engine control KIA FORTE 2018 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: FORTE, Model: KIA FORTE 2018Pages: 584, PDF Size: 15.14 MB

Page 497 of 584

735

Maintenance

ENGINE COOLANT

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, at

the beginning of the winter season,

and before traveling to a colder cli-

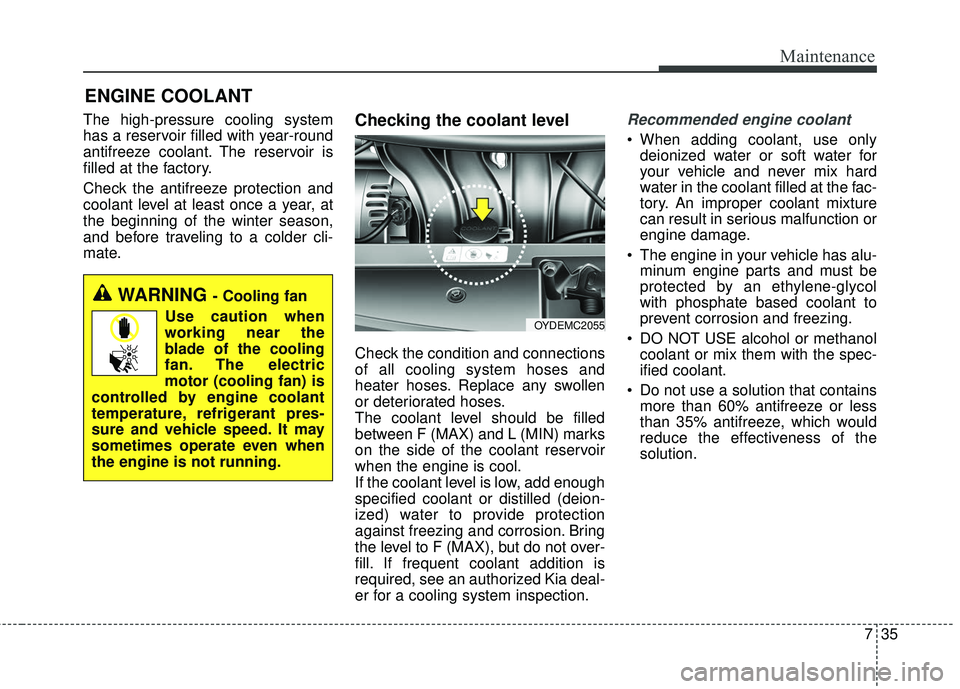

mate.Checking the coolant level

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between F (MAX) and L (MIN) marks

on the side of the coolant reservoir

when the engine is cool.

If the coolant level is low, add enough

specified coolant or distilled (deion-

ized) water to provide protection

against freezing and corrosion. Bring

the level to F (MAX), but do not over-

fill. If frequent coolant addition is

required, see an authorized Kia deal-

er for a cooling system inspection.

Recommended engine coolant

When adding coolant, use onlydeionized water or soft water for

your vehicle and never mix hard

water in the coolant filled at the fac-

tory. An improper coolant mixture

can result in serious malfunction or

engine damage.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycol

with phosphate based coolant to

prevent corrosion and freezing.

DO NOT USE alcohol or methanol coolant or mix them with the spec-

ified coolant.

Do not use a solution that contains more than 60% antifreeze or less

than 35% antifreeze, which would

reduce the effectiveness of the

solution.

WARNING - Cooling fan

Use caution when

working near the

blade of the cooling

fan. The electric

motor (cooling fan) is

controlled by engine coolant

temperature, refrigerant pres-

sure and vehicle speed. It may

sometimes operate even when

the engine is not running.

OYDEMC2055

Page 511 of 584

749

Maintenance

When recharging the battery,

observe the following precautions:

The battery must be removed fromthe vehicle and placed in an area

with good ventilation.

Watch the battery during charging, and stop or reduce the charging

rate if the battery cells begin

gassing (boiling) violently or if the

temperature of the electrolyte of

any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

Before performing maintenance or recharging the battery, turn off all

accessories and stop the engine.

