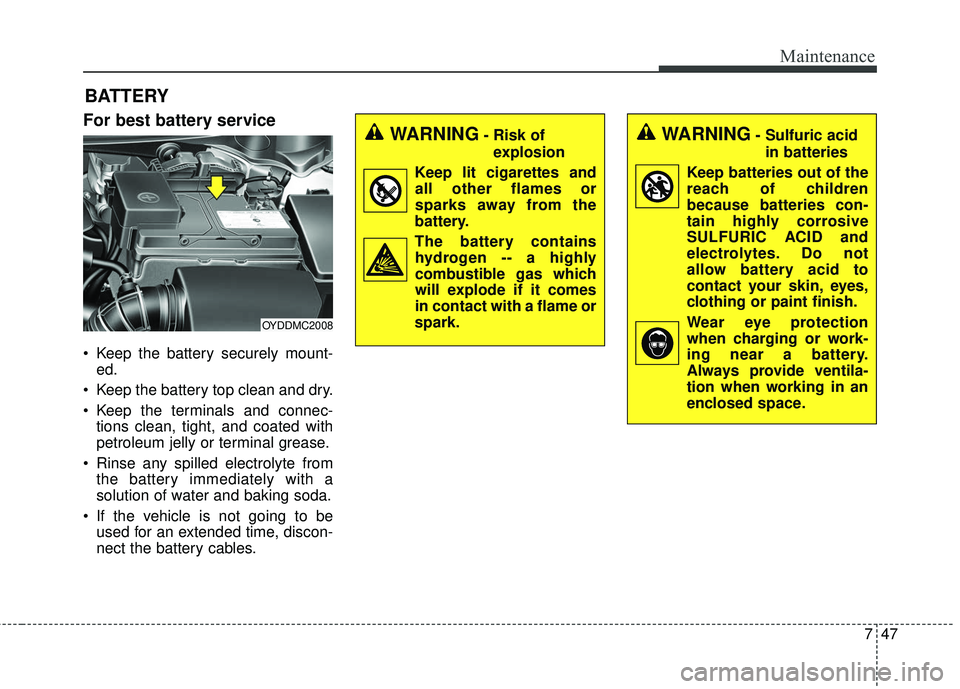

BATTERY

For best battery service

Keep the battery securely mount-ed.

Keep the battery top clean and dry.

Keep the terminals and connec- tions clean, tight, and coated with

petroleum jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a

solution of water and baking soda.

If the vehicle is not going to be used for an extended time, discon-

nect the battery cables.

WARNING- Risk of

explosion

Keep lit cigarettes and all other flames or

sparks away from the

battery.

The battery contains hydrogen -- a highly

combustible gas which

will explode if it comes

in contact with a flame or

spark.WARNING- Sulfuric acid

in batteries

Keep batteries out of the reach of children

because batteries con-

tain highly corrosive

SULFURIC ACID and

electrolytes. Do not

allow battery acid to

contact your skin, eyes,

clothing or paint finish.

Wear eye protection when charging or work-

ing near a battery.

Always provide ventila-

tion when working in an

enclosed space.

OYDDMC2008

Page 511 of 584

749

Maintenance

When recharging the battery,

observe the following precautions:

The battery must be removed fromthe vehicle and placed in an area

with good ventilation.

Watch the battery during charging, and stop or reduce the charging

rate if the battery cells begin

gassing (boiling) violently or if the

temperature of the electrolyte of

any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

Before performing maintenance or recharging the battery, turn off all

accessories and stop the engine.

The negative battery cable must be removed first and installed last

when the battery is disconnected.Reset items

Items should be reset after the bat-

tery has been discharged or the bat-

tery has been disconnected.

Auto down window (See chapter 4)

Sunroof (See chapter 4)

Trip computer (See chapter 4)

Climate control system (See chapter 4)

Clock (See chapter 4)

Audio (See chapter 4)

Page 522 of 584

Maintenance

60

7

Intended Outboard Sidewall: The

side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa): The metric unit for

air pressure.

Light truck (LT) tire: A tire designat-

ed by its manufacturer as primarily

intended for use on lightweight trucks

or multipurpose passenger vehicles.