The negative battery cable must be removed first and installed last

when the battery is disconnected.Reset items

Items should be reset after the bat-

tery has been discharged or the bat-

tery has been disconnected.

Auto down window (See chapter 4)

Sunroof (See chapter 4)

Trip computer (See chapter 4)

Climate control system (See chapter 4)

Clock (See chapter 4)

Audio (See chapter 4)

Page 526 of 584

Maintenance

64

7

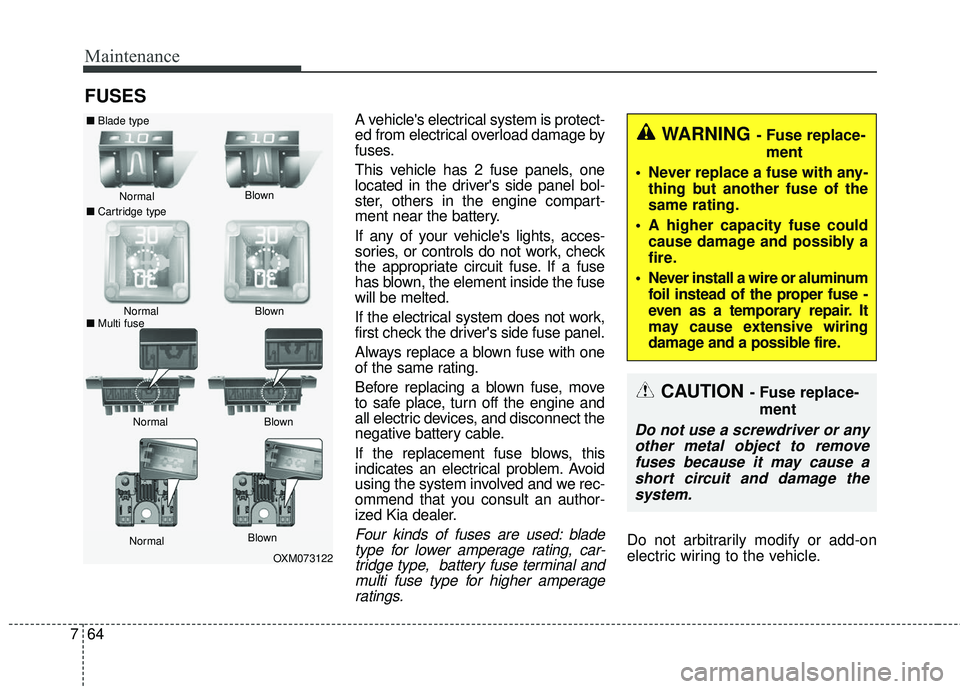

FUSES

A vehicle's electrical system is protect-

ed from electrical overload damage by

fuses.

This vehicle has 2 fuse panels, one

located in the driver's side panel bol-

ster, others in the engine compart-

ment near the battery.

If any of your vehicle's lights, acces-

sories, or controls do not work, check

the appropriate circuit fuse. If a fuse

has blown, the element inside the fuse

will be melted.

If the electrical system does not work,

first check the driver's side fuse panel.

Always replace a blown fuse with one

of the same rating.

Before replacing a blown fuse, move

to safe place, turn off the engine and

all electric devices, and disconnect the

negative battery cable.

If the replacement fuse blows, this

indicates an electrical problem. Avoid

using the system involved and we rec-

ommend that you consult an author-

ized Kia dealer.

Four kinds of fuses are used: blade

type for lower amperage rating, car-tridge type, battery fuse terminal andmulti fuse type for higher amperageratings.Do not arbitrarily modify or add-on

electric wiring to the vehicle.

WARNING - Fuse replace-

ment

Never replace a fuse with any- thing but another fuse of the

same rating.

A higher capacity fuse could cause damage and possibly a

fire.

Never install a wire or aluminum foil instead of the proper fuse -

even as a temporary repair. It

may cause extensive wiring

damage and a possible fire.

CAUTION - Fuse replace-

ment

Do not use a screwdriver or anyother metal object to removefuses because it may cause ashort circuit and damage thesystem.

OXM073122

Normal

Normal

■

Blade type

■ Cartridge type

■ Multi fuse Blown

Blown

Normal Blown

Normal Blown

Page 536 of 584

Maintenance

74

7

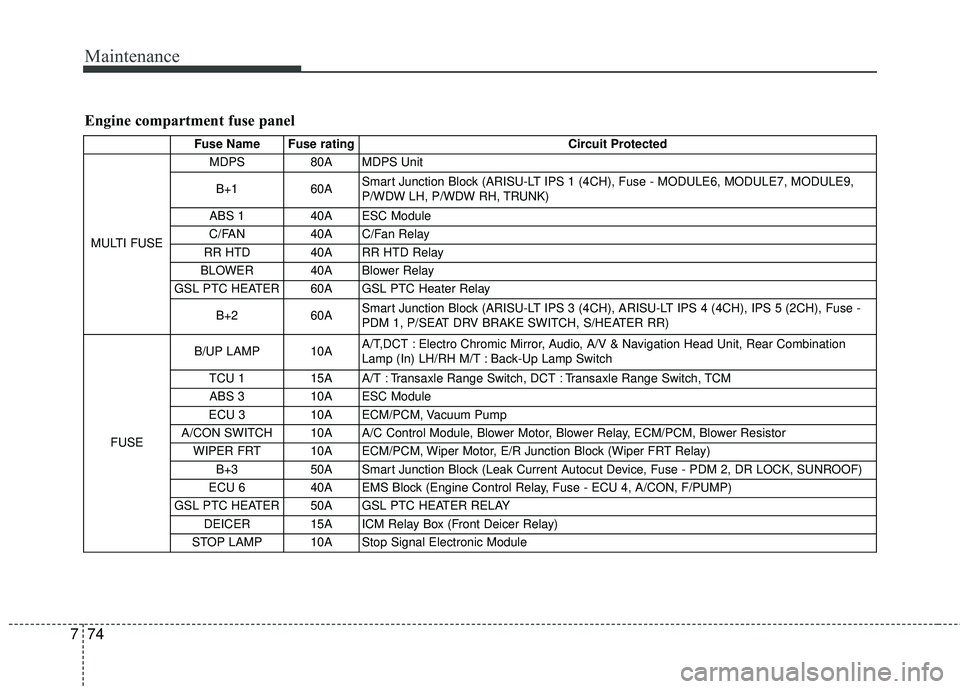

Engine compartment fuse panel

Fuse Name Fuse rating Circuit Protected

MULTI FUSE MDPS 80A MDPS

Unit

B+1 60A Smart Junction Block (ARISU-LT IPS 1 (4CH), Fuse - MODULE6, MODULE7, MODULE9,

P/WDW LH, P/WDW RH, TRUNK)

ABS 1 40A ESC Module

C/FAN 40A C/Fan Relay

RR HTD 40A RR HTD Relay

BLOWER 40A Blower Relay

GSL PTC HEATER 60A GSL PTC Heater Relay

B+2 60A Smart Junction Block (ARISU-LT IPS 3 (4CH), ARISU-LT IPS 4 (4CH), IPS 5 (2CH), Fuse -

PDM 1, P/SEAT DRV BRAKE SWITCH, S/HEATER RR)

FUSE B/UP LAMP 10A

A/T,DCT : Electro Chromic Mirror, Audio, A/V & Navigation Head Unit, Rear Combination

Lamp (In) LH/RH M/T : Back-Up Lamp Switch

TCU 1 15A A/T : Transaxle Range Switch, DCT : Transaxle Range Switch, TCM

ABS 3 10A ESC Module

ECU 3 10A ECM/PCM, Vacuum Pump

A/CON SWITCH 10A A/C Control Module, Blower Motor, Blower Relay, ECM/PCM, Blower Resistor WIPER FRT 10A ECM/PCM, Wiper Motor, E/R Junction Block (Wiper FRT Relay) B+3 50A Smart Junction Block (Leak Current Autocut Device, Fuse - PDM 2, DR LOCK, SUNROOF)