Load ratings: The maximum load

that a tire is rated to carry for a given

inflation pressure.

Load Index: An assigned number

ranging from 1 to 279 that corre-

sponds to the load carrying capacity

of a tire.

Maximum Inflation Pressure: The

maximum air pressure to which a

cold tire may be inflated. The maxi-

mum air pressure is molded onto the

sidewall.

Maximum Load Rating: The load

rating for a tire at the maximum per-

missible inflation pressure for that tire. Maximum Loaded Vehicle Weight:

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight:

The

number of occupants a vehicle is

designed to seat multiplied by 68 kg

(150 pounds).

Occupant Distribution: Designated

seating positions.

Outward Facing Sidewall: The side

of a asymmetrical tire that has a par-

ticular side that faces outward when

mounted on a vehicle. The outward

facing sidewall bears white lettering

or bears manufacturer, brand, and/or

model name molding that is higher or

deeper than the same moldings on

the inner facing sidewall.

Passenger (P-Metric) Tire: A tire

used on passenger cars and some

light duty trucks and multipurpose

vehicles.

Ply: A layer of rubber-coated parallel

cords. Pneumatic tire:

A mechanical

device made of rubber, chemicals,

fabric and steel or other materials,

that, when mounted on an automo-

tive wheel, provides the traction and

contains the gas or fluid that sustains

the load.

Production options weight: The

combined weight of installed regular

production options weighing over 2.3

kg (5 lb.) in excess of the standard

items which they replace, not previ-

ously considered in curb weight or

accessory weight, including heavy

duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure:

Vehicle manufacturer's recommend-

ed tire inflation pressure and shown

on the tire placard.

Radial Ply Tire: A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim: A metal support for a tire and

upon which the tire beads are seated.

Page 543 of 584

781

Maintenance

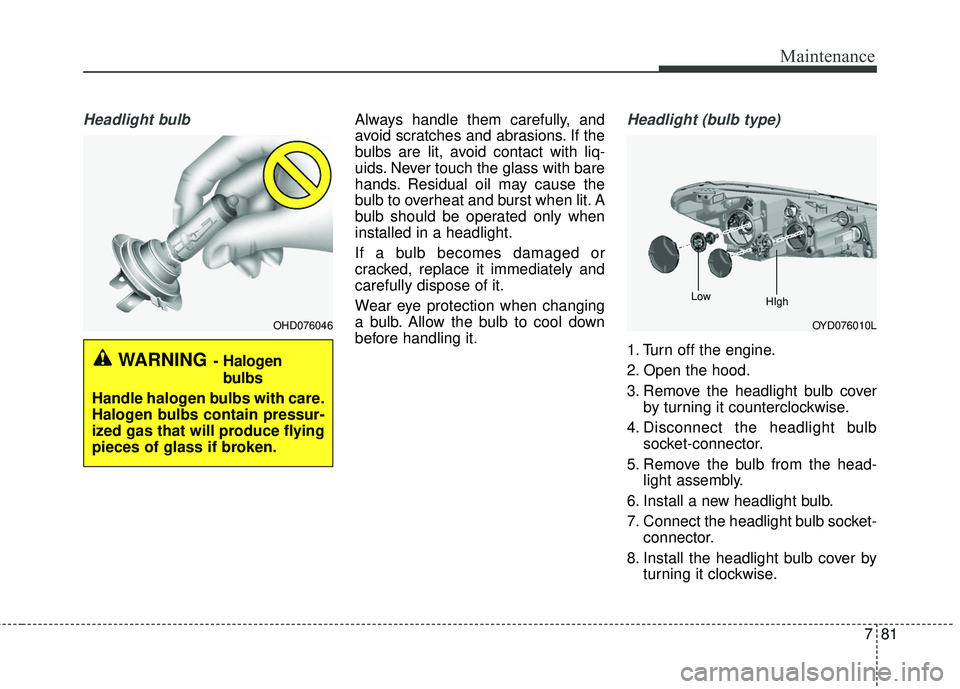

Headlight bulbAlways handle them carefully, and

avoid scratches and abrasions. If the

bulbs are lit, avoid contact with liq-

uids. Never touch the glass with bare

hands. Residual oil may cause the

bulb to overheat and burst when lit. A

bulb should be operated only when

installed in a headlight.