ECU 6 40A EMS Block (Engine Control Relay, Fuse - ECU 4, A/CON, F/PUMP)

GSL PTC HEATER 50A GSL PTC HEATER RELAY DEICER 15A ICM Relay Box (Front Deicer Relay)

STOP LAMP 10A Stop Signal Electronic Module

Page 539 of 584

777

Maintenance

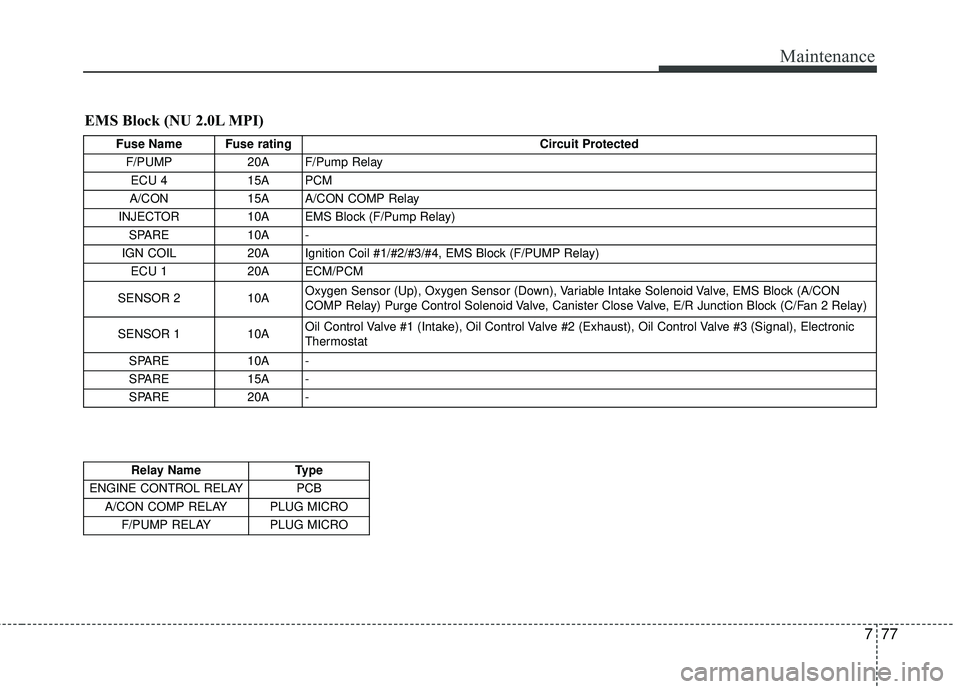

EMS Block (NU 2.0L MPI)

Fuse Name Fuse ratingCircuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

SPARE 10A -

IGN COIL 20A Ignition Coil #1/#2/#3/#4, EMS Block (F/PUMP Relay)

ECU 1 20A ECM/PCM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay) Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)

SENSOR 1 10A Oil Control Valve #1 (Intake), Oil Control Valve #2 (Exhaust), Oil Control Valve #3 (Signal), Electronic

Thermostat

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PLUG MICRO F/PUMP RELAY PLUG MICRO