If a bulb becomes damaged or

cracked, replace it immediately and

carefully dispose of it.

Wear eye protection when changing

a bulb. Allow the bulb to cool down

before handling it.Headlight (bulb type)

1. Turn off the engine.

2. Open the hood.

3. Remove the headlight bulb coverby turning it counterclockwise.

4. Disconnect the headlight bulb socket-connector.

5. Remove the bulb from the head- light assembly.

6. Install a new headlight bulb.

7. Connect the headlight bulb socket- connector.

8. Install the headlight bulb cover by turning it clockwise.

OHD076046

WARNING- Halogen

bulbs

Handle halogen bulbs with care.

Halogen bulbs contain pressur-

ized gas that will produce flying

pieces of glass if broken.

OYD076010L

Low

HIgh

Page 562 of 584

Maintenance

100

7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the

Warranty & Consumer Information

manual in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

vehicle inspected and maintained by

an authorized Kia dealer in accor-

dance with the maintenance sched-

ule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch.

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again.1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol (including ORVR:

Onboard Refueling Vapor

Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to

allow the vapors from the fuel tank to

be loaded into a canister while refu-

eling at the gas station, preventing

the escape of fuel vapors into the

atmosphere.)

Page 563 of 584

7101

Maintenance

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

3. Exhaust emission control system

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

Vehicle modifications

This vehicle should not be modified.

Modification of your vehicle could

affect its performance, safety or

durability and may even violate gov-

ernmental safety and emissions reg-

ulations.

In addition, damage or performance

problems resulting from any modifi-

cation may not be covered under

warranty.

If you use unauthorized electronic

devices, it may cause the vehicle to

operate abnormally, wire damage,

battery discharge and fire. For your

safety, do not use unauthorized

electronic devices.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present with other exhaust fumes.

Therefore, if you smell exhaust

fumes of any kind inside your vehi-

cle, have it inspected and repaired

immediately. If you ever suspect

exhaust fumes are coming into

your vehicle, drive it only with all

the windows fully open. Have your

vehicle checked and repaired

immediately.

WARNING - Exhaust

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-

soning.

Page 564 of 584

Maintenance

102

7

Do not operate the engine in con-

fined or closed areas (such as

garages) any more than what is

necessary to move the vehicle in or

out of the area.

When the vehicle is stopped in an open area for more than a short

time with the engine running,

adjust the ventilation system (as

needed) to draw outside air into the

vehicle.

Never sit in a parked or stopped vehicle for any extended time with

the engine running.

When the engine stalls or fails to start, excessive attempts to restart

the engine may cause damage to

the emission control system.Operating precautions for catalyt-

ic converters (if equipped)

Your vehicle is equipped with a cat-

alytic converter emission control

device.

Therefore, the following precautions

must be observed: Use only UNLEADED FUEL for

gasoline engines.

Do not operate the vehicle when there are signs of engine malfunc-

tion, such as misfire or a noticeable

loss of performance.

Do not misuse or abuse the engine. Examples of misuse are

coasting with the ignition off and

descending steep grades in gear

with the ignition off.

Do not operate the engine at high idle speed for extended periods (5

minutes or more).

Do not modify or tamper with any part of the engine or emission con-

trol system. All inspections and

adjustments must be made by an

authorized Kia dealer.

Avoid driving with an extremely low fuel level. Running out of fuel could

cause the engine to misfire, dam-

aging the catalytic converter.

Failure to observe these precautions

could result in damage to the catalyt-

ic converter and to your vehicle.

Additionally, such actions could void

your warranties.

WARNING- Fire

Do not park, idle or drive the vehicle over or near flamma-

ble objects, such as grass,

vegetation, paper, leaves, etc.

A hot exhaust system can

ignite flammable items under

your vehicle.

Also, do not remove the heat sink around the exhaust sys-

tem, do not seal the bottom of

the vehicle or do not coat the

vehicle for corrosion control.

It may present a fire risk under

certain conditions.

WARNING- Catalytic

converter

Keep away from the catalytic

converter and exhaust system

while the vehicle is running or

immediately thereafter. The

exhaust and catalytic systems

are very hot and may burn you.