Page 540 of 584

Maintenance

78

7

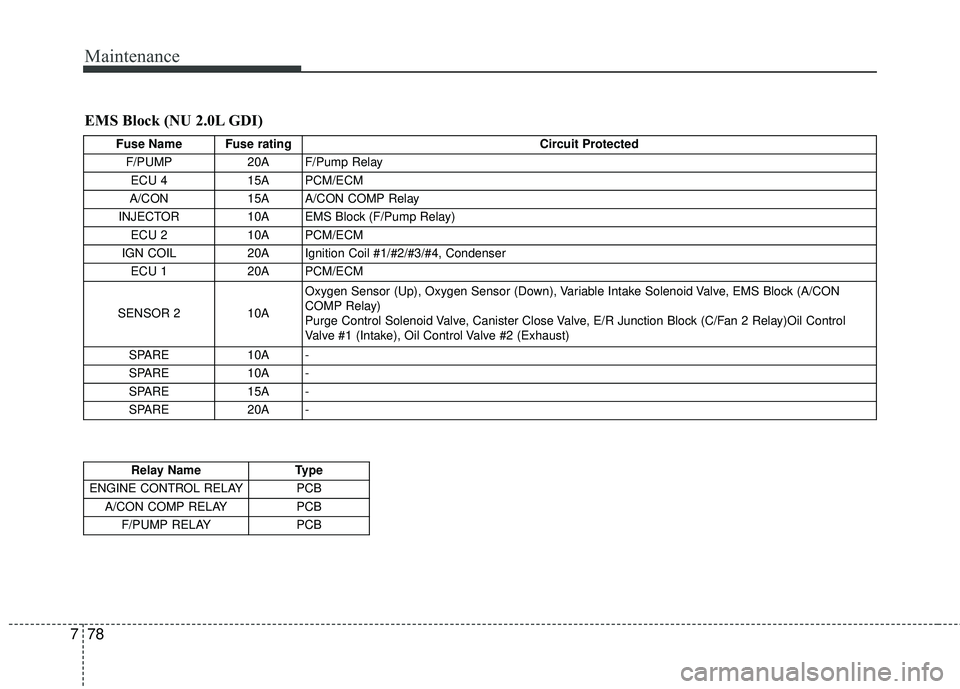

EMS Block (NU 2.0L GDI)

Fuse Name Fuse rating Circuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM/ECM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

ECU 2 10A PCM/ECM

IGN COIL 20A Ignition Coil #1/#2/#3/#4, Condenser

ECU 1 20A PCM/ECM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay)

Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)Oil Control

Valve #1 (Intake), Oil Control Valve #2 (Exhaust)

SPARE 10A -

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PCB

F/PUMP RELAY PCB

Page 541 of 584

779

Maintenance

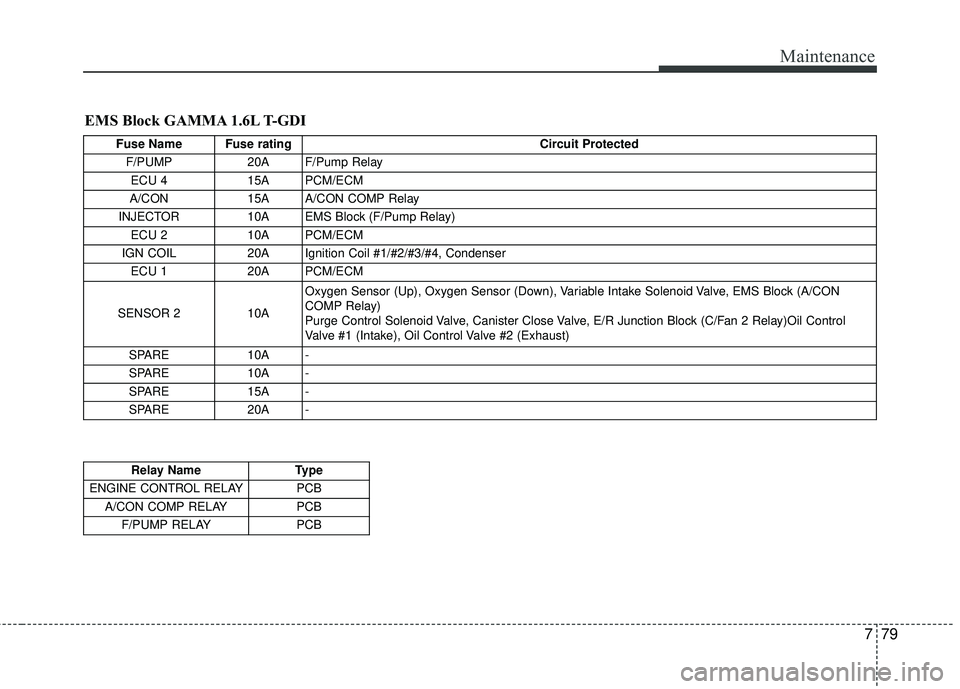

EMS Block GAMMA 1.6L T-GDI

Fuse Name Fuse ratingCircuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM/ECM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

ECU 2 10A PCM/ECM

IGN COIL 20A Ignition Coil #1/#2/#3/#4, Condenser

ECU 1 20A PCM/ECM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay)

Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)Oil Control

Valve #1 (Intake), Oil Control Valve #2 (Exhaust)

SPARE 10A -

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PCB

F/PUMP RELAY PCB

Page 563 of 584

7101

Maintenance

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

3. Exhaust emission control system

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

Vehicle modifications

This vehicle should not be modified.

Modification of your vehicle could

affect its performance, safety or

durability and may even violate gov-

ernmental safety and emissions reg-

ulations.

In addition, damage or performance

problems resulting from any modifi-

cation may not be covered under

warranty.

If you use unauthorized electronic

devices, it may cause the vehicle to

operate abnormally, wire damage,

battery discharge and fire. For your

safety, do not use unauthorized

electronic devices.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present with other exhaust fumes.

Therefore, if you smell exhaust

fumes of any kind inside your vehi-

cle, have it inspected and repaired

immediately. If you ever suspect

exhaust fumes are coming into

your vehicle, drive it only with all

the windows fully open. Have your

vehicle checked and repaired

immediately.

WARNING - Exhaust

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-

soning.

Page 564 of 584

Maintenance

102

7

Do not operate the engine in con-

fined or closed areas (such as

garages) any more than what is

necessary to move the vehicle in or

out of the area.

When the vehicle is stopped in an open area for more than a short

time with the engine running,

adjust the ventilation system (as

needed) to draw outside air into the

vehicle.

Never sit in a parked or stopped vehicle for any extended time with

the engine running.

When the engine stalls or fails to start, excessive attempts to restart

the engine may cause damage to

the emission control system.Operating precautions for catalyt-

ic converters (if equipped)

Your vehicle is equipped with a cat-

alytic converter emission control

device.

Therefore, the following precautions

must be observed: Use only UNLEADED FUEL for

gasoline engines.

Do not operate the vehicle when there are signs of engine malfunc-

tion, such as misfire or a noticeable

loss of performance.

Do not misuse or abuse the engine. Examples of misuse are

coasting with the ignition off and

descending steep grades in gear

with the ignition off.

Do not operate the engine at high idle speed for extended periods (5

minutes or more).

Do not modify or tamper with any part of the engine or emission con-

trol system. All inspections and

adjustments must be made by an

authorized Kia dealer.

Avoid driving with an extremely low fuel level. Running out of fuel could

cause the engine to misfire, dam-

aging the catalytic converter.

Failure to observe these precautions

could result in damage to the catalyt-

ic converter and to your vehicle.

Additionally, such actions could void

your warranties.

WARNING- Fire

Do not park, idle or drive the vehicle over or near flamma-

ble objects, such as grass,

vegetation, paper, leaves, etc.

A hot exhaust system can

ignite flammable items under

your vehicle.

Also, do not remove the heat sink around the exhaust sys-

tem, do not seal the bottom of

the vehicle or do not coat the

vehicle for corrosion control.

It may present a fire risk under

certain conditions.

WARNING- Catalytic

converter

Keep away from the catalytic

converter and exhaust system

while the vehicle is running or

immediately thereafter. The

exhaust and catalytic systems

are very hot and may burn you.

Page 579 of 584

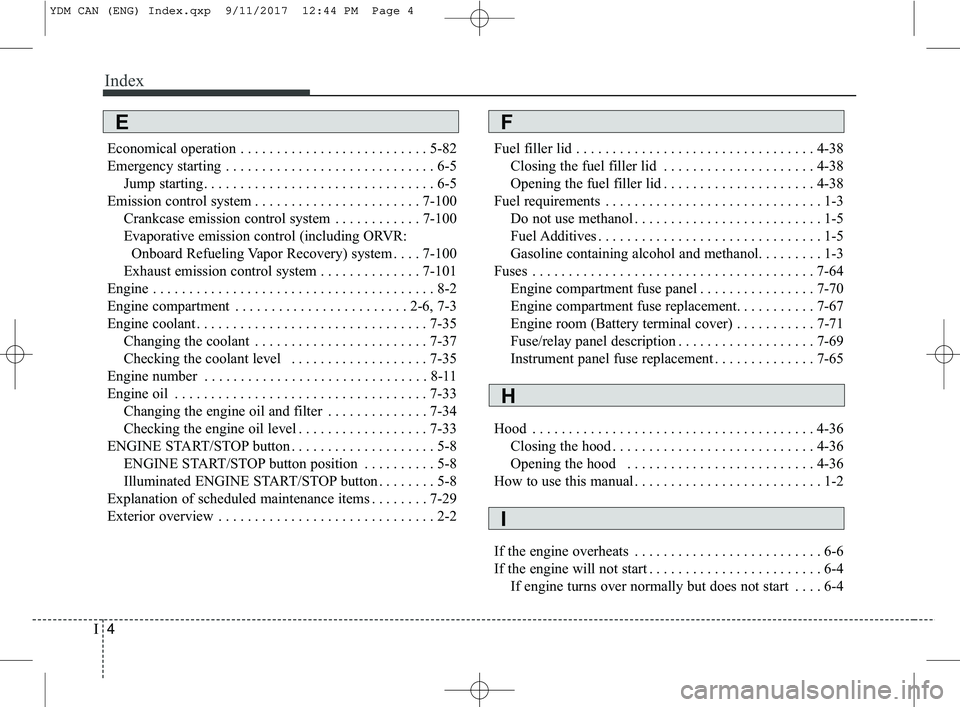

Index

4I

Economical operation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-82

Emergency starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5Jump starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Emission control system . . . . . . . . . . . . . . . . . . . . . . . 7-100 Crankcase emission control system . . . . . . . . . . . . 7-100

Evaporative emission control (including ORVR: Onboard Refueling Vapor Recovery) system . . . . 7-100

Exhaust emission control system . . . . . . . . . . . . . . 7-101

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . 8-2

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 2-6, 7-3

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35 Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Checking the coolant level . . . . . . . . . . . . . . . . . . . 7-35

Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

33 Changing the engine oil and filter . . . . . . . . . . . . . . 7-34

Checking the engine oil level . . . . . . . . . . . . . . . . . . 7-33

ENGINE START/STOP button . . . . . . . . . . . . . . . . . . . . 5-8 ENGINE START/STOP button position . . . . . . . . . . 5-8

Illuminated ENGINE START/STOP button . . . . . . . . 5-8

Explanation of scheduled maintenance items . . . . . . . . 7-29

Exterior overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 Fuel filler lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Closing the fuel filler lid . . . . . . . . . . . . . . . . . . . . . 4-38

Opening the fuel filler lid . . . . . . . . . . . . . . . . . . . . . 4-38

Fuel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 Do not use methanol . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Fuel Additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Gasoline containing alcohol and methanol. . . . . . . . . 1-3

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . 7-64 Engine compartment fuse panel . . . . . . . . . . . . . . . . 7-70

Engine compartment fuse replacement. . . . . . . . . . . 7-67

Engine room (Battery terminal cover) . . . . . . . . . . . 7-71

Fuse/relay panel description . . . . . . . . . . . . . . . . . . . 7-69

Instrument panel fuse replacement . . . . . . . . . . . . . . 7-65

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . 4-36 Closing the hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Opening the hood . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

If the engine overheats . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

If the engine will not start . . . . . . . . . . . . . . . . . . . . . . . . 6-4 If engine turns over normally but does not start . . . . 6-4

EF

H

I

YDM CAN (ENG) Index.qxp 9/11/2017 12:44 PM Page 